MERITECH CleanTech 500-c User manual

CleanTech®500-C

INSTALLATION AND OPERATION MANUAL

2

CLEANTECH® 500-C

Station

Automated Hand and Glove Cleansing Station

INSTALLATION AND OPERATION MANUAL

Manufactured by:

Meritech Systems, LLC

720 Corporate Circle, Suite K

Golden, CO 80401 USA

Phone:(800) 932-7707

Fax:(303) 790-4859

www.meritech.com

E-mail: [email protected]

E-mail: [email protected]

WARNING: The performance and effectiveness of CleanTech® Stations have been extensively tested

when using solutions provided by Meritech Systems, LLC. Satisfactory performance or effectiveness

cannot be guaranteed when other solutions are used.

FAILURE TO USE MERITECH SYSTEMS, LLC SUPPLIED

CHEMICALS WILL VOID ANY AND ALL WARRANTIES.

May 20, 2021

3

Meritech Systems, LLC CleanTech® 500-C

Installation & Operation Manual

Index

3

Introduction

4

Overview

5

Facility Installation Instructions

In-Counter

6

New construction Rough-In Diagram (28”, 32” & 36” counter heights)

7

Counter Cutout Diagram

8

Station Installation In-Counter

8

Who to Call if You Need Help

9

The Hand Cleansing Cycle

10

Helpful Pointers for Trouble Free Operation

11

Top Cover Indicators

12-13

Detailed Station Reference

14

Water and Temperature Controls

Cylinder Rotation

Solutions Delivery

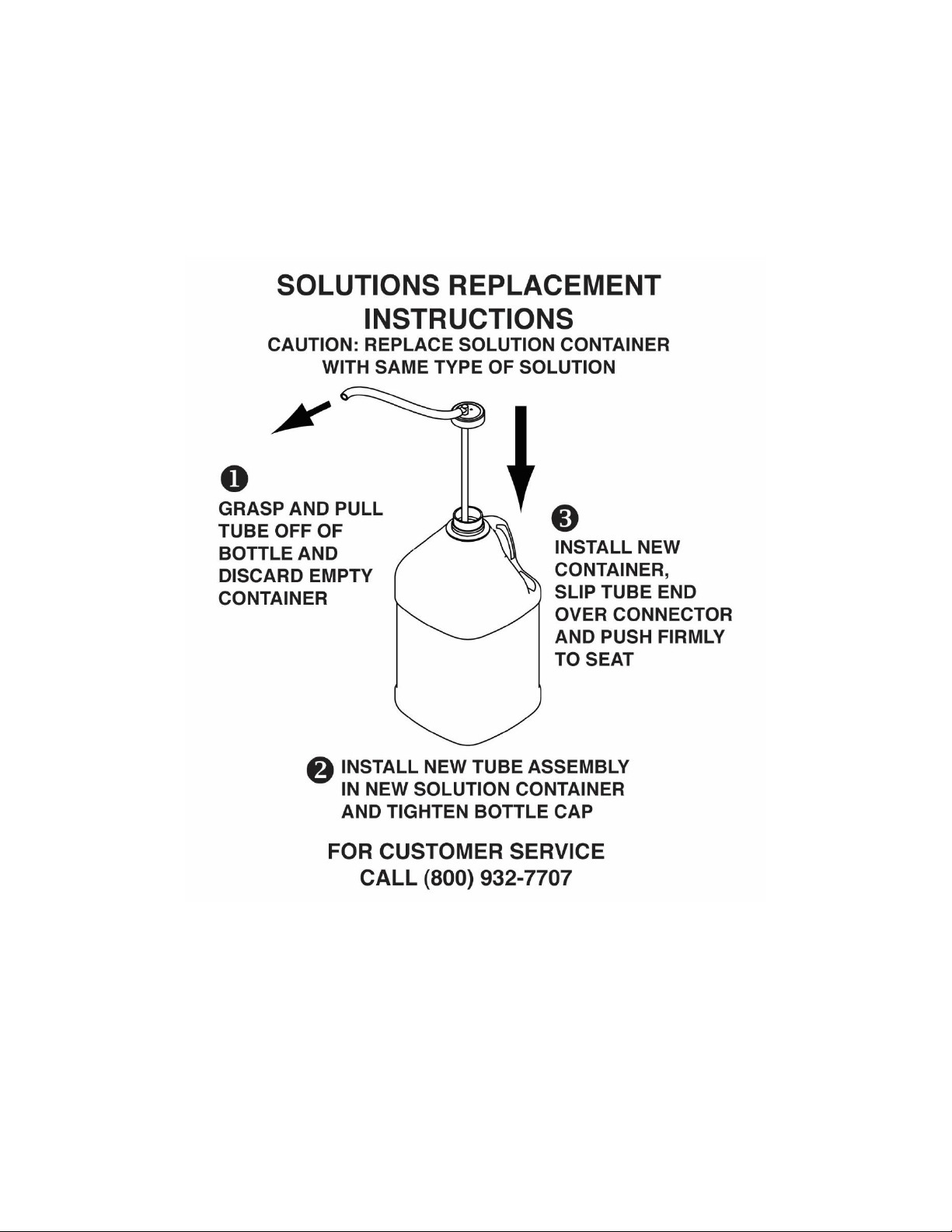

Changing Solution Container

15

Installing a New Container

Removing and Empty Container

Solutions Replacement Diagram –1 Gallon

16

Solutions Replacement Diagram –2 ½ Gallon

17

Maintenance

18

Installation Guide

19

Cut Sheet

20

Station Specifications

21-22

Unpacking Instruction

22

If External Backflow Prevention is needed

23

Warning Symbols

24

Contacting Meritech

25

Meritech Systems, LLC Warranty

26

Terms & Conditions of Sale

27

4

Introduction

Thank you for selecting the CleanTech® 500-C Automated Hand Cleansing Station as a component in

your handwashing regimen. We designed this Station to provide your facility with an automated,

turnkey Station that meets or exceeds your handwashing requirements for compliance, standardization,

and effectiveness.

This manual describes everything you will need to properly site, install and maintain your Station. The

CleanTech® 500-C will connect to your standard hot and cold-water lines and drain. A more detailed

description of the installation procedure can be found in the Installation Guide of this manual.

Select an area for installation that encourages frequent use in your facility. We recommend positioning

the Station near the main work area, lunch facilities, restroom facilities, and close to the entrance and

exit doors. Station below is shown with custom cabinet.

