Metal-Fach SEG PELLET Operator's manual

METAL-FACH Heating Technology

1

Table of contents

Introduction 2

Symbols used in the manual 2

Introductory acts 3

General information 4

Application 5

Boiler equipment 6

Basic elements of boiler construction 7

Technical data of the boiler 10

Boiler dimensions 12

Safety automation and control 14

Fuel 15

Requirements for the boiler house and boiler installation 16

Boiler installation 19

Connection of the boiler to the heating system 21

Connection of the boiler to a closed heating system 26

Requirements for the expansion vessel 29

Boiler connection to the electrical installation 30

Connection of boiler to chimney 33

Boiler start-up 34

When using the boiler, remember 36

Cleaning and maintenance of the boiler 37

Instructions for disposal of the boiler at the end of its service life 38

List of spare parts 38

Examples of equipment failure 39

Warranty conditions 41

Confirmation of inspection, warranty repair, maintenance service 44

EC/EU Declaration of Conformity 47

Warranty card 49

Notification of complaint 51

Report on the first start-up of the boiler 53

Report on the first start-up of the boiler 55

METAL-FACH Heating Technology

2

Introduction

Dear customer, thank you for purchasing METAL-FACH heating boiler. We hope that the operation of the device

will meet your expectations and provide much satisfaction. The heating boiler has been designed and

manufactured in accordance with applicable norms and standards, which guarantee safe and reliable operation.

Operation of the boiler in strict observance of the instructions included in the manual attached to the device will

ensure optimal and reliable operation of the central heating boiler for many years. The product is not intended

for use by persons of diminished physical / mental capacity or lack of experience and knowledge, if such

persons are supervised or instructed by a person responsible for their safety. Operation by children is

prohibited.

Symbols used in the manual

NOTE!

Very important information, always read it if it is present.

TIP!

It is worth familiarising yourself with this information, it makes it easier to use.

METAL-FACH Heating Technology

3

Introductory acts

(User)

