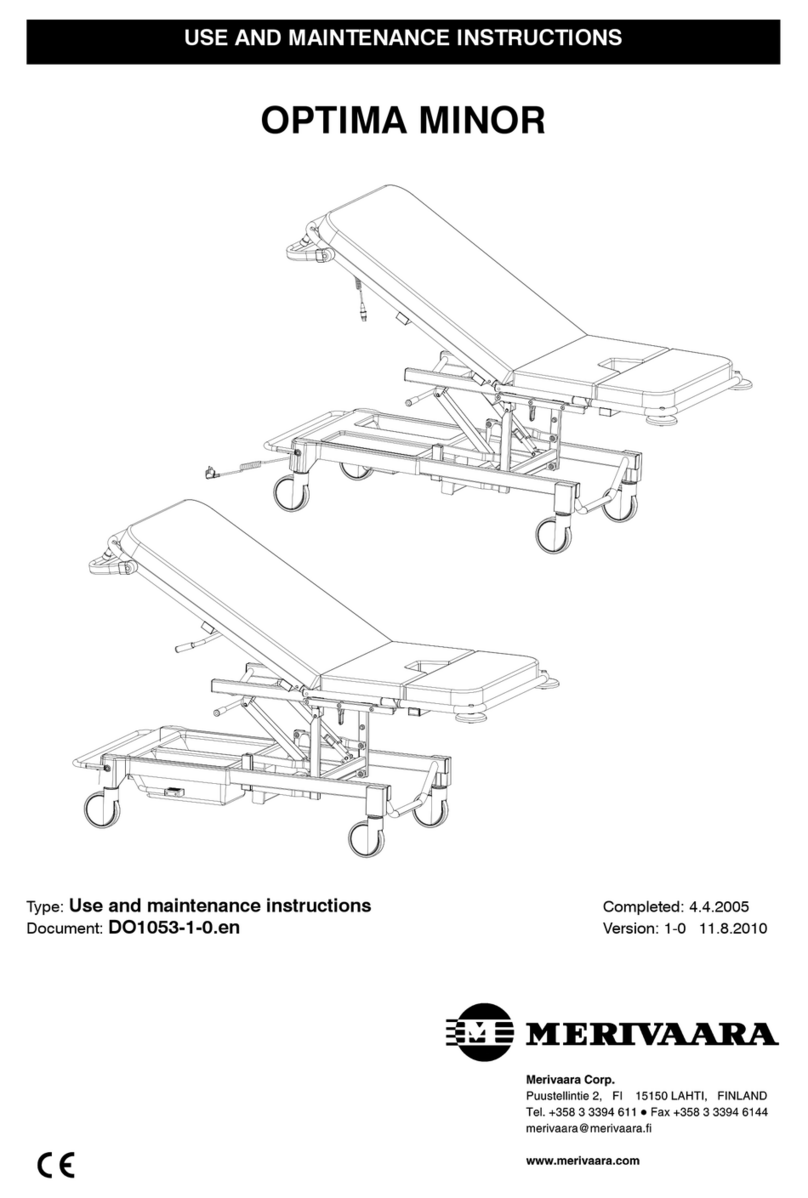

Merivaara PRACTICO User manual

MAINTENANCE MANUAL

PRACTICO OPERATING TABLE

o

1

0

4

7

b

.

p

d

f

Drafted by: Markku Luokkanen Type:

Maintenance manual

Completed: 15.3.2003

Approved by: Arto Koski-Laulaja Document:

