LES RAYONS D’ARC PEUVENT BRÛLER LES YEUX

Ne regardez jamais de soudage à arc électrique sans une protection oculaire appropriée. Les arcs engendrés par le

processus de soudage génèrent des rayons intenses visibles et invisibles (ultraviolets et infrarouges) qui peuvent

brûler les yeux et la peau. Des étincelles chaudes sont générées par la soudure et peuvent brûler les yeux et la peau.

• Portez des lunettes de soudage comprenant un filtre adéquatement teinté pour protéger votre visage et vos yeux

lorsque vous effectuez du soudage ou que vous observez des activités de soudage.

• Portez des lunettes de sécurité homologuées comprenant des écrans latéraux sous vos lunettes de soudage

• Lisez les instructions du fabricant concernant les métaux, les consommables, les revêtements, les nettoyants et

les dégraissants.

• Utilisez des écrans ou des barrières de protection pour protéger les autres des éclats lumineux et de la lumière

éblouissante. Avertissez les autres personnes se trouvant dans la zone de travail de ne pas regarder l’arc.

• Portez des vêtements de protection fabriqués à partir de matériaux durables et ignifuges, des gants de soudage en

cuir et une protection complète des pieds.

LE SOUDAGE PEUT PROVOQUER UN INCENDIE OU UNE EXPLOSION

Le soudage sur des contenants fermés comme des réservoirs, des fûts ou des tuyaux peut les faire exploser. Des

étincelles peuvent jaillir de l’arc de soudage. Les étincelles propulsées dans les airs et la pièce à souder ainsi que

l’équipement chauds peuvent provoquer des incendies et des brûlures. Le contact accidentel de l’électrode avec des

objets métalliques peut provoquer des étincelles, une explosion, une surchauffe ou un incendie. Effectuez une

vérification et assurez-vous que la zone est sûre avant d’effectuer une soudure.

• Gardez toujours un extincteur à portée de main et restez à l’affut des incendies.

LE MÉTAL PROJETÉ PEUT BLESSER LES YEUX

• Portez des lunettes de sécurité homologuées par l’Americain National Standards Institute (ANSI, Institut national de

normalisation américaine) comprenant des écrans latéraux sous vos lunettes de soudage.

• Le soudage, le burinage, le brossage métallique et le meulage provoquent des étincelles et la projection de métal.

Les soudures peuvent projeter des scories lorsqu’elles refroidissent.

LES PIÈCES CHAUDES PEUVENT PROVOQUER DES BRÛLURES GRAVES

• Ne touchez jamais de pièces chaudes à mains nues.

• Laissez la pièce à souder refroidir pendant une période adéquate avant de la toucher.

15

14

• Veuillez lire et vous assurer de comprendre l’ensemble de ce manuel d’utilisation avant de tenter d’assembler,

d’utiliser ou d’entretenir cet outil.

• Les matériaux susceptibles d’entrer en contact avec la peau de l’utilisateur peuvent provoquer des réactions

allergiques chez les personnes sensibles.

• Les protections oculaires contre les particules projetées à grande vitesse portées sur des lunettes ophtalmiques

standard peuvent ne pas protéger des impacts, créant ainsi un danger pour la personne qui les porte.

• Si une protection contre les particules projetées à grande vitesse à des températures extrêmes est requise, la

protection oculaire sélectionnée doit être marquée d’une lettre “T” immédiatement après la lettre d’impact,

c’est-à-dire FT (à faible énergie), BT (à énergie moyenne) ou AT (à haute énergie). Si la lettre d’impact n’est pas

suivie de la lettre “T”, la protection oculaire ne doit être utilisée qu’en guise de protection des particules à grande

vitesse à température ambiante.

• Si les niveaux de protection des différentes parties de l’équipement de protection ne sont pas les mêmes, le niveau

de protection le plus bas doit être attribué.

• Les oculaires à filtre en matériau renforcé ne doivent être utilisés qu’en conjonction avec un oculaire d

support approprié.