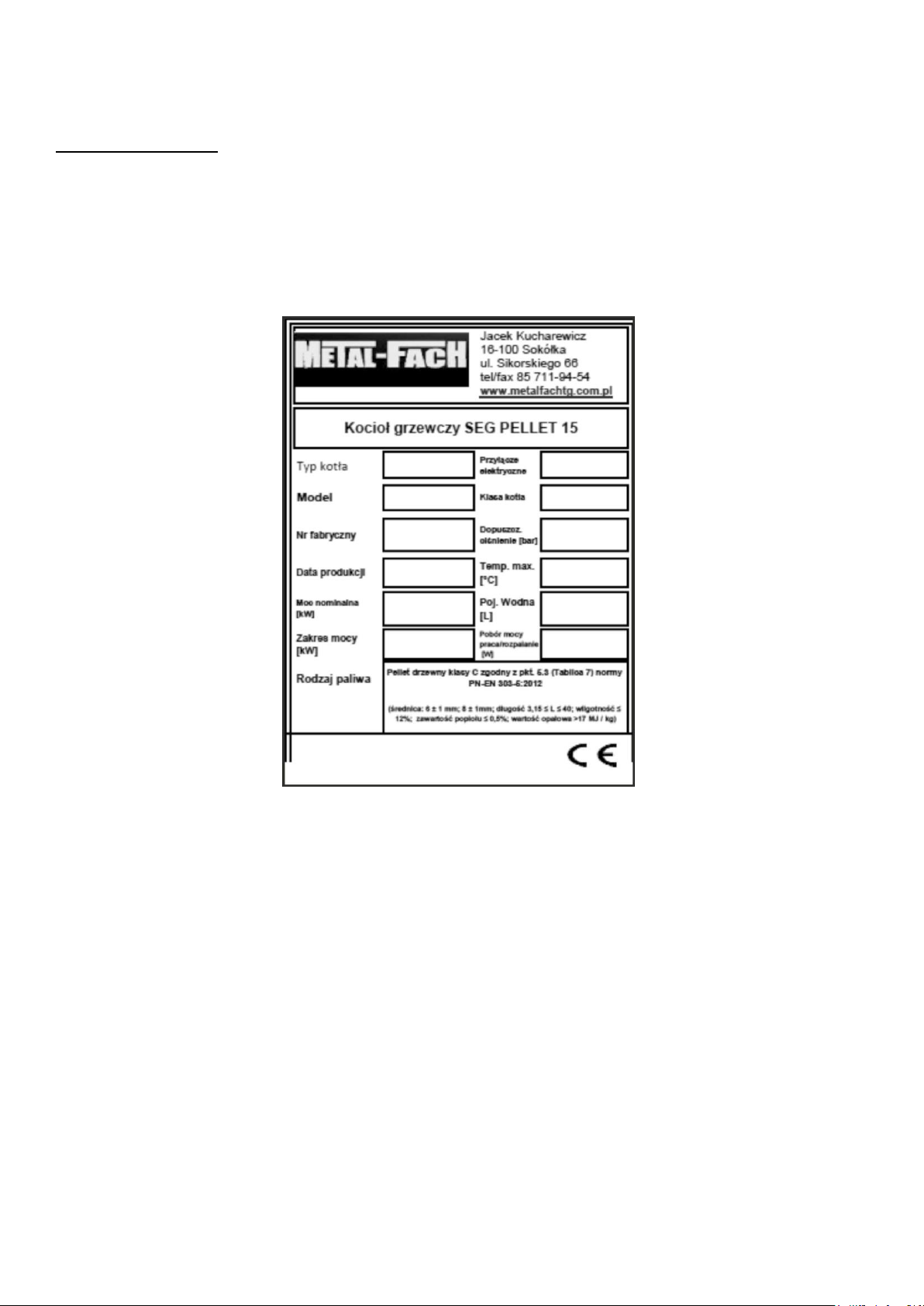

Activities to be performed during the METAL-FACH boiler acceptance:

●Check carefully that the boiler has been delivered complete (Chapter: Boiler accessories) and that it has

not been damaged in transit,

●Compare the rating plate mounted on the boiler casing on the left or right side with your order,

●Carefully read this manual - it contains information you need to use the boiler correctly.

In case of any problems, please contact the service department or METAL-FACH Jacek Kucharewicz authorized

service. These persons have appropriate training and access to original parts, which enable the proper

performance of service and installation of boilers METAL-FACH Jacek Kucharewicz, confirmed by a certificate

issued in the seat of the company.

METAL-FACH Heating Technology

4

General information

(User)

The Operation and Technical Manual is one of the product parts which are supplied together with the purchased

central heating boiler. The Operation and Technical Manual includes data concerning the construction and

installation as well as the method of operation of boilers with a self-cleaning pellet burner of the SEG PELLET

series. Careful reading of this manual ensures correct and safe operation of our boiler

NOTE!

The user is advised to observe all instructions regarding the appliance contained in this

Operation and Maintenance Manual, the Warranty Conditions and the generally applicable

legal provisions.

The boilers are delivered in an assembled condition. They are set up and fixed permanently to a pallet.

Additional protection in the form of foil packaging is used.

When transporting the boiler, it is necessary to secure it against shifting or rotation on the truck body by means

of securing devices, e.g. belts. The transport of boilers should be carried out in accordance with the rules

concerning the transport of materials. Loading and unloading should be carried out with lifting devices (forklift)

with a lifting capacity of more than 1000 kg.

METAL-FACH Heating Technology

5

Application

(User | Installer)

The boilers are designed for heating residential buildings such as: single-family and multi-family houses, farm

buildings, public utility buildings, and domestic hot water. They are equipped with an automatic fuel feeding system.

Thanks to the use of modern construction solutions the SEG PELLET boiler reaches efficiency of ≤90%. Correct

operation and achieving the full capacity of the boiler depend on the quality of the executed installation, appropriate

chimney draught, correct operation and maintenance of the boiler.

NOTE!

The boilers are designed for operation in open and closed water systems with gravity or

forced circulation, with safeguards in accordance with the requirements of the current

standard PN-B-02413 Heating and Heat Engineering and closed system in accordance with

PN-EN 12828 Heating Installations in Buildings. Design.

METAL-FACH Heating Technology

6

Boiler equipment

(User)

The scope of delivery includes both basic and additional elements, depending on the order. Upon receipt, the

product must be carefully inspected to ensure that it has not been damaged during transport and to check that

the equipment is complete. The elements included in the basic and additional equipment are described below.

Basic equipment:

Unit of

measurement

Quantity

Central heating boiler

pcs.

1

Microprocessor controller

pcs.

1

Blower fan

pcs.

1

Fuel feed system with a pellet burner, self-cleaning

cpl.

1

Fuel tank

pcs.

