2

TABLEOFCONTENTS

Understanding the Manual ................................................................................................................. 3

Safety Information................................................................................................................................ 4

Owners' Responsibilities .......................................................................................................... 5

Operators' Responsibilities ...................................................................................................... 5

Important Precautions ............................................................................................................ 6

Safety Rules ........................................................................................................................................... 7

General Safety Guidelines ...................................................................................................... 8

Safety Before Operation ......................................................................................................... 8

Safety During Operation ......................................................................................................... 9

Transportation Safety .............................................................................................................. 9

Warning Labels ....................................................................................................................................10

Location of Labels ..................................................................................................................12

General Operating Instructions .........................................................................................................13

Storage ................................................................................................................................................13

Maintenance ......................................................................................................................................14

Maintenance Schedule .........................................................................................................14

Maintenance Record .............................................................................................................15

BoltTorqueSpecications......................................................................................................16

Imperial and Metric Conversion Tables ...............................................................................17

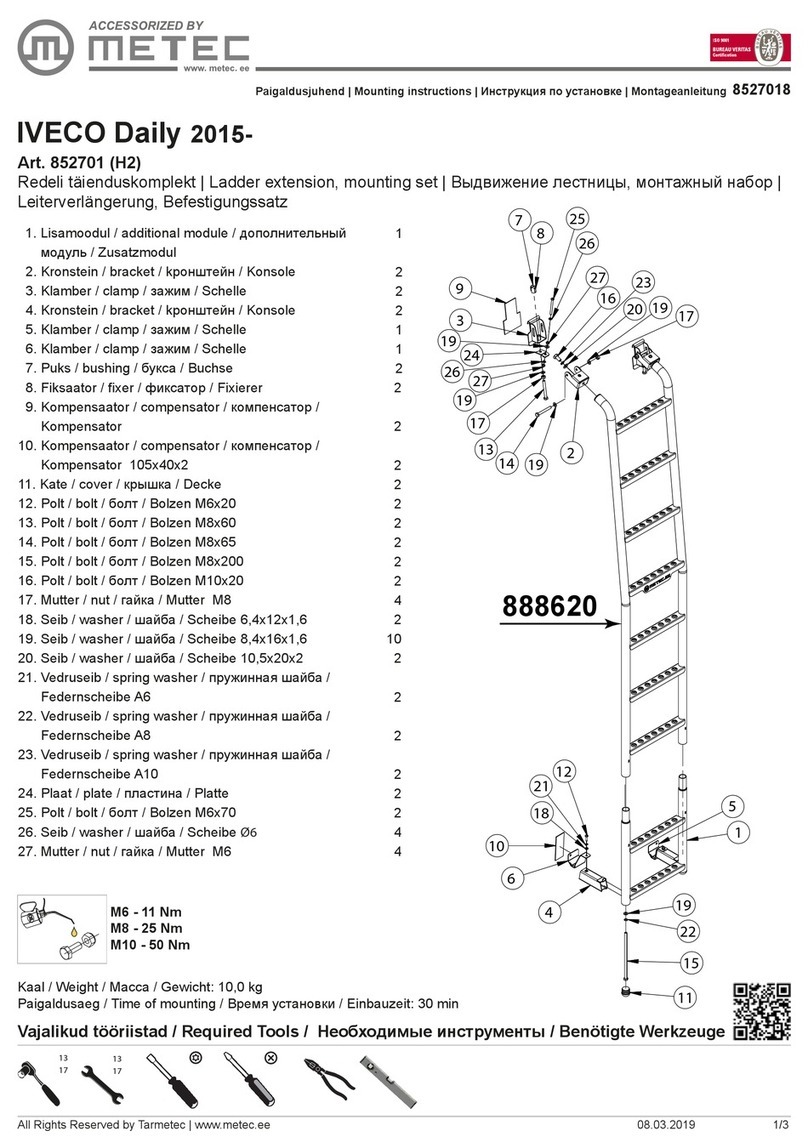

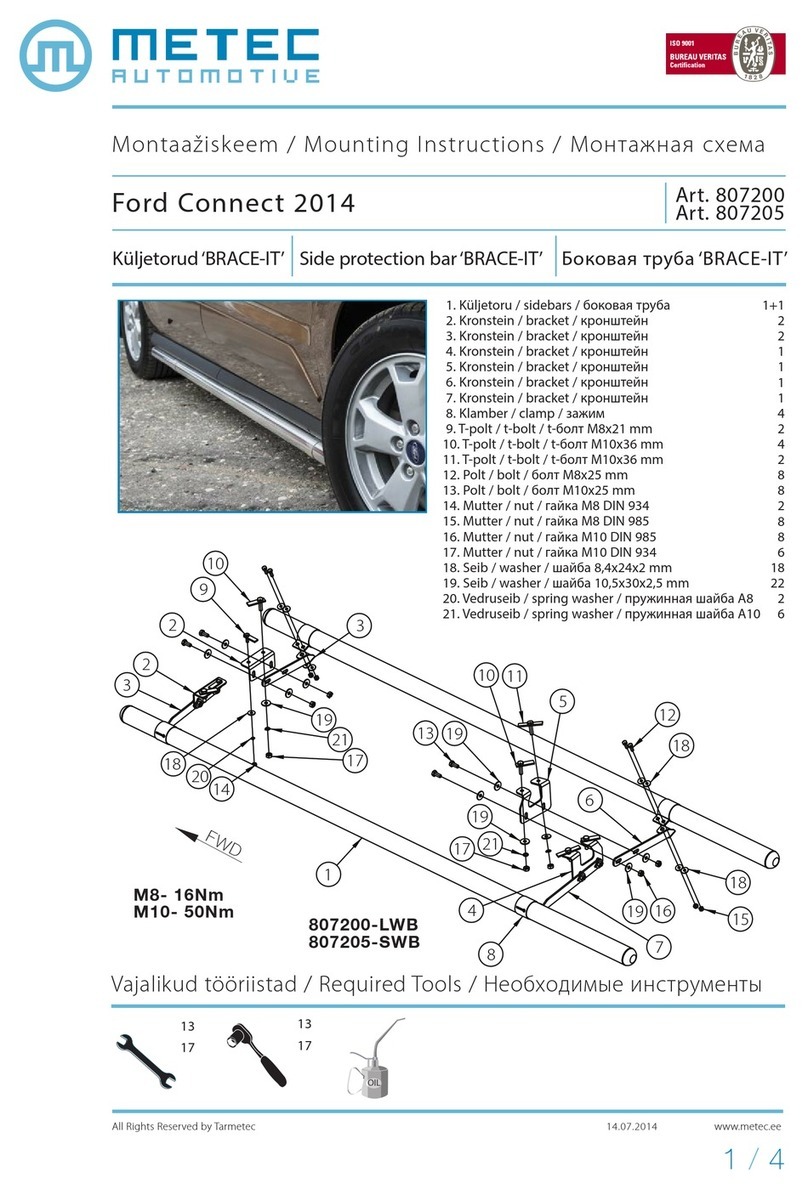

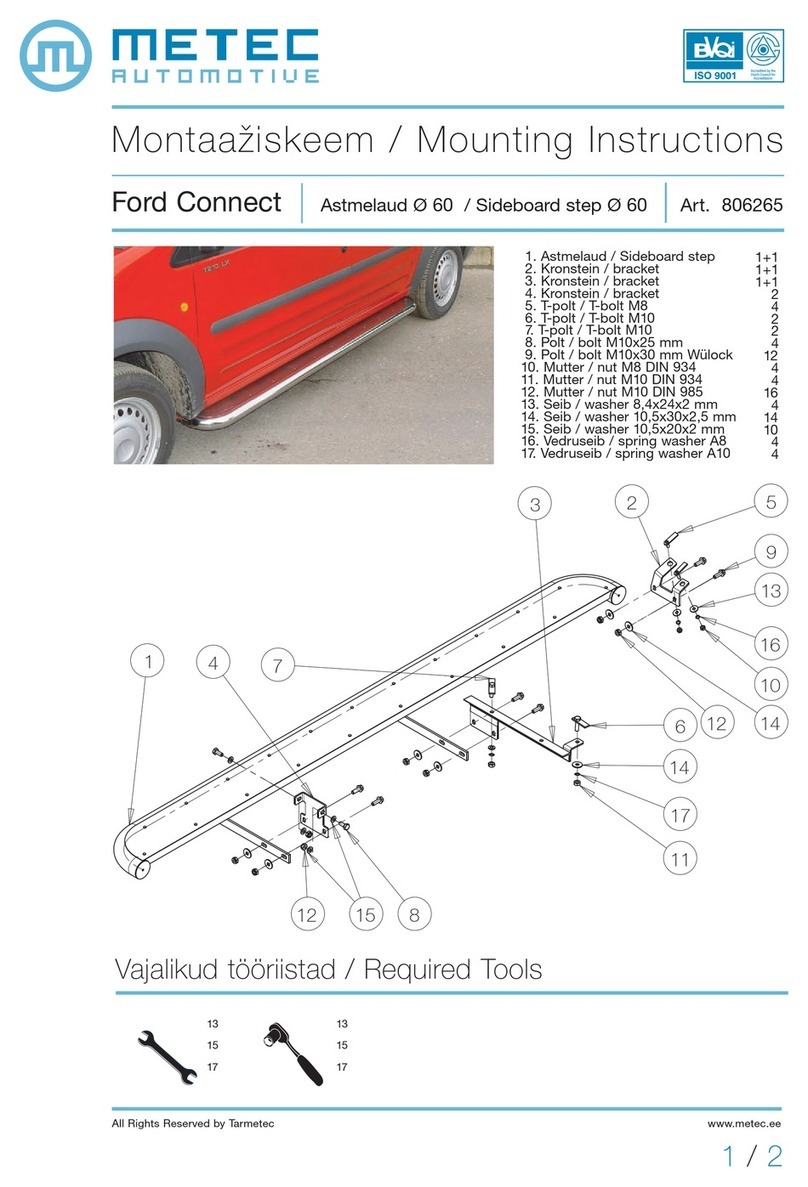

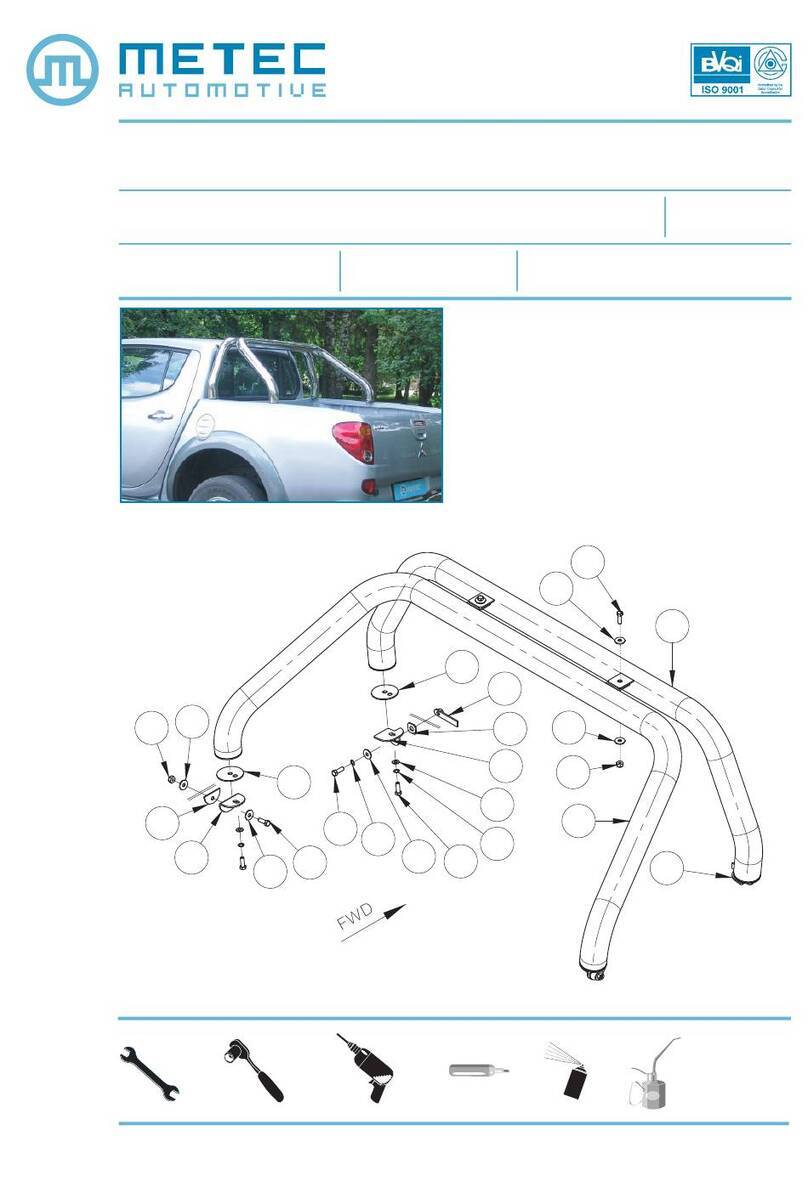

Parts ...................................................................................................................................................18

Warranty ..............................................................................................................................................24

DISCLAIMER

METEC Metal Technology Inc. provides this publication "as is" without warranty of any kind, either expressed or implied.

While every precaution has been taken in the preparation of this manual METEC assumes no responsibility for errors

or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein.

METECreservestherighttoreviseandimproveitsproductsasitseest.Thispublicationdescribesthestateofthis

productatthetimeofitspublication,andmaynotreecttheproductinthefuture.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Manual 2021 v1