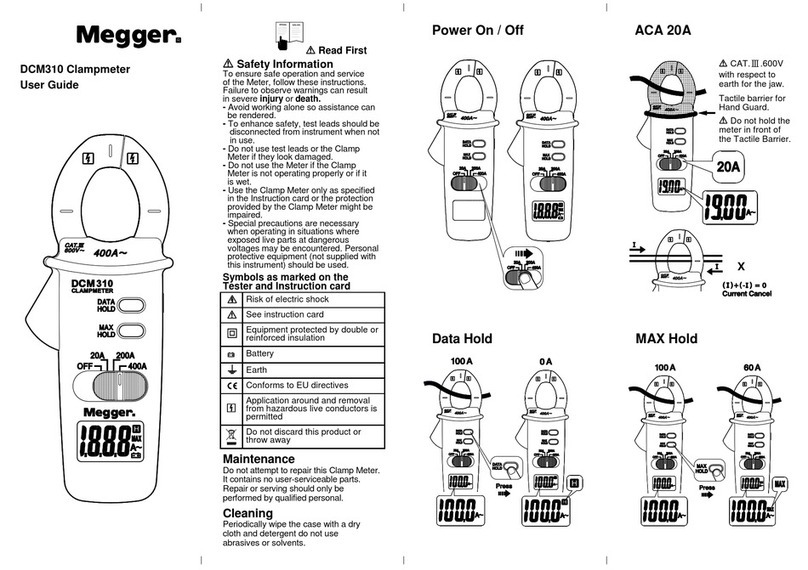

3. Close the ICLAMP around the conductor

under test.

4. Set the rotary selector switch to the

Aposition.

5. The ground current flowing in the

conductor will be displayed.

Resistance measurement using ART

1. Ensure the rotary selector switch is in the

position.

2. Connect the instrument as shown.

3. Close the ICLAMP around the conductor

under test.

4. Set the rotary selector switch to the 3P

or 4P position.

5. Press and release the button [by

holding the button, the resistance

measurement will be continually updated].

6. The instrument will perform pre-measure-

ment checks, the status of which will be

indicated on the display.

7. The three-terminal or four-terminal

resistance reading using ART will be dis-

played.

SPECIFICATIONS

Measurement range: 1mA to 1200 A

Transformation ratio:1000 : 1

Output signal: 1mA / A (1 A @ 1000 A)

Accuracy

1mA to 100 mA : ≤3% of reading

0.1 A to 1 A : ≤2% of reading

1 A to 10 A : ≤1% of reading

10 A to 100 A : ≤0.5% of reading

Operating temperature

-10°C to +50°C / 14°F to 122°F

0% to 85% RH at +35°C / 95°F

Storage temperature

-20°C to +70°C / -4°F to 158°F

Jaw opening: 57 mm maximum (2.3 in)

Maximum conductor size: 52 mm (2.1 in)

Insulation: Double insulation

Voltage rating: 600 V CAT III

Current rating: 1200 A for 20 minutes

Ingress protection: IP40

Safety

EN61010-2-032

EMC

EN 50081-1 Class B

EN 50082-2

Dimensions: 111 mm x 216 mm x 45 mm

(4.4 in x 8.5 in x 1.8 in)

Weight: 0.5 kg approximately (1.2lb)

TEST

TEST

OFF

PREPARATIONS FOR USE

1. Ensure that the ICLAMP jaw mating surfaces

are free of dust and contamination and that

they contact completely when the ICLAMP

is closed.

2. Currents carried by conductors in close

proximity to the ICLAMP may affect

calibration and reduce the accuracy of

measurements made.

CALIBRATION OF THE ICLAMP

The ICLAMP should be calibrated once at

each test site to take into account the effects

of transportation, temperature and humidity

on the ICLAMP.

1. Ensure the rotary selector switch is in the

position.

2. Connect the instrument as shown.3.

Connect the C1 and C2 terminals together

using the calibration lead supplied with the

ICLAMP [X and C terminals for DET3TC].

4. Ensure that the ICLAMP is not clamped

around a conductor.

5. Press and hold the button and

switch instrument ON to the A

setting using the selector switch.

6. Release the button.

7. Press and hold the button until a “0”

reading is obtained on the display

8. Close the ICLAMP around the calibration

lead which connects the C1 and C2

terminals [X and C terminals for DET3TC].

9. Press and hold the button until a

“100” reading is obtained on the display.

10. Switch the instrument using the

selector switch.

11. The instrument is now calibrated to the

ICLAMP and the calibration stored in non-

volatile memory.

OPERATION OF THE ICLAMP

Measurement of ground current

1. Ensure the rotary selector switch is in the

position.

2. Connect the instrument as shown.

OFF

OFF

TEST

TEST

TEST

TEST

OFF