VEUILLEZ LIRE ATTENTIVEMENT ET SUIVRE LES INSTRUCTIONS AVANT UTILISATION

AVANT LA PREMIÈRE UTILISATION

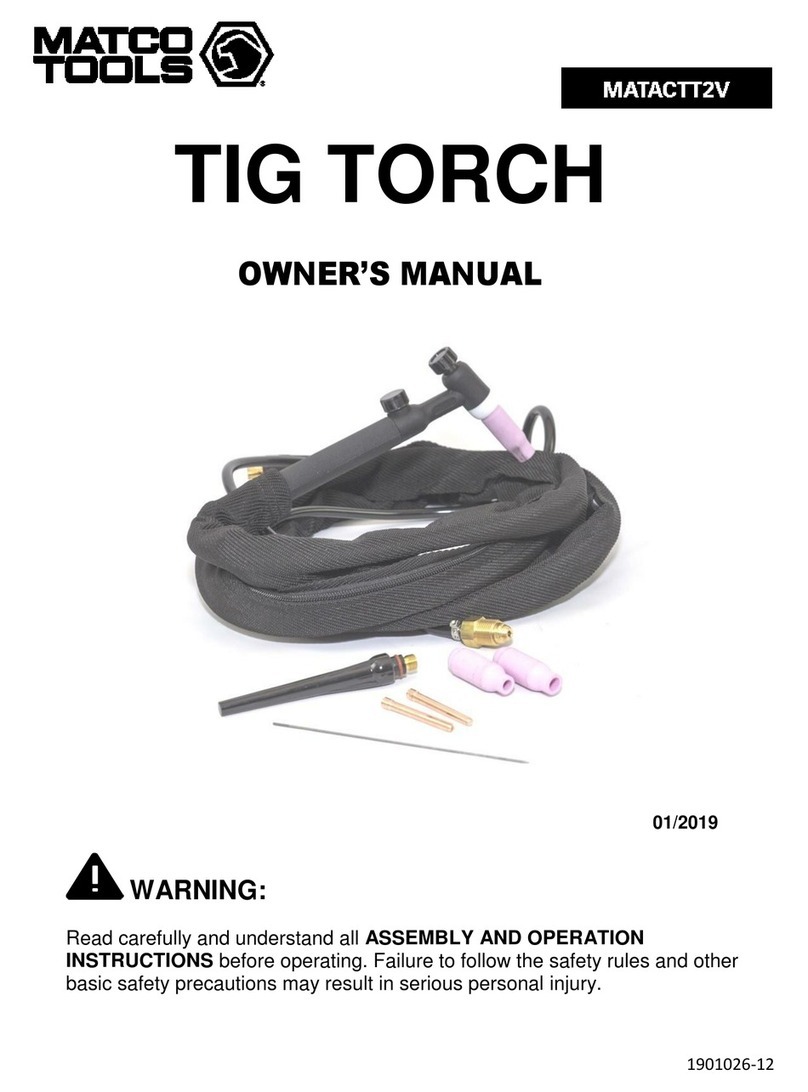

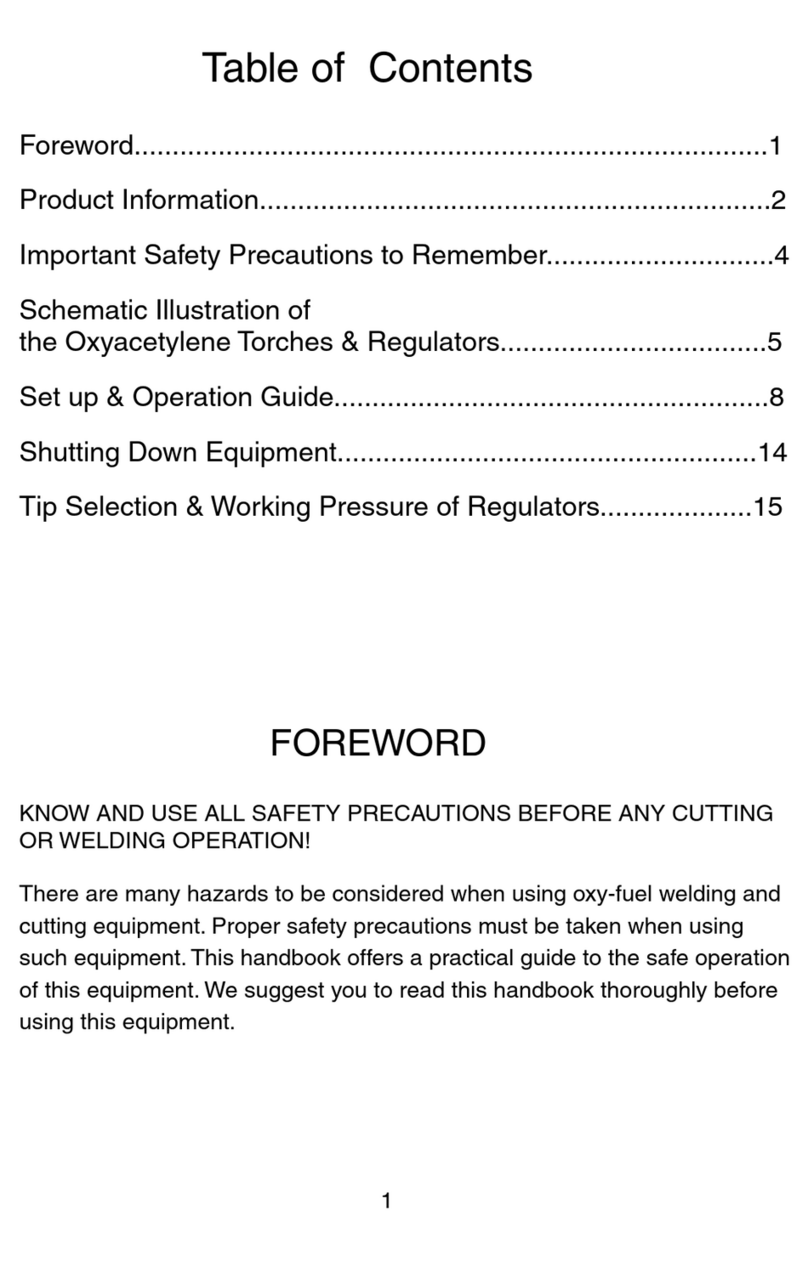

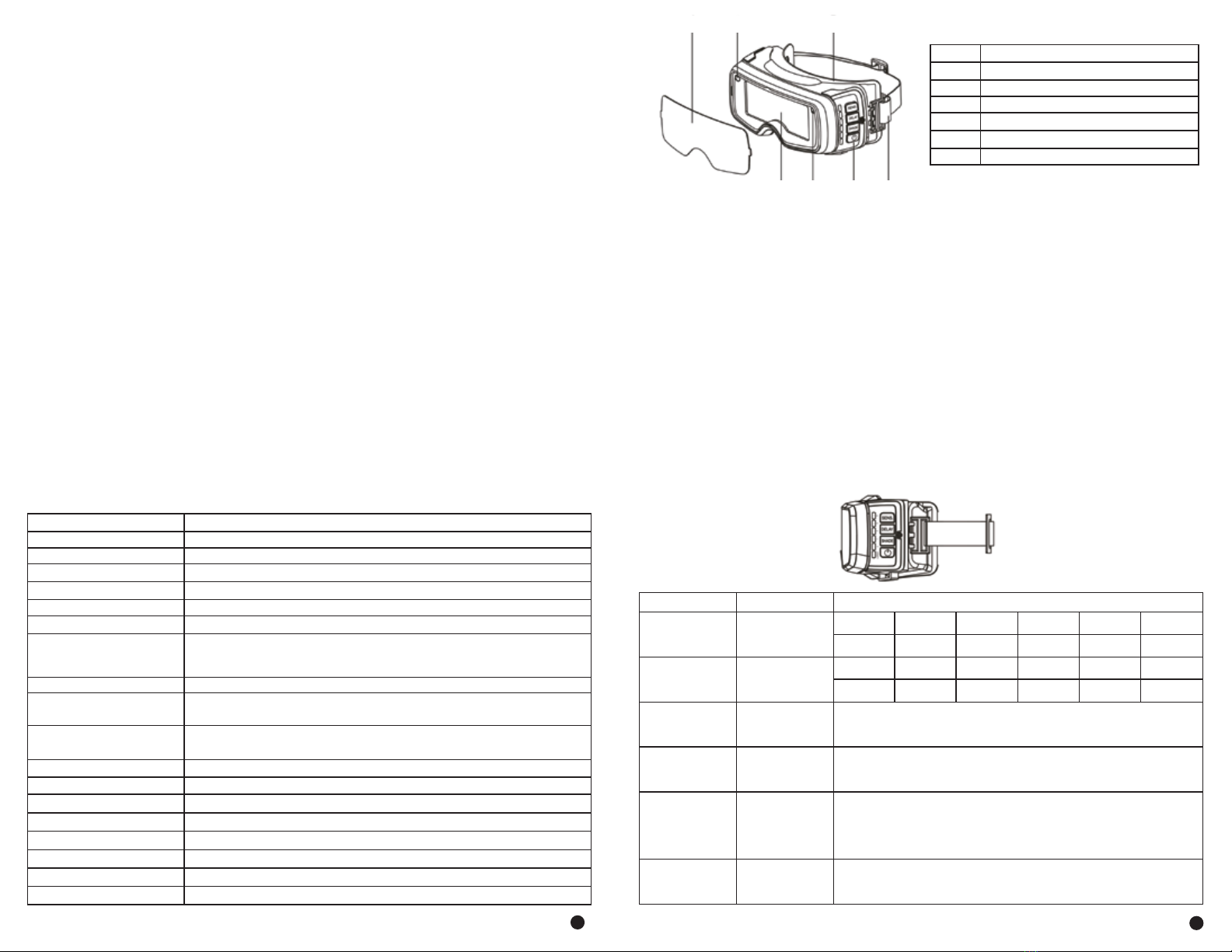

