Meggitt VibroSmart VSA301 User manual

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

Meggitt SA

Route de Moncor 4

PO Box 1616

CH - 1701 Fribourg

Switzerland

www.meggittsensingsystems.com

www.vibro-meter.com

Title page

HARDWARE MANUAL

VibroSmart®

Distributed Monitoring System (DMS)

This document contains important

information about products that are

intended for use in potentially

explosive atmospheres.

Ex

ii

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

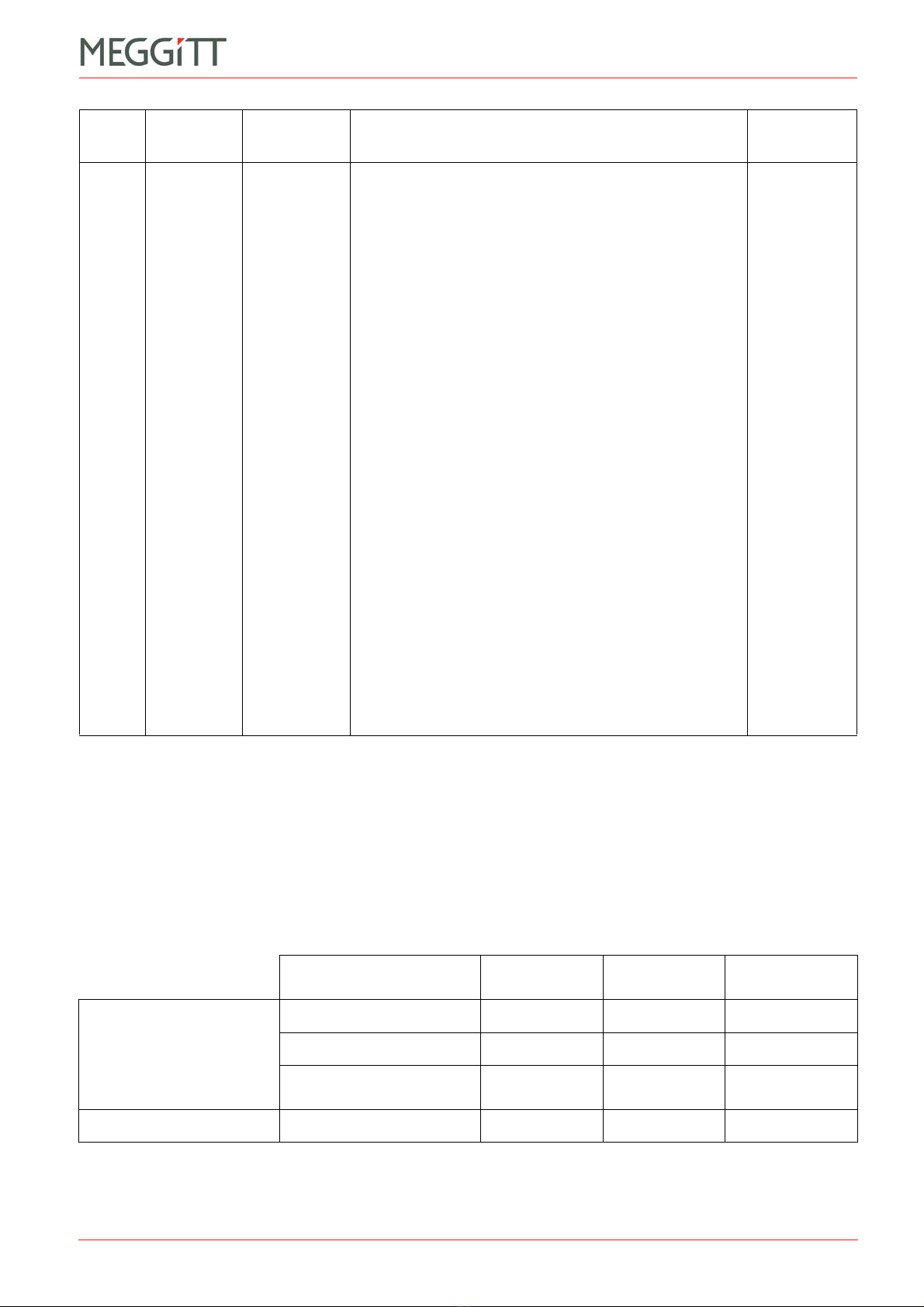

REVISION RECORD SHEET

Edition Date

of issue Written by /

modified by Description Signature

1 25.08.2014 P. Ward Original edition. PW

2 20.04.2015 P. Ward

Removed all references to the VSV310 vibration monitoring

module (deprecated), the VSR020 relay module (under

development) and the embedded/plug-in signal conditioners

(under development).

Added basic information on the VSAxxx accessories.

Updated the VibroSight software architecture drawing

(see Figure 1-2).

Updated the LED activity for the VSB010 and VSB300 terminal

bases (see Table 2-1). Updated the LED activity for the front

panels of the VSV300 vibration monitoring module, VSI010

communications interface module and VSN010 real-time

Ethernet switch (see Table 2 -3, Table 2-4 and Table 2 -5).

Swapped the order of chapters 3 and 4.

Added input range and power rating to the power supply

information in 3.13.1 Device power supply (input).

Restructured and updated 3 VibroSmart DMS features and

system elements with improved information on the system bus

(SBUS), time synchronisation including NTP requirements,

hot-swapping, operating modes and other VibroSmart DMS

features.

