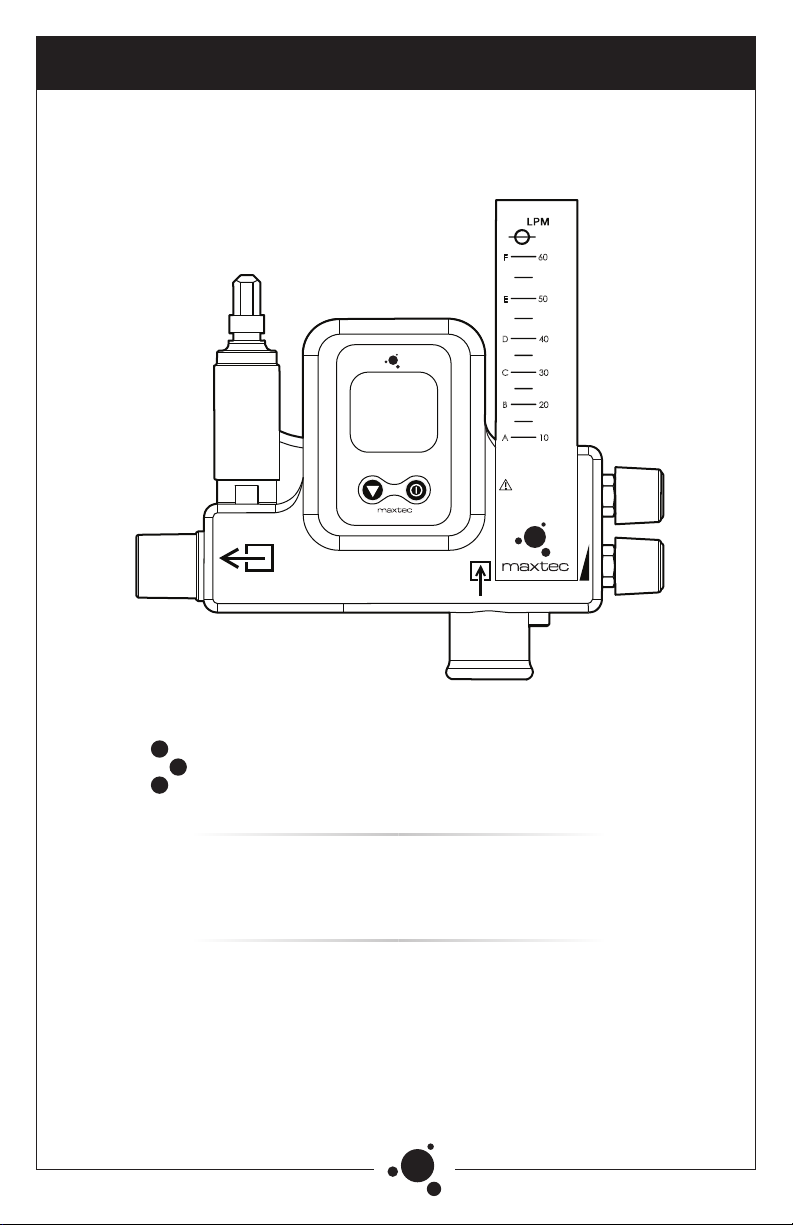

II 866.4.Maxtec www.maxtec.com

WARNINGS

Indicates a potentially hazardous situation, if not avoided, could result in death or serious injury.

» This device is not intended for use with life supporting devices/systems.

» Failure to comply with the warnings and precautions in this manual could result in

instrument damage and possibly jeopardize the wellbeing of the patient and/or health care

professional. Improper use of this device can cause inaccuracy of flow and oxygen readings

which can lead to improper treatment, hypoxia or hyperoxia, or other patient injury or

discomfort. Follow the procedures outlined in this user manual.

» Not for use in an MRI environment.

» If the O2% drifts away from the level to which it was set, check to make sure the nasal prongs

on the patient interface are not occluded by sputum or the nasal septum. Flow restriction to the

circuit or patient interface will cause the oxygen level to increase. Flow restriction downstream of

the venturi unit will not be detected by the flow meter.

» This device does not have any alarms for interruption in oxygen supply.

» Allow oxygen reading to stabilize before adjusting oxygen content.

» This device does not have any alarms for oxygen level high or low alarms.

» Never allow excess length of tubing near the patient’s head or neck which could result in strangulation.

» Use only Maxtec replacement sensors. Use of any other sensor will void warranty and may lead

to product damage, product malfunction, improper treatment to patient, hypoxia, or hyperoxia.

DO NOT use this device near any type of flame or flammable/explosive substances, vapors or

atmosphere. Operating the oxygen analyzer in these environments may result in fire or explosion.

» This device in its entirety (including electronics) is not suitable for use in the presence of

flammable anaesthetic mixtures or in an atmosphere of explosive gases. Operating the oxygen

analyzer in these environments may result in fire or explosion.

DO NOT attach a humidifier or any other source gas to the room air inlet. It should be occupied

at all times by the filter listed in the disposables list. The inlet filter prevents

entrainment of ambient contamination and silences venturi noise. The filter provided with the

MaxVenturi is single-patient use only.