500-C Station shown in a Custom Cabinet (cabinet not included)

5

Overview

Achieving the Optimum Wash

The CleanTech® 500-C Station provides a no-touch, completely automatic hand wash by sequentially

delivering handwashing solution and water in a stimulating spray to the hands or gloves from fingertips

to wrist. The Station uses the Ultrapure hygiene solution and water to remove 99.9% and greater

pathogens from the hands or gloves. The Station can also remove particles, sodium’s, and other

contaminants. The standard Station configuration is 12 seconds which consists of a wash cycle using

hand washing solution that clean and sanitize and a potable water rinse cycle. A helical configuration of

jet nozzles located within the two rotating cylinders is used to spray the mixture of solutions and

pressurized water onto the hands followed by a potable water rinse.

To minimize cross-contamination, an infrared photo optical sensor positioned directly above the

cylinders automatically senses the presence of your hands when they enter the cylinders. To trigger a

wash cycle, it will not be necessary to touch any part of the Station; simply insert your hands into the

cylinders.

One complete hand wash cycle will automatically dispense the appropriate volume of hygiene solution

followed by a potable water rinse. The minimum time interval between user cycles is approximately 2

seconds.

6

Facility Installation Instructions

In-Counter:

The 500-C station can be installed in any type of countertop material and the station has a

stainless-steel trim ring mounted to the unit. The Trim ring is not used when installed in the

optional stainless-steel cabinet.

1. Remove the Counter cut-out template from packaging.

2. Place template on top of counter at desired location with the round portion of the template

facing the front of the counter and the 2 tap cutouts towards the back. When placing

template on counter insure there is a 2” minimum clearance front and back and a 2 ½”

minimum clearance on the sides around the cutout above and below counter. Also make

certain that the centerline of the template is no more 3 –3 ½” offset to either the left or right

side of the drain centerline maximum for proper drain alignment and P-trap fitment. The top

of counter must be a minimum of 16” above the wall drain. Trace the outline of the template

onto the countertop.

a. Additional Notes:

i. Insure when Station is in counter that there is 2 ½” minimum clearance on

both sides of the Station above and below the counter for accessibility to the

inside of the Station.

ii. See drawings on the following pages of this manual for further instructions.

