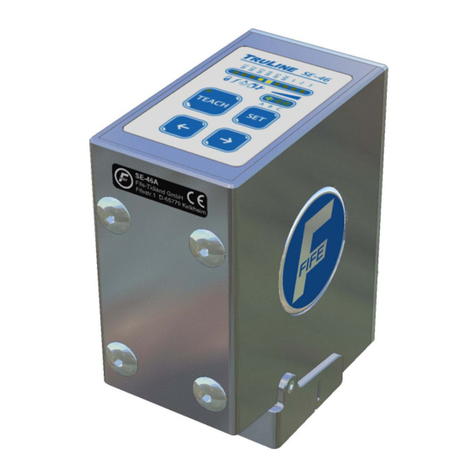

SE-45 TRUWIDE ULTRASONIC SENSOR

USER MANUAL

TABLE OF CONTENTS

COPYRIGHT.................................................................................................................................................. i

TABLE OF CONTENTS .............................................................................................................................. iii

GENERAL INTRODUCTION ........................................................................................................................ 1

DEFINITION OF TERMS ................................................................................................................. 1

SE-45 TRUWIDE ULTRASONIC SENSOR GENERAL INFORMATION ........................................ 2

CAUTIONS AND WARNINGS ......................................................................................................... 2

GETTING STARTED .................................................................................................................................... 3

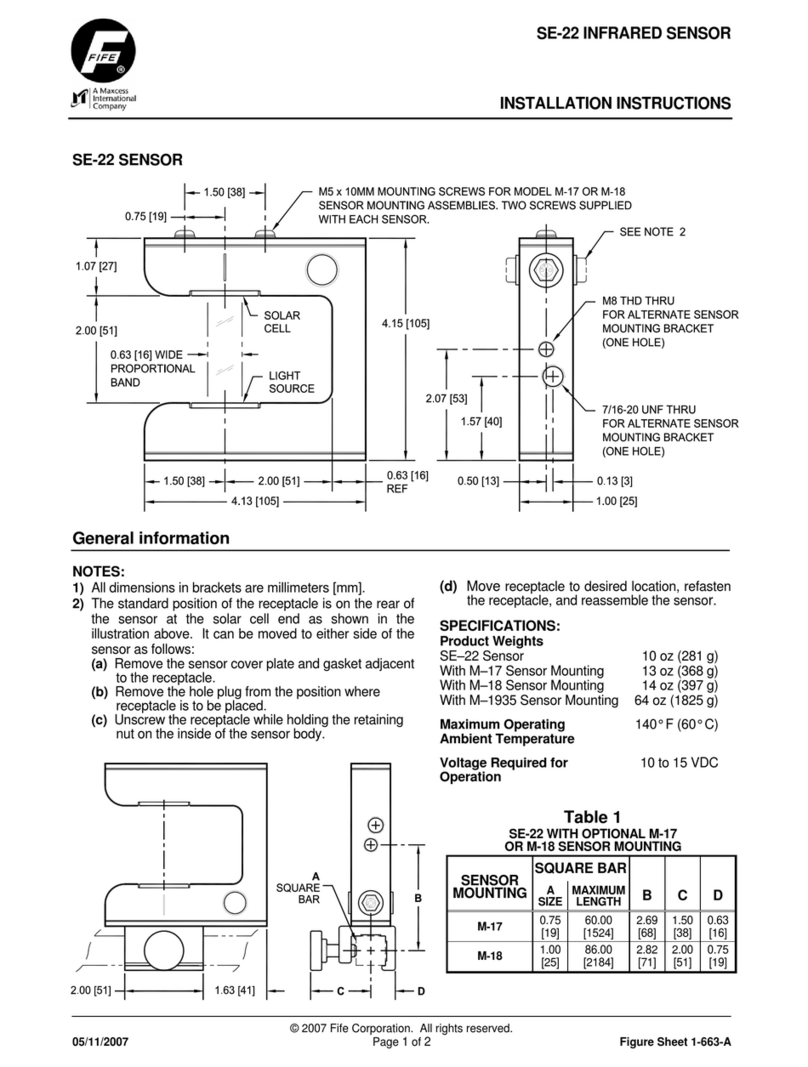

CONNECTIONS, SE-45 SENSOR .................................................................................................. 3

POWER CONNECTION .................................................................................................................. 3

NETWORK CONNECTION..............................................................................................................4

SENSOR OPERATION................................................................................................................................. 5

SE-45 BASIC OPERATION ............................................................................................................. 5

Analog Outputs ................................................................................................................... 5

Digital Outputs..................................................................................................................... 5

Sensor Jobs ........................................................................................................................ 5

OPERATION MODES...................................................................................................................... 6

SE-45 Single Proportional Band Mode Of Operation ......................................................... 6

SE-45 Multiple Proportional Band Mode Of Operation ....................................................... 7

Edge Learning..................................................................................................................... 7

Proportional Band Size ....................................................................................................... 7

Virtual Sensor Linking ......................................................................................................... 7

MODBUS/TCP INTERFACE............................................................................................................8

Default Signals .................................................................................................................... 8

Default Data ........................................................................................................................ 9

Remote Control ................................................................................................................. 10

SE-45 WEB PAGE ......................................................................................................................... 15

OPERATOR INTERFACE .......................................................................................................................... 17

SE-45 HOME SCREEN ................................................................................................................. 17

KEY DEFINITIONS ........................................................................................................................ 18

MENUS ....................................................................................................................................................... 21

MENU NAVIGATION NOTES........................................................................................................ 21

JOB SETTINGS ............................................................................................................................. 21

Set Sensor Mode .............................................................................................................. 21

Job Settings Menu Structure............................................................................................. 22

SELECT JOB ................................................................................................................................. 23

Select Job Menu Structure................................................................................................ 23

HARDWARE SETTINGS ...............................................................................................................24

Calibrate Transducers....................................................................................................... 24

Hardware Settings Menu Structure................................................................................... 24

CONTROL OPTIONS .................................................................................................................... 25

Job Enable ........................................................................................................................ 25

Remote Control ................................................................................................................. 25

Length Unit........................................................................................................................ 25

Control Options Menu Structure ....................................................................................... 25

CONFIGURATION ......................................................................................................................... 26

Names............................................................................................................................... 26

Serial Number ...................................................................................................................26

FW Number.......................................................................................................................26

5/19/2009 Page iii of iv Figure Sheet 1-903-A