Operating manual MELAseal®101

Page 3

3. Accessories

3.1. Work platform _____________________________________________________________

The sealing rail is 250 mm wide, so that it is possible

to seal several narrow packages next to one another

in one sealing operation. The work platform, which

can be attached at the two mounting points (5) at

the front of the MELAseal® Package Sealing Device,

makes it easier to seal packages, especially if these

contain heavy instruments.

MELAG Art. No. 104

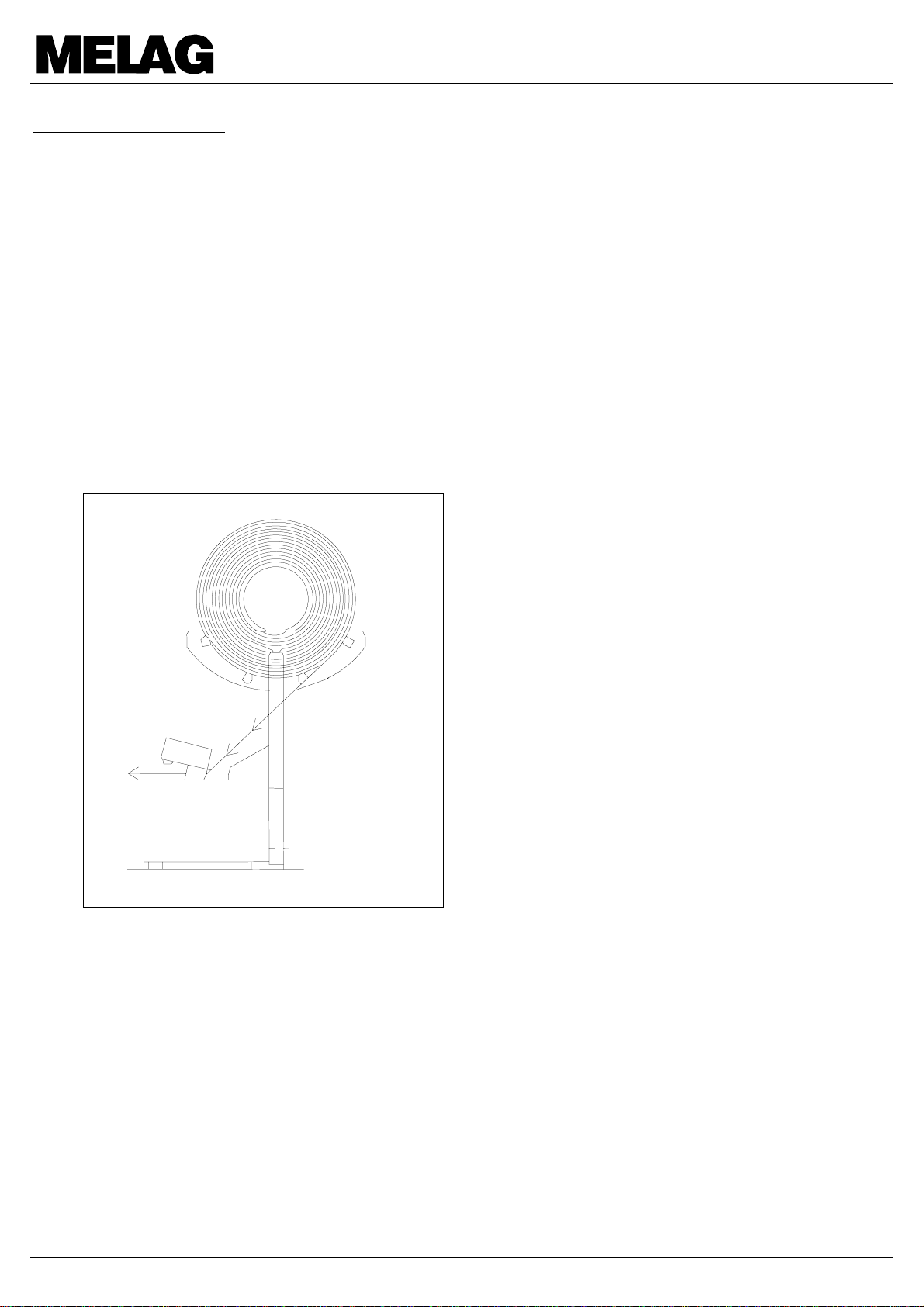

3.2. Unit-mounted roll holder "Comfort" ___________________________________________

The "Comfort" unit-mounted roll-holder can be used

to save space by mounting the rolls of sterilisation

pack directly onto the MELAseal® Package Sealing

Device. Bolts are supplied to attach it to the rear

side of the Sealing Device.

