MODEL TM500 SPECIFICATIONS

INPUT VOLTAGE:

120V 60Hz 1 Phase

MAX. CURRENT:

10 Amps (at 120V, 3/4HP, Single Phase)

MOTOR:

TEFC 3/4 HP, 1 Phase

EXTERNAL ARM:

5 ft. long by 4” diameter steel tube with 350 degree

movement and two joints, or 7 ft. long by 6” diameter ex

duct with magnetic hood.

DIMENSIONS: 39” h. X 16” w. X 16” l.

ACTUAL WEIGHT:

4” arm: 148 lbs.

6” ex: 138 lbs.

PACKAGE CONTENTS:

1 Ea. TM500

OPTIONS (These items are separately packed):

1 ea. 4” dia. by 5’ Arm Assembly

1 ea. 6” dia. by 7’ Flex Assembly

Caution:

All electrical work must be done by a

qualied electrician according to local, state

and national codes.

PRE-OPERATING INSTRUCTIONS:

NOTE: The following instructions will vary depending on

options received.

1. Remove the shipping crate, shipping straps and plastic

wrapping from the unit.

2. Remove the TM500 from the shipping skid and set on a

level surface.

3. Remove the attachment option from the shipping

carton.

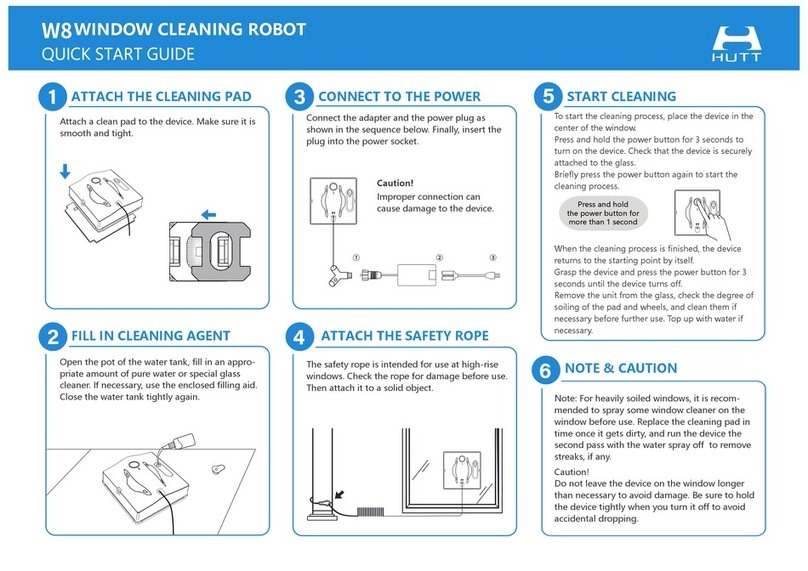

4. If equipped, install the arm assembly onto the base unit

(Fig. 1).

5. If equipped, install the ex assembly onto the base unit

(Fig. 2).

OPERATING INSTRUCTIONS:

1. Choose a suitable, level place near the workstation and

position the unit so that the hose/arm assembly will be

placed near the source of pollution being generated.

2. Grasp the hood by the handle ring and position within

18” of the source of pollution.

3. Plug the power cord into a outlet of the appropriate

voltage and phase

4. Turn the power switch on.

5. Adjust the hood to capture the maximum amount of

contaminants. Periodically adjust the position of the

hood to keep it in maximum capture range.

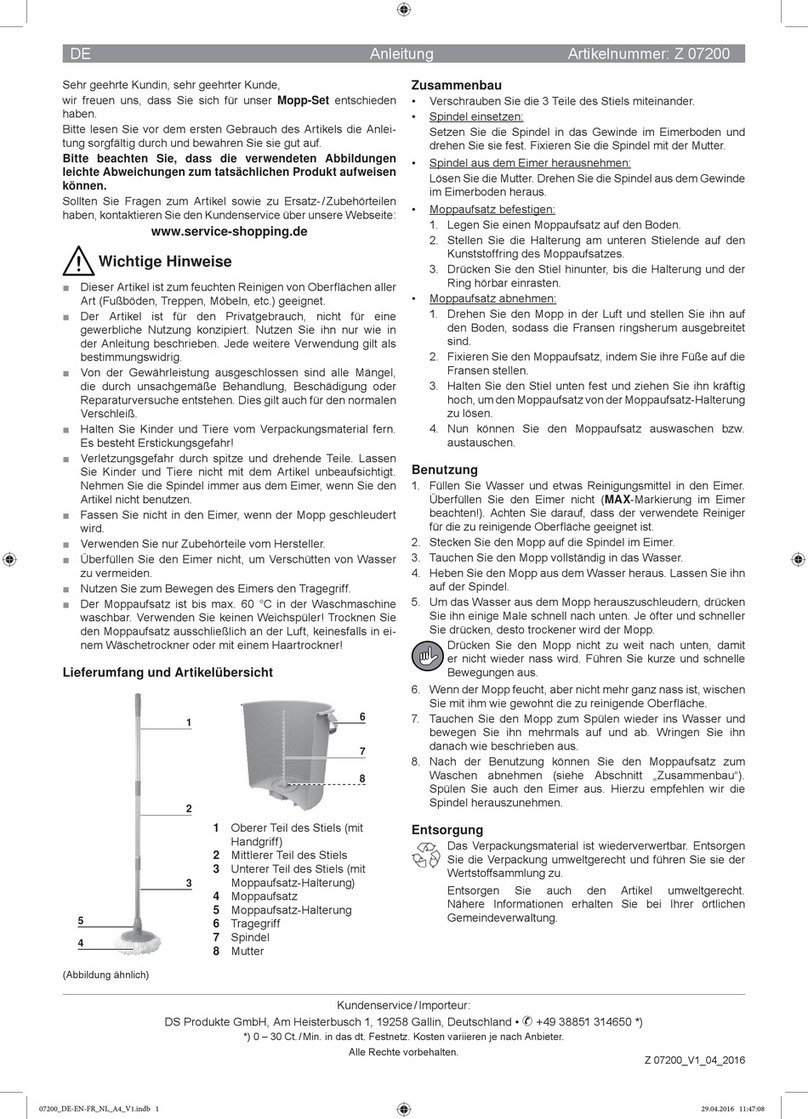

CHANGING FILTERS:

Caution:

Always make sure that the unit is turned

o and power disconnected before changing

lters or servicing the unit.

1. Turn the TM500 o and remove the lter access panel.

2. Remove the lter.

3. Slide new lter into the cabinet.

4. Replace the lter access panel (Fig. 3).

MICRO AIR®TM500

CLEAN AIR SYSTEMS

!

2

Fig. 1

!

Fig. 2