Maxwell Marine International Ltd – HRC10 Series 3

OPERATION

CAUTION:

Make sure that you do not operate the footswitch

accidentally while putting extra turns on the capstan.

Keep your fingers clear of the chainwheel and/or capstan.

When operating the windlass:

-

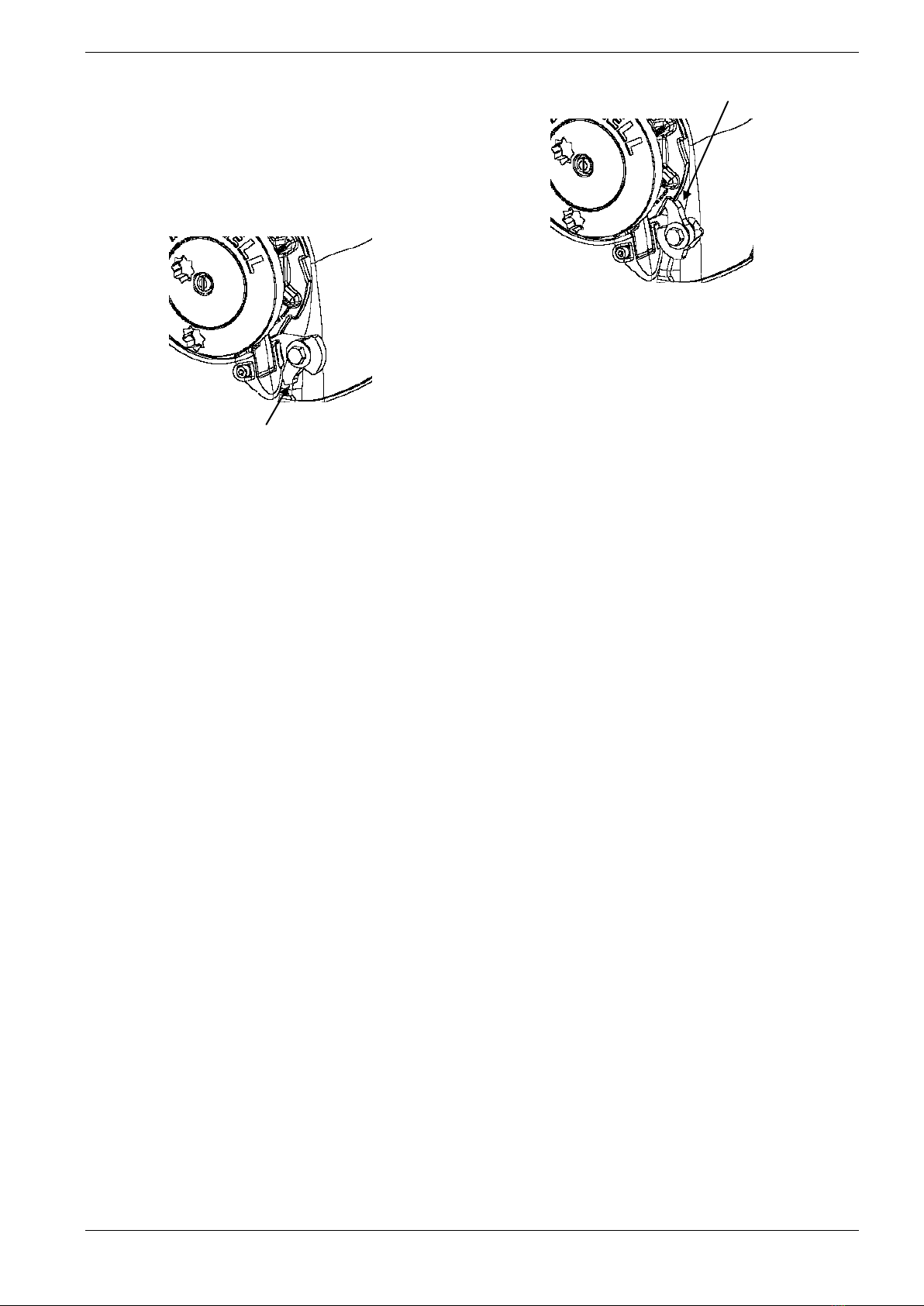

Ensure the pawl is in the disengaged position when

paying out the anchor.

Pawl In Disengaged position

-Do not switch immediately from one direction to the other.

Wait for the windlass to stop in one directio

applying power in the other direction.

-

Run the boat’s motor(s) at sufficient rpm to activate the

charging system.

Always make sure the isolator switch is turned off when

the system is not being used.

Lowering the Anchor

Insert the clutch handle into the clutch nut and tighten the

clutches by turning the nut clockwise. Only tighten

sufficiently so that you can easily pull up the anchor.

REMOVE THE CLUTCH HANDLE.

Operate the windlass by pressing the toggle switch down

on the remote up/down control panel to pay out the

rope/chain (or press the "Down" footswitch if fitted).

Pay out sufficient rope/chain to set the anchor.

Watch as the rope/chain is being fed out. Any jam might

cause damage to the windlass.

Raising the Anchor

Insert the clutch handle into the clutch nut and tighten the

clutches by turning the nut clockwise. Only tighten

sufficiently so that you can easily pull up the anchor.

REMOVE THE CLUTCH HANDLE. NOTE: Over tightening

the clutches can cause damage to the motor when docking

the anchor.

Operate the windlass by pressing the toggle switch up on

the remote up/down control panel (or press the "Up"

footswitch if fitted).

Motor up to the anchor while retrieving it. Do not use the

windlass to pull the boat to the anchor.

To avoid damaging the bow fitting, retrieve the last meter

(3’) of rope/chain slowly and take care when docking the

anchor.

Note: To avoid applying the full force of the windlass to the

bow fitting when docking the anchor, adjust the clutch nut

so that there is some slippage when docking the anchor.

Free falling the Anchor

Insert the clutch handle into the clutch nut and loosen by

slowly turning the handle anticlockwise.

Tightening the clutch nut clockwise will control the rate of

descent.

CAUTION: Do not

allow the chainwheel to free wheel

uncontrolled as this will allow dangerously high speeds to

Raising the Anchor Manually:

Move the pawl into the engaged position.

Insert the clutch handle into the clutch nut and turn

anticlockwise to loosen the clutch. Note the chain wheel

may pay out the anchor until the pawl

chainwheel.

Insert the clutch handle into the outer bi-square of the

chainwheel and rotate anticlockwise to pull in the line. A

bi-square to ½” socket adator has been provided with your

windlass. This can be used with any ½” ratchet to recover

the rode.

Using the Capstan Drum for Rope Warping:

The capstan can be used independently from the

chainwheel. This is ideal for handling mooring or docking

lines, or retrieving a second anchor. For safety reasons, a

footswitch is highly recommended.

To haul in using the capstan:

Make sure the anchor is secured.

Insert the clutch handle into the clutch nut and turn

anticlockwise until rotation stops. This will release the

mechanism so that the chainwhe

while you operate the capstan.

Take three turns of rope around the drum in a clockwise

direction.

While holding the tail of the rope, press the "Up"

footswitch. The capstan will rotate clockwise.