16 20-07457-UK-02

! Important information:

- The Product does not require periodic maintenance in cases where it has a responsible prescriber in the healthcare

sector. In markets outside of Sweden and Norway where a distributor has sold the Product directly to the user (where

applicable), and therefore there is no responsible prescriber, periodic maintenance must be carried out every other

year during the Product’s entire life cycle according to sections 1-12 in this section.

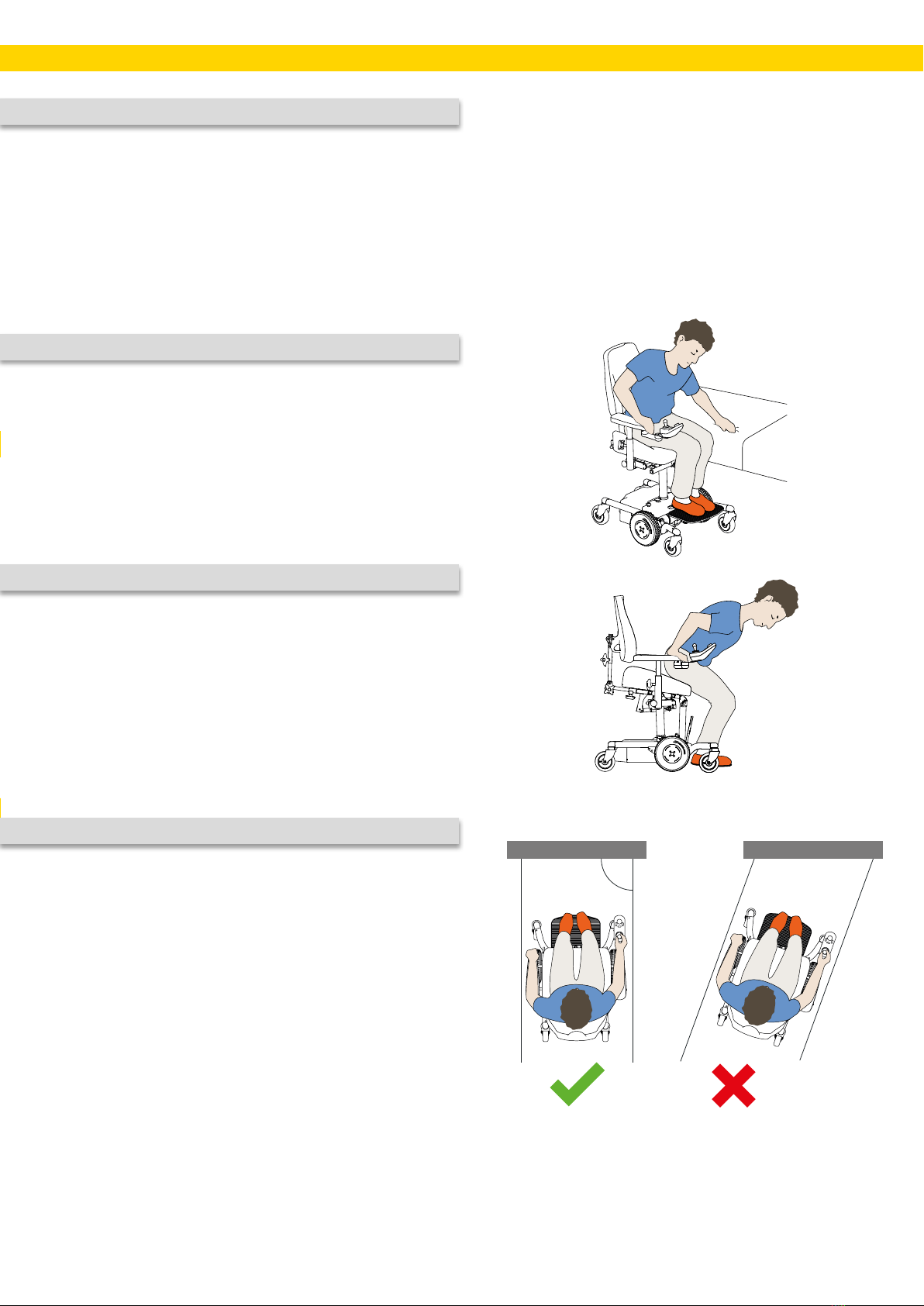

- A thorough visual inspection must be performed of the Product’s main components in connection with service and

reconditioning in order to ensure the user’s safety. This includes the chassis, lifting mechanism, seat frame, back

recliner and U-bars for armrests. The check must include welds, lockable functions, cabling and settings.