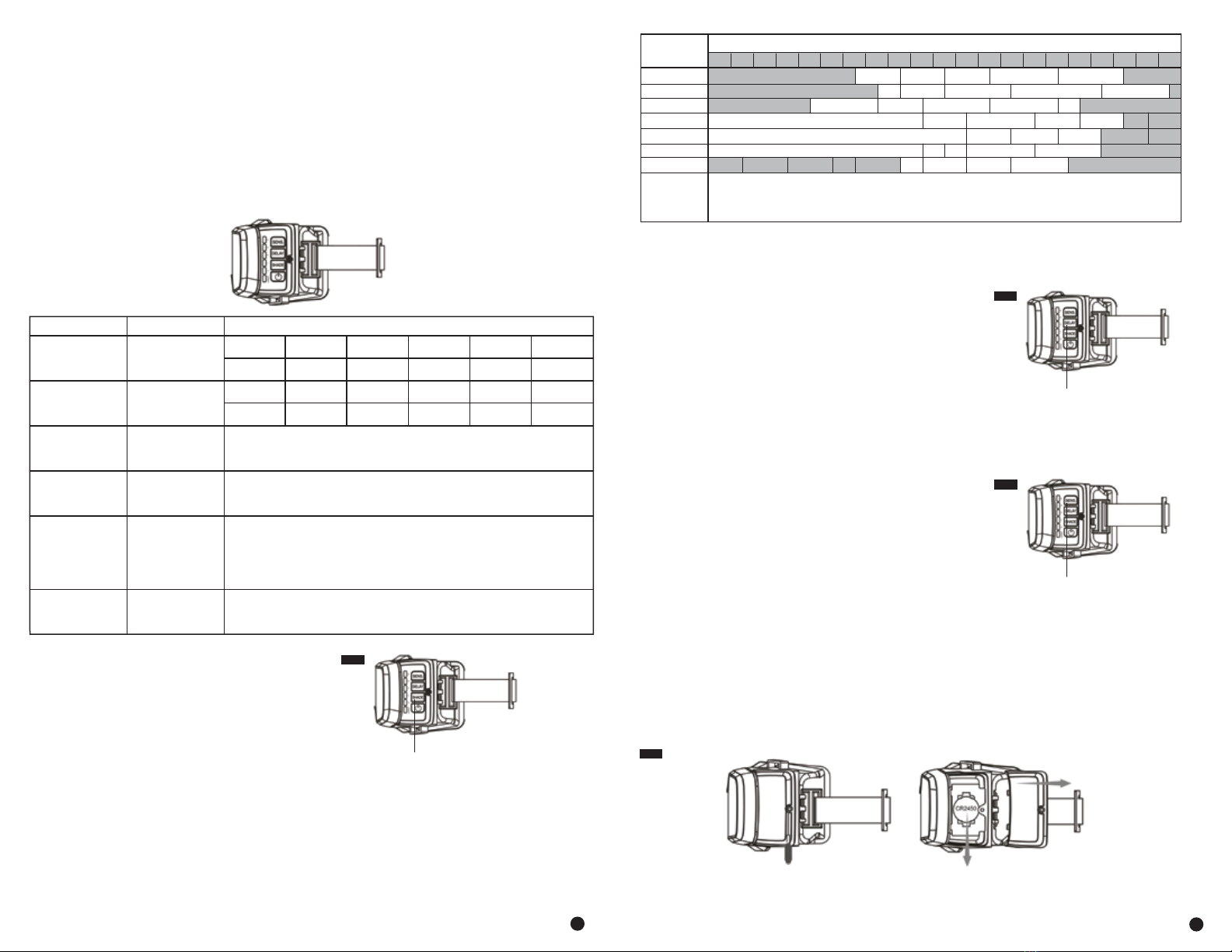

LUNETTES DE SOUDAGE NUMÉRIQUES

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

• Le soudage peut produire des émanations et des gaz dangereux pour la santé. Gardez la tête hors des émanations.

Ne respirez pas les émanations.

• Si vous êtes à l’intérieur, ventilez la zone ou utilisez un dispositif d’échappement près de l’arc pour éliminer les

émanations et les gaz de soudage.