3. Cut out counter using appropriate tools and wearing the proper PPE and following safety

procedures.

4. Run a ¼” bead of clear of silicone ½” away from the entire counter cutout.

5. Slowly lower the hand-wash unit into the counter opening and press down to around the

edges of the plate so the silicone sticks to the countertop and the 500-C trim ring. Verify

station is square with the cabinet countertop front lip.

6. Center the unit in the opening.

7. Run a bead of silicone caulk (color of your choice) around the outside the trim ring and the

countertop and allow time for it to cure and hold the station in place.

8. Connect the hot/cold supply and drain lines. Do not hard pipe to water inlets of the Station –

Use flexible hoses. Plug in power cord. Install hand hygiene solution per instructions.

9. Turn water on and inspect for leaks.

10. Run 2-5 hand washes to prime Station. Station is now ready for operation.

CAUTION: Do not ground metal chassis during installation or operation.

Consult local and national codes: conformity and compliance to local and national codes is the

responsibility of the installer.

7

New Construction Rough-In Diagram

8

New Construction Rough-In Diagram –Counter Cutout

Station Installation In-Counter

9

Who to call if you need help

The CleanTech® 500-C connects easily to your existing hot and cold-water lines using standard 3/4 inch

"garden hose" style fittings. These fittings were chosen because they are commonly available, very

reliable and can be disconnected quickly. You will also need a grounded 120V electrical outlet, and a

standard 1 1/2” drain line.

If these hook-ups are not readily available, you will need to consult with your commercial plumber or

electrician. Because of the different building codes and licensing regulations, Meritech cannot accept

responsibility for providing plumbing and electrical modifications to your facility, however, the Meritech

representative will be happy to provide the necessary guidance to ensure a correct installation. Follow

the instructions in the installation guide of this manual for further installation information.

Consult local and national codes: conformity and compliance to local and national codes is the

responsibility of the installer.

IF YOU SHOULD EXPERIENCE ANY DIFFICULTY OR ARE UNSURE ABOUT THE

INSTALLATION PROCEDURE, WE ENCOURAGE YOU TO CONSULT

IMMEDIATELY WITH MERITECH SYSTEMS, LLC.

Manufactured by:

Meritech Systems, LLC

720 Corporate Circle, Suite K

Golden, CO 80401 USA

Phone:(800) 932-7707

Fax:(303) 790-4859

www.meritech.com

E-mail: [email protected]

E-mail: [email protected]

10

The Hand Cleansing Cycle

Check all water hook-ups to ensure they are open and not leaking. Plug the power cord into an outlet

and verify power on (the Compliance Monitor will be illuminated). The Station is ready for handwashing.

Solution will be drawn from the solution container (1-gallon) installed on the wall near the station.

When the Solutions container is empty the “RED” LED on the top of the station will illuminate. Replace

the container per the instructions in this manual. No handwash solution will be used if the container is

empty.

FOLLOWING THIS PROCEDURE WILL ENSURE THE MOST EFFECTIVE WASH IN THE SHORTEST PERIOD

OF TIME

1

To initiate a cycle, stand directly in front of the Station and place your hands

simultaneously into the center of each cylinder.

2

The wash cycle automatically triggers as your hands enter the cylinders. Position your

hands at a depth so the outer most ring of the water spray covers the wrist.

3

You will receive the most effective dispersal of the antimicrobial wash if you relax,

center your hands within the cylinders and spread your fingers slightly. It is not

necessary to touch the cylinder walls.

4

Allow your hands to remain in the cylinders until they stop turning indicating the wash

cycle has been completed. Shake hands in cylinders to remove excess water droplets,

remove and dry.

NOTE: The infrared photo optical sensor will not reset for the next cycle until the hands are removed.

11

Helpful Pointers for Trouble Free Operation

Avoid touching or resting your hands and forearms on the blue cylinders themselves. If you apply

pressure to the cylinder walls, the cylinders have been designed to slow there rotation and will resume

normal speed once you have stopped impeding their rotation.

