Users of this equipment and/or their employers are reminded that National

Health and Safety Legislation requires them to carry out valid risk assessments

of all electrical work so as to identify potential sources of electrical danger and

risk of electrical injury such as inadvertent short circuits. Where the

assessments show that the risk is significant then the use of fused test leads

may be appropriate.

Symbols used on the instrument:

GCaution: refer to accompanying notes

tEquipment protected throughout by Double Insulation

(Class II)

cEquipment complies with relevant EU Directives

Equipment complies with ‘C tick’ requirements

Do not dispose of in the normal waste stream

Maximum input voltage 600 V rms

Application

BS EN 61010 defines measurement categories from I to IV relating transient

over voltages and the location within the electrical installation. This

instrument is designed for use at Category III (Building

installation/distribution board level) up to 600 V (maximum) rms to earth and

600 V (maximum) rms between terminals. It may also be used at Category IV

(Primary supply level) on 300 V rms phase to earth systems.

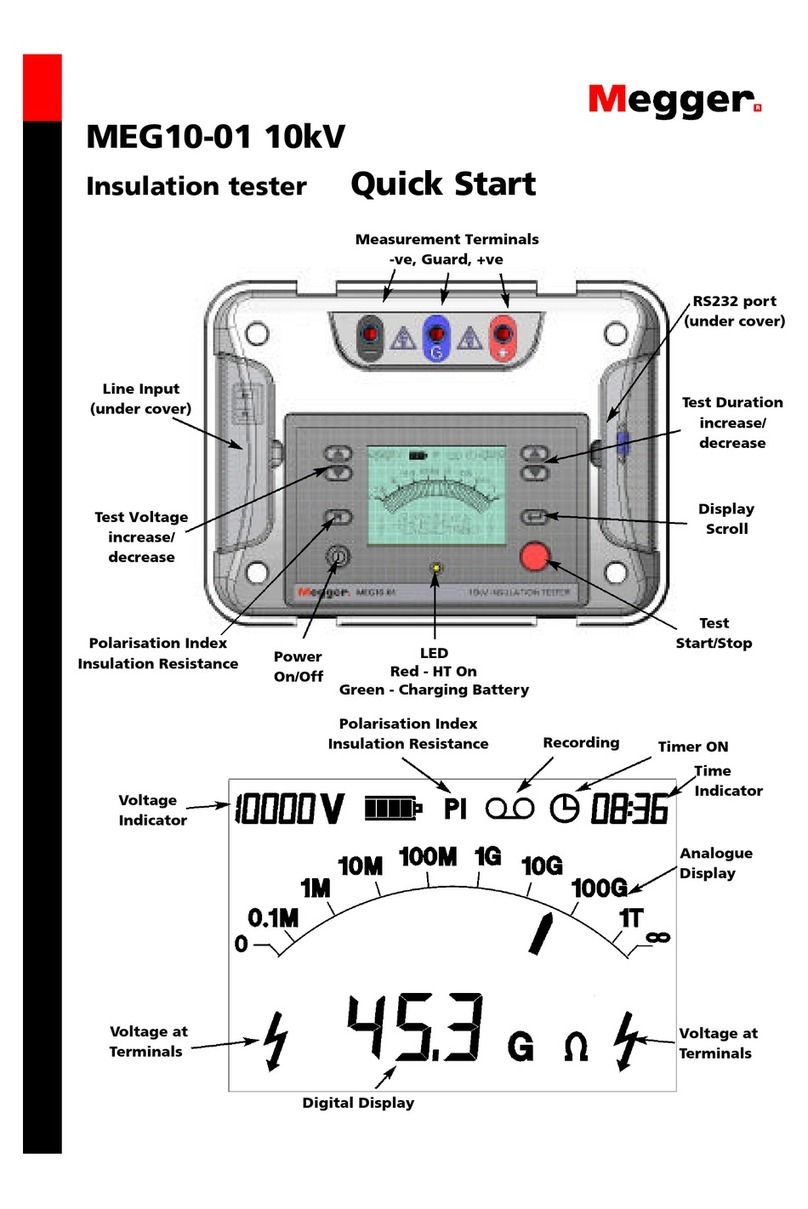

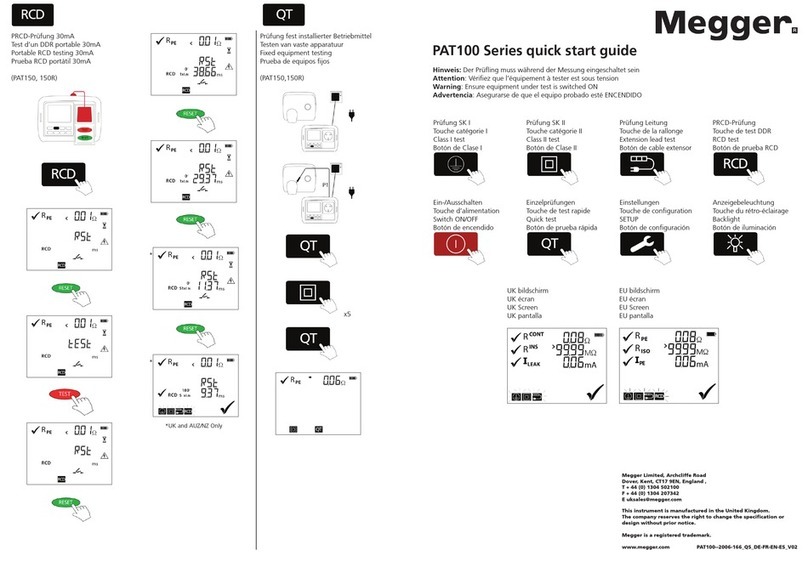

Display layout

Accuracy (at 20° C) ±3%, ±2 digits (or 30% of reading

200 kΩto 10 MΩ)

Continuity ranges

Measuring Range: 0,01 Ω-100 Ω(0 -50 Ωon analogue

scale)

Open Circuit Voltage: 5 V ±1V

Short Circuit Current: 205 mA, ± 5 mA (0 to 10 Ω)

(>20 mA up to 100 Ω)

Accuracy (at 20° C): ±3% ±2 digits

Null Offset Adjust: 0 – 9 Ω

Continuity Buzzer: Operates at < 5 ΩResponse time

<20 ms

Default voltmeter: all test modes except off

Test inhibit: >50 V

AutoPower Down: Operates after 10 minutes if left in

standby mode.

Environmental

Operating Range: -10°C to +55°C

Operating Humidity: 93% R.H. at +40°C max.

Storage Range: -25°Cto +65°C

Dimensions: 195 mm x 98 mm x 40 mm

Weight: 550 gms

Battery: 6 x 1,5 V cells IEC LR6 type (AA

alkaine) or NiMH rechargeable

Battery life: 3000 consecutive tests (5 sec/test)

on any test using 2Ah batteries

Fuses

Terminals: 500 mA (F) 600 V, 32 x 6 ceramic HBC

50 kA minimum

Safety

Meets the requirements of BS EN61010-1, Cat III 600 V phase to earth. Refer to

safety warnings supplied.

Automatic discharge

After an insulation test, the circuit under test will be discharged automatically.

Any voltage present will be indicated on the display so that the discharge can

be monitored.

EMC

