2B-2 - ELECTRICAL 90-852396 MAY 1996

Battery

Precautions

WARNING

If battery acid comes in contact with skin or eyes,

wash skin immediately with a mild soap. Flush

eyes with water immediately and see a doctor.

When charging batteries, an explosive gas mixture

forms in each cell. Part of this gas escapes through

holes in vent plugs and may form an explosive atmo-

sphere around battery if ventilation is poor. This ex-

plosive gas may remain in or around battery for sev-

eral hours after it has been charged. Sparks or

flames can ignite this gas and cause an internal ex-

plosion which may shatter the battery.

The following precautions should be observed to pre-

vent an explosion.

1. DO NOT smoke near batteries being charged or

which have been charged very recently.

2. DO NOT break live circuits at terminals of batter-

ies because a spark usually occurs at the point

where a live circuit is broken. Always be careful

when connecting or disconnecting cable clamps

on chargers. Poor connections are a common

cause of electrical arcs which cause explosions.

3. DO NOT reverse polarity of battery terminal to

cable connections.

Specific Gravity Readings

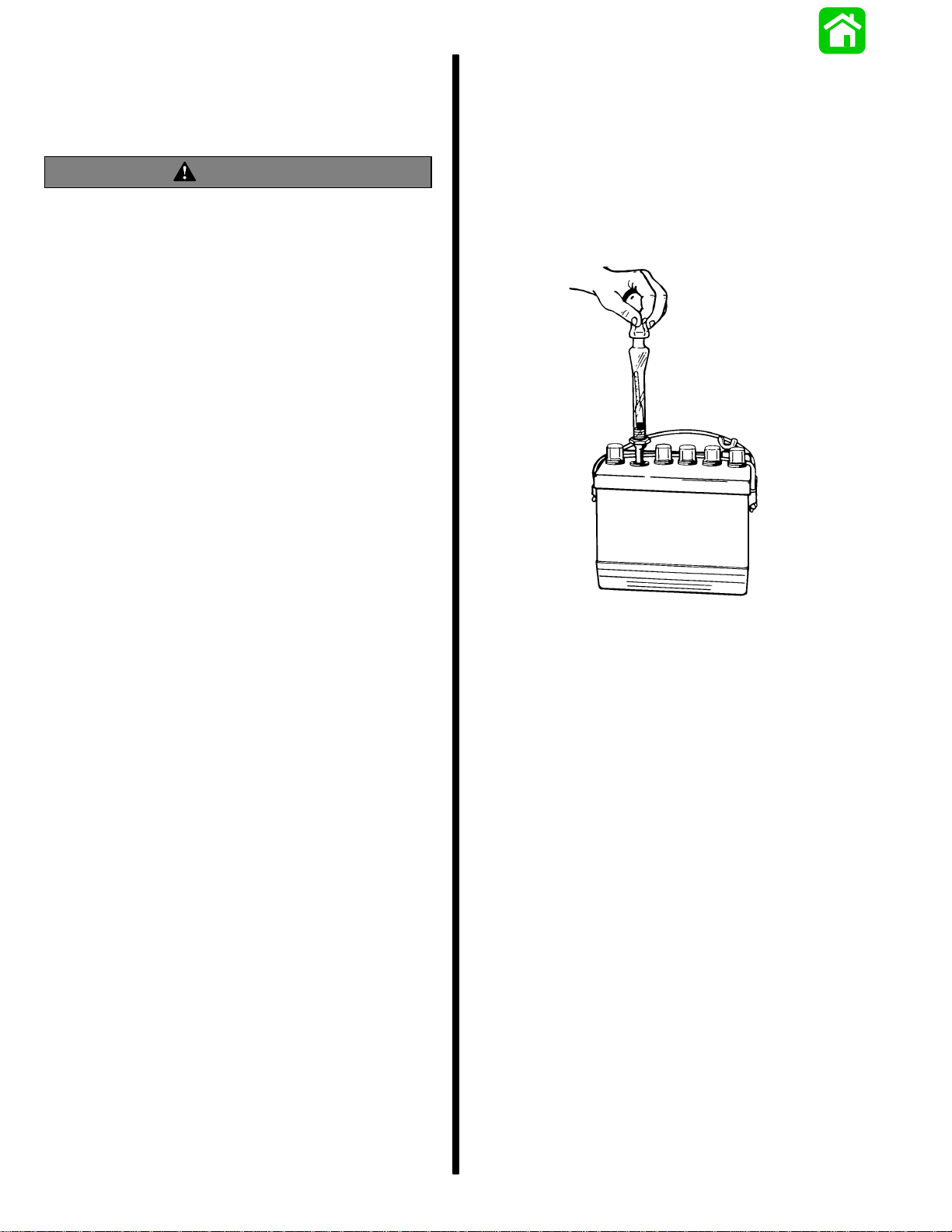

Use ahydrometer to measure specific gravity of elec-

trolyte in each cell.

Hydrometer measures percentage of sulfuric acid in

battery electrolyte in terms of specific gravity. As a

battery drops from a charged to a discharged condi-

tion, acid leaves the solution and enters the plates,

causing a decrease in specific gravity of electrolyte.

An indication of concentration of electrolyte is ob-

tained with a hydrometer.

When using a hydrometer, observe the following

points:

1. Hydrometer must be clean (inside and out) to in-

sure an accurate reading.

2. Never take hydrometer readings immediately af-

ter water has been added. Water must be thor-

oughly mixed with electrolyte by charging for at

least 15 minutes at a rate high enough to cause

vigorous gassing.