1

Tools for cleaning the boiler:

●poker

●brush

●scraper

pcs.

1

Boiler levelling feet

pcs.

4

Additional equipment:

Unit of

measurement

Quantity

LAMBDA SONDA* module

pcs.

1

Device for dissipating excess heat power

pcs.

1

Documentation:

Unit of

measurement

Quantity

Technical and propulsory documentation of the boiler

pcs.

1

Operating instructions and warranty card for the controller

pcs.

1

Operating instructions and warranty card for the blower fan

pcs.

1

NOTE!

The user should carefully read the operating instructions for the controller, fan and

feeder together with the self-cleaning pellet burner.

NOTE!

METAL-FACH reserves the right to introduce changes to the technical parameters,

equipment and specifications of the offered goods without prior notice.

METAL-FACH Heating Technology

7

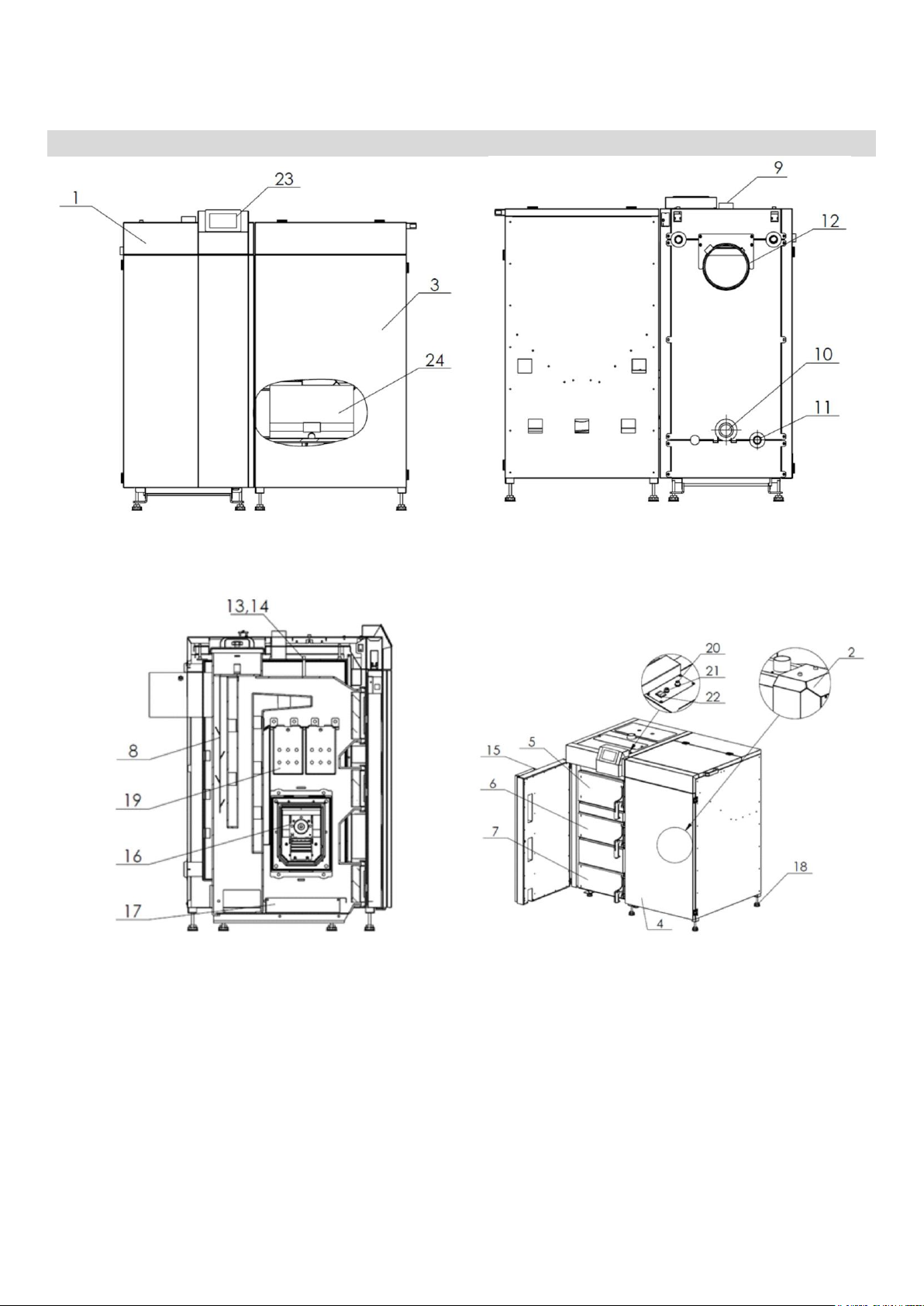

Basic elements of boiler construction

(User | Installer)