In accordance with IEC 61326 including amendment No.1

Included accessories

Test lead set (red and black) with crocodile clips 6220-779

Hard carry case 5410-346

M

MIT200 Series

Insulation and Continuity Testers

User guide

Operation

All circuits must be isolated before an insulation or continuity test.

Automatic Voltage detection

The instrument will automatically display voltage between 25 V and 600 Vac

or dc when connected to the circuit under test.

Remove the source of any voltage before continuing to test.

Test lead check

1. Before each use of the instrument, inspect the test leads, prods and

crocodile clips to confirm that their condition is good, with no damaged or

broken insulation.

2. Check continuity of the test leads by firmly shorting the leads together and

read the test lead resistance measurement directly from the display.

Backlight operation

1. Turn the instrument backlight on by selecting the position. Backlight

stays on for 1 minute.

2. When the backlight is activated, select the desired test position.

3. Change range or press [TEST] to re-initialise backlight for another minute.

Test lead null

To remove test lead resistance before continuity tests:

1. Switch the instrument to [Ω]

2. Short test leads together, wait for a stable reading and press the test button

on the instrument. The display should read 0.00 Ωand display the [z]

symbol.

Lead null value is automatically stored until reset.

To remove, press the TEST button again with leads open circuit.

Continuity Measurement [Ω]

1. Set range switch to [Ω].

2. Connect the red and black test leads to the circuit to be tested. The

instrument will automatically display continuity resistance when connected

(up to 99.9 Ω).

NOTE: If “>100.0 Ω“ is displayed the resistance of the circuit is over-range.

Continuity Buzzer [ ]

1. Set the instrument to [ ] range.

2. Connect the test leads to the circuit to be tested.

3. The buzzer will sound automatically when a circuit is made

(<5Ω)

4. If a circuit voltage >2 V is detected the test will be inhibited.

Insulation testing [ MΩ] all instruments

1. Set range switch to [250 V], [500 V] or [1 kV] as available.

2. Press and hold down the TEST button to start test. The display will settle,

and show the insulation test resistance in MΩ.

3. If a circuit voltage of >25 V is detected the instrument will give a warning

Beep but allow testing to continue.

If a circuit voltage >50 V is detected, further testing will be prevented.

