5

Condensation on the Canopy

The polyester canopy fabric absorbs much less water than nylon, so the

inner tent walls will usually feel dryer than nylon would, and, unlike nylon,

will not stretch and sag in damp conditions. MEC’s proprietary Tensilk-HTTM

polyester is exceptionally strong, yet weighs about the same as no-see-

um mesh. Tensilk-HT gets its strength from an extremely tight weave, so

under very cold conditions (minus 15°C or below) some condensation and

icing may occur on the inside of the canopy. If it does, simply brush off and

sweep out any accumulated frost before packing the tent.

Ultralight Set-up

Using a custom Footprint (available separately), you can erect just the fly.

This configuration provides a very light, compact, and basic shelter, and

will dry more quickly in the morning because of better airflow. However,

the set-up is not readily bug-proof, it is subject to more condensation

forming on the inside of the fly, and it does not keep foul weather out as

effectively.

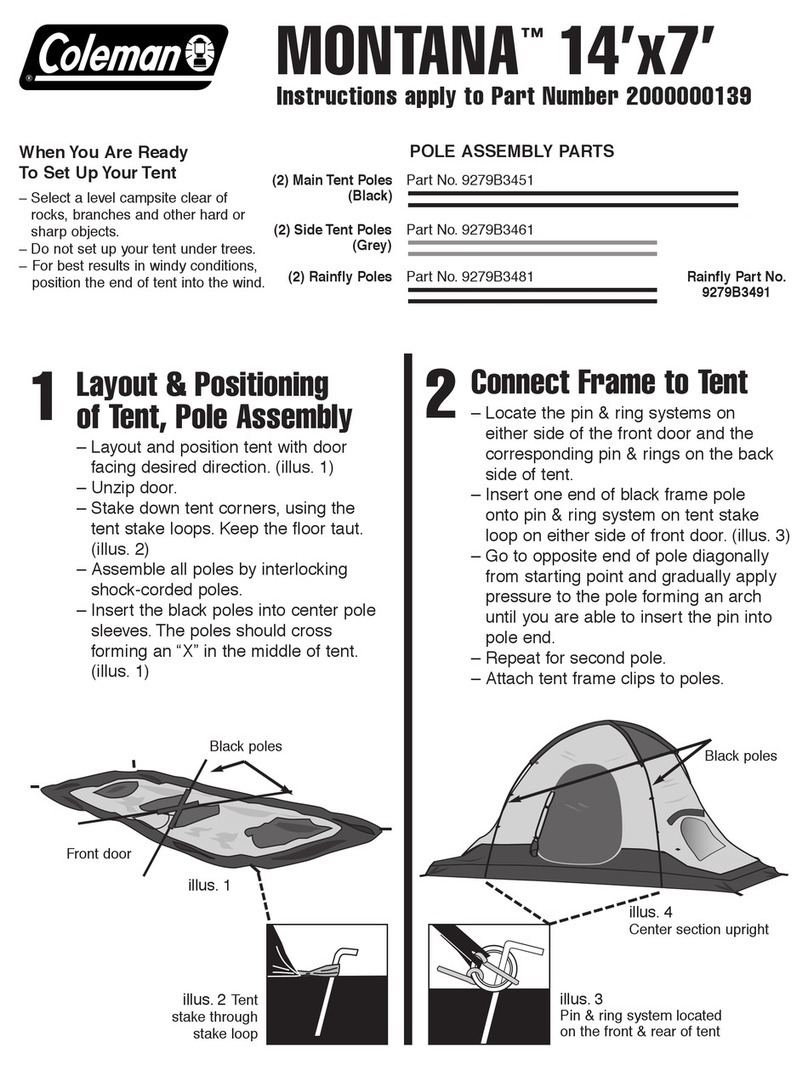

This set-up is easiest with two people. Spread the Footprint out flat on

the ground. Insert the two long gold poles into the appropriate grommets

at the front and back corners of the Footprint, while one person holds

the two poles steady at the point where they cross. Spread the fly over the

poles (and the person). Ensure the fly doors are correctly oriented to the

Footprint, then use the Velcro fasteners at the centre inside top of the fly to

secure the pole crossing by wrapping around the crossover point. Insert the

two short black poles into the appropriate Footprint grommets, with the

angled pole to the front. Secure them to the gold poles at the four crossing

points using the Velcro strips on the fly. Attach the remaining Velcro strips

directly to individual poles. Attach the grommet strips at the base of the

fly to the pole tips, folding them under as for usual set-up. The tent may

be guyed and pegged out as usual. In wind, peg out the Footprint before

beginning. Keep vents and doors open as much as possible to minimize

condensation. Snow, sand, etc. may be piled up or scooped away around

the base of the fly to vary the airflow through the tent. Disturb soil as little

as possible to leave the site untouched for others to enjoy.

Anchoring the Tent

The #7001-T6 aluminum stakes included with the tent are suitable for

general use on relatively soft ground. However, in very hard-packed

ground you will need stronger (and heavier!) stakes that can withstand

the force needed to drive them in. On snow, sand, or other loose-packed

surfaces, wider T-Stakes or aluminum snow stakes will hold better; these

stakes hold best buried horizontally. You can also improvise with other

“stakes” (hiking staffs, ice axes, branches, rocks, trees), using the tent’s

stake loops or cord as required.

Lightfield eng.indd 5Lightfield eng.indd 5 3/1/05 2:32:26 PM3/1/05 2:32:26 PM