DO1046.en

Version: 2 -1.12.2004

2

1 WARNINGS AND OBSERVATIONS

5

2 GENERAL

7

2.1 Opening packaging 8

2.2 Removing operating table from pallet 8

3 TECHNICAL SPECIFICATIONS

9

3.1 Type plate 9

3.1.1 Figure symbols 9

3.1.2 Surface materials 9

3.2 Properties 10

3.2.1 Environmental conditions 10

3.2.2 Electrical properties 10

3.2.3 Rating specifications 10

3.2.4 Settings 11

3.2.5 Weights and dimensions 11

3.3 Structure 12

3.3.1 Main components 12

4 MAINTENANCE AND REPAIR

13

4.1 Maintenance procedures 13

4.1.1 Daily maintenance 13

4.1.2 Monthly maintenance 13

4.1.3 Annual maintenance 13

4.2 Troubleshooting and checklist 14

4.3 Removal of casings 15

4.3.1 Table base casing 15

4.3.2 When table base casing height is sufficient 15

4.3.3 When table base casing is to be raised and turned 15

4.3.4 Removal of upper bellows end 15

4.3.5 Removal of column casings 16

4.3.6 Height adjustment motor stuck in lowest position 16

3

4.4 Replacement of table base components 17

4.4.1 Battery pack 17

4.4.2 Control unit 17

4.4.3 Power source 18

4.4.4 Charging/charge status controller 18

4.4.5 Fuses 19

4.4.5.1 Distribution fuses 19

4.4.5.2 Battery fuse 19

4.4.5.3 Power source fuses 19

4.5 Replacement of motors 20

4.5.1 Removal/mounting of height adjustment motor 20

4.5.2 Removal/mounting of back section adjustment motor 20

4.5.3 Removal of Trendelenburg motor 21

4.5.4 Mounting of Trendelenburg motor 21

4.5.5 Removal of side tilt motor 22

4.5.6 Mounting of side tilt motor 22

4.5.7 Removal/mounting of mattress base longitudinal adjustment motor 22

4.6 Replacement of gas springs 23

4.6.1 Removal of Trendelenburg gas spring 23

4.6.2 Mounting of Trendelenburg gas spring 23

4.6.3 Removal of side tilt gas spring 23

4.6.4 Mounting of side tilt gas spring 23

4.6.5 Replacement of head section gas spring 24

4.6.6 Removal of gas spring from protective tubing 24

4.6.7 Removal of back section gas spring 24

4.6.8 Replacement of leg section gas spring 25

4.7 Replacement of castors 26

4.7.1 Castor adjustment 26

4.8 Adjustment of column wedges 27

4.9 Removal/mounting of back section 26

4.10Schematics 27

4

5 CLEANING 29

5.1Daily cleaning and disinfecting 29

5.1.1 Disinfecting: 29

5.1.2 Drying 29

6 RECYCLING 29

6.1Metals and plastics 29

6.1.1 Gas springs 29

5

In order to ensure optimal surgical safety, all operating table users should

carefully read the operating table and maintenance instructions before using the table.

The entire surgical ward staff should be familiar with the correct use of the PRACTICO Operating table as well

as all warnings and observations concerning it.

Warnings and observations found in this instruction manual are indicated as follows:

WARNING!

Please observe to ensure patient safety.

NOTE! Please observe in order to avoid causing damage to the equipment or its parts.

When setting the operating table into different positions, ensure that the patient’s fingers, hands or other

parts of the body are not caught between moving parts on the back/leg section or seat.

Always follow manufacturer instructions when using diatherm or defibrillation equipment.

Combustible anaesthetic gases must not be used with the table.

Before making any adjustment of the operating table, ensure that the patient will not fall.

Lock the castors before using the operating table.

Set the operating table surface as low as possible while transporting to ensure transport comfort. Transport

the operating table with the leg section at the front. Remember the directional castor!

Note! If the operating table surface is not raised high enough when the leg section is dropped into its lowest

position, it may impact with the table base casing damaging the operating table and creating pinching

hazard.

Note! If the operating table surface is not raised high enough when trendelenburg and side tilt are in their

extreme positions, back section may impact the table base casing damaging the operating table and

creating pinching hazard.

1. WARNINGS AND OBSERVATIONS

!

!

!

!

!

!

!

!

!

!

!

6

When using the table, ensure that all accessories are properly mounted to it and check the function of acces-

sory lockings and adjustments.

When using the speciality headrest (100020126), ensure patient safety by releasing the headrest locking

before adjusting the back section. A warning label is affixed to the headrest.

The antistatic properties of the operating table require the use of Merivaara brand mattresses and antistatic

flooring.

Gas spring dismantling instructions are available from your sales representative. The release of nitrogen gas

is strictly prohibited, without following the proper instructions.

If the operating table has been in the cold, it must be allowed to warm up at room temperature for at least 6

hours before recharging the battery or switching on, to allow any condensation formed to evaporate.

All packaging cardboard should be recycled. Wood and plastics are energy waste.

The operating table is heavy (165 kg).