The water body is made as a welded structure from approved steel sheets P265GH with a thickness of 5mm (for

furnace elements) and S235JR with a thickness of 4mm (for water jacket elements)

The automatic feeder delivers fuel (pellets) to a pellet burner located in the combustion chamber at the side of

the boiler. A ceramic plate is placed in front of the burner, steel screens are placed in the rest of the combustion

chamber.

The convection part of the boiler consists of horizontal water channels with flue gas swirlers. The boiler

exchanger is insulated with mineral wool covered with a thin-walled sheet. The insulated bottom of the boiler is

not water cooled.

The flue gas flue with diameter ɸzew = 180mm (in 15, 20, 25, 30 kW outputs) does not have a damper.

The ash pan for combustion waste is located under the burner. The steel door is lined with insulating panels on

the inside.

The boiler is equipped with boiler water supply and return connections of diameter

G 1 ½", water drain connection diameter G ¾", connection for boiler temperature sensor and STB. The boiler

operation and combustion process is controlled by a microprocessor controller.

METAL-FACH Heating Technology

8

SEG PELLET boiler

METAL-FACH Heating Technology

9

1. Exchanger

2. Self-cleaning pellet burner

3. Fuel tank

4. Tank inspection door

5. Clean-out doors

6. Inspection doors

7. Ash door

8. Exhaust gas turbochargers

9. Supply spigot with thread

G11/2 "Flue gas turbulators

10. Supply spigot with thread

G11/2"

11. Return stub with thread G

11/2"