- If faults or damage are discovered, avoid using the chair until it has been inspected and approved by qualified service

personnel.

- The user must not sit in the chair while it is being reconditioned or serviced or during maintenance.

- For safety reasons, before a used chair is prescribed to a new user, the seat frame and the back recliner should be

replaced.

- Do not use high pressure washers when cleaning the chair.

1. Electronics unit

1.1. Electronics/function/cleaning

Connect the Wizard program and read

off the diagnostics. Check active errors

and diagnostics. Fix any errors and

reset the log.

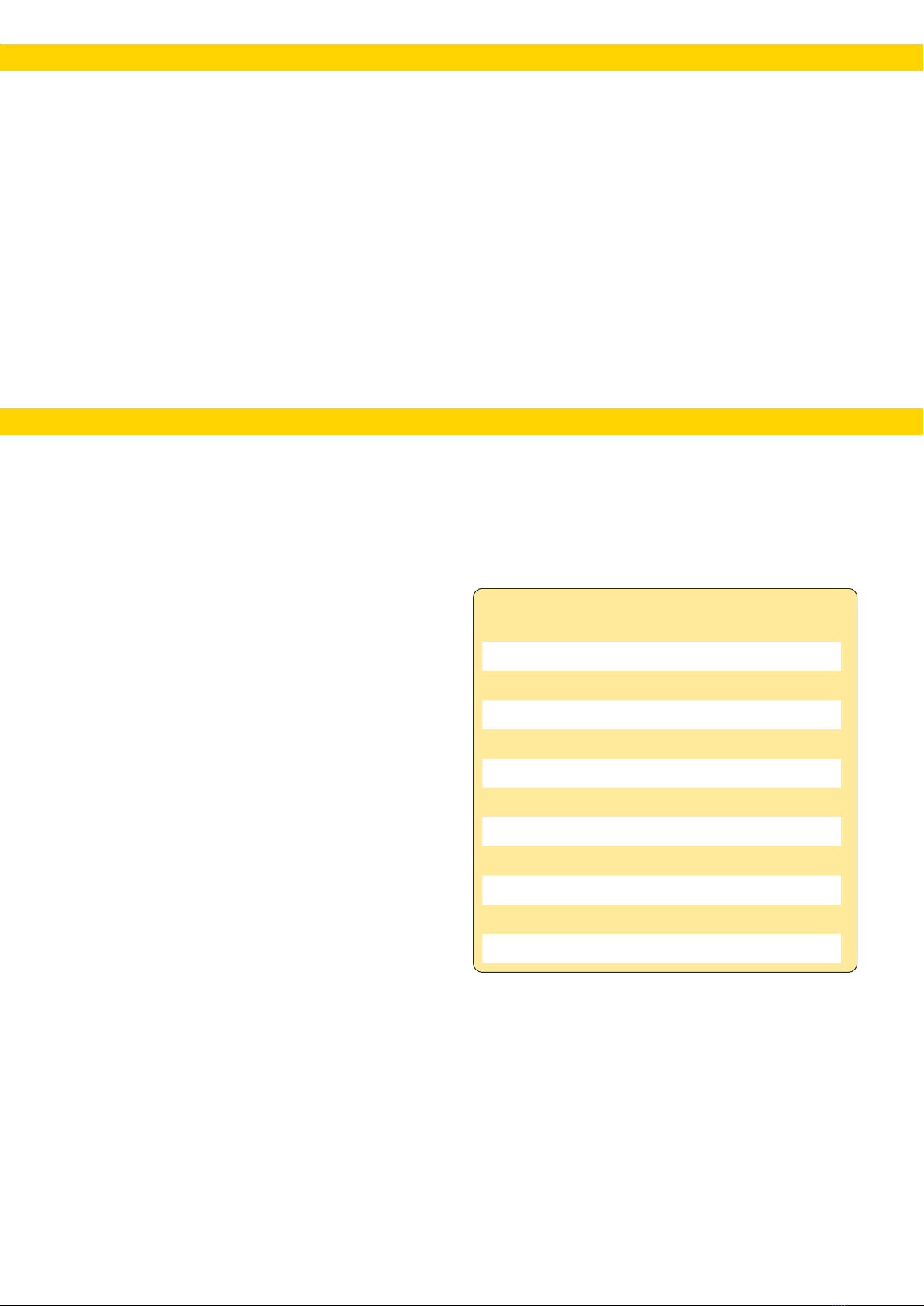

1.2. Control unit/function/cleaning

Check the control unit functions, check

that the joystick bellows is intact and

that all buttons are working. Wipe

the control unit with a cloth lightly

dampened with disinfectant; this is to

avoid the risk of spreading infection.