MELAG Art. No. 105

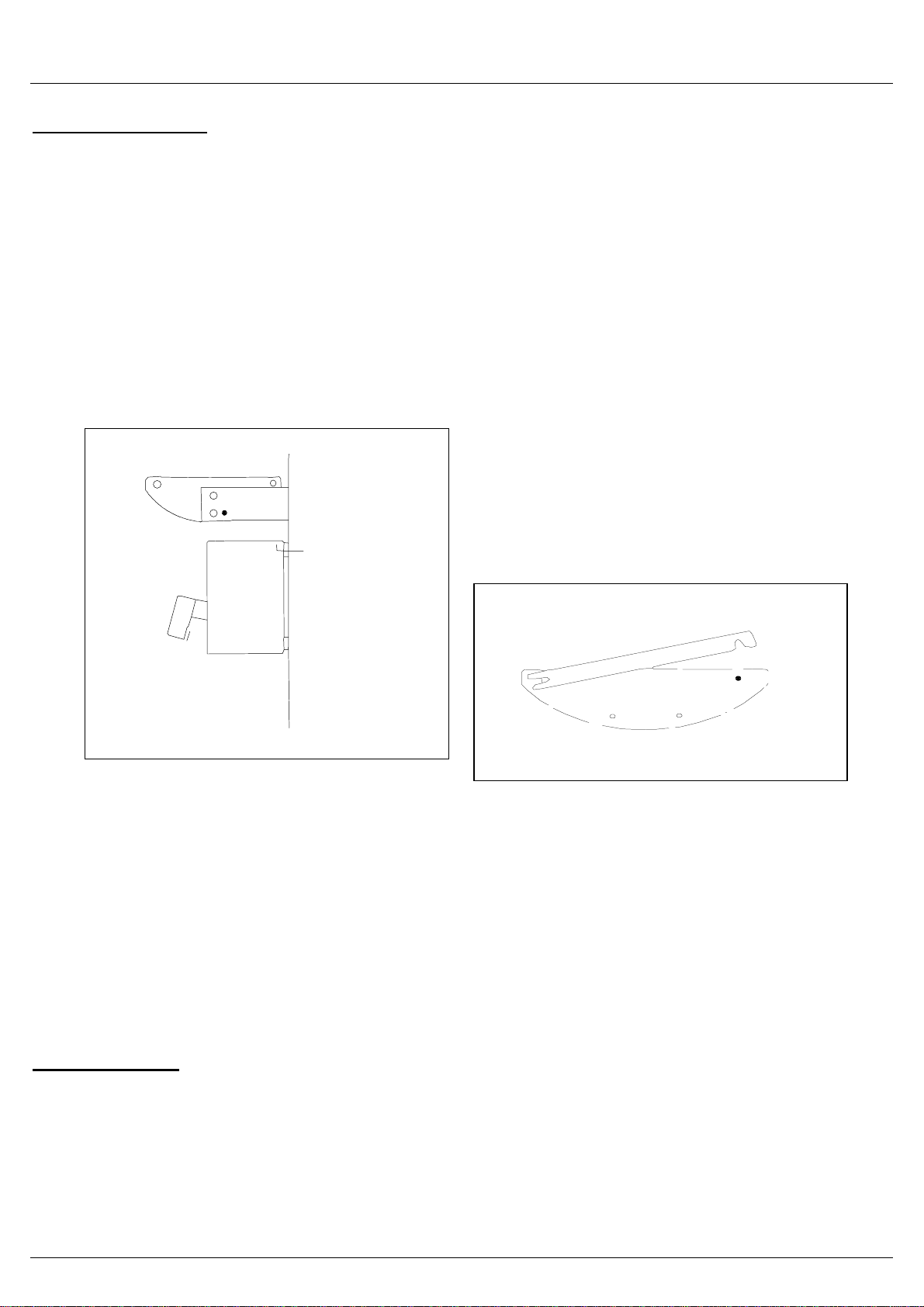

3.3. Wall-mounted roll holder ____________________________________________________

If the MELAseal®Package Sealing Device is placed

against the wall, or if it is mounted directly on the

wall, then it is best to have a wall-mounted roll

holder positioned directly above it. The wall-

mounted roll-holder can also be installed in a wall

cupboard above the package sealing device, and

the packaging foil fed through a slit in the base of

the cupboard.

Three different positions can be selected, depending

on the width of the roll used, in order to ensure that

the packaging foil is fed properly to the package

sealing device.

MELAG Art. No. 106

3.4. Acrylic hood _______________________________________________________________

The acrylic hood fits over either the "Comfort" roll

holder or the wall-mounted roll holder, to protect the

packaging roll from dust, soiling, etc.