Added additional information on use in potentially explosive

atmospheres in Equipment used in potentially explosive

atmospheres, 1.3.2 Ex-related systems, 3.10 Grounding,

3.5.1 Live removal and insertion (“hot-swapping”) in potentially

explosive atmospheres,

3.9.1 Relay switching capacity in potentially explosive

atmospheres, 6.1 Introduction and 18.2 Requirements for

equipment used in potentially explosive atmospheres.

Added all available Ex certificates (see Appendix E: IECEx

certifications, Appendix C: ATEX certifications and Appendix

D: cCSAus certifications).

Updated the requirements for the types of Ethernet cabling

(see 5.3.1 Network cabling).

Added electrical safety information on power supply power

ratings in 6.1 Introduction.

Added a table summarising the processing modes and

measurements (extracted data) that are available from a

VSV300 vibration monitoring module (see Ta bl e 8 - 1 ).

Improved the information on the VSI010 (see 10 VSI010

communications interface module) and added information on

configuring Modbus interfaces (11 VSI010 Modbus fieldbus

interface).

Improved the information on the VSN010 (see 12 VSN010

real-time Ethernet switch).

Updated the electrical safety standard used in 13.2.2 Switch or

circuit breaker.

PW

VibroSmart DMS hardware manual MADMS-HW/E

iii

Edition 3 - September 2015

3 24.09.2015 P. Ward

Added and improved the information on the VSA301 buffered

output amplifier (see 9 VSA301 buffered output amplifier and

16 Interfacing to a VSA301 buffered output amplifier).

Added information on cross-section requirements for power

supply cables (see 6.2 Power supply cabling) and clearances

around power supply connectors (see 13.2.2 Switch or circuit

breaker).

Removed first-out alarms (not yet implemented).

Updated Appendix C: ATEX certifications: added

LCIE 15 ATEX 1014 X (VSA301) and updated

LCIE 14 ATEX 1027 X (VSI010, VSB010 and VSF00x).

Updated Appendix E: IECEx certifications: added

IECEx LCIE 15.0024X (VSA301) and updated

IECEx LCIE 14.0056X (VSI010, VSB010 and VSF00x).

Added pin number and orientation information for terminal base

screw-terminal connectors (see 15 Interfacing to a VSV300

vibration monitoring module and 17 Interfacing to a VSI010

communications interface module).

More consistent treatment of the terminal base DIP switches in

drawings.

Added 2.6.2.2 Removable screw terminals and updated the

safety information in 3.5.1 Live removal and insertion

(“hot-swapping”) in potentially explosive atmospheres and

13.5.2.1 Which VibroSmart devices can be hot-swapped?.

Added advance information on the VSF003 CAN fieldbus

communications adaptor (under development) in

10.5.3 Fieldbus interface adaptors.

Added additional information, including current and voltage

input transfer ratios, to 7.6.2.1 Buffered outputs. Also updated

15.2.1 Connecting a sensor to a dynamic input channel and

15.2.2 Connecting a sensor to an auxiliary input channel,

correcting the current sensing resistor values in Figure 15-2

and Figure 15-3.

PW

Department Name Date Signature

Technical content

approved by

ATEX Responsible J. Perriard 14.09.2015 JP

Engineering T. Roccaro 21.09.2015 TR

Product Management A. Hubbard 24.09.2015 AH

Document released by Technical Publications P. Ward 24.09.2015 PW

The duly signed master copy of this page is stored by the Technical Publications Department of Meggitt SA and

can be obtained by writing to Technical Publications.

Edition Date

of issue Written by /

modified by Description Signature

iv

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

COPYRIGHT

Important notice

IMPORTANT NOTICE

All statements, technical information, and recommendations in this document which relate to the products supplied

by Meggitt Sensing Systems are based on information believed to be reliable, but unless otherwise expressly

agreed in writing with Meggitt SA the accuracy or completeness of such data is not guaranteed. Before using this

product, you must evaluate it and determine if it is suitable for your intended application. Unless otherwise expressly

agreed in writing with Meggitt SA, you assume all risks and liability associated with such use. Meggitt Sensing

Systems takes no responsibility for any statements related to the product which are not contained in a current

English language Meggitt Sensing Systems publication, nor for any statements contained in extracts, summaries,

translations or any other documents not authored and produced by Meggitt Sensing Systems.

EXPORT CONTROL

The information contained in this document may be subject to export control regulations of the European

Community, USA or other countries. Each recipient of this document is responsible for ensuring that the transfer or

use of any information contained in this document complies with all relevant export control regulations. ECN N/A.

COPYRIGHT

Copyright

©

2014-2015 Meggitt SA

All rights reserved

Published and printed by Meggitt SA in Fribourg, Switzerland

The names of actual companies and products mentioned

herein may be the trademarks of their respective owners.

The information contained in this document is subject to change without notice.

This information shall not be used, duplicated or disclosed, in whole or in part,

without the express written permission of Meggitt Sensing Systems.

VibroSmart DMS hardware manual MADMS-HW/E

v

Edition 3 - September 2015

PREFACE

About this manual

This manual provides reference information on the VibroSmart® distributed monitoring

system (DMS) from Meggitt Sensing Systems’ Vibro-Meter® product line, including

information on the installation, configuration and general use of the following VibroSmart

devices:

• VSA301 buffered output amplifier

• VSI010 communications interface module

• VSN010 real-time Ethernet switch

• VSV300 vibration monitoring module.

About Meggitt, Meggitt Sensing Systems and Vibro-Meter

Headquartered in the UK, Meggitt PLC is a global engineering group specialising in extreme

environment components and smart sub-systems for aerospace, defence and energy

markets.

