CONTENTS

1.0 INTRODUCTION 5

1.1 About these operating instructions ................................................................. 5

1.2 Product overview............................................................................................. 6

1.3 Model number ................................................................................................ 6

1.4 Serial number.................................................................................................. 6

1.5 DST-1 components......................................................................................... 7

1.6 Ordering information ...................................................................................... 7

2.0 SAFETY 8

2.1 Instructions for use......................................................................................... 8

2.2 Symbols used.................................................................................................. 8

2.3 Basic safety information.................................................................................. 9

3.0 INSTALLATION 11

3.1 Product dimensions ...................................................................................... 11

3.2 Mounting the DST-1 operator interface ........................................................ 12

3.2.1 Wall mount ........................................................................................ 12

3.2.2 Panel mount ...................................................................................... 13

3.2.3 DST-1 mounting bracket assembly ................................................... 14

3.3 Electrical ....................................................................................................... 15

3.4 Wiring diagrams............................................................................................ 15

3.5 Analog outputs ............................................................................................. 16

3.5.1 DST-1 Analog output 1 and 2 ........................................................... 16

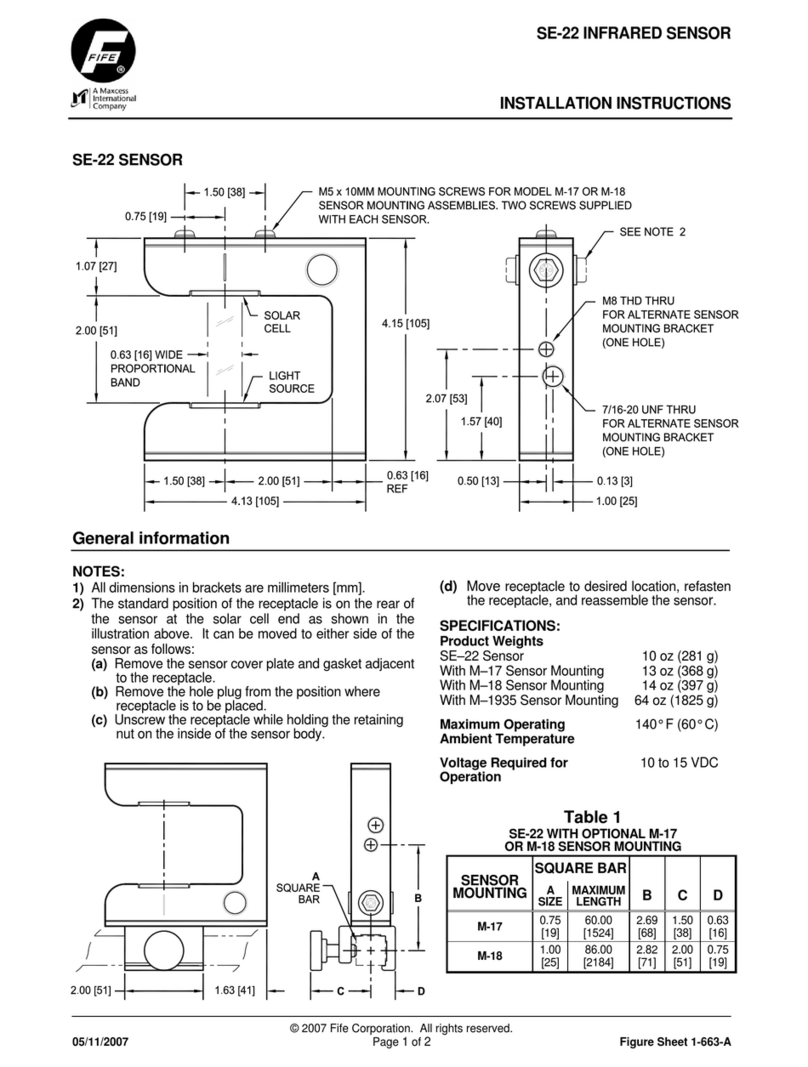

3.6 Optical sensor installation ............................................................................ 17

3.6.1 Optical sensor guidelines for installation .......................................... 17

3.6.2 Sensor placement guidelines ............................................................. 18

4.0 DST-1 PASSWORD SECURITY 19

4.1 Overview ....................................................................................................... 19

4.2 Set up password security (first time use)...................................................... 20

4.3 Identifying security status............................................................................. 22

4.4 Change password protection settings ........................................................... 22

4.5 Change password or password type.............................................................. 23

5.0 DST-1 OPERATOR INTERFACE MENU STRUCTURE 24

6.0 SENSOR OPERATING PARAMETERS 26

6.1 Global parameter group ................................................................................ 27

6.2 Manual setup parameters.............................................................................. 29

6.2.1 Camera parameters ........................................................................... 29

6.3 Signal function types .................................................................................... 30

6.4.1 Edge/Line detection functions........................................................... 32

6.4.2 ROI definition and configuration ....................................................... 33

6.4.3 Using DST-1 OI touch screen to set ROI ............................................ 34

AUTOMATIC SETUP PROCEDURE 35