MELAG Art. No. 107

3.5. "Standard" roll holder _______________________________________________________

The "Standard" roll holder can be used to hold the

packaging role directly on the MELAseal® Package

Sealing Device. This roll holder is fixed on the two

mounting points on the rear side of the package

sealer.

MELAG Art. No. 109

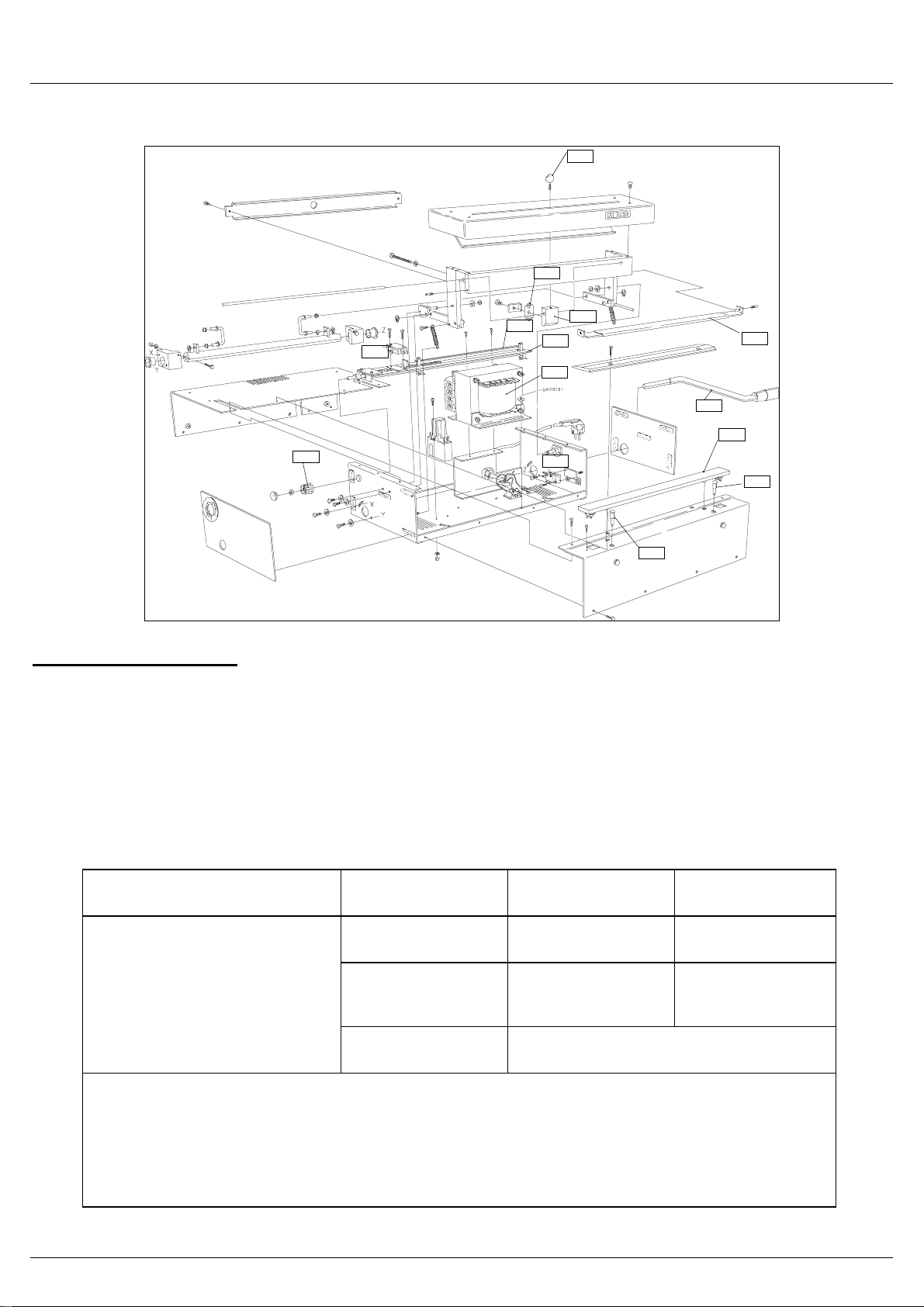

4. Servicing

4.1. Exchanging the sealing rail __________________________________________________

First, always disconnect the MELAseal®Package

Sealing Device from the mains power supply. This is

important for all repairs, maintenance and servicing

work. The sealing rail (3) is supplied as a complete

unit by your dealer. Remove the screw to the left of

the defective sealing rail, then push the rail to the

left, and pull it up and forward to remove it.

Disconnect the electrical leads, and attach the

connections to the new sealing rail. Position the

replacement sealing rail on the package sealing

device and then push it to the right until it sits tightly,

Wall