Meggitt Sensing Systems is the operating division of Meggitt specialising in sensing and

monitoring systems, which has operated through its antecedents since 1927 under the

names of ECET, Endevco, Ferroperm Piezoceramics, Lodge Ignition, Sensorex, Vibro-Meter

and Wilcoxon Research. Today, these operations are integrated under one strategic

business unit called Meggitt Sensing Systems, headquartered in Switzerland and providing

complete systems, using these renowned brands, from a single supply base.

The Meggitt Sensing Systems facility in Fribourg, Switzerland was formerly known as

Vibro-Meter SA, but is now Meggitt SA. This site produces a wide range of vibration and

dynamic pressure sensors capable of operation in extreme environments, leading-edge

microwave sensors, electronics monitoring systems and innovative software for aerospace

and land-based turbo-machinery. This includes the VibroSmart DMS produced for the

Vibro-Meter product line.

Who should use this manual?

This manual is written for integrators and operators of condition monitoring systems and

machinery protection systems using VibroSmart® DMS hardware and VibroSight® software.

Integrators and operators are assumed to have the necessary technical training to install,

configure and use systems created with these products.

NOTE: Personnel involved in the installation of Meggitt Sensing Systems equipment are

assumed to have the necessary technical training in electronics and/or mechanical

engineering (professional certificate/diploma or equivalent) to enable them to

install the equipment correctly and safely.

vi

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

Applicability of this manual

This manual applies to the currently available version of VibroSmart DMS and reflects the

features available with the current versions of the VSA301, VSI010, VSN010 and VSV300.

Some information may not be applicable to earlier or later versions of the devices.

Note that this manual refers to the use of the VibroSight software on a Windows® computer

in English. If using a different operating system or locale, you may need to modify certain

parameters, for example, use a comma (“,”) as the decimal point in numbers.

Respect the instructions!

Personnel involved in the installation of Meggitt Sensing Systems equipment must respect

general safety procedures as well as general and specific machine constructor guidelines

and instructions.

Limitation of this document

Not all possibilities are described in this manual. Nevertheless, several specific

configurations are described in detail. These can often be adapted to specific applications.

When in doubt, contact Meggitt Sensing Systems so that an optimum measurement solution

can be determined.

Related publications and documentation

Further information on the VibroSmart modules and the VibroSight software can be found in

the following documentation:

•APF 196 AC-DC converter (24 V, 3 A) data sheet.

•APF 197 AC-DC converter (24 V, 5 A) data sheet.

•APF 198 AC-DC converter (24 V, 7.5 A) data sheet.

•APF 200 AC-DC converter (24 V, 3.75 A) with Ex approval data sheet.

•APF 201 AC-DC converter (24 V, 7.5 A) with Ex approval data sheet.

•VibroSmart VSA002, VSA003, VSA004 and VSA005 BNC cable assemblies and

patch panels data sheet.

•VibroSmart VSA301 buffered output amplifier data sheet.

•VibroSmart VSI010 communications interface module data sheet.

• VibroSmart VSN010 real-time Ethernet switch data sheet.

• VibroSmart VSV300 vibration monitoring module data sheet.

• VibroSight software data sheet.

•Getting started with VibroSight® installation guide.

•VibroSight help (VibroSight.chm), which is copied to the computer as part of the

VibroSight software installation process.

These documents can be obtained from your local Meggitt Sensing Systems representative.