Do not use solvents, bleach, polishes,

synthetic detergents, polishing waxes

or sprays on the chair.

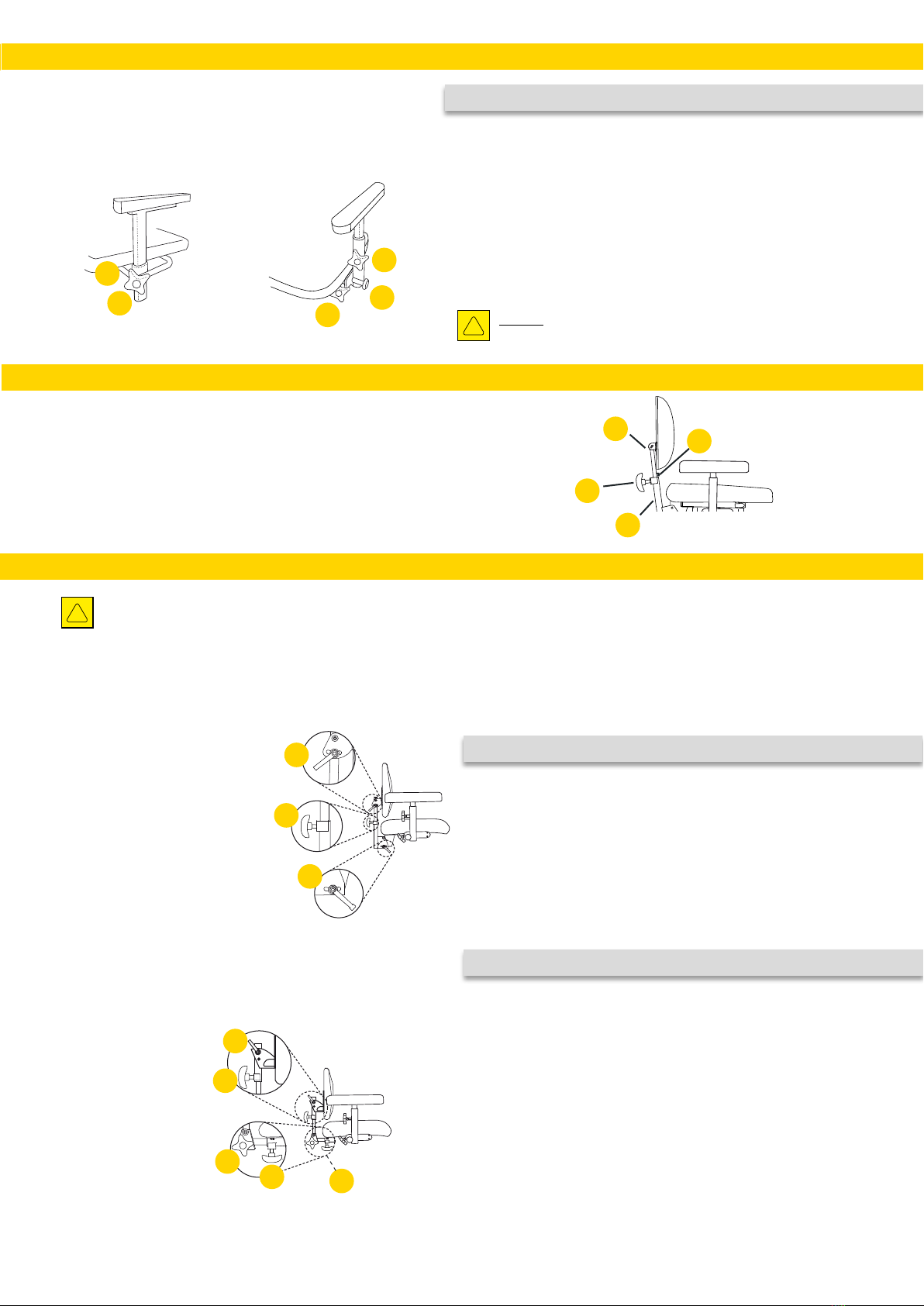

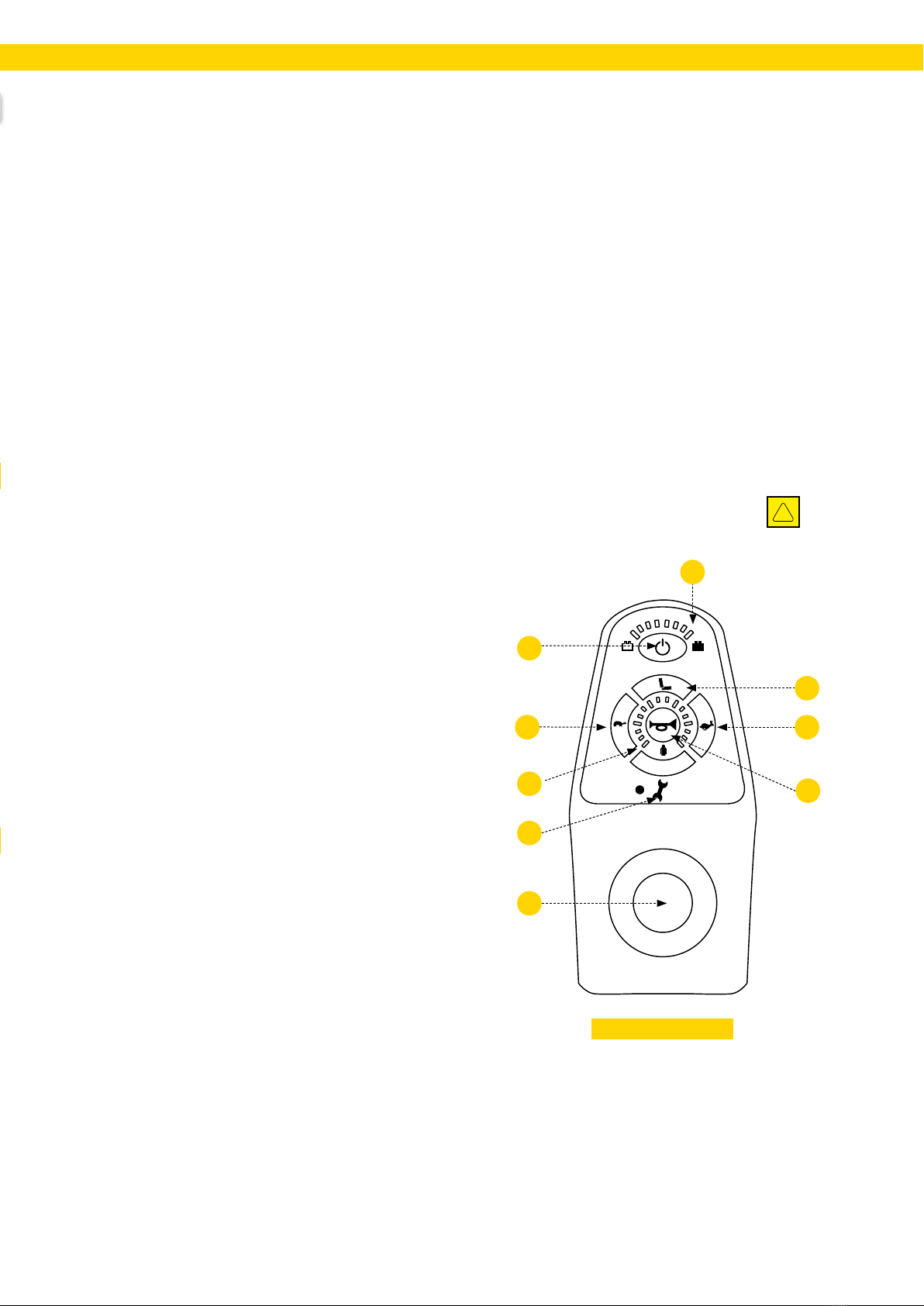

1.3. Electrical seat functions (DCI)/

function

Check that plugged in electrical

functions are working and that the 12-

pin connector on the power module is

not loose or has any visible damage.

1.4. Connectors, attachment

Check that cables and connectors are

intact and properly secured. Make sure

that cables and connectors cannot be

pinched or crushed.

1.5. Batteries/battery charger/

function

Check that the charger is working

and that the housing and cables are

undamaged. Measure the battery

voltage and check that the difference

in battery charge level is not too great;

this indicates that a battery cell has

failed.

1.6. Electric seat tilt/function

Check that the actuator is not visibly

damaged. Check the function of the

actuator’s moving parts. Ensure that all

locking screws are tightened to avoid

any play in the end position.

1.7. Electric backrest/function

Check that the actuator is not visibly

damaged. Check the function of the

actuator’s moving parts. Ensure that all

locking screws are tightened to avoid

any play in the end position.