12. Drain stub with thread G3/4"

13. Flue

14. Bushing for boiler temperature

sensor

15. STB bushing

16. Boiler doors

17. Burner head

18. Ash drawer Ash drawer

19. Levelling feet

20. Steel screens

21. STB

22. Fuse

23. Main switch

24. Controller display

25. Controller

METAL-FACH Heating Technology

10

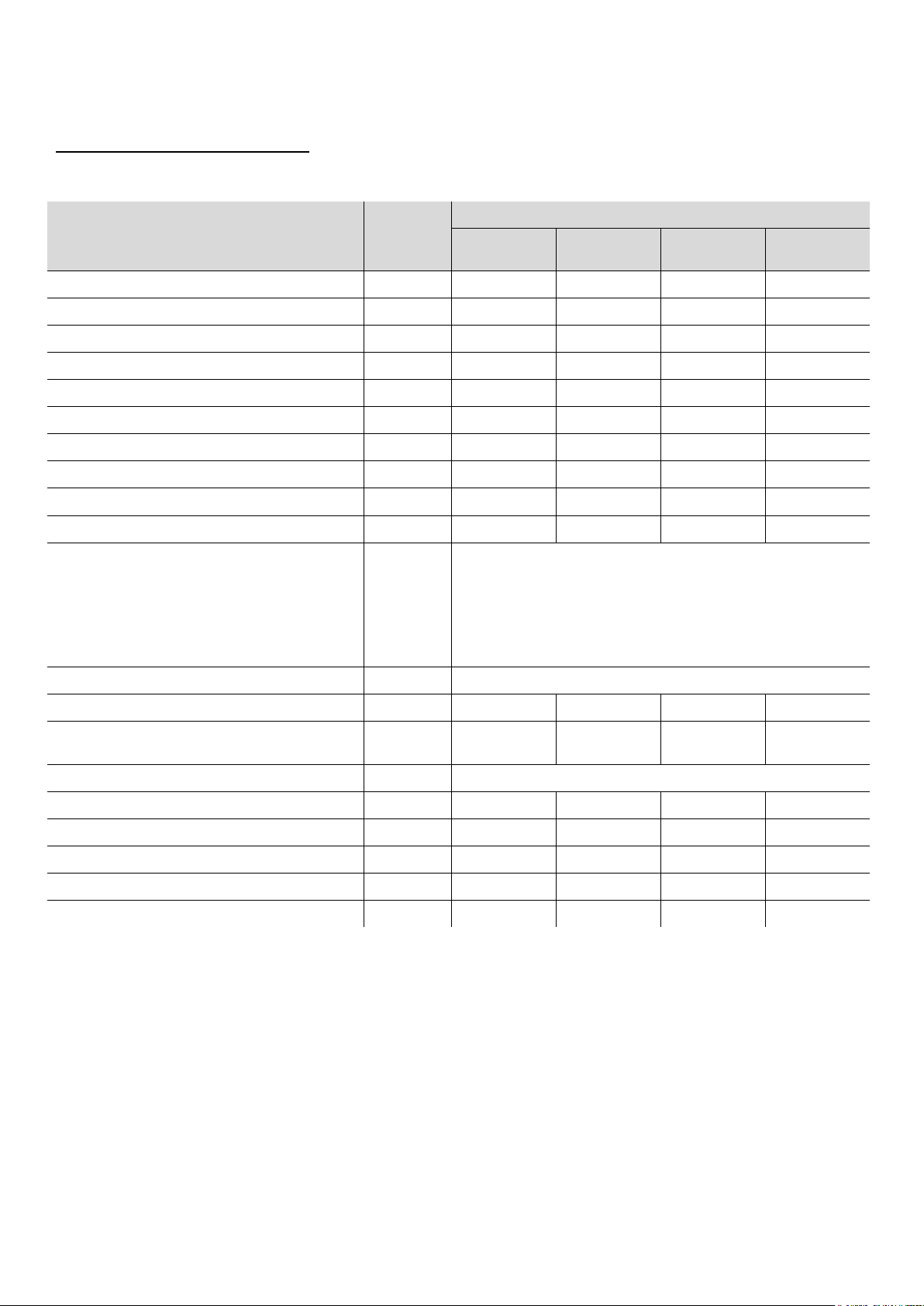

Technical data of the boiler

(User | Installer)

Parameters

S.I. Unit.

Boiler model

SEG PELLET

15

SEG PELLET

20

SEG PELLET

25

SEG PELLET

30

Nominal heat output

[kw].

15

20

25

30

Boiler output range

[kw].

4,5-15

6-20

7,5-25

9-30

Heating surface

[m2]

2,10

2,54

2,85

3,11

Water capacity

[L]

66

74

83

95

Maximum operating pressure

[bar].

3

3

3

3

Maximum operating temperature

[°C]

80

80

80

80

Test pressure

[bar].

4,5

4,5

4,5

4,5

Boiler class

[-]

5

5

5

5

Boiler efficiency

[%]

≤90,6

≤90,3

≤91,2

≤91,1

Fuel tank capacity

[L]

150

220

230

230

Fuel

[-]

Wood pellets of class C in accordance with pt. 5.3

(Table 7) of PN EN 303-5:2012 standard:

(diameter: 6 ± 1 mm; 8 ± 1mm, length 3.15 ≤ L ≤ 40,

moisture content ≤ 12%, ash content ≤ 0.5%, calorific

value >17 MJ / kg)

Electrical connection

[-]

2A; ~230V; 50Hz

Electrical power consumption

[W]

120

120

120

120

Electric power consumption

(instantaneous at start-up)

[W]

420

420

420

420

Setting range of temperature controller

[°C]

60-80 (in 1°C steps)

Required chimney draught

[Pa]

24

26

28

30

Exhaust mass flow

[g/s].

10,19

13,87

17,88

19,29

Design flow resistance ΔT [10K]

[mbar].

5,47

9,74

12,33

15,8

Design flow resistance ΔT [20K]

[mbar].

1,36

2,43

3,80

4,3

Boiler weight

[kg].

379

453

484

488,5

* Boiler weight +/- 5kg.

METAL-FACH Heating Technology

11

METAL-FACH Heating Technology

12

Boiler dimensions

(User | Installer)

NOTE!

Boiler feet are present:

- from SEG PELLET 15 to SEG PELLET 30

Their height is 30 mm.

METAL-FACH Heating Technology

13

Type

SEG PELLET 15

SEG PELLET 20

SEG PELLET 25

SEG PELLET 30

A

1150

1150

1110

1160

B

530

530

530

580

C

1185

1380

1440

1440

D

780

815

860

860

E

908

1105

1162

1162

F

413

423

472

472

G

G3/4''

G3/4''

G3/4''

G3/4''

H

G11/2''

G11/2''

G11/2''

G11/2''

I

180

180

180

180

J

G11/2''

G11/2''

G11/2''

G11/2''

K*

214

250

246

246

L*

214

210

206

206

M

615

615

570

540

O

125

125

125

125

P

930

970

1020

1020

*Dimension does not include the height of the boiler levelling feet.