VibroSmart DMS hardware manual MADMS-HW/E

vii

Edition 3 - September 2015

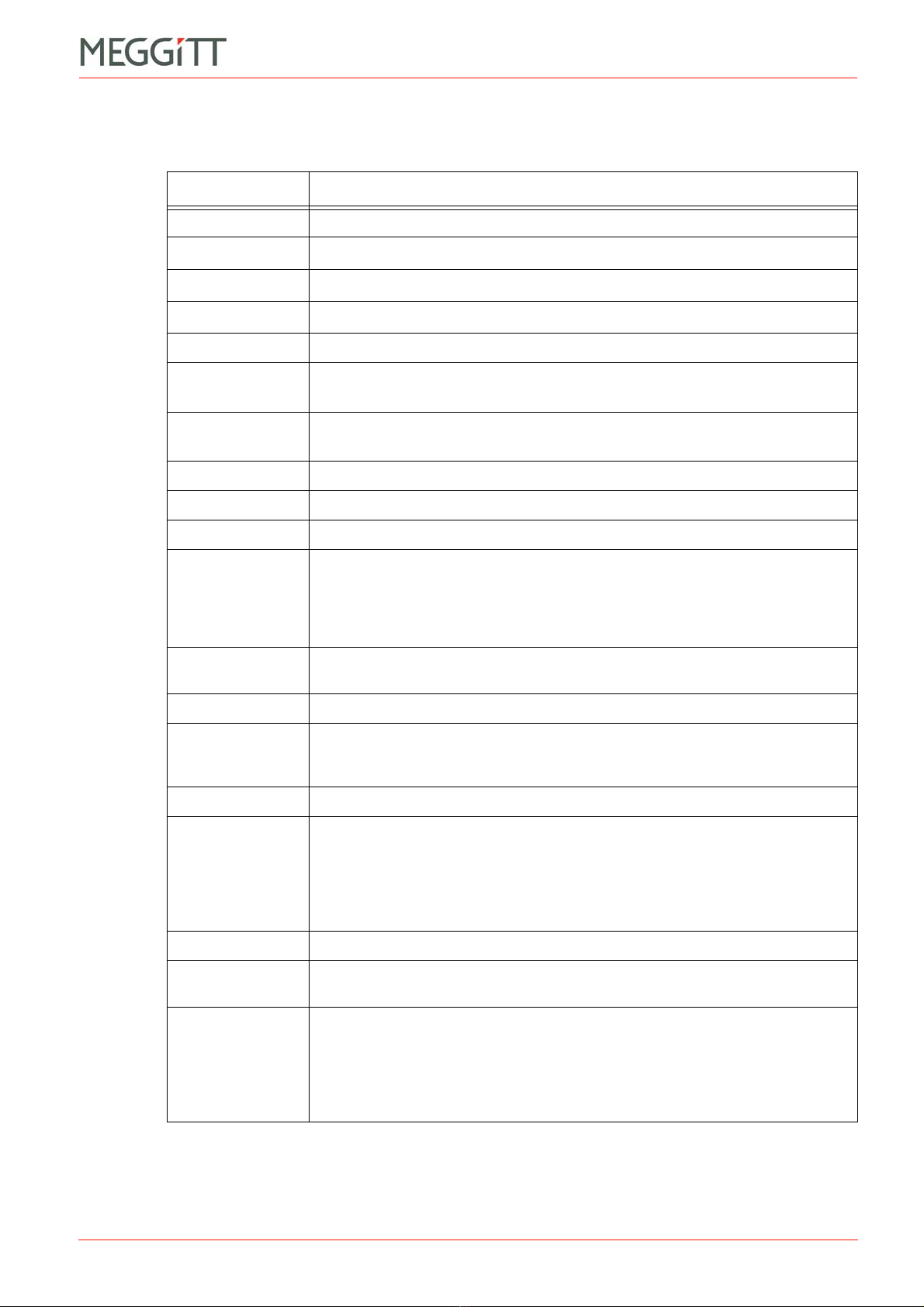

Abbreviations and glossary

The following table defines some useful abbreviations and terms found in this manual.

Term Definition

AB Alarm bypass, a DSI input signal

APF 196 +24 V

DC

power supply with a 3 A output, suitable for use in a VibroSmart DMS

APF 197 +24 V

DC

power supply with a 5 A output, suitable for use in a VibroSmart DMS

APF 198 +24 V

DC

power supply with a 7.5 A output, suitable for use in a VibroSmart DMS

APF 19x Refers to APF 196, APF 197 and APF 198 power supplies

APF 200 +24 V

DC

power supply with a 3.75 A output and Ex approval, suitable for use in a

VibroSmart DMS

APF 201 +24 V

DC

power supply with a 7.5 A output and Ex approval, suitable for use in a

VibroSmart DMS

APF 20x Refers to APF 200 and APF 201 power supplies

APF xxx Refers to APF 196, APF 197, APF 198, APF 200 and APF 201 power supplies

AR Alarm reset, a DSI input signal

Border device

A VibroSmart DMS module / terminal base using an Ethx connector to connect to and

communicate with a computer running the VibroSight software. A border device is an

interface between a VibroSmart DMS or measurement block and the VibroSight

software and all communications (non-real-time) with VibroSight must pass through a

module / terminal acting as a border device.

DANH Doubly attached node implementing the HSR protocol (a network device that can use

two Ethernet ports to connect to a redundant network)

DMS Distributed monitoring system

DSI

Discrete signal interface, control signal input signals that allow certain functions of the

VibroSmart DMS to be controlled in response to external signals that typically come

from a control room

FBCS Fieldbus communications stop, a DSI input signal

Measurement block

Multiple VibroSmart modules, connected logically as a group, for example, to monitor

the same machine. (A measurement block can be connected physically together as a

group on the same DIN rail, but this is not a prerequisite.)

Measurement blocks are defined in a configuration (using VibroSight Configurator) in

order to allow inter-module communication, that is, the sharing of alarm, tachometer

and some trigger type messages between modules.

NIC Network interface card (also known as a network adapter)

SAN Singly attached node (a network device that uses one Ethernet port to connect to a

standard (non-redundant) network)

Sensor OK check

A mechanism for monitoring the high and low voltage limits corresponding to an open

or a short-circuited sensor (transducer) connection. Any problem with a sensor,

conditioner or connecting cable that causes the signal to deviate beyond the

configured normal levels will cause and alarm.

The Sensor OK check (Lower Level and Upper Level) parameters are defined in the

configuration (using VibroSight Configurator) for each input channel.

viii

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

SBUS

SBUS is the system bus, based on real-time Ethernet, used by a VibroSmart DMS for

all communications.

The SBUS supports inter-module communication between VibroSmart modules such

as the transfer of non-real-time information and real-time information such as

tachometric timestamps, triggers and alarms.

The SBUS supports extra-module communications such as the exchange of

commands, configuration information and measurement data between VibroSmart

modules and a computer running the VibroSight software, and communication

between VibroSmart modules and a network time server.

Status indicator LEDs are used as status indicators for VibroSmart devices

VibroSmart module A VibroSmart module is a signal processing module that clips into a terminal base that

mounts on a DIN rail.

VibroSmart device

A VibroSmart device is any VibroSmart system component used in a VibroSmart DMS

that is not a VibroSmart module. This includes more general devices such as the

VSN010 real-time Ethernet switch and APF xxx power supplies.