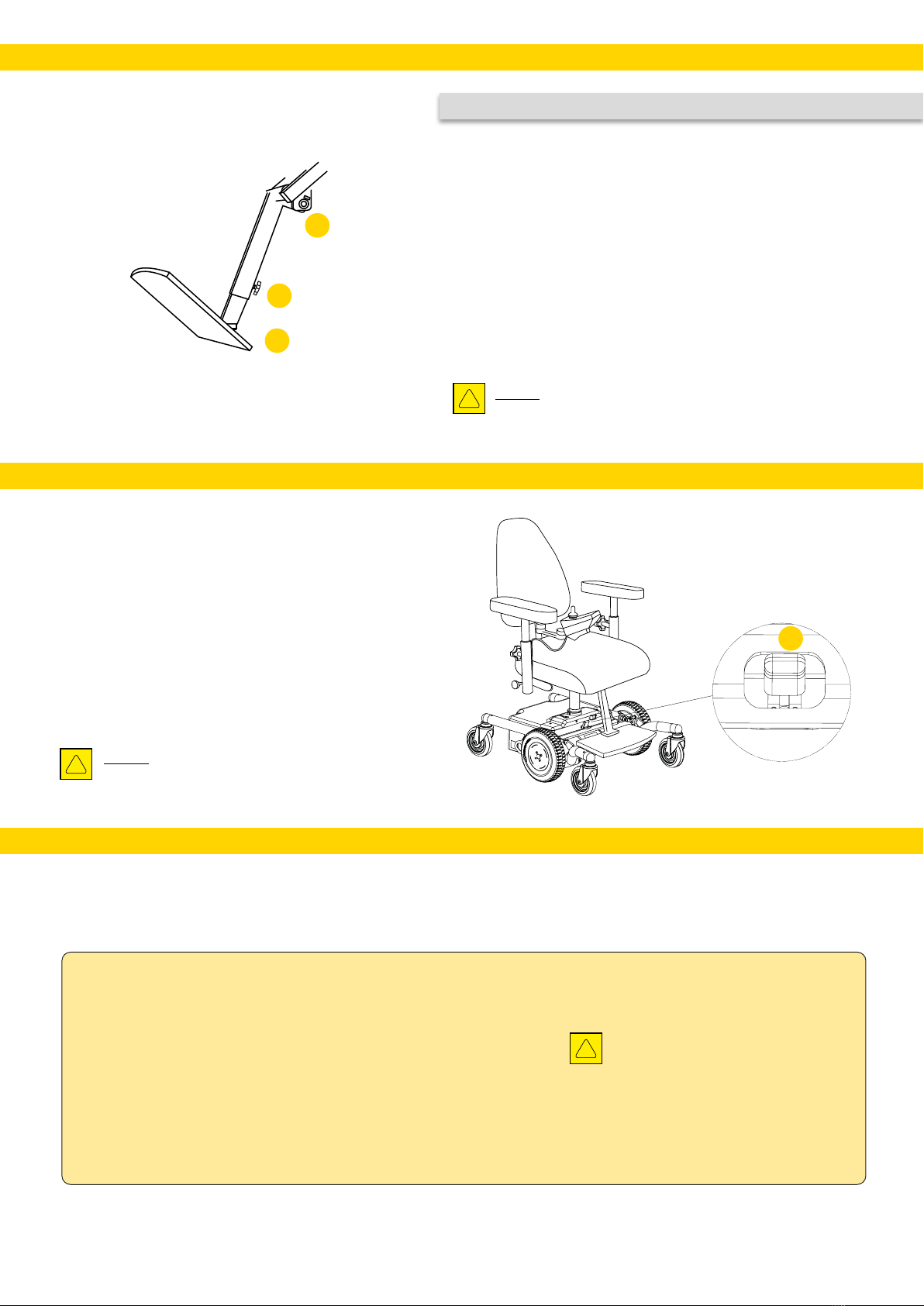

1.8. Electric leg support/function

Check that the actuator is not visibly

damaged. Check the function of the

actuator’s moving parts. Ensure that all

locking screws are tightened to avoid

any play in the end position. Check

all joints and that the lower clamping

bracket is securely tightened

2. Electric lifting mechanism

2.1. Noise / sliding clutch

Listen for any abnormal noise in

the gearbox bearings, and replace

the electric lifting mechanism if

a bearing is defective in any way.

The electric lifting mechanism can

be sent to Mercado Medic AB for

repair/reconditioning. Load the

chair and check that the electric

lifting mechanism does not slip in

its bottom position. If the electric

lifting mechanism slips, tighten the

safety clutch until the electric lifting

mechanism no longer slips.