Occasionally you may encounter a condition where you have placed your hands into the cylinders, but

nothing happens. This condition generally occurs when the next cycle is requested before the previous

wash cycle is completed. To reset the cycle, simply remove your hands, wait for 3 seconds, and reinsert

your hands into the cylinders.

During periods of infrequent use, the water temperature may cool. This will have no effect on the

antimicrobial quality of the wash you will receive, the cleansing solution works properly through a broad

range of temperatures. The period of time for the warm water to return to the cylinders will depend on

the distance of the hot water source from the Station. In extreme cases or in cold environments it may

be beneficial to have a booster water heater near the Station.

The Series 500-C has been designed to be left in the power "on" mode over normal periods of operation.

During extended periods of time (a month or longer) when the Station will not be used, we recommend

removing the solution container, placing the pick-up tube from the solution container, into a container

of hot water and running several hand washes cycles. This will flush the lines of solutions, which tend to

thicken significantly with time and may clog the Station. After flushing the lines, close the facility water

shut-off valves and unplug the Station.

12

Top Cover Indicators

The CleanTech 500-C Station is equipped with an LCD display and solutions empty indicator light. The

station has a display that will indicate; date, time, cycle count, station status (ready, washing,

complete, solutions empty) and has a solution empty indicator light that will illuminate RED when

solutions are empty. See photos below for various top cover indicators.

Solutions Empty

Indicator Light

Station LCD Display

Date & Time

Station Status

Cycle Count

Station Shown without Display on top cover.

Public venue installations will be manufactured

this way. Display is located below in cabinet.

13

Top Cover Indicators/LCD Display - Continued

Remove Hands

After a Wash is

Complete

Solutions Empty

Washing Status

Wash Complete

Status

14

Detailed Station Reference

Water and Temperature Controls

The CleanTech® 500-C blending valve opens or closes the hot water inlet to attempt to achieve 105°F

(unless calibrated differently) blended water temperature. This temperature is dependent upon the

hot and cold-water inlet temperatures and pressures from the facility.

Hot water is NOT manufactured by the CleanTech® Station. If facilities hot water is not 135°F or

greater, the CleanTech® Station may not be able to achieve the recommended 105°F hand wash

temperature. In cold rooms where the hot water loses its heat through the hot water pipe and cold-

water temperature is extremely low, it may be necessary to have a booster heater located near the

CleanTech® Station. CleanTech® Stations are not compatible with instantaneous or tankless water

heaters. For specific application assistance, contact Meritech at 1-800-932-7707.

Consult with local plumbing authorities for proper connections and installation requirements. The

customer installed hot and cold-water control shut-off valves should be located near the Station.

These valves control the supply of water from the main water lines to the Station. If you detect a

water leak, close both the hot and cold water shut-off valves and unplug the Station.

Cylinder Rotation

The wash cylinders are made of an ABS plastic and can be slowed at any time by placing light pressure

on the cylinder walls. This feature has been designed in to ensure safe operation at all times.

Do not worry if large pieces of debris fall into the cylinders. The bottom of the cylinders will act as a

trap. Simply wash your hands as normal and then at the completion of the handwash cycle, reach in

and remove the debris. Smaller pieces of debris will fall through the cylinder and out through the

Station drain.

Solution Delivery

During each wash cycle, approximately 5 –7 ml (or as specified) of antimicrobial solution is aspirated

from its container and delivered to the hands through the jet nozzles located in the walls of the

cylinders and mixed at the correct part per million 200-300 ppm. The CleanTech® 500-C ensures the

uniform delivery and dispersal of the antimicrobial solution mixed with water at the adequate water

pressure to the Station. At least 40-PSI dynamic (during water flow) inlet water pressure is required.

The handwash cycle consists of a wash and potable water rinse. The wash portion of the cycle mixes

cleansing and sanitizing solution with water followed by a potable water rinse. The cycle length is

normally 12 seconds but can be programmed over a wide timing range. All Station programming is

done either at the factory or by an authorized Meritech technician. DO NOT ATTEMPT TO PROGRAM

OR REPROGRAM YOUR STATION.