TM Trip multiply, a DSI input signal

VibroSmart®

VibroSmart is the name of a family of modular and scalable modules and products,

from Meggitt Sensing Systems’ Vibro-Meter product line, that can be assembled and

configured to create a distributed monitoring system

VibroSight®

The VibroSight total monitoring solution, from Meggitt Sensing Systems’ Vibro-Meter

product line, is a highly integrated software suite that supports the effective condition

monitoring of all rotating machinery.

The VibroSight software is compatible with both VM600 rack-based systems and

VibroSmart module-based (DMS) systems.

VSA002 BNC cable assembly – terminated with BNC connectors (male) for use with

standard test and measurement equipment

VSA003 BNC cable assembly – terminated with BNC connectors (female) for use with

VSA004 and VSA005 BNC patch panels

VSA004 BNC patch panel – DIN rail mounting BNC patch panel with 10 slots

VSA005 BNC patch panel – 19rack mounting BNC patch panel with 21 slots

VSA301 Buffered output amplifier for use with a VibroSmart VSV300 module

VSB010 Terminal base for use with a VibroSmart VSI010 module

VSB300 Terminal base for use with a VibroSmart VSV300 module

VSI010 Communications interface module for use in a VibroSmart DMS

VSN010 Real-time Ethernet switch for use in a VibroSmart DMS

VSV300 Vibration monitoring module for use in a VibroSmart DMS

Term Definition

VibroSmart DMS hardware manual MADMS-HW/E

ix

Edition 3 - September 2015

Symbols and styles used in this manual

SAFETY

SAFETY

Symbols and styles used in this manual

The following symbols are used in this manual where appropriate:

NOTE: This is an example of the NOTE paragraph style. This draws the operator’s

attention to complementary information or advice relating to products or their

installation.

The WARNING safety symbol

T

HIS

INTRODUCES

DIRECTIVES

,

PROCEDURES

OR

PRECAUTIONARY

MEASURES

WHICH

MUST

BE

EXECUTED

OR

FOLLOWED

. F

AILURE

TO

OBEY

A

WARNING

CAN

RESULT

IN

INJURY

TO

THE

OPERATOR

OR

THIRD

PARTIES

.

The CAUTION safety symbol

This draws the operator's attention to information, directives or procedures

which must be executed or followed. Failure to obey a caution can result in

damage to equipment.

The ELECTROSTATIC SENSITIVE DEVICE symbol

This indicates that the device or system being handled can be damaged by

electrostatic discharges.

Refer to Handling precautions for electrostatic sensitive devices on page xi

for further information.

x

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

Important remarks on safety

SAFETY

Important remarks on safety

Every effort has been made to include specific safety-related procedures in this manual using

the symbols described above. However, operating personnel are expected to follow all

generally accepted safety procedures.

Safety procedures should be communicated to all personnel who may operate any piece of

equipment described in this manual.

Meggitt Sensing Systems does not accept any liability for injury or material damage caused

by failure to obey any safety-related instruction or due to any modification, transformation or

repair carried out on the equipment without written permission from Meggitt SA. Any

modification, transformation or repair carried out on the equipment without written permission

from Meggitt Sensing Systems will invalidate any warranty.

Equipment used in potentially explosive atmospheres

Read this manual carefully and observe the safety instructions before using

the equipment described.

T

HIS

MANUAL

COVERS

EQUIPMENT

THAT

CAN

BE

USED

IN

POTENTIALLY

EXPLOSIVE

ATMOSPHERES

,

AS

WELL

AS

EQUIPMENT

THAT

CANNOT

BE

USED

IN

POTENTIALLY

EXPLOSIVE

ATMOSPHERES

.

T

O

ENSURE

THAT

THE

EQUIPMENT

CAN

SAFELY

BE

USED

IN

POTENTIALLY

EXPLOSIVE

ATMOSPHERES

,

IT

IS

ESSENTIAL

TO

:

•V

ERIFY

IT

IS

IDENTIFIED

WITH

SPECIAL

MARKING

DESCRIBED

IN

THE

“EC T

YPE

E

XAMINATION

C

ERTIFICATE

”

FOR

THE

PRODUCT

.

•R

ESPECT

THE

CRITERIA

MENTIONED

IN

THE

SAME

“EC T

YPE

E

XAMINATION

C

ERTIFICATE

”.

R

EFER

TO

THE

RELEVANT

E

X

CERTIFICATES

IN

THE

APPENDICES

OF

THIS

MANUAL

FOR

FURTHER

INFORMATION

: A

PPENDIX

E: IECE

X

CERTIFICATIONS

, A

PPENDIX

C: ATEX

CERTIFICATIONS

AND

A

PPENDIX

D:

C

CSA

US

CERTIFICATIONS

.

A

N

“

X

”

OR

A

“U”

PLACED

AFTER

THE

CERTIFICATE

NUMBER

INDICATES

THAT

THE

EQUIPMENT

IS

SUBJECT

TO

SPECIAL

CONDITIONS

FOR

SAFE

USE

. T

HESE

CONDITIONS

ARE

MENTIONED

IN

THE

“

SCHEDULE

”

SECTION

OF

THE

CERTIFICATE

.

A

NY

V

IBRO

S

MART

DMS

PRODUCTS

(

DEVICES

)

WITH

PROTECTION

MODE

N

A

LOCATED

IN

AN

E

X

Z

ONE

2 (

HAZARDOUS

AREA

)

SHALL

BE

INSTALLED

INSIDE

AN

ENCLOSURE

WITH

A

PROTECTION

RATING

OF

AT

LEAST

IP54 (

OR

EQUIVALENT

),

WITH

DUE

CONSIDERATION

FOR

THE

MAXIMUM

THERMAL

DISSIPATION

STATED

IN

THE

CORRESPONDING

E

X CERTIFICATES

.