2.2. Rotation lock / lubrication

Check that there is no play in the

electric lifting mechanism in the

direction of rotation. If there is, replace

the electric lifting mechanism. The

electric lifting mechanism can be

sent to Mercado Medic AB for repair/

reconditioning.

3.3. Attachment/tightening

Check that the attachments to the seat

frame and base are securely tightened.

4.4. Cabling/wear

Inspect cables for any signs of wear,

pinching or crushing.

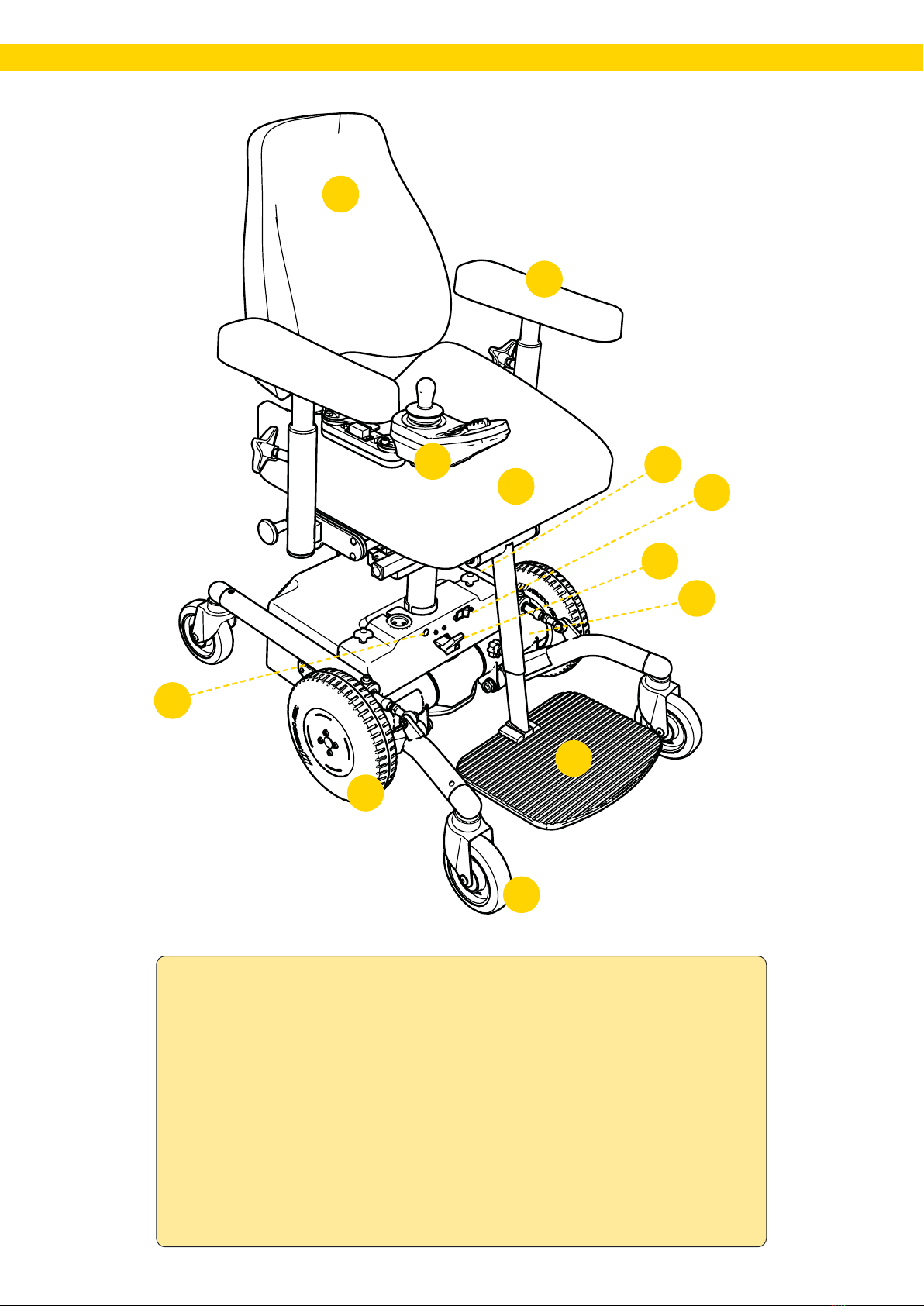

3. Chassis

3.1. Welds

Check all welds carefully for signs of

cracks, corrosion, movement, etc.