METAL-FACH Heating Technology

14

Safety automation and control

(User | Installer)

1. Boiler automatics enables setting:

●boiler temperature;

●the hot water temperature;

●temperature in the central heating system;

●operation of auxiliary pumps;

●fuel feeder operation;

●manual control of the feeder fan

2. Thermal sensor

Mechanical STB protection is located in the boiler and protects the heating system from overheating. It is set at

95oC. Above this temperature it switches off the fan, switching on the central heating and hot water pumps, as

well as two additional ones, and opens the mixing valve.

METAL-FACH Heating Technology

15

Fuel

(User)

The fuel for boilers equipped with a self-cleaning pellet burner is:

Wood pellets of class C in accordance with pt. 5.3 (Table 7) of PN EN 303-5:2012 standard:

●diameter: 6 ± 1mm; 8 ± 1mm;

●length 3,15 ≤ L ≤ 40;

●moisture content ≤ 12%;

●ash content ≤ 0.5%;

●calorific value >17 MJ/kg;

The fuel should not contain stones, pieces of wood or other impurities.

METAL-FACH Heating Technology

16

Requirements for the boiler house and boiler installation

(User | Installer)

In Poland, boiler houses built for solid fuel should meet the requirements of the PN-87/B-02411 standard "Boiler

houses built for solid fuel" and OJ. 2015.0.1422 These are divided into two types:

1. For small boiler plants up to 25 kW capacity, the following requirements should be met:

●The boiler should be placed as centrally as possible to the rooms to be heated and in a separate room;

●The material of which the boiler room floor is made should be non-flammable; in case of combustible

material, the floor should be covered with 0.7 mm thick steel sheet at a distance of at least 50 cm from

the edge of the boiler; the boiler should be placed on a foundation made of non-flammable materials,

protruding 0.05 m above the floor level and edged with steel angles;

●there should be artificial lighting in the room, natural lighting is also advisable;

●The distance from the back of the boiler to the wall should not be less than 70 cm, from the side of the

boiler to the wall not less than 100 cm and from the front of the boiler to the opposite wall not less than

200 cm;

●The height in new buildings should be at least 220 cm, in existing buildings the height of the boiler room

is at least 190 cm, with proper ventilation (supply and exhaust);

●Supply ventilation should be by means of an unsealed opening with a minimum cross-section of 200 cm2

and placed up to a maximum of 100 cm above floor level;

●exhaust ventilation should be carried out with an exhaust duct made of non-flammable material,

minimum cross-section 14 x 14 cm, with an inlet opening under the boiler room ceiling; the exhaust duct

should be led above the roof and placed close to the chimney; there must be no devices allowing to

close it on the exhaust duct

●the section of the chimney should not be smaller than 20 x 20 cm;

●there should be a floor drain in the floor of the boiler room;

●The optimal place for fuel storage is a separate room close to the boiler room;

●ash and slag must be collected in suitable containers which can be emptied daily.

2. Boiler houses with a heat output of 25 kW and over shall in addition meet the following requirements:

●The distance of the boiler furthest from the chimney, for gravity draught, must not exceed 50 cm of

chimney height;

●Fuel storage and slag storage should be located next to the boiler hall at a storage height of up to 220

cm with a minimum of 50 cm free space above the fuel;

●facilities and equipment shall be provided to enable the vertical and horizontal transport of fuel and

slag;

●Fuel storage rooms shall have natural unforced ventilation, providing for one complete change of air per

hour in the fuel storage room and three complete changes of air in the slag storage room;

●the entrance door to the boiler room shall be non-combustible (class 0.5 fire resistance), minimum width

80 cm, opening outwards; it shall have a handleless locking system enabling it to be opened outwards

under pressure and inwards using a handle;

METAL-FACH Heating Technology

17

●ventilation requirements are the same as for boiler houses of smaller capacity; in addition, in boiler

houses whose capacity exceeds 400 kW, in addition to supply and exhaust ventilation, there should be

mechanical ventilation, activated periodically during fuel filling and slagging of boilers, ensuring a

minimum of 10 full air changes per hour;

●natural lighting shall be provided in the boiler room, illuminating the boiler from the front, and the

window area shall be a minimum of 1/15 of the boiler room floor area; half of the installed windows

shall be operable; electric lighting and an electric socket, of a voltage not exceeding 24 V, shall also be

provided in the room;

●there should be a drainage sump in the floor to allow cooling of the water and its capacity should be

equal to the water capacity of the largest boiler, but not more than 2 m3;

●in the boiler room, the thermal pipes should be insulated;

●The boiler position with the minimum required distances is shown in the boiler room diagram below.

