mcr FID B single-plane fire dampers

“MERCOR” SA – The company reserves the right to modify and change the document. Version FID B 21.07.30.02 5/22

Execution versions

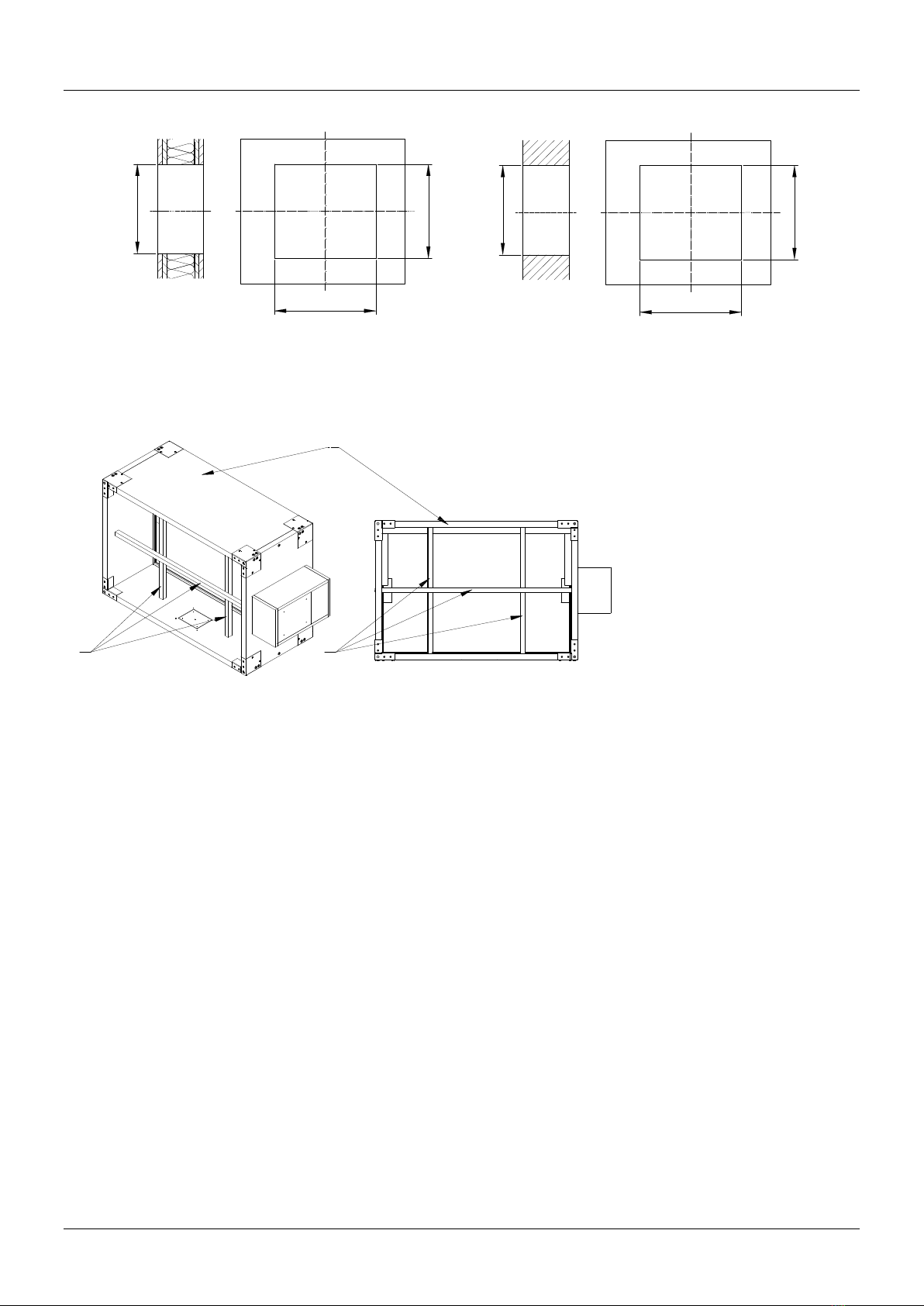

mcr FID B dampers can be made as rectangular dampers.

Dimension type series

mcr FID B fire dampers are manufactured in the following size ranges:

Width: 200 to 1200 mm

Height: 200 to 800 mm

Width: 600 mm

Aside from the standard dimensions, the fire dampers may also be manufactured in intermediate sizes.

The damper casing can be made longer on request. Maximum surface area of type mcr FID B dampers:

0,96 m2. The minimum damper surface area is 0,04 m2.