3.2. Bolted joints

Check and tighten all bolted joints.

Replace screws that have damaged

heads or threads.

4. Drive wheels

4.1. Function/wear

Check that the drive wheels have good

tyre treads and that they have not

dried out (will result in poor friction to

the floor).

4.2. Bearings/wheel tracks

Check that the drive wheels are rolling

properly and that there is no play in the

motors’ gears.

4.3. Attachments/tightening

Remove the drive wheels and check

the motor screw joints. If necessary,

blow off all dust and dirt from the

motors.

5. Castors

5.1. Function / roll / swivel

Remove hair and dust from the castors

and check castors and castor housings

for wear and play, which may indicate

defective bearings. Check that the

castors swivel and the housings

rotate as expected. Replace castors if

necessary.

5.2. Attachment/tightening

Check that the castor screws are intact

and tightened.

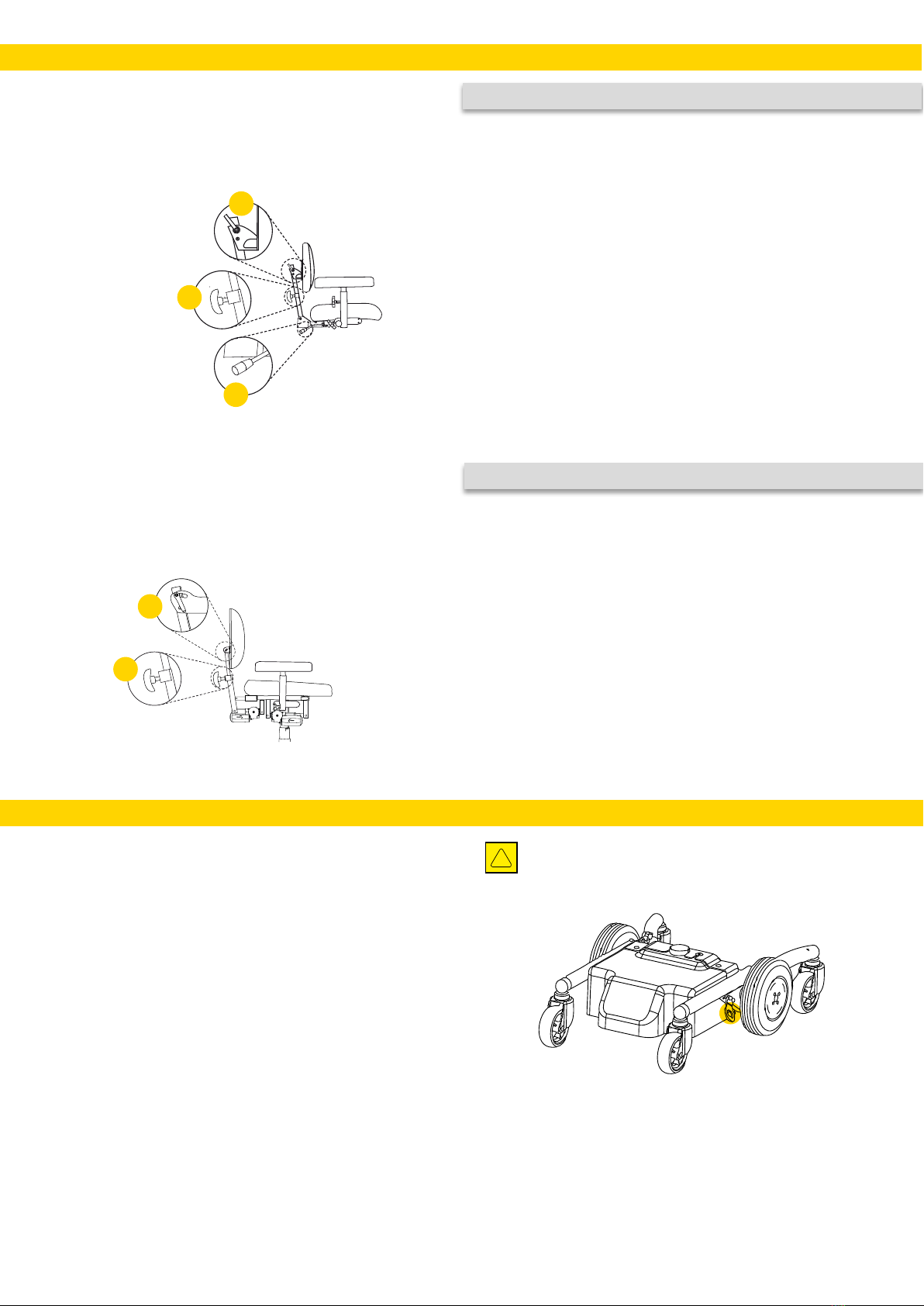

6. Brake release

6.1. Function

Check that there is no play in the

brake release control and that the

magnet activates the sensor upon

disconnection. Make sure that the drive

wheels rotate easily when disengaged.

