METER TEROS 11 Assembly Instructions

TEROS 11/12 INTEGRATOR GUIDE

18224-02

2.15.2019

SENSOR DESCRIPTION

The TEROS 11 Soil Moisture and Temperature sensor and the TEROS 12 Soil Moisture, Temperature,

and Electrical Conductivity (EC) sensor are accurate tools for monitoring volumetric water content

(VWC), temperature in soil and soilless substrates, and electrical conductivity (TEROS 12 only). The

TEROS11/12 determines VWC using capacitance/frequency-domain technology. The sensor uses a 70 MHz

frequency, which minimizes textural and salinity effects, making the TEROS 11/12 accurate in most mineral

soils. The TEROS 11/12 uses a thermistor in the center needle to measure temperature and electrical

conductivity (TEROS 12 only) using a stainless-steel electrode array.

For a more detailed description of how this sensor makes measurements, refer to the TEROS 11/12 User Manual.

APPLICATIONS

TEROS 11

• Volumetric water content VWC

• Soil/substrate water balance

• Irrigation management

• Soil/substrate temperature measurement

• Plant growth research

TEROS 12

• Volumetric water content VWC

• Soil/substrate water balance

• Irrigation management

• Soil/substrate temperature measurement

• Solute/fertilizer movement

• Soil EC measurement

ADVANTAGES

• Three-wire sensor interface: power, ground, and data

• Digital sensor communicates multiple measurements over serial interface

• Robust thermistor for accurate temperature measurements

• Low-input voltage requirements

• Low-power design supports battery-operated data loggers

• Robust epoxy encapsulation resists corrosive environments

• Supports SDI-12 or DDI serial communications protocols

• Modern design optimized for low-cost sensing

PURPOSE OF THIS GUIDE

METER provides the information in this integrator guide to help customers establish communication

between these sensors and their data acquisition equipment or field data loggers. Customers using data

loggers that support SDI-12 sensor communications should consult the data logger user manual. METER

sensors are fully integrated into the METER system of plug-and-play sensors, cellular-enabled data loggers,

and data analysis software.

COMPATIBLE FIRMWARE VERSIONS

This guide is compatible with firmware versions 1.07 or newer.

Figure 1 TEROS 11/12 sensor

METER Group, Inc. USA

2365 NE Hopkins Court, Pullman,WA 99163

T +1.509.332.2756 F +1.509.332.5158

E info@metergroup.com W metergroup.com

2

Cable Length

5 m (standard)

75 m (maximum custom cable length)

NOTE: Contact Customer Support if a nonstandard cable

length is needed.

Connector Types

3.5-mm stereo plug connector or stripped and

tinnedwires

Dimensions

Length 9.4 cm (3.70 in)

Width 2.4 cm (0.95 in)

Height 7.5 cm (2.95 in)

Prong Length

5.5 cm (2.17 in)

Volumetric Water Content (VWC)

Range

Mineral soil

calibration

0.00–0.70 m3/m3

Soilless

media

calibration

0.0–1.0 m3/m3

Apparent

dielectric

permittivity (εa )

1 (air) to 80 (water)

NOTE: The VWC range is dependent on the media the sensor

is calibrated to. A custom calibration will accommodate the

necessary ranges for most substrates.

Resolution 0.001 m3/m3

Accuracy

Generic

calibration

±0.03 m3/m3typical

in mineral soils that

have solution electrical

conductivity < 8 dS/m

Medium specific

calibration

±0.01–0.02 m3/m3in any

porous medium

Apparent

dielectric

permittivity (εa )

1–40 (soil range),

±1 εa(unitless)

40–80, 15% of

measurement

Dielectric Measurement Frequency

70 MHz

Temperature

TEROS 11

Range −40 to +60 °C

Resolution 0.1 °C

Accuracy ±1 °C from −40 to 0 °C

±0.5 °C from 0 to +60 °C

NOTE: Temperature measurement, for applicable sensors,

may not be accurate if sensor is not fully immersed in the

medium of interest, due to longer equilibration time.

TEROS 12

Range −40 to +60 °C

Resolution 0.1 °C

Accuracy ±0.5 °C from −40 to 0 °C

±0.3 °C from 0 to +60 °C

Electrical Conductivity (ECb) (TEROS 12 Only)

Range 0–20 dS/m (bulk)

