mcr FID 240 single-blade fire dampers

“MERCOR” SA – The company reserves the right to modify and change the document. Version FID 240 21.07.29.1 5/19

4. DESIGN AND OPERATING PRINCIPLE

Design

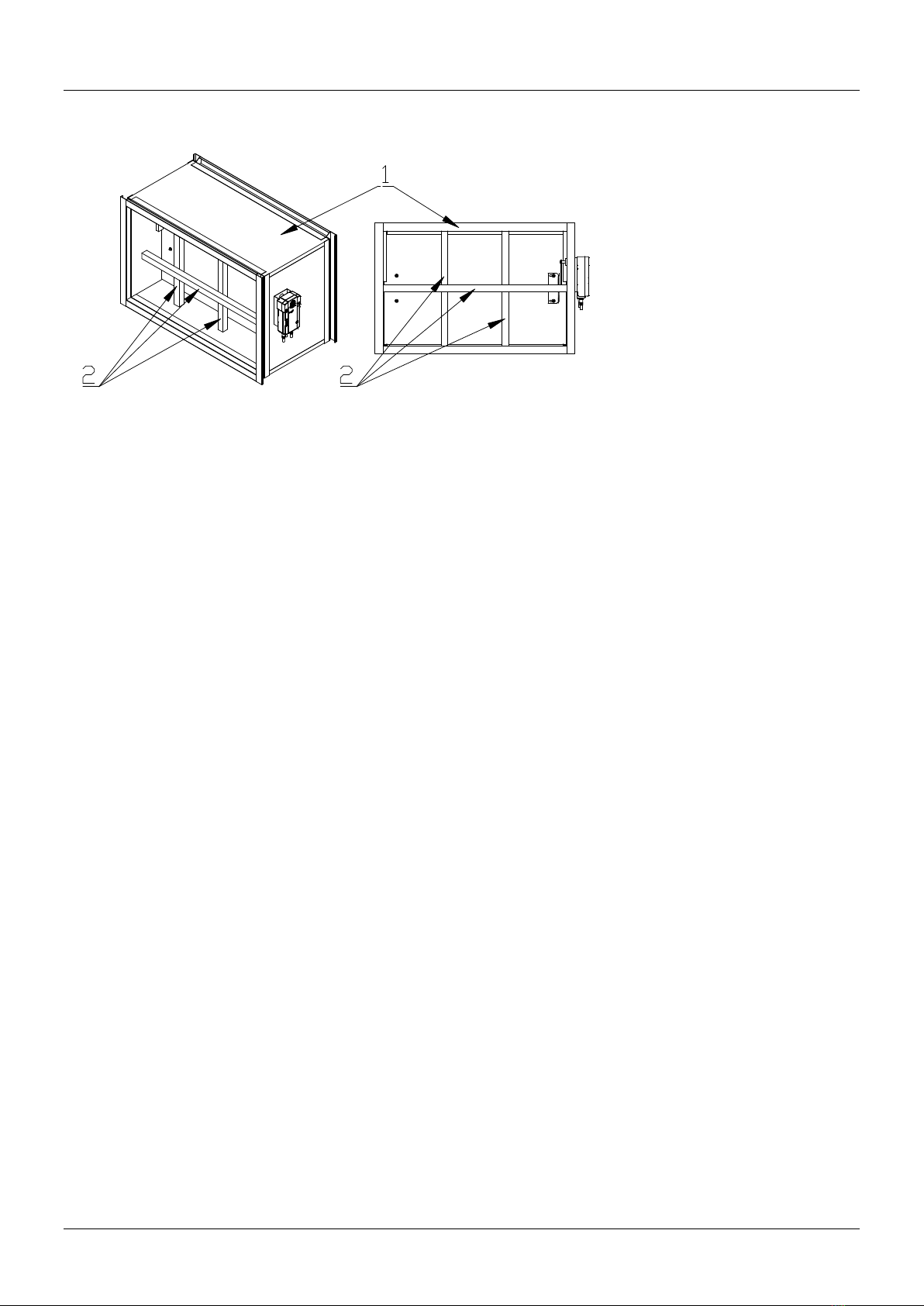

The mcr FID 240 single-blade fire dampers comprise a casing with a rectangular cross-section, a moving

isolation partition and a trigger control gear which is tripped remotely or automatically by tripping a thermal

trigger. The damper casing and moving isolation partition is made of fire-proof panel. The isolation partition

is set in a reinforcement profile made of metal sheet. The inner side of the fire damper casing features a

intumescent gasket. There are stop shapes fastened to the inner casing surface and made offire-proof

panel, which limit the rotating motion of the isolation partition. The damper has both ends of body with

flanged connections.

Function

The operating principle and behaviour of the mcr FID 240/... single-blade dampers depend on their

application versions:

cut-off fire dampers – mcr FID 240 /S

In the normal operating position the dampers are open. The dampers are closed (to the safety

position) as follows:

automatically, by tripping the thermoelectric trigger

manually, by pressing the control button on the thermoelectric trigger

remotely, by tripping an electric axial actuator with a return spring caused by isolation from the

supply voltage

automatically, by tripping the thermal trigger and the driving spring

cut-off fire dampers for fire ventilation systems – mcr FID 240 /V

In the normal operating position the dampers are closed. The dampers are opened (to the safety

position) as follows:

remotely, by tripping an electric axial actuator without a return spring, as a result of applying the

supply voltage to the actuator in the right manner

remotely, by tripping the electromagnetic release and a spring as a result of applying the voltage

cut-off fire dampers for mixed fire ventilation systems – mcr FID 240 /V-M

In normal operation the dampers are closed or open, depending on the function carried out. The

dampers are opened/closed (to the safety position) as follows:

remotely, by tripping the electrical axial actuator without a return spring in order to apply supply

voltage to the actuator in the right manner

remotely, by tripping the electromagnetic release and a spring as a result of applying the voltage

transfer fire dampers – mcr FID 240 /T

In the normal operating position the dampers are open or closed. The dampers are switched to the

safety position as follows:

automatically, by tripping the thermoelectric trigger

manually, by pressing the control button on the thermoelectric trigger

remotely, by tripping an electric axial actuator with a return spring caused by isolation from the

supply voltage

automatically, by tripping the thermal trigger and the driving spring

relief fire dampers – mcr FID 240 /G

In normal operation the dampers are closed or open, depending on the function carried out. The

dampers are opened/closed (to the safety position) as follows:

remotely, by tripping an electric axial actuator with a return spring caused by isolation from the

supply voltage The actuator has no thermoelectric trigger.

It is possible to manually service check the proper performance of the dampers with electrical actuators

by placing a special hex wrench in the socket marked on the actuator and rotating it to set the damper

isolating partition in the relevant position. Rotate the wrench slowly, smoothly and carefully. Rotating the

wrench too fast or too rapidly may damage the internal actuator gear or the drive transmission system.

The mcr T2 tester is recommended to check the proper performance of dampers with electric actuators.