We recommend recharging the battery regularly overnight after a day’s use. This ensures that the table is

always ready for use and it extends the battery life. Charging takes approx. 5-10 hours, depending on the

battery charge status. The batteries also have sufficient capacity to be charged only once a week.

The equipotential point (DIN 42801) is located on the table base.

We recommend use of the equipotential point whenever operating and when using

patient monitoring equipment. Read all manufacturer instructions.

Dry the operating table carefully by wiping down with a dry cloth immediately after cleaning or disinfecting.

If the operating table batteries should quit during a procedure, connect the table to the main power supply

and continue as normal. Batteries can be charged while adjusting the table.

The switch in the table base can also be used as an emergency shutoff, if necessary.

Because batteries are problem waste, they must taken to a problem waste disposal facility.

When moving the operating table, ensure that any accessories mounted on the side or the back section

kidney elevator crank do not cause any damage.

WARNINGS AND OBSERVATIONS

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

7

Dear operating table owner, The safe and fault-free use and maintenance of the equipment requires careful

adherence to these instructions. When mounting accessories to the equipment, the instructions provided

with them must be followed closely. Always keep the instructions for accessories together with this manual.

The Practico Operating Table meets the following standards: IEC 601-2-46, IEC 601-1-2 (EMC) and SFS-EN

60601-1. The table complies with directive 93/42/EEC (MDD) product class

I

, and bears a CE marking based

on this classification.

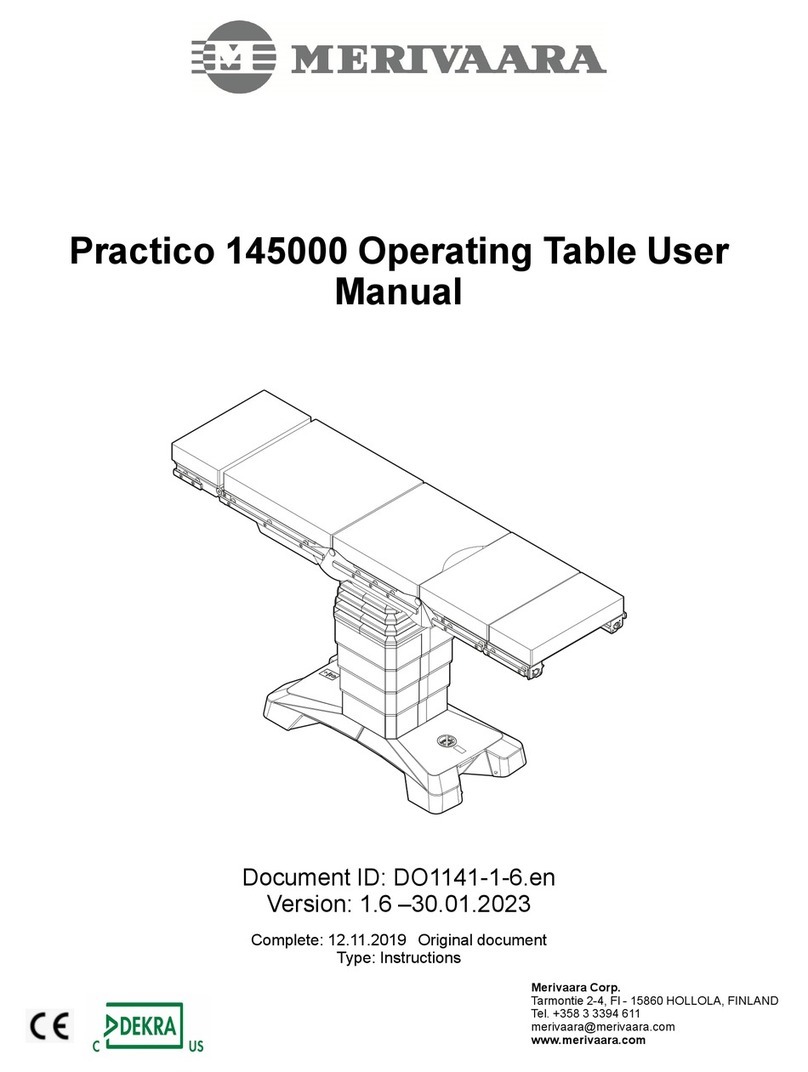

Intended use

The Merivaara Practico Operating Table is intended for general surgical use. It is also well suited for

outpatient surgical applications. The Practico works on both battery and mains power. The Practico can be

moved from one place to another. easily.