F

OR

A

NY

V

IBRO

S

MART

DMS

PRODUCTS

(

DEVICES

)

LOCATED

IN

AN

E

X

Z

ONE

2

IN

N

ORTH

A

MERICA

(

C

CSA

US

),

THE

FINAL

ENCLOSURE

IN

WHICH

THESE

PRODUCTS

ARE

INSTALLED

MUST

HAVE

THE

SPECIFIC

CAUTION

AND

WARNING

DESCRIBED

IN

THE

CORRESPONDING

C

CSA

US

CERTIFICATES

(

SEE

A

PPENDIX

D:

C

CSA

US

CERTIFICATIONS

).

S

EE

ALSO

18 M

AINTENANCE

FOR

ADDITIONAL

INFORMATION

.

VibroSmart DMS hardware manual MADMS-HW/E

xi

Edition 3 - September 2015

General handling precautions

In general, Meggitt Sensing Systems’ products are rugged devices which can withstand a

certain amount of careless handling. Nevertheless, certain precautions should be taken when

handling this equipment.

• Do not drop the device onto a hard surface or subject it to violent shocks.

• Protect the device using the associated protective packing material when it is being

handled, stored or transported. Remove this protection only when inspecting, installing

or testing the device.

• Check for dents when inspecting the device as this is a sign that it could have suffered a

physical shock by impact. This may have caused damage to components within the

device.

• For cables, do not excessively bend any cables associated with the device, especially

sensor cables. Respect the minimum bend radius quoted in the appropriate data sheet.

• When storing and using the equipment, respect the environmental specifications

(temperature, humidity) quoted in the appropriate data sheet.

• Refer also to Handling precautions for electrostatic sensitive devices on page xi.

Handling precautions for electrostatic sensitive devices

Certain devices used in electronic equipment can be damaged by electrostatic discharges

resulting from built-up static electricity. Because of this, special precautions must be taken to

minimise or eliminate the possibility of these electrostatic discharges occurring.

• Before handling electronic circuits, discharge the static electricity from your body by

touching and momentarily holding a grounded metal object (such as a pipe or cabinet).

• Avoid the build-up of static electricity on your body by not wearing synthetic clothing

material, as these tend to generate and store static electric charges. Cotton or cotton

blend materials are preferred because they do not store static electric charges.

• Do not handle electronic circuits unless it is absolutely necessary. Only hold modules by

their enclosures.

• Do not touch printed circuit boards, their connectors or their components with conductive

devices or with your hands.

• Put the electronic circuit, printed circuit board or module containing electronic

components into an antistatic protective bag immediately after removing it from the

system.

Read the following recommendations carefully before handling devices.

Read the following recommendations carefully before handling electronic

circuits, printed circuit boards or modules containing electronic

components.

xii

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

THIS PAGE INTENTIONALLY LEFT BLANK

VibroSmart DMS hardware manual MADMS-HW/E

xiii

Edition 3 - September 2015

TABLE OF CONTENTS

TABLE OF CONTENTS

TITLE PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

REVISION RECORD SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

COPYRIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

IMPORTANT NOTICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 What is VibroSmart DMS? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Simplicity and ease of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3.1 Safety-related systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.2 Ex-related systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 General overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4.1 VibroSmart DMS hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4.2 VibroSight software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.5 Communicating with a VibroSmart DMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.6 System size considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.6.1 VibroSmart DMS modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.6.2 Required bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.7 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

2 OVERVIEW OF VIBROSMART DMS HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 VibroSmart device naming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 VibroSmart DMS hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.1 VibroSmart modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 VibroSmart DMS terminal bases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2.1 Operation of status indicators on VibroSmart DMS

terminal bases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2.2 VibroSmart DMS module and terminal base compatibility . . . . 2-5

xiv

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

TABLE OF CONTENTS

2.2.2.3 VibroSmart DMS signal conditioning (VSV300) . . . . . . . . . . . . 2-5

2.2.2.4 VibroSmart DMS communications adaptors (VSI010) . . . . . . . 2-5

2.2.3 VibroSmart devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3 DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4 VibroSmart measurement modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.1 VSV300 vibration monitoring module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.1.1 VSV300 front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.1.2 VSB300 terminal base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5 VibroSmart communications modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.1 VSI010 communications interface module . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.1.1 VSI010 front panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.1.2 VSB010 terminal base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6 Other VibroSmart DMS devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6.1 VSN010 real-time Ethernet switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6.1.1 VSN010 front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6.2 VSA301 buffered output amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.6.2.1 VSA301 front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6.2.2 Removable screw terminals . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6.3 APF 196, APF 197 and APF 198 power supplies . . . . . . . . . . . . . . . . . . . 2-18

2.6.3.1 APF 196, APF 197 and APF 198 front panels. . . . . . . . . . . . . 2-19

2.6.4 APF 200 and APF 201 power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.6.4.1 APF 200 and APF 201 front panels. . . . . . . . . . . . . . . . . . . . . 2-21

2.7 Industrial housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

3 VIBROSMART DMS FEATURES AND SYSTEM ELEMENTS . . . . . . . . . . . . . . . . . . . . 3-1

3.1 VibroSmart DMS communications (SBUS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 VibroSmart DMS device Ethernet ports and connectors. . . . . . . . . . . . . . . . . . . . . 3-3