• Si la ventilation est médiocre, utilisez un appareil à adduction d’air homologué.

• Lisez les instructions du fabricant concernant les métaux, les consommables, les revêtements, les nettoyants et

les dégraissants.

• N’effectuez pas de soudage lorsque des activités de dégraissage, de nettoyage ou de pulvérisation ont lieu à

proximité. La chaleur et les rayons de l’arc peuvent réagir avec les vapeurs et former des gaz hautement toxiques

et irritants.

• Ne soudez pas des métaux comprenant un revêtement, comme l’acier galvanisé, plombé ou cadmié, à moins que

le revêtement soit retiré de la zone de soudure, que la zone soit ventilée et, si nécessaire, de porter un appareil à

adduction d’air. Les revêtements et tous les métaux contenant ces éléments peuvent dégager des émanations

toxiques s’ils sont soudés.

• Ne travaillez dans un espace confiné que s’il est bien ventilé ou si vous portez un appareil à adduction d’air.

Assurez-vous toujours qu’un surveillant formé se trouve à proximité. Les émanations et les gaz de soudage

peuvent avoir pour effet de déplacer l’air et d’abaisser le niveau d’oxygène, et ainsi causer des blessures ou la

mort. Assurez-vous que l’air respiré est sécuritaire.

WG3000/

WG3000S

WG3000/

WG3000S

LE BRUIT PEUT ENDOMMAGER L’OUÏE

• Le bruit de certains processus ou équipements peut endommager l’ouïe.

• Portez une protection auditive homologuée si le niveau de bruit est élevé.

INFORMATIONS GÉNÉRALES

• Les lunettes de soudage WG3000/WG3000S ne protègent pas contre les risques d’impact graves comme les

meules ou les disques abrasifs cassés, les dispositifs explosifs ou les liquides corrosifs. Les dispositifs de

protection des appareils ou des lunettes de protection contre les éclaboussures doivent être utilisés lorsque ces

risques sont présents.

• Les filtres de soudage à assombrissement automatique sont conçus pour le soudage à arc électrique ou le

coupage. Le dispositif convient à tous les procédés de soudage à arc électrique, comme les procédés MIG

(soudage sous gaz inerte), MAG (sous gaz actif), TIG (au tungstène sous gaz inerte), SMAW (à l’électrode enrobée),

au plasma, à l’arc et à l’arc au carbone.

• Ce filtre de soudage à assombrissement automatique n’est pas recommandé pour le soudage au-dessus des

épaules ou au laser, ou l’usinage au laser.

• En cas de panne électronique, le soudeur reste protégé contre les rayonnements ultraviolets (UV) et infrarouges

(IR) grâce à la teinte 11.

• Le filtre de soudage à assombrissement automatique doit toujours être utilisé avec les lentilles de protection

d’origine ou de remplacement de l’équipementier.

• Le fabricant n’est pas responsable de tout défaut dû à des modifications du filtre de soudage ou à l’utilisation du

filtre provenant d’un casque d’un autre fabricant.

• Protégez-vous et protégez les autres des étincelles projetées et du métal chaud.

• N’effectuez pas de soudage là où des étincelles projetées peuvent entrer en contact avec des matériaux

inflammables.

• Retirez tous les matériaux inflammables de la zone de soudage. Si cela n’est pas possible, couvrez-les

hermétiquement avec des revêtements homologués.

• Soyez conscient que les étincelles de soudage et les matériaux chauds provenant du soudage peuvent facilement

traverser de petites fissures et ouvertures communiquant avec les zones adjacentes.

• Soyez conscient que le soudage sur un plafond, un plancher ou une cloison peut provoquer un incendie du côté que

vous ne voyez pas.

• Ne soudez pas sur des contenants fermés comme des réservoirs, des fûts ou des tuyaux à moins que ceux-ci

soient correctement préparés selon les normes F4.1 de l’American Welding Society (AWS, Société de soudage

américaine).

• Raccordez le câble de travail aussi près que possible de la zone de soudage pour éviter que le courant de soudage

parcoure de longs trajets, possiblement inconnus, et puisse provoquer des décharges électriques et des

risques d’incendie.

• N’utilisez jamais de soudeuse à arc électrique pour faire dégeler des tuyaux.

• Retirez l’électrode du porte-électrode lorsqu’elle n’est pas utilisée.

• Portez des vêtements de protection exempts d’huile comme des gants en cuir, une chemise épaisse, un pantalon

sans revers, des chaussures hautes et une casquette.

• Retirez tous les combustibles comme les briquets ou les allumettes se trouvant sur vous avant de commencer

le soudage.