2. GENERAL

Expertise is essential.

The patient is the most important part of treatment.

This is precisely why the equipment used in

treatment must be absolutely

safe and convenient to use. As a health care

professional, you deserve the very best tools,

allowing you to concentrate on your own field of

expertise. Merivaara is an expert in providing

hospital equipment.

Merivaara products have been designed to

function

efficiently and flexibly during the various stages of

treatment. They assist you in the performance of

your work, without distracting you from the task at

hand.

Our integrated equipment system includes state-

of-the-art equipment for hospital procedures and

hospital room environments as well as for nursing

8

2.1 Removing packaging

The operating table is preassembled in its packaging. Inspect the operating table for any shipping damage.

NOTE!

If the operating table has been in the cold, allow it to warm up at room temperature for at least

6 hours before recharging the battery or switching on, to allow any condensation formed

to evaporate.

NOTE!

All packaging cardboard should be recycled. Wood and plastics are energy waste.

2.2 Removal of operating table from pallet.

• Unscrew the M10x75 screw under the pallet.

• The permitted lifting area is indicated in Figure A.

NOTE!

The operating table is heavy (165/175 kg).

!

!

o

1

0

4

5

b

.

p

d

f

M10x75

!

9

3.1 Type plate

The type plate is located on the table base.

3.1.1 Figure symbols

STAND BY

Grounding

Equipotentiality

~

Alternating current

B-type device

Read instructions

Maximum allowable load (includes patient, mattress and accessories)

135 kg Maximumallowableload onoperatingtablewithlongitudinaltablesurface

adjustment

Surface materials

• Stainless steel (accessory rails, mattress base parts)

• High-pressure laminate base panels

• Anodised aluminium

• Polyester (hand control board)

• EPDM rubber (bellows)

• ABS (column, table base casing)

3. TECHNICAL SPECIFICATIONS

Serial number

o

1

0

4

5

h

.

p

d

f

Periodical operation (max) 1 min/10 min

Specific voltage, frequency and input power

Enclosure rating

Model

o

1

0

0

2

h

.

e

p

s

!

o

1

0

1

4

b

.

e

p

s

=180 kg

10

3.2 Properties

3.2.1 Environmental conditions

Ambient temperature +10- +40 °C

Ambient air pressure 700- 1060 mbar

Relative humidity 30 %- 75 %

Transport temperature -10- +40 °C

Storage temperature +10- +40 °C

3.2.2 Electrical properties

If you would like more detailed information, please contact the Merivaara Service Department.

3.2.3 Classifications data

The Practico Operating table is classified in accordance with SFS-EN 60601-1 as follows::

Electrical shock protection Internally powered equipment class I equipment

Degree of shock protection B-type equipment

Fluid protection Water-resistant device (IPX4)

Cleaning and disinfecting See section 5. page 29.

Function type Intermittent operation

Combustible anaesthetic gas protection Do not use with combustible gases

230 V 120 V

Maintenance-free lead/gel battery 36 V / 7.2 Ah 36 V / 7.2 Ah

Max current consumption 4 A 4 A

Charger primary: 230 V ~ 50/60 Hz primary: 120 V ~ 50/60 Hz

secondary: 41.4V / 4 A secondary: 41.4V / 4 A

Normal charging time 5-10 h (depending on battery

charge status) 5-10 h (depending on battery

charge status)

Adjustment operating time on fully

charged new battery

(uninterrupted operation)

approx. 180 min. approx. 180 min.

Max uninterrupted operating time 1 min. 10 min. 1 min. 10 min.