Warning:

After testing ensure the display returns to Zero (circuit is discharged) before

removing test leads.

Error messages:

>100.0 ΩContinuity over-range

<0.01 M ΩInsulation test result is under-range

>1000 M ΩInsulation test result is over-range

UNC Uncalibrated

E17 Instrument not configured to a specific type.

Battery replacement

Low battery voltage is indicated by the symbol in the display. To

maintain performance the batteries should be replaced at this point.

Uses 6 x 1.5 V AA (LR6) alkaline dry cells or NiMH rechargeable batteries.

To replace batteries switch off instrument and disconnect test leads from the

circuit under test.

Remove the rear battery cover and replace the batteries. Do not mix old and

new batteries.

Warning: OBSERVE CORRECT POLARITY. Incorrect battery polarity could

cause batteries to leak and damage the instrument.

Fuse replacement

A blown fuse is indicated by the symbol in the display.

To replace the fuse remove battery cover and replace fuse with type: 500 mA

(F) HBC 50 kA 600 V.

Cleaning: Wipe disconnected instrument with a clean cloth dampened with

soapy water or Isopropyl Alcohol (IPA).

Specification

Insulation ranges

Test voltage accuracy: -0% +25% over full operating

temperature

Nominal Test Voltage: 1000 V, 500 V, 250 V (d.c.)

Measuring Range: 10 kΩ- 999 MΩon all ranges

Short Circuit Current: 2 mA -1 mA +0 mA

Test Current on Load: 1 mA at min. pass values of

insulation (as specified in BS 7671,

EN61557, HD 384 and IEC 364)

GSafety Warnings and Precautions

These must be read and understood before the instrument is

used. They must be observed during use.

■The circuit under test must be switched off, de-energised and isolated

before test connections are made when carrying out insulation and

continuity tests.

■Circuit connections and exposed metalwork of an installation or equipment

under test must not be touched. Remember remote conductors may be

charged to the test voltage.

■The live circuit warning and automatic discharge are additional safety

features which may fail and therefore safe working

procedures/practices must be observed.

■The voltage function will only work if the instrument is functional and

switched on.

■After insulation tests, capacitive circuits must be allowed to discharge

before disconnecting test leads.

■The instrument, test-leads, probes and crocodile clips must be in good

order, clean and with no broken or cracked insulation.

■Ensure that hands remain behind guards of probes/clips when testing.

■National Safety Authorities may recommend the use of fused test leads

when measuring voltage on high-energy systems.

■Replacement fuses must be of the correct type and rating. to observe this

will result in a safety hazard.

■The rear cover must be in place whilst conducting tests.

NOTE

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED

AND COMPETENT PERSONS.

Optional accessories

2wire fused probe and clip set 6220-787

Rubber holster (Boot) 5410-346

Repair and Warranty

The instrument contains static sensitive devices, and care must be taken in

handling the printed circuit board. If an instrument’s protection has been

impaired it should not be used, but sent for repair by suitably trained and

qualified personnel. The protection is likely to be impaired if for example, it

shows visible damage, fails to perform the intended measurements, has been

subjected to prolonged storage under unfavourable conditions, or has been

subjected to severe transport stresses.

NEW INSTRUMENTS ARE GUARANTEED FOR 3 YEARS FROM THE

DATE OF PURCHASE BY THE USER.

Note: Any unauthorized prior repair or adjustment will automatically

invalidate the Warranty.

CALIBRATION, REPAIR AND SPARE PARTS

For service requirements for Megger Instruments contact:

Megger Limited or Megger

Archcliffe Road Valley Forge Corporate Centre

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502 243 Tel: +1 610 676 8579

Fax: +44 (0) 1304 207 342 Fax: +1 610 676 8625

Megger operate fully traceable calibration and repair facilities, ensuring your

instrument continues to provide the high standard of performance and

workmanship you expect. These facilities are complemented by a worldwide

network of approved repair and calibration companies to offer excellent in-

service care for your Megger products.

Returning your product to Megger - UK and USA service centres

1. When an instrument requires recalibration, or in the event of a repair being

necessary, a Returns Authorisation (RA) number must first be obtained

from one of the addresses shown above. You will be asked to provide the

following information to enable the Service Department to prepare in

advance for receipt of your instrument, and to provide the best possible

service to you.

■Model, e.g. MIT200.

■Serial number, to be found on the underside of the case or on

the calibration certificate (e.g. 6111-357/050305/1234)

■Reason for return, e.g. calibration required, or repair.

■Details of the fault if the instrument is to be repaired.

2. Make a note of the RA number. A returns label can be emailed or faxed to

you if you wish.

f

Analogue arc

display

Battery level

Digital display

Lead null indicator

Fuse blown

G>600V