» Use of this device with a pressurized oxygen bottle may result in inaccurate oxygen

concentration readings when used above 40 LPM and at high oxygen concentrations. High tank

pressures result in cooling oxygen supply temperatures which affect the accuracy of the oxygen

sensor. It is suggested that the device be connected with a long supply hose. Use a 15 ft supply

hose where possible — Maxtec P/N (R127P35).

» Use patient circuits that are approved for use with the manufacturer’s humidifier as listed in

their individual instructions for use.

DO NOT attempt to clean the inside of the flow meter. If any malfunction is detected in the

function of the flow meter, if any debris or contamination is detected in the flow meter, or if the float

sticks in the flow tube, discontinue use immediately and return the device to Maxtec for service.

» Never install the sensor in any location other than the sensor port in the device.

SENSOR WARNINGS: The Maxtec MAX-250 oxygen sensor is a sealed device containing a mild

acid electrolyte, lead (Pb), and lead acetate. Lead and lead acetate are hazardous waste constituents

and should be disposed of properly, or returned to Maxtec for proper disposal or recovery.

DO NOT use ethylene oxide sterilization.

DO NOT immerse the sensor in any cleaning solution, autoclave or expose the sensor to high

temperatures.

» Dropping or severely jarring the sensor after calibration may shift the calibration point enough to

require recalibration.

CAUTION: Indicates a potentially hazardous situation, if not avoided, could result in minor or

moderate injury and property damage.

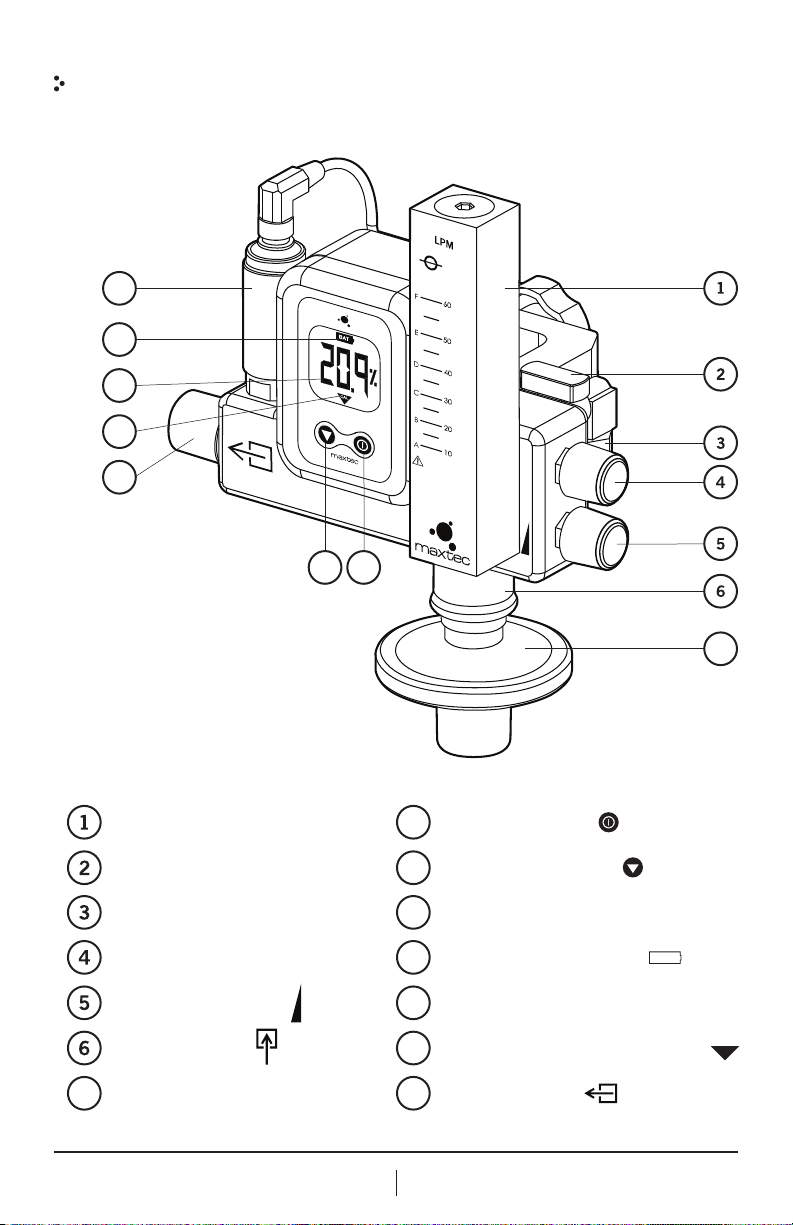

» The MaxVenturi is intended for use with specific patient interface configurations. The numbered scale

is intended for use with Fisher & Paykel* heated humidifier (MR850) and the Optiflow high flow patient

interface system (OPT846, OPT570) and Comfort Flo® Circuits (2415 & 2416) with the Hudson RCI®

Neptune®Heated Humidifier (425-00). The lettered scale (Labeled A through F) is intended for the

alternate patient circuits found on the chart provided in Section 2.