11

3.2.4 Adjustments

Height adjustment 730-1030mm

Height adjustment, longitudinaldisplacement of table top 80-1080mm

Longitudinal displacement of table top 300mm

Side tilt

±

20°

Back section 100020120/100020130 -4° - +70°

Back section 100020131/100020135 -30° - +70°

Back section 100020122 -30° - +70°

Back section 100020125 -15° - +70°

Leg section -90° - +25°

Trendelenburg and anti-Trendelenburg 26°

Headrest (standard) - 45°- +30°

3.2.5 Weights and dimensions

Taulukko 1. Dimensions

STANDARD LONGITUDINAL

ADJUSTMENT

Operating table surface 4-part 4-part

Operating table weight 165 kg 175 kg

Length (A) 2040 mm 2040 mm

Width (B) 535 mm 535 mm

Height (C) 730-1030 mm 780-1080 mm

Table base length (D) 1080 mm 1080 mm

Mattress width (E) 540 mm 540 mm

Mattress base width (F) 594 mm 594 mm

Base panel height (G) 40 mm 40 mm

Castors 125 mm 125 mm

Longitudinal adjustment of mattress base 300mm

o

1

0

4

5

i

.

p

d

f

Split leg section H=535mm

One-piece leg section H=505mm

12

3.3 Structure

3.3.1 Main components

Hand control

Head section

Seat section

Leg section

Equipotential point

o

1

0

4

5

d

.

p

d

f

Directional castor

Control unit

Batteries

o

1

0

4

6

t

.

p

d

f

Side tilt motor

motor

Trendelenburg motor

Back section

Height adjustment

Charging outlet 230/120V

Switch

Power source

controller

Charging/charge status

Distribution fuses

Side tilt gas spring

Trendelenburg gas spring

13

4.1 Maintenance procedures

We recommend the following advance check-up and maintenance procedures to ensure continued

maintenance and trouble-free operation.

4.1.1 Daily maintenance

• During normal cleaning of the table, make a general visual inspection to ensure that it is in proper

working order.

• The PRACTICO Operating Table must be cleaned after each surgical procedure.

• We recommend that the batteries be charged every day. This will ensure a sufficient battery charge

and long service life

4.1.2 Monthly maintenance

• Lubricate all table joints with light machine oil.

• Ensure that all castors roll easily and lock securely.

• Check all table functions by fully extending and retracting them.

• Ensure that motor-equipped back sections are properly mounted to the seat. If necessary, tighten the

locking screws. See section 4.9 page 26.

• Ensure that the accessory rails are properly mounted.

4.1.3 Annual maintenance

• Perform all the same inspections as in monthly maintenance.

• Check and adjust column clearance, if required.

• Check cables and their connections.

All electrical repairs must be performed by a licensed electrician.

Before performing maintenance procedures:

• Disconnect power supply

• Turn switch to STAND BY position

• Support the table part being repaired before removing the motor or gas spring.

4. MAINTENANCE AND REPAIR

!

!

o

1

0

4

6

b

.

p

d

f

14

4.2 Troubleshooting and checklist

When troubleshooting, check the following items first:

• Does the malfunction affect all table functions?

• Does the malfunction only affect one control function?

• If the problem only affects one control function, does it do so in both directions?

• Is the malfunction that the table does not move or that it will not maintain its position?

The following components are common to all systems. If there is a malfunction in these, all control functions

will be affected.

• Control unit

• Hand control unit

• Battery

• Power source/battery

If there is a malfunction in one of the following components, it usually affects only one function.

• Motor

• Gas spring

Malfunction Cause

Table adjustments do not function. • Switch is in STAND BY position

• Hand control is unplugged

• Battery is dead

• Fuse is blown

• Faulty hand control

• Faulty control unit

Table functions are sluggish and weak. • Low battery charge

•Faultymotor

Operating table function duration is short, even

though the battery has been charged in accordance

with instructions.

• Faulty charger

• Faulty battery

• Battery too old

Castors make abnormal noises when rolling • Pedal in wrong position

• Castor bearings worn

• Incorrect castor adjustment

15

4.3 Removal of casings

4.3.1 Table base casing

4.3.2 When table base casing height is sufficient

• Disconnect power supply

• Remove casing screws (3) 2 pcs.

• Raise the casing (2) from its seat and hang from the mattress base or separate from the table base

with suitable spacers.

• Remove cover (4) by lifting it upwards.

4.3.3 When table base casing is to be raised and turned

• Disconnect power supply

• First, remove the four screws (1)

• Raise the telescoping column casings and hang from the mattress base.

• Disconnect the hand control connector from the table base.

• Remove casing screws (3) 2 pcs. Raise the casing from its seat, turn into the desired position and

hang from the mattress base or separate from the table base with suitable spacers. Remove cover (4)

by lifting it upwards.