Resolution 0.001 dS/m

Accuracy ±(5% + 0.01 dS/m)

from0–10 dS/m

±8% from 10–20 dS/m

PHYSICAL SPECIFICATIONS

SPECIFICATIONS

MEASUREMENT SPECIFICATIONS

COMMUNICATION SPECIFICATIONS

Output

DDI serial or

SDI-12 communication protocol

Data Logger Compatibility

METER ZL6, EM60, and Em50 data loggers

or any data acquisition system capable of

4.0- to 15-VDC power and serial or SDI-12

communication

3

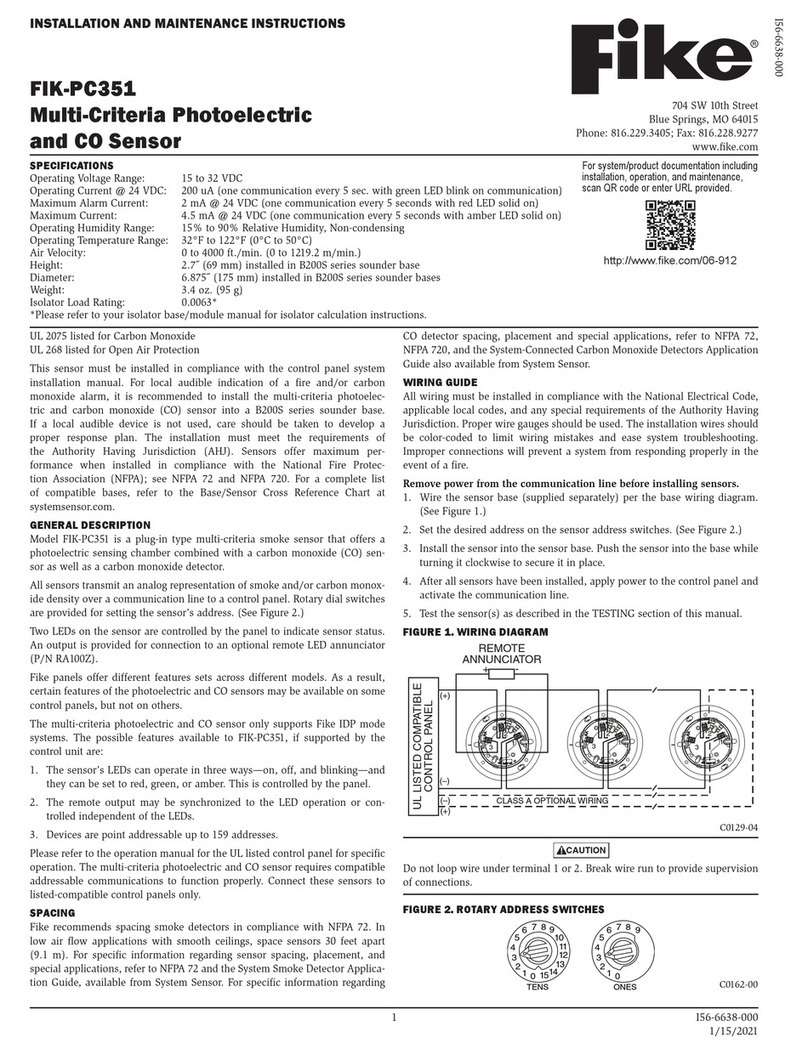

EQUIVALENT CIRCUIT AND CONNECTION TYPES

Refer to Figure 2 and Figure 3 to connect the TEROS 11/12 to a data logger. Figure 2 provides a low-impedance

variant of the recommended SDI-12 specification.

PIGTAIL CABLE

Ground (bare)

Data output (orange)

Power (brown)

GND

DATA

GND

510

R1

R2

100K

C1

220PF

L1

10UH

Figure 2 Equivalent circuit diagram

Supply Voltage (VCC to GND)

Minimum 4.0 VDC

Typical NA

Maximum 15.0 VDC

Digital Input Voltage (logic high)

Minimum 2.8 V

Typical 3.6 V

Maximum 3.9 V

Digital Input Voltage (logic low)

Minimum –0.3 V

Typical 0.0 V

Maximum 0.8 V

Digital Output Voltage (logic high)

Minimum NA

Typical 3.6 V

Maximum NA

Power Line Slew Rate

Minimum 1.0 V/ms

Typical NA

Maximum NA

Current Drain (during 25-ms measurement)

Minimum 3.0 mA

Typical 3.6 mA

Maximum 16.0 mA

Current Drain (while asleep)

Minimum NA

Typical 0.03 mA

Maximum NA

Operating Temperature Range

Minimum –40 °C

Typical NA

Maximum +60 °C

NOTE: Sensors may be used at higher temperatures under

certain conditions; contact Customer Support for assistance.

Power Up Time (DDI serial)

Minimum 80 ms

Typical NA

Maximum 100 ms

Power Up Time (SDI-12)

Minimum NA

Typical 245 ms

Maximum NA

Measurement Duration

Minimum 25 ms

Typical NA

Maximum 50 ms

COMPLIANCE

Manufactured under ISO 9001:2015

EM ISO/IEC 17050:2010 (CE Mark)

2014/30/EU and 2011/65/EU

EN61326-1:2013 and EN55022/CISPR 22