Minimum distances for positioning the boiler in the boiler room

METAL-FACH Heating Technology

18

NOTE!

Mechanical exhaust ventilation should not be used in the boiler room.

NOTE!

Ensuring a sufficient supply of fresh air into the boiler room will enable efficient

combustion of the fuel.

NOTE!

Excessive carbon dioxide in the room should be prevented.

NOTE!

More detailed information on the requirements for the construction of a boiler house can

be found in the Regulation of the Minister of Infrastructure of 12 March 2009.

TIP!

The above-mentioned provisions are guidelines to be reviewed as the Regulation is subject

to revision.

Table of contents

Other Metal-Fach Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Yamaha

Yamaha Rhino YXR66FAV owner's manual

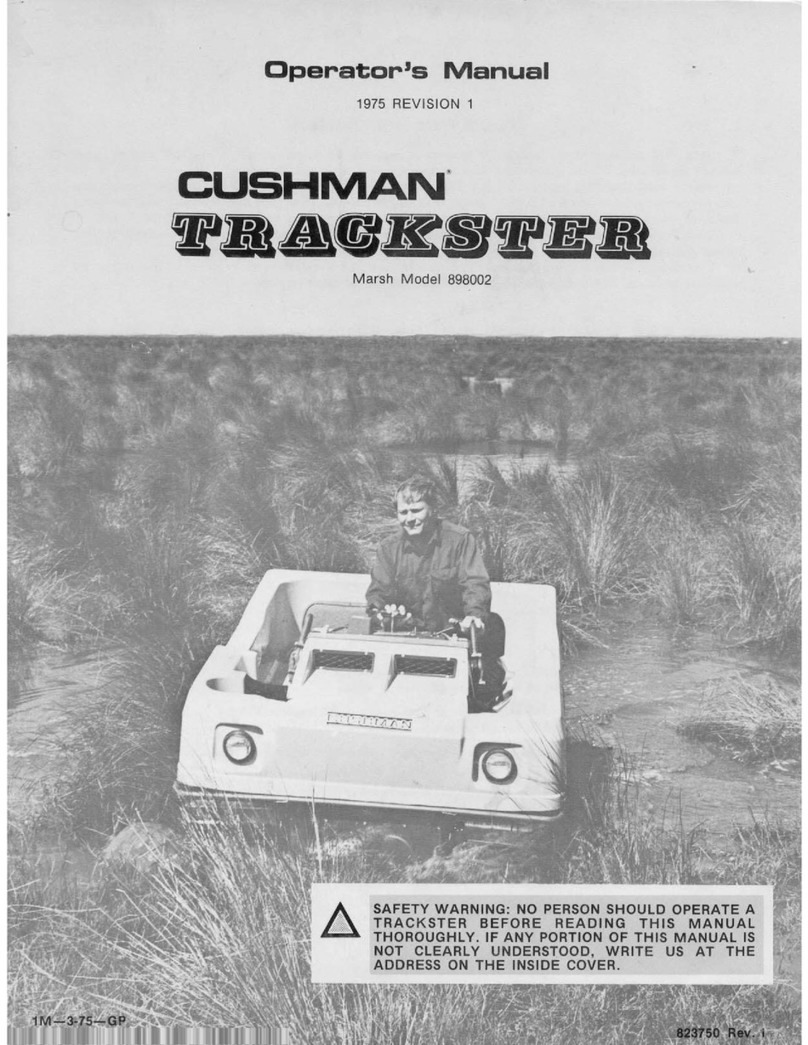

Cushman

Cushman Trackster 898002 Operator's manual

Winget

Winget 2B1500 Operators Handbook & Parts

CORVUS

CORVUS TERRAIN DX4 PRO user manual

Columbia Vehicle Group

Columbia Vehicle Group Tomberlin ESCAPE 2018 Owner's and operator's manual

American Sportworks

American Sportworks 3171 owner's manual