3. If hydrometer has built-in thermometer, draw liq-

uid in several times to ensure correct tempera-

ture before taking reading.

4. Hold hydrometer vertically and draw in just

enough liquid from battery cell so that float is free-

floating. Hold hydrometer at eye level so that float

is vertical and free of outer tube, then take read-

ing at surface of liquid. Disregard curvature

where liquid rises against float stem due to capil-

larity.

22532

5. Avoid dropping electrolyte on boat or clothing, as

it is extremely corrosive. Wash off immediately

with baking soda solution.

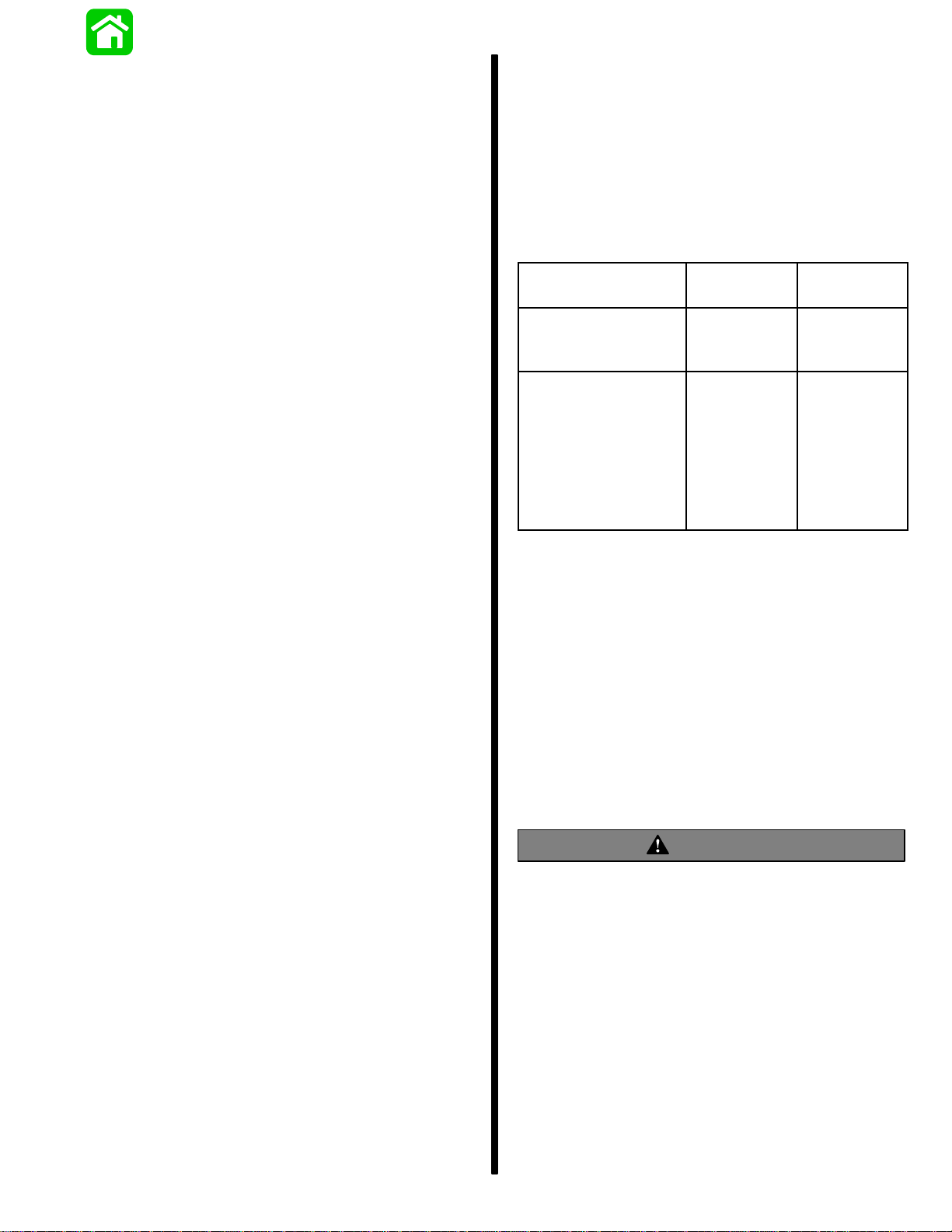

Specific gravity of electrolyte varies not only with per-

centage of acid in liquid but also with temperature. As

temperature increases, electrolyte expands, so that

specific gravity is reduced. As temperature drops,

electrolyte contracts, so that specific gravity in-

creases. Unless these variations in specific gravity

are taken into account, specific gravity obtained by

hydrometer may not give a true indication of acid in

electrolyte.

A fully charged battery will have a specific gravity

reading of approximately 1.270 at an electrolyte tem-

perature of 80°F (27°C). If electrolyte temperature

is above or below 80°F, additions or subtractions

must be made in order to obtain a hydrometer read-

ing corrected to 80°F standard. For every 10°F (3.3°

C) above 80°F, add 4 specific gravity points (.004) to

hydrometer reading. Example: A hydrometer reading

of 1.260 at 110°F (43°C) would be 1.272 corrected

to 80°F, indicating a fully charged battery.

For every 10°below 80°F, subtract 4 points (.004)

from the reading. Example: A hydrometer reading of

1.272 at0°F (-18°C) would be 1.240 corrected to 80°

F, indicating a partially charged battery.