3.2.1 VibroSmart DMS modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.1.1 Sidebus connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.1.2 Ethernet connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.2 Other VibroSmart DMS devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 VibroSmart DMS measurement block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 VibroSmart DMS device configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.1 Device compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5 Live removal and insertion of VibroSmart DMS modules

(“hot-swapping” capability) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5.1 Live removal and insertion (“hot-swapping”) in potentially

explosive atmospheres. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

VibroSmart DMS hardware manual MADMS-HW/E

xv

Edition 3 - September 2015

TABLE OF CONTENTS

3.6 Discrete signal interface (DSI) control inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.6.1 DSI Master and discrete signal interface (DSI) signal sharing . . . . . . . . . 3-10

3.7 Tacho signal sharing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.8 Logical functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.9 Relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.9.1 Relay switching capacity in potentially explosive atmospheres . . . . . . . . 3-14

3.9.2 Relay terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.9.3 Operation of relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.10 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.10.1 Grounding concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.11 Time synchronisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.11.1 VibroSmart DMS local time synchronisation . . . . . . . . . . . . . . . . . . . . . . 3-16

3.11.2 VibroSmart DMS global time synchronisation . . . . . . . . . . . . . . . . . . . . . 3-17

3.11.3 VibroSight Server time reference requirements . . . . . . . . . . . . . . . . . . . . 3-17

3.11.3.1 NTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.11.3.2 VibroSmart DMS without an NTP server (NTP-free) . . . . . . . 3-19

3.11.3.3 VibroSmart DMS with an NTP server . . . . . . . . . . . . . . . . . . . 3-19

3.12 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.12.1 Power-on self test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.12.2 Initialisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

3.13 Power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.13.1 Device power supply (input) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.13.2 Sensor power supplies (output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.14 Zero-configuration networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.15 Supported network topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.16 Mechanical key coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

4 ASSEMBLING AND MOUNTING VIBROSMART DMS DEVICES . . . . . . . . . . . . . . . . . 4-1

4.1 VibroSmart DMS terminal bases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Terminal base front panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.2 Terminal base DIP switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.3 Terminal base rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2 Assembling a VibroSmart DMS module and a terminal base. . . . . . . . . . . . . . . . . 4-5

4.3 Disassembling a VibroSmart DMS module and a terminal base . . . . . . . . . . . . . . 4-5

4.4 Mounting a single VibroSmart DMS terminal base on a DIN rail . . . . . . . . . . . . . . 4-6

4.5 Mounting a VibroSmart DMS terminal base side-by-side with an existing

terminal base on a DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.6 Removing a VibroSmart DMS terminal base from a DIN rail . . . . . . . . . . . . . . . . . 4-8

xvi

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

TABLE OF CONTENTS

4.7 Mounting a VibroSmart VSN010 real-time Ethernet switch on a DIN rail . . . . . . . . 4-8

4.8 Removing a VibroSmart VSN010 real-time Ethernet switch from a DIN rail . . . . . . 4-8

5 VIBROSMART DMS NETWORKING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 VibroSmart DMS communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 VibroSmart DMS networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.1 Network cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.4 VibroSmart DMS point-to-point networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4.1 Point-to-point topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4.2 Advantages of a point-to-point topology . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4.3 Disadvantages of a point-to-point topology. . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4.4 VibroSmart DMS point-to-point network example. . . . . . . . . . . . . . . . . . . . 5-4

5.4.5 Effect of replacing a VibroSmart DMS module in a point-to-point network . 5-5

5.5 VibroSmart DMS linear networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.1 Linear topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.2 Advantages of a linear topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.3 Disadvantages of a linear topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.4 VibroSmart DMS linear network example . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.5 Effect of replacing a VibroSmart DMS module in a linear network . . . . . . . 5-8

5.6 VibroSmart DMS HSR ring networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.1 HSR ring topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.2 Advantages of a HSR ring topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.3 Disadvantages of a HSR ring topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.4 VibroSmart DMS HSR ring network example . . . . . . . . . . . . . . . . . . . . . . 5-10

5.6.5 Effect of replacing a VibroSmart DMS module in a HSR ring network . . . 5-11

5.7 VibroSmart DMS hybrid networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.7.1 Effect of replacing a VibroSmart DMS module in a hybrid network . . . . . 5-12

6 VIBROSMART DMS POWER SUPPLY DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Power supply cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 VibroSmart device power supply inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3.1 Redundant power supply inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 VibroSmart device power supply distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4.1 Redundant power supply distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.5 Power supply derating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.6 Power supply distribution example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

VibroSmart DMS hardware manual MADMS-HW/E

xvii

Edition 3 - September 2015

TABLE OF CONTENTS

7 VSV300 VIBRATION MONITORING MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.1 About the VSV300 vibration monitoring module. . . . . . . . . . . . . . . . . . . . . 7-1

7.1.2 VSV300 features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.3 VSV300 signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2 Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.1 Operation of status indicators on the VSV300 module. . . . . . . . . . . . . . . . 7-3

7.2.2 Operation of status indicators on the VSB300 terminal base. . . . . . . . . . . 7-3

7.3 VSV300 interface diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4 Overview of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.4.1 Machinery vibration monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.4.2 Continuous parallel data acquisition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.4.3 Signal qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.4.3.1 Peak qualifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.4.4 Alarm monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.4.4.1 Monitoring possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.4.4.2 Logical combinations of alarms. . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.4.4.3 Adaptive monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.4.4.4 Trip multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.4.4.5 Alarm bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.5 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.5.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.5.2 Dynamic input channels (CH1, CH2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.5.3 Auxiliary input channel (AUX). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.5.4 Discrete signal interface (DSI) control inputs . . . . . . . . . . . . . . . . . . . . . . 7-12

