man_vlf_cr_40_60_standalone_en_03-4.doc 7

Index Of Figures

Fig 1: Representation of the test voltage characteristics (Device option Plus).............. 19

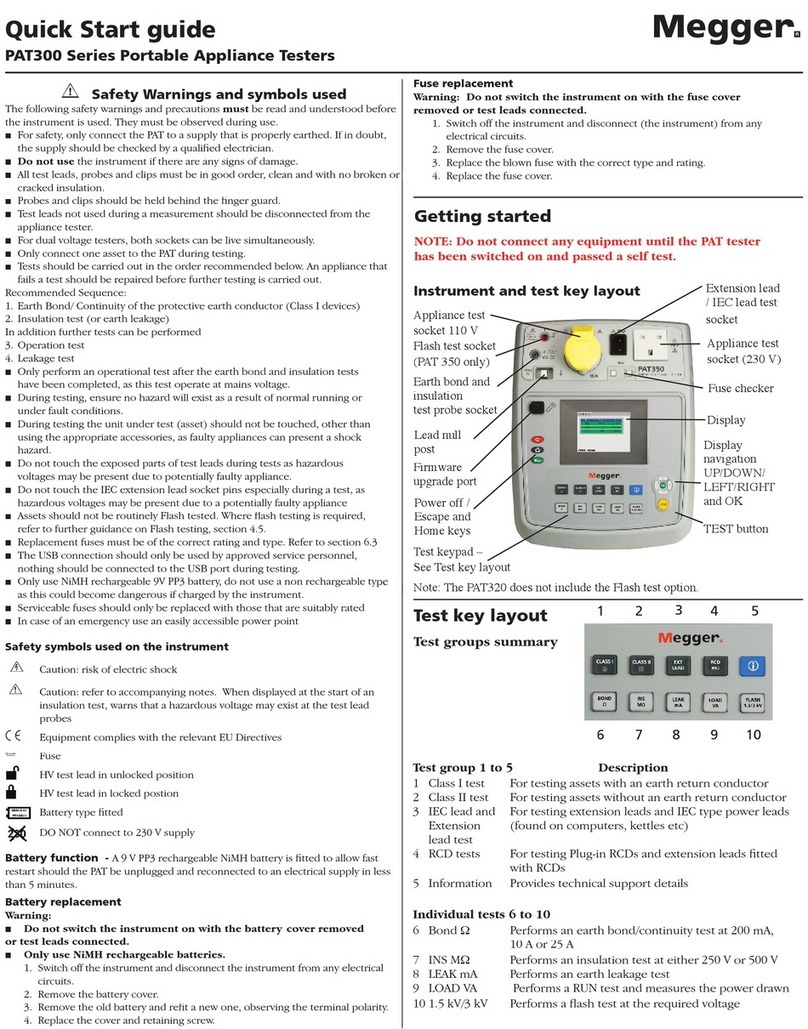

Fig 2: voltage waveform during polarity inversion ......................................................... 19

Fig 3: Operating module, Front View ............................................................................ 20

Fig 4: Display of the Operating module (View of the standard operating mode) ........... 21

Fig 5: Connections at the right hand side of the VLF Test System ............................... 22

Fig 6: Connectors on the rear of the VLF Test System................................................. 23

Fig 7: Protection cover of the Operating module........................................................... 24

Fig 8: Shorting device / Protection cover of the HV module.......................................... 24

Fig 9: Transportation protection bottom from the Operating module............................. 25

Fig 10: Connection of the test object ...........................................................................4-31

Fig 11: Start menu.......................................................................................................5-32

Fig 12: Selection of the operation mode ......................................................................5-32

Fig 13: Selection of the test voltage.............................................................................5-33

Fig 14: Selection of the test time .................................................................................5-33

Fig 15: Selection of the pulse rate ...............................................................................5-34

Fig 16: HV on5-34

Fig 17: Cable test ........................................................................................................5-35

Fig 18: Start menu after the test has been finished .....................................................5-36

Fig 19: User Setup: Language.....................................................................................6-37

Fig 20: Setup: System Informationen ..........................................................................6-37

Fig 21: Setup: Parameters...........................................................................................6-38

Fig 22: Setup: Enter password ....................................................................................6-39

Fig 23: Setup: Entered password ok............................................................................6-39

Fig 24: Setup: Enter new password.............................................................................

6-40

Fig 25: Setup: New password stored ...........................................................................6-40

Fig 26: Setup: Return to start menu.............................................................................6-40

Fig 27: Breakdown detection .......................................................................................7-41

Fig 28: Setup: Protocol Printout Off .............................................................................7-42

Fig 29: Setup: Protocol Printout Standard ...................................................................7-42

Fig 30: Setup: Protocol Off ..........................................................................................7-46

Fig 31: Setup: Protocol Extended ................................................................................7-46

Fig 32: Start menu with SystemCard inserted..............................................................7-48

Fig 33: Start menu after new system settings have been stored .................................7-48

Fig 34: Setup: User Profile ..........................................................................................7-49

Fig 35: Setup, Memory ................................................................................................7-50

Fig 36: Setup Date / Time............................................................................................7-51

Fig 37: Setup Date / Time: adjusting the day of the week............................................7-51

Fig 38: Setup Date / Time: adjusting the minutes ........................................................7-51

Fig 39: Setup Date / Time: Saving by F1.....................................................................7-51

Fig 40: Unscrewing the printer front cover .......................... Fig 41: Removing the front cover 8-52

Fig 42: Removing the ribbon cartridge .......................... Fig 43: Inserting the ribbon cartridge 8-52

Fig 44: Inserting the paper roll into the printer ............................... Fig 45: Paper feed button 8-53