• Reassemble in reverse order.

4.3.4 Removal of upper bellows end

• Remove the four screws (3), which fasten the

bellows to the seat.

1 2

3

o1046b.pdf

4

3 3

o

1

0

4

6

c

.

p

d

f

o1046v.pdf

16

4.3.5 Removal of column casings

• Remove the 13 screw caps (1) and screws (2), which fasten

the bellows and casing to the column.

4.3.6 Height adjustment motor stuck in lowest position

WARNING!

Before removing the pin on top of the height adjustment motor (3), ensure that the seat

will not fall.

• Push the top of the bellows down and remove the lock ring (1)

• Remove the pin (2) and raise the seat.

WARNING!

The seat must not be raised more than 250 mm.

Support the seat so that it will not fall.

• Remove the table base casing (see section 4.3.1 page 15)

• Reassemble in reverse order.

2

1

!

!

2

1

3

17

4.4 Replacement of table base components

4.4.1 Battery pack

• Disconnect power supply

• Turn switch to STAND BY position

• Raise and turn the table base casing (see section 4.3.3 page 15)

• Disconnect the battery pack connector.

• Remove the mounting bar by unscrewing (1)

• Lift out the battery pack.

.

4.4.2 Control unit

• Disconnect power supply

• Turn switch to STAND BY position

• Raise and turn the table base casing (see section 4.3.3 page 15)

• Disconnect the control unit by pulling it up.

• Disconnect all connectors. Remember the positions of each connector!

Mounting bar

Battery pack

1

o

1

0

4

6

g

.

p

d

f

Control unit

o

1

0

4

6

g

.

p

d

f

18

4.4.3 Power source

• Disconnect power supply

• Turn switch to STAND BY position

• Raise and turn the table base casing (see section 4.3.3 page 15)

• Disconnect the battery pack connector.

• Disconnect the power source connection.

• Unscrew the mounting screws a few turns.

• Move the power source slightly to the side and lift out.

.

4.4.4 Charging/charge status controller

• Disconnect power supply

• Turn switch to STAND BY position

• Raise and turn the table base casing (see section 4.3.3 page 15)

• Disconnect the battery pack connector.

• Disconnect power source (see section 4.4.3 page 18)

• Disconnect charging/charge status controller connectors

• Unscrew the mounting screws a few turns.

• Lift out the charging/charge status controller.

Mounting screws

Mounting screws

Power source

o

1

0

4

6

g

.

p

d

f

Move in the direction

of the arrow.

Screw Charging controller

o

1

0

4

6

h

.

p

d

f

19

4.4.5 Fuses

4.4.5.1 Mains fuses

• Position (see section 3.3.1 page 12)

• Open the fuse box and replace fuses.

4.4.5.2 Battery fuse

• Open battery casing cover

• Replace fuse

• Carfuse 15A Size: 5.3 x 19.1 x 18.7 mm.

4.4.5.3 Power source fuses

• Located inside the power source.

• Fuse T6.3A (2 pcs.)

Fuses T6.3A

o

1

0

4

6

f

.

p

d

f

20

4.5 Replacement of motors

WARNING!

Before opening the table base casing, disconnect the power supply.

WARNING!

Before removing gas springs, ensure that the piston rod is locked or the spring is

unloaded.

4.5.1 Removal/mounting of height adjustment motor

• Loosen table base casing screws (see section 4.3.3 page

15).

• Remove upper bellows end (see section 4.3.4 page 15).

• Remove column casings (see section 4.3.5 page 16).

• Remove support plate (3).

• Remove top of motor (see section 4.3.6 page 16).

• Remove the lock ring (1) from the bottom of the motor and

remove the joint pin (2).

• Disconnect the motor from the control unit.

• Transfer the support tubing (4) to the new motor.

4.5.2 Removal/mounting of back section adjustment motor

• Disconnect the motor from the control unit (3).

• Remove lock rings (1)

• Hold the back section in place and remove joint

pins (2).

!

!

3

4

2

1

o

1

0

4

6

i

.

p

d

f

2

o

1

0

4

6

p

.

p

d

f

1

1

2

3

o1046x.pdf

Table of contents

Other Merivaara Medical Equipment manuals