Once you have installed a new solutions container; run 2-5 handwashes to re-prime the solutions

line. You can expect approximately 750 washes per gallon container when the Station is calibrated to

deliver 5 ml approximately per wash. When the solutions container is “EMPTY” the stations LCD

display will display “EMPTY” and the solutions Empty indicator light will illuminate “RED”

15

Changing Solution Container

Installing a New Container

The solution container can be installed quickly and easily. Each case of solutions contains 4-gallons of

Hygiene Solutions and two solution tube assemblies (each assembly consists of a cap, tube barb with

tube). Follow these steps for all installations:

1. Unscrew the protective cap from the new 1-gallon solutions container and discard.

2. Place the new container in the solutions basket hanging on the wall.

3. Install the pickup tube assembly from the Station into the new container and tighten cap.

4. After installing the new solutions container, run 5 handwashes to re-prime the solutions line

and empty indicator light is no longer illuminated.

FOR FURTHER ASSISTANCE CHANGING THE SOLUTIONS CONTAINERS, REFER TO THE SOLUTIONS

REPLACEMENT DIAGRAM LOCATED ON PAGE 15 OF THIS MANUAL OR THE DIAGRAM FOR THE

OPTIONAL 2 ½ GALLON CONTAINER ON PAGE 16 OF THIS MANUAL.

Removing an Empty Container

1. To remove an empty container, just simply remove the tube assembly from the top of the

container and once removed from the basket turn upright to prevent dripping on solutions on

the person or floor. DISPOSE OF CONTAINER ACCORDING TO LOCAL, STATE, AND FEDERAL

REGULATIONS.

16

Solutions Replacement Diagram

1 - Gallon (4L) Container Solution Replacement Diagram

17

Solutions Replacement Diagram –Continued

Optional 2 ½ - Gallon (10L) Container Solution Replacement Diagram

(This option is not available in 28” height cabinets)

18

Maintenance

Weekly:

•Pour, rub, or spray bleach, ammonium chloride, hydrogen peroxide or other hard surface disinfectant into each

cylinder to kill any bacteria that may be in the Station or facility drain.

•Clean front surfaces and cylinders with a cleaning agent that removes mineral deposits.

Quarterly:

•Clean photo optical sensor lenses with water and a clean, soft cloth.

•Remove all solutions bottles. Fill a container with hot water; put pick up tube in the hot water. Run 20-30 hand wash

cycles to flush the hot water through the soap lines. Let soak for 15 minutes. Reinstall tube and solutions bottle. Plug

Station back in and run Station through (12) hand wash cycles.

Biannually:

•Unplug Station and close facility water shut off valves. Remove hose fittings from hot and cold-water inlets. Remove

water filter screens, rinse clean with tap water and reinstall water filter screens and hot and cold inlet lines. Turn

facility water shut off valves on, plug Station in and check for leaks.

•The Station should be serviced by a Meritech technician to perform biannual maintenance.

As Needed:

•Replace cylinders every 30,000 –50,000 hand wash cycles or when mineral deposits buildup or water splash out

becomes excessive. This should be done by a Meritech technician.

ADJUSTMENTS:

Adjustments should be made by a Meritech technician. (See page 25 for contact information)

19

Installation Guide

Installation & First Time Start-up

Instructions for installation

1

The facility will need to provide the appropriate grounded electrical outlet, hot and cold-

water supply lines with shut off valves and standard 3/4” male garden hose fittings for each

supply, and a drain connection of 1.5” diameter minimum (see Station specification of this

manual for further assistance).

2

Connect the facility drain to the Station drain with “P” trap.

3

Connect the facility hot and cold lines to the Station hot and cold inlets.

4

Install the solution container (see changing solution container section of this manual).

5

Apply water pressure by opening the facility supplied inlet valves and check for leaks.

6

Plug in the power cord.

7

Perform several handwash cycles by blocking the photo optical sensor in the cylinder.

Allow enough time for the hot water supply to reach the Station.

THE UNIT IS NOW READY FOR NORMAL HANDWASH OPERATION

20

Cut Sheet

Table of contents

Other MERITECH Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Ecolab

Ecolab MM Series installation guide

Dibo

Dibo HOTBOX- GK 50/10 Original instructions

Homak

Homak RD00913191 Owner's manual & operating instructions

Flowplant

Flowplant 320 Series Quick reference service guide

Qleen

Qleen DISY Electro quick guide

MICRO-AIR

MICRO-AIR TM500 Installation and operation manual