Table of contents

Table of contents

Chapter 1 – Performance Specifications.........5

Intended Use............................................................... 5

Chapter 2 – Device description.......................6

Scope of delivery......................................................... 6

Views of the device...................................................... 6

Status display and acoustic signals............................. 7

Chapter 3 – Commissioning............................8

Transport and storage ................................................. 8

Conditions of storage and installation.......................... 8

Requirements of the installation location..................... 8

Commissioning............................................................ 9

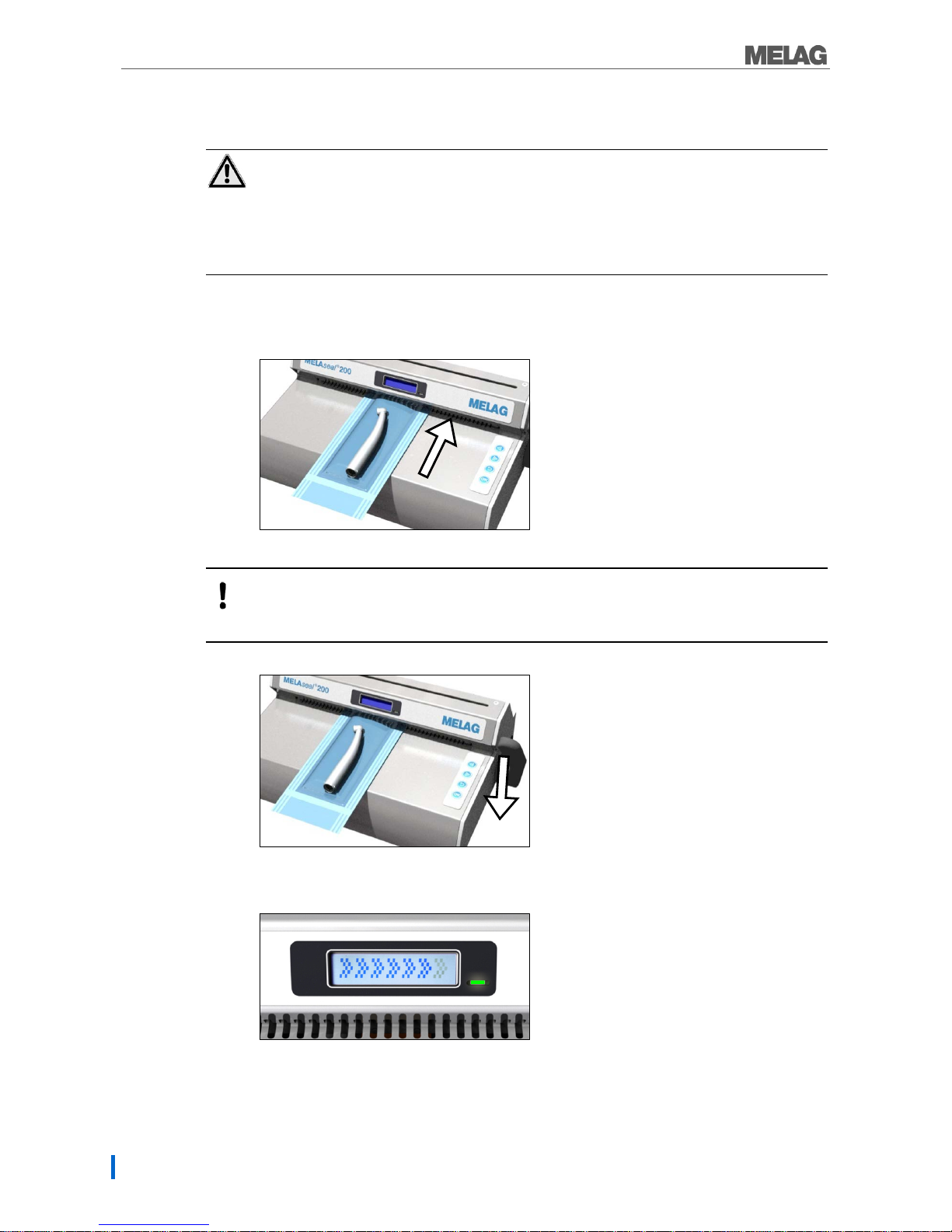

Simple sealing procedure...........................................10

Sealing procedure for roll stock..................................11

Seal seam width.........................................................13

Chapter 4 – Settings .....................................14

Menu structure............................................................14

Setting the date and time............................................14

Changing the sealing temperature..............................15

Switching the signal tones on and off.........................16

Selecting between up to 10 users...............................16

Eco Mode and Standby..............................................17

Chapter 5 – Logging .....................................18

Using the USB flash drive as an output medium ........18

Using the computer as an output medium..................19

File names and ending...............................................19

Reading logs correctly................................................20

Chapter 6 – Optional Accessories.................21

Roll dispenser “standard”............................................21

Roll dispenser "comfort" and "deluxe" ........................21

Wall-mounted roll dispenser.......................................22

Chapter 7 – Maintenance..............................23

Pause times................................................................23

Replacing the blade....................................................23

Cleaning and regular controls.....................................24

Maintenance...............................................................24

Validation....................................................................24

Software update .........................................................24

Chapter 8 – Malfunctions..............................26

Manufacturer's Recommendation for Routine

Operation......................................................28

DIN Specifications........................................30

Terms.........................................................................30

General information regarding the packaging and

sealing procedure.......................................................30

Seal seam width.........................................................30

Clearance of the seal seam to the cutting edge.........30

Strength of seal seam................................................30

Storage length for sterile medical products................31

Accessories and Spare Parts .......................32

Technical Data .............................................32