Contents

Contents

1 General guidelines ...............................................................................................................................................................4

Symbols used.......................................................................................................................................................................4

Formatting rules ...................................................................................................................................................................4

MELAconnect App ...............................................................................................................................................................4

2 Safety.....................................................................................................................................................................................5

3 Description of the device.....................................................................................................................................................6

Intended use ........................................................................................................................................................................6

Scope of delivery..................................................................................................................................................................6

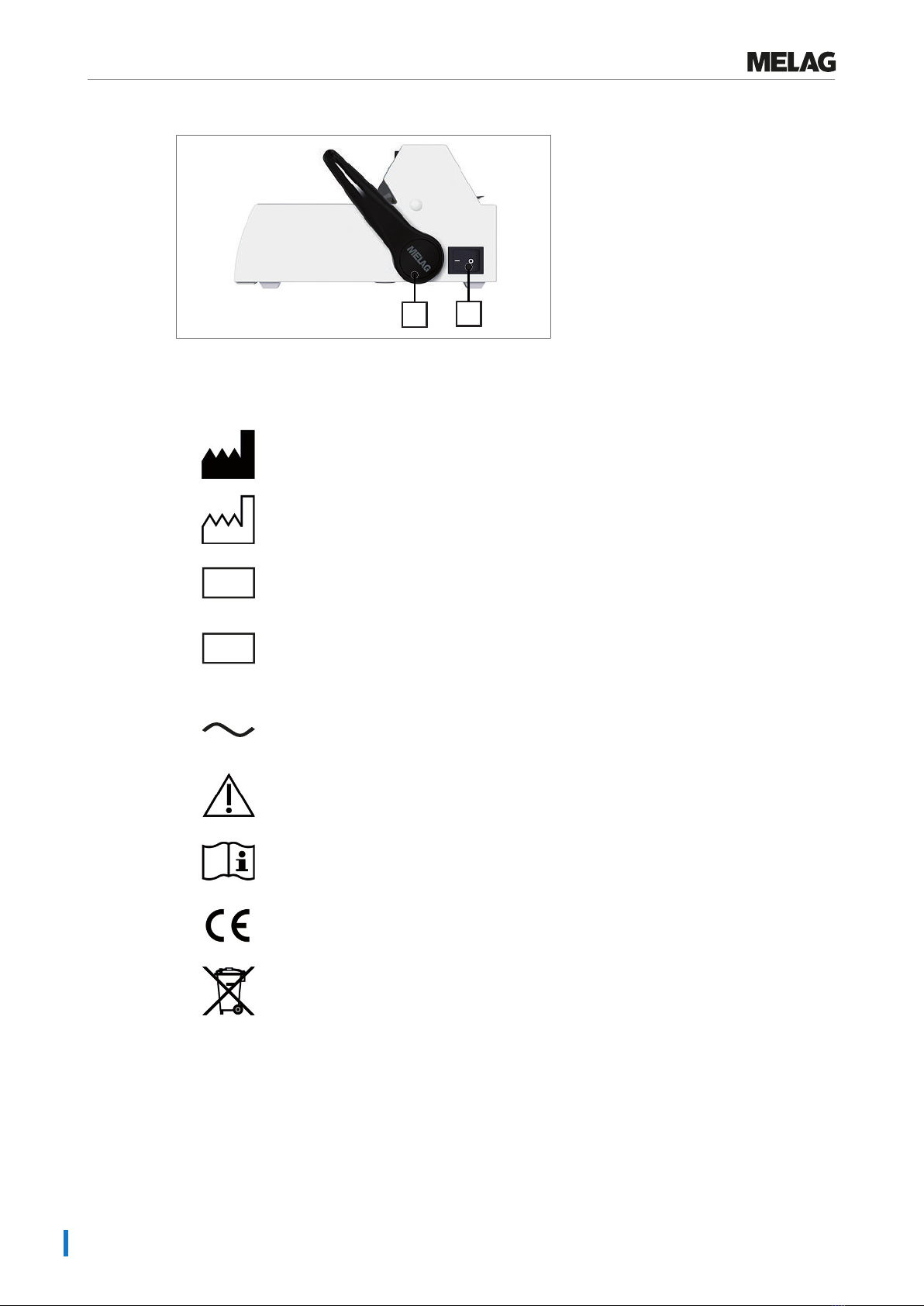

Views of the device ..............................................................................................................................................................7

Symbols on the device .........................................................................................................................................................8

Status display and acoustic signal .......................................................................................................................................9

4 Commissioning...................................................................................................................................................................10

Requirements of the installation location ...........................................................................................................................10

Wall mounting ....................................................................................................................................................................10

Connecting the sealing device ...........................................................................................................................................11

Switching on the sealing device .........................................................................................................................................11

5 Sealing.................................................................................................................................................................................12

Sealing temperature...........................................................................................................................................................12

Sealing procedure with pre-finished film bags ...................................................................................................................12

Sealing procedure for film rolls...........................................................................................................................................13

6 Maintenance........................................................................................................................................................................15

Cleaning and regular controls ............................................................................................................................................15

7 Pause times ........................................................................................................................................................................16

Pause times .......................................................................................................................................................................16

Transport and storage........................................................................................................................................................16

8 Optional accessories .........................................................................................................................................................17

Roll dispenser “standard” ...................................................................................................................................................17

Roll dispenser “comfort” .....................................................................................................................................................17

Roll dispenser “Deluxe”......................................................................................................................................................18

Wall-mounted roll dispenser...............................................................................................................................................18

9 Manufacturer's recommendation for routine operation .................................................................................................19

Performing the peel test .....................................................................................................................................................20

MELAG seal seam stability test .........................................................................................................................................20

10 Standard specifications...................................................................................................................................................21

11 Technical Data ..................................................................................................................................................................23

12 Accessories and spare parts ..........................................................................................................................................24