Megger Easytest 20 kV User manual

Other Megger Test Equipment manuals

Megger

Megger RCDT300 Series User manual

Megger

Megger MVCT User manual

Megger

Megger PA-9 Series User manual

Megger

Megger MEG10-01 User manual

Megger

Megger MIT300 User manual

Megger

Megger BMM500 Series User manual

Megger

Megger SG32-1500M User manual

Megger

Megger BITE 2 User manual

Megger

Megger CM500 User manual

Megger

Megger DDA-1 User manual

Megger

Megger VLF Sinus User manual

Megger

Megger TRS1PLUS User manual

Megger

Megger T 22/1 User manual

Megger

Megger DET14C User manual

Megger

Megger MFT1800 series User manual

Megger

Megger BM5200 User manual

Megger

Megger TDR2000/3 User manual

Megger

Megger PAT120 User manual

Megger

Megger T22/13B User manual

Megger

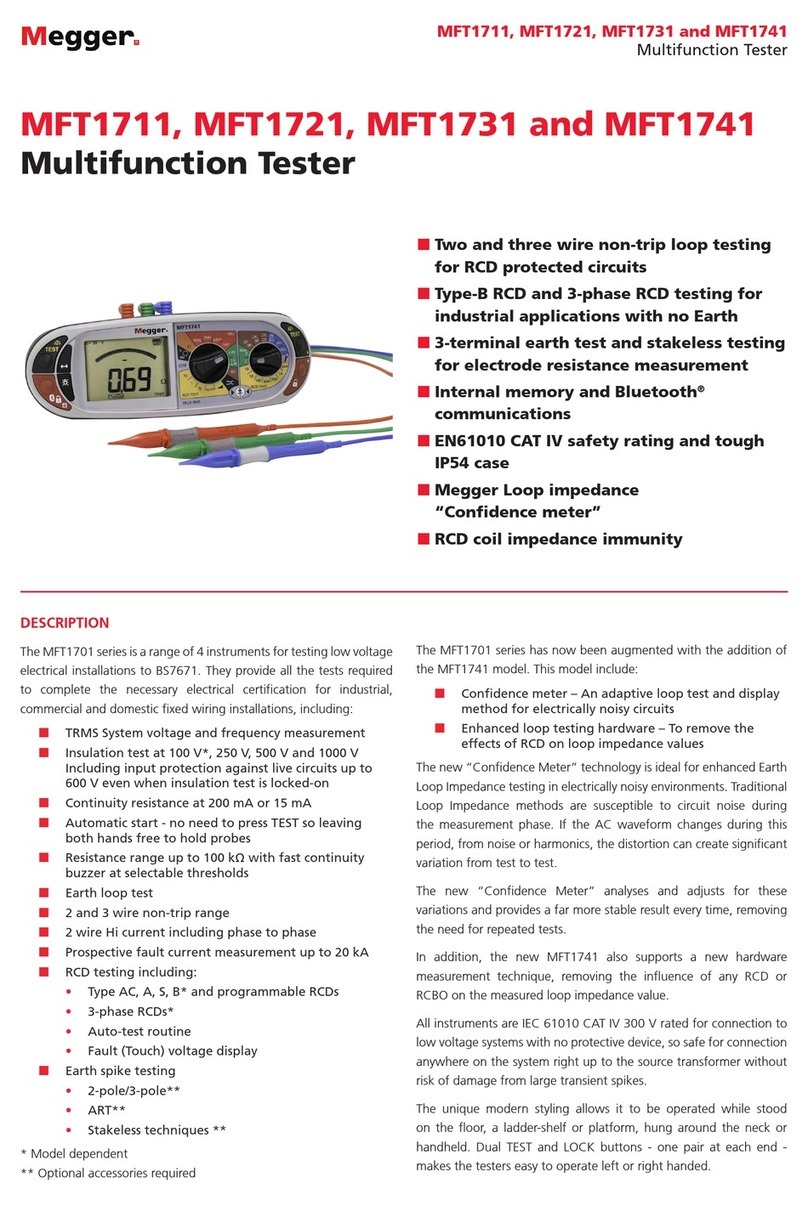

Megger MFT1711 User manual