7.6 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.6.1 Sensor power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.6.2 Analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.6.2.1 Buffered outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.6.2.2 AC outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.6.2.3 DC outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.6.3 VSV300 logical functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.6.4 VSV300 relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.7 System checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.7.1 Sensor OK check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.7.1.1 Failure behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.7.2 Built-in test equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

xviii

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

TABLE OF CONTENTS

7.8 Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.9 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

8 VSV300 PROCESSING MODES AND APPLICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 General overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 Absolute vibration monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.1.2 Relative vibration monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.1.3 Narrow band vibration monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.1.4 Position processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.2 Asynchronous absolute bearing vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.2.1 Signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.2.2 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.2.3 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.3 Shaft relative vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.3.1 Signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.3.2 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.3.3 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.4 Narrow band vibration processing block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.4.1 Signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.4.2 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.4.3 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.5 Position processing block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.5.1 Signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.5.2 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.5.3 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.6 Broad band pulsation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.6.1 Signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.6.2 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8.6.3 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

9 VSA301 BUFFERED OUTPUT AMPLIFIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.1 About the VSA301 buffered output amplifier. . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.2 VSA301 features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.2.1 Operation of status indicators on the VSA301 amplifier . . . . . . . . . . . . . . . 9-2

9.3 VSA301 interface diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

VibroSmart DMS hardware manual MADMS-HW/E

xix

Edition 3 - September 2015

TABLE OF CONTENTS

9.4 Overview of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.4.1 Short-distance signal transmission using one VSA301 . . . . . . . . . . . . . . . 9-6

9.4.2 Long-distance signal transmission using two VSA301s . . . . . . . . . . . . . . . 9-8

9.4.3 VSA301 modes of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.5 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.5.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.5.2 Dynamic channels (CH1, CH2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.5.3 Auxiliary channel (AUX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.5.4 DIP switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.6 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.6.1 Dynamic channels (CH1, CH2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.6.2 Auxiliary channel (AUX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.7 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

10 VSI010 COMMUNICATIONS INTERFACE MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1.1 About the VSI010 communications interface module. . . . . . . . . . . . . . . . 10-1

10.1.2 VSI010 features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1.3 VSI010 data processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2 Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2.1 Operation of status indicators on the VSI010 module . . . . . . . . . . . . . . . 10-3

10.2.2 Operation of status indicators on the VSB010 terminal base. . . . . . . . . . 10-3

10.3 VSI010 interface diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.4 Overview of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.4.1 Data communications bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.5 Fieldbus ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.5.1 Serial-based fieldbus interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10.5.2 Ethernet-based fieldbus interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.5.3 Fieldbus interface adaptors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.5.4 Combining fieldbus interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.5.5 Redundant fieldbus communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.5.6 PROFIsafe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.5.7 Example VibroSmart measurement blocks with a VSI010 module . . . . 10-10

10.6 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.6.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.6.2 Discrete signal interface (DSI) control inputs . . . . . . . . . . . . . . . . . . . . . 10-11

xx

VibroSmart DMS hardware manual MADMS-HW/E

Edition 3 - September 2015

TABLE OF CONTENTS

10.7 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.7.1 VSI010 logical functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.7.2 VSI010 relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

10.8 VibroSmart DMS data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

10.8.1 Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10.8.1.1 Measurement encoding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-16

10.8.1.2 Byte ordering (endianness) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

10.8.2 Measurement alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-19

10.8.3 Sensor status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-20

10.8.4 Module status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-21

10.8.5 Logical function outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

10.8.6 Discrete signal interface (DSI) signals . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.9 System checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

10.9.1 Built-in test equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

10.10 Operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

10.11 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

11 VSI010 MODBUS FIELDBUS INTERFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.1 Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.1.1 General overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.1.2 Modbus communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

11.1.3 VibroSmart DMS VSI010 module support for Modbus . . . . . . . . . . . . . . . 11-2

11.1.4 VibroSight support for Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.1.5 VSI010 Modbus communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.1.6 Modbus registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

11.2 Identifying the fieldbus protocol supported by a VSI010 module . . . . . . . . . . . . . 11-6

11.3 Configuring a VSI010 module for operation as a Modbus server . . . . . . . . . . . . . 11-7

11.3.1 Adding a VSI010 module to a VibroSmart DMS measurement block. . . . 11-7

11.3.1.1 Configuring a VSI010 module as the DSI master for a

VibroSmart DMS measurement block . . . . . . . . . . . . . . . . . . . 11-9

11.3.2 Adding a Modbus port to a VSI010 module and configuring the

communications options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.3.3 Adding VibroSmart DMS data to a Modbus port and configuring the

encoding options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

11.4 Example VSI010 Modbus configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

This manual suits for next models

3

Table of contents

Other Meggitt Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Badger Meter

Badger Meter PRESO COIN user manual

PCE Health and Fitness

PCE Health and Fitness MiniAir20 operating instructions

VIRTINS

VIRTINS VT RTA-168A/B manual

OHAUS

OHAUS ST20M Series instruction manual

Pitney Bowes

Pitney Bowes DMI100i Operator's guide

Sapphire Instruments

Sapphire Instruments SI-9010 manual