6.2. Setting/tightening

If the brake release does not properly

reconnect, adjust the brake release

mechanism.

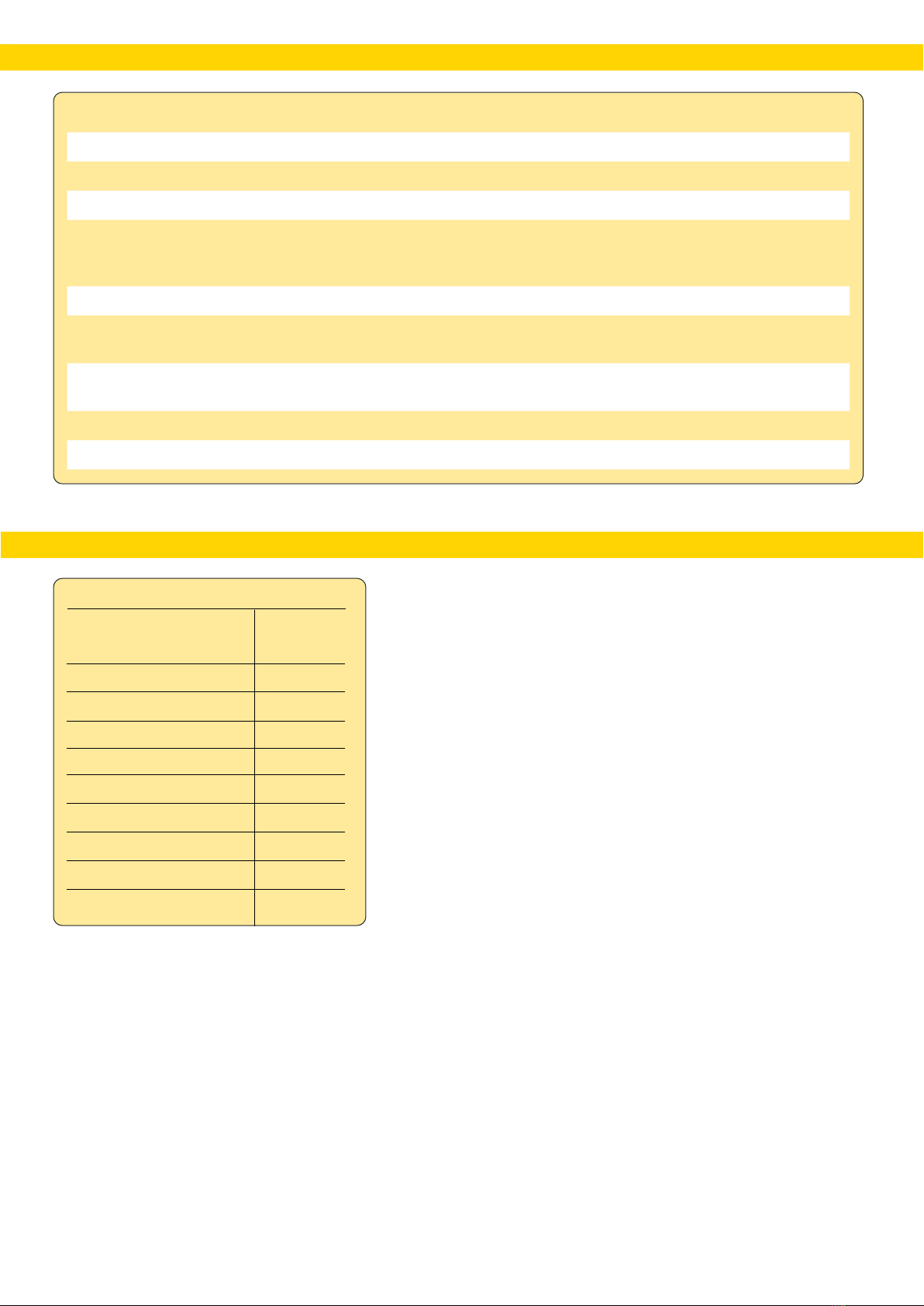

CHECKLIST RECONDITIONING AND SERVICE REAL 6100 PLUS