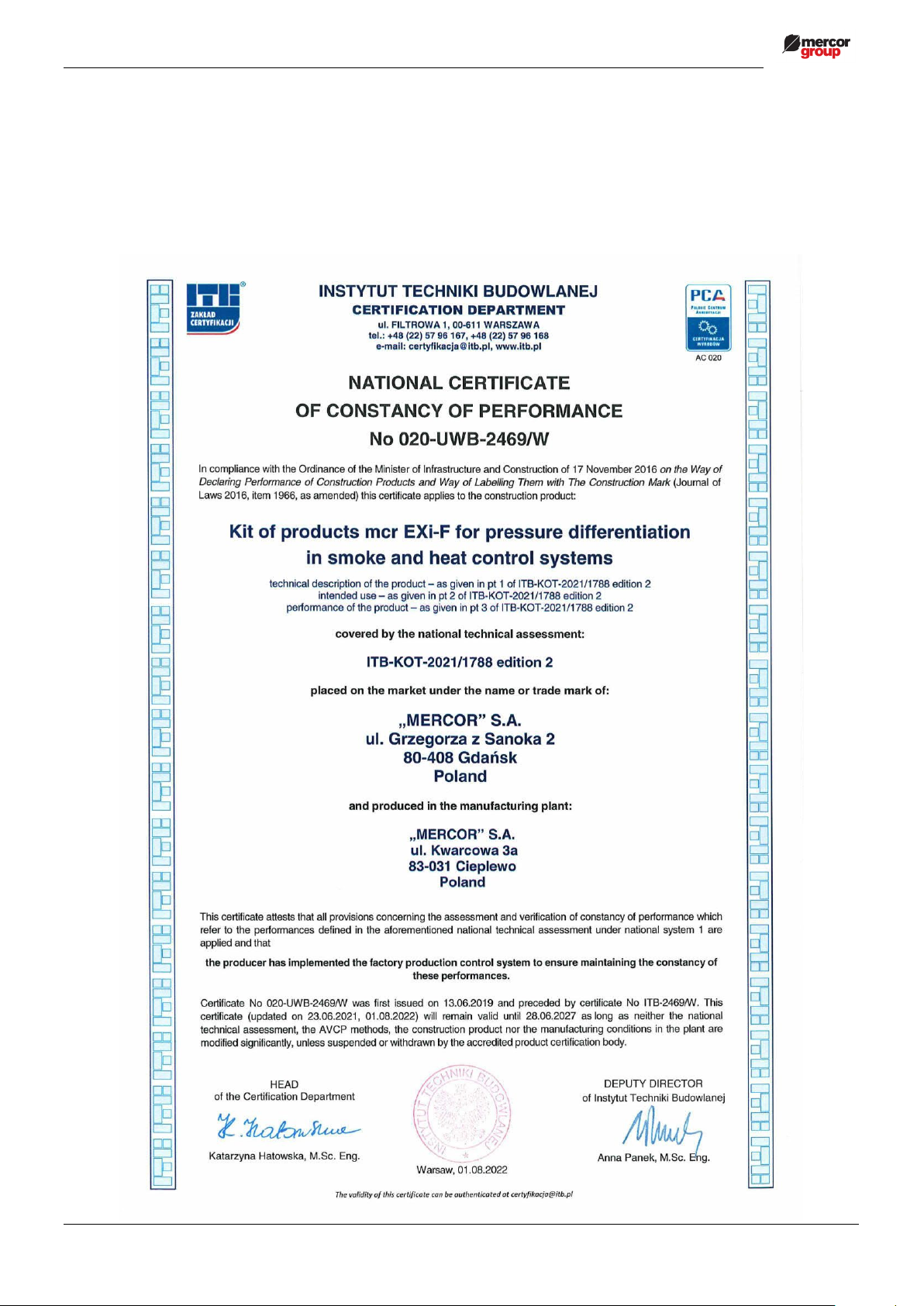

OMM - mcr EXi-F

Version mcr EXI-F 23.07.28.1 Page 2/99

CONTENTS

1. INTRODUCTION INTO TRADING ........................................................................................................4

2. FOREWORD .....................................................................................................................................5

3OBJECT OF THE DOCUMENTATION ..................................................................................................5

4INTENDED PURPOSE OF THE DEVICE..............................................................................................5

4.1 Application ......................................................................................................................................5

4.2 System elements ............................................................................................................................5

4.3 System mode of operation ..............................................................................................................5

4.4 System selection principle ..............................................................................................................7

4.4.1. Requirements of the EN 12101-13 standard ......................................................................................8

4.4.2. Requirements in the Manual no. 378/2002 of the Construction Technology Institute.......................9

4.4.3. Requirements concerning the design of a fire ventilation system.................................................11

5. SYSTEM COMPONENTS..................................................................................................................12

5.1. Design of the mcr EXi-F air supply unit.........................................................................................12

5.1.1. Fan................................................................................................................................................16

5.1.2. Shut-off damper (non-insulated/insulated)...................................................................................17

5.1.3. Service disconnector.....................................................................................................................18

5.1.4. Vibration and noise dampening elements (optional)......................................................................18

5.1.5. Installation feet (optional) .............................................................................................................19

5.1.6. LAM louvered vents (optional) ......................................................................................................19

5.2. Explosion pressure relief panels (PL, PLD) and system permanent unsealing module (PRC)

(optional)................................................................................................................................................20

5.3. mcr OMEGA control panel .............................................................................................................23

5.3.1. Description and principle of operation ..........................................................................................23

5.3.2. Signaling .......................................................................................................................................25

5.3.3. Specifications................................................................................................................................25

5.3.4. mcr ICR pro positive pressure regulator.......................................................................................27

5.4. mcr ICS pro differential pressure transmitter...............................................................................28

5.5. mcr PSR / mcr PSRC manual control panel ..................................................................................30

5.6. mcr WPS elevated control panel ...................................................................................................31

5.7. Duct smoke detector .....................................................................................................................32

5.8. Intake vent switching system........................................................................................................33

5.9. mcr ICP lobby controller ...............................................................................................................34

5.10. mcr PP connection box .................................................................................................................37

5.11. Damper for lobby systems ............................................................................................................38

5.12. mcr HT anti-icing system ..............................................................................................................39

5.13. mcr SEP network separators........................................................................................................41

5.14. Temperature transmitter...............................................................................................................42

5.15. Magnetic sensors (reeds)..............................................................................................................43

5.16. Differential pressure switch..........................................................................................................43

6. ELECTRICAL CONNECTION............................................................................................................44

6.1. Electrical connections of devices to the mcr Omega panel ...........................................................62

6.1.1. EXI-F unit air supply fan................................................................................................................62

6.1.2. Service disconnector.....................................................................................................................63

6.1.3. Shut-off damper............................................................................................................................63

6.1.4. mcr PLD explosion pressure relief panels....................................................................................64