4. DESIGN AND OPERATING PRINCIPLE

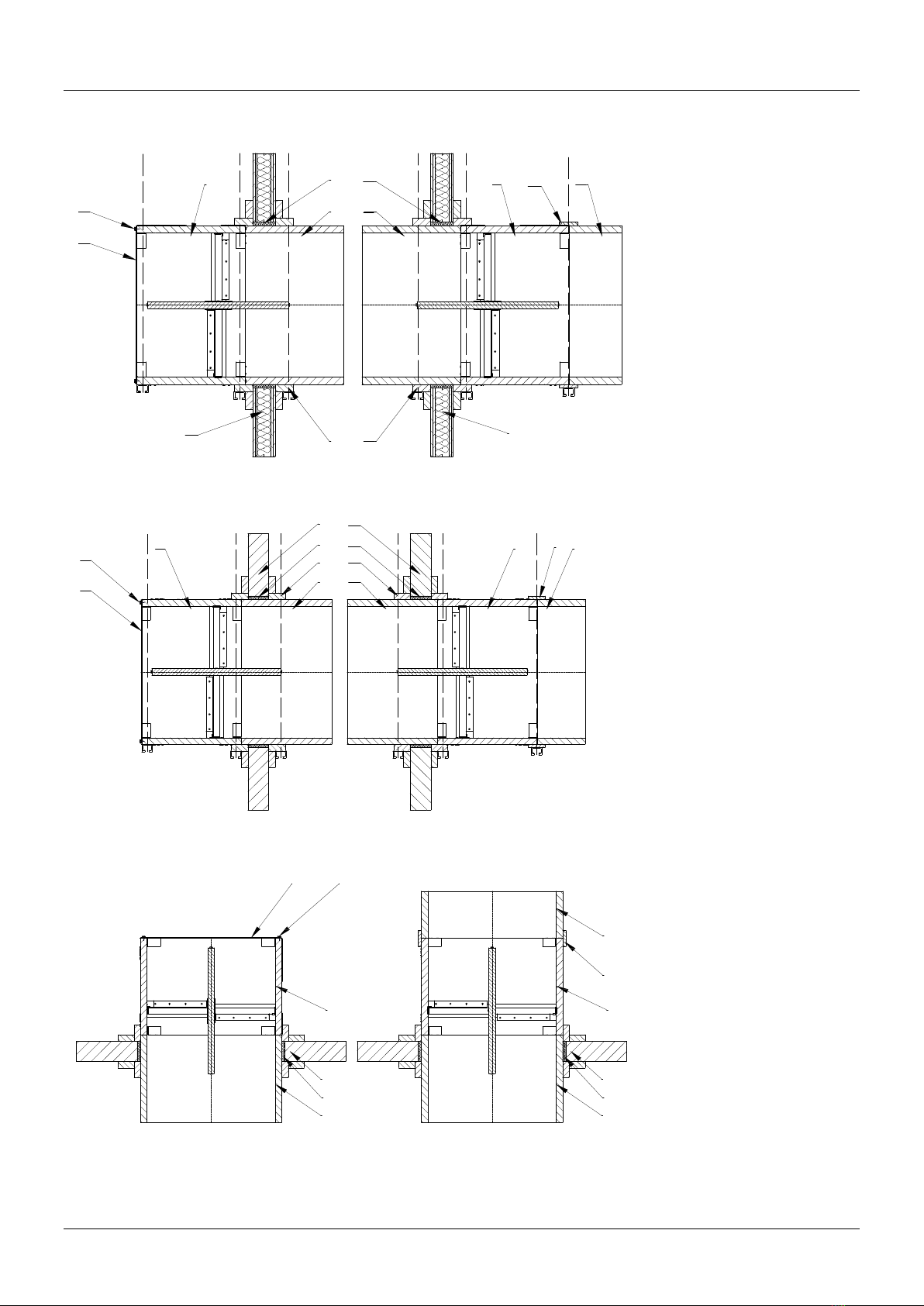

Design

The mcr FID B dampers consist of a casing with a rectangular cross-section consisting of fireproof boards,

a movable cut-off partition and an actuator operated manually or remotely. The cut off partition of the

dampers is made of a fireproof boards and is set in a sheet-metal profile. There is a ventilation gasket on

the inside of the housing. Retaining sections made of fireproof boards are attached to the inner surface of

the housing, limiting the movement of the rotating partition. The sections are covered with a ventilation

gasket. Corners made of steel, galvanized or stainless steel are attached to the outer surface of the

housing in the corners. For chemically aggressive environments, special enclosures are used, where the

fireproof boards are impregnated.

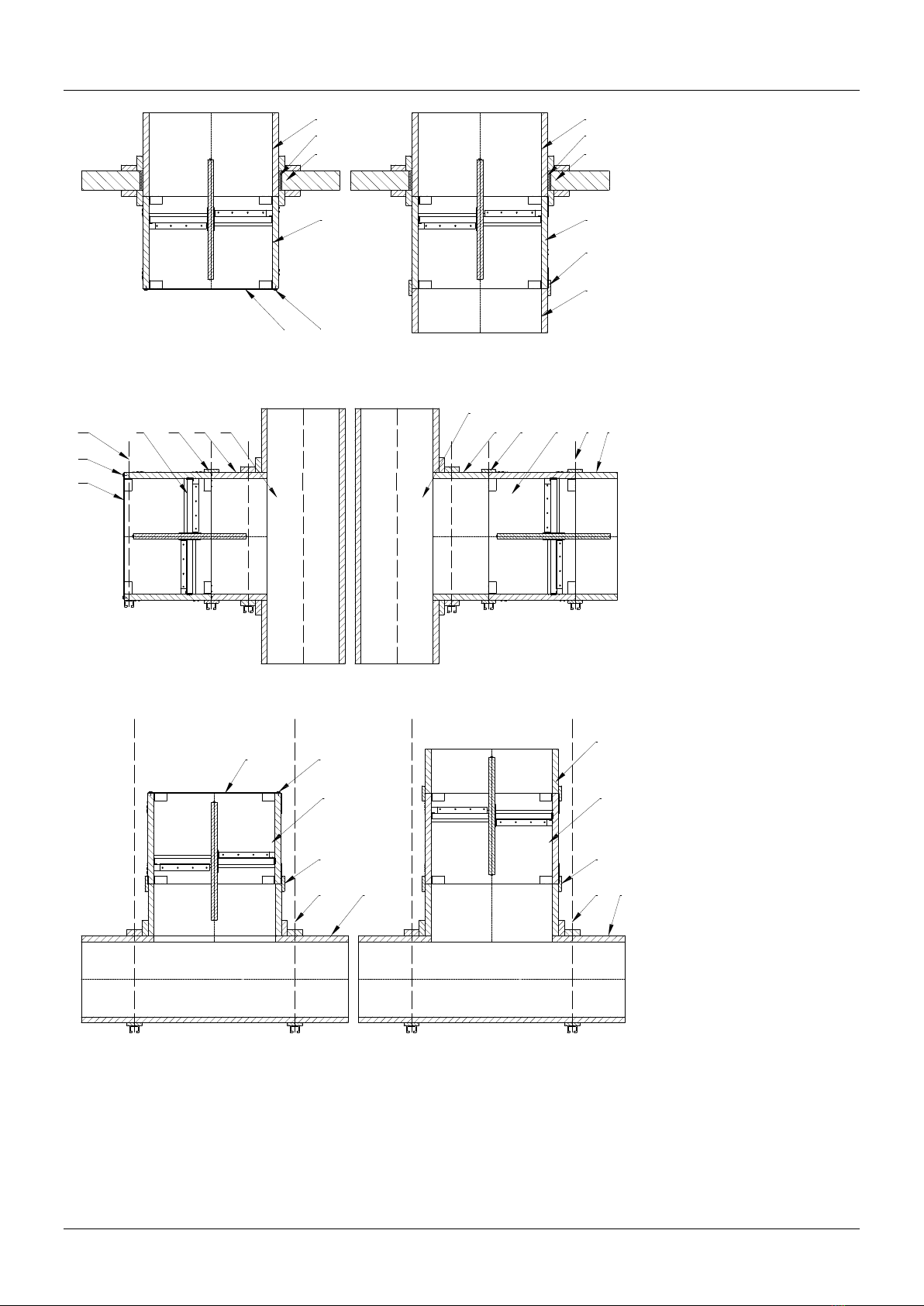

Function

The operating principle and behaviour of the mcr FID B single-plane dampers depend on their application

versions:

cut-off fire dampers – mcr FID B/S

In the normal operating position the dampers are open. The dampers are closed (to the safety position)

as follows:

automatically, by tripping the thermoelectric trigger

remotely, by tripping an electric axial actuator with a return spring caused by isolation from the supply

voltage

automatically, by tripping the thermal trigger and the driving spring

cut-off fire dampers for fire ventilation systems – mcr FID B/V

In the normal operating position the dampers are open or close depending on the function. The dampers

are closed/ opened as follows:

remotely, by tripping an electric axial actuator without a return spring, as a result of applying the

supply voltage to the actuator in the right manner. The damper blade can change position without loss

of device functionality for 25 minutes from the time of activation of operation.

remotely, by tripping the electromagnetic release and a spring as a result of applying the voltage

cut-off fire dampers for mixed fire ventilation systems – mcr FID B/M

In the normal operating position the dampers are open or close depending on the function. The dampers

are closed/ opened as follows:

remotely, by tripping an electric axial actuator without a return spring, as a result of applying the

supply voltage to the actuator in the right manner. The damper blade can change position without loss

of device functionality for 25 minutes from the time of activation of operation.

remotely, by tripping the electromagnetic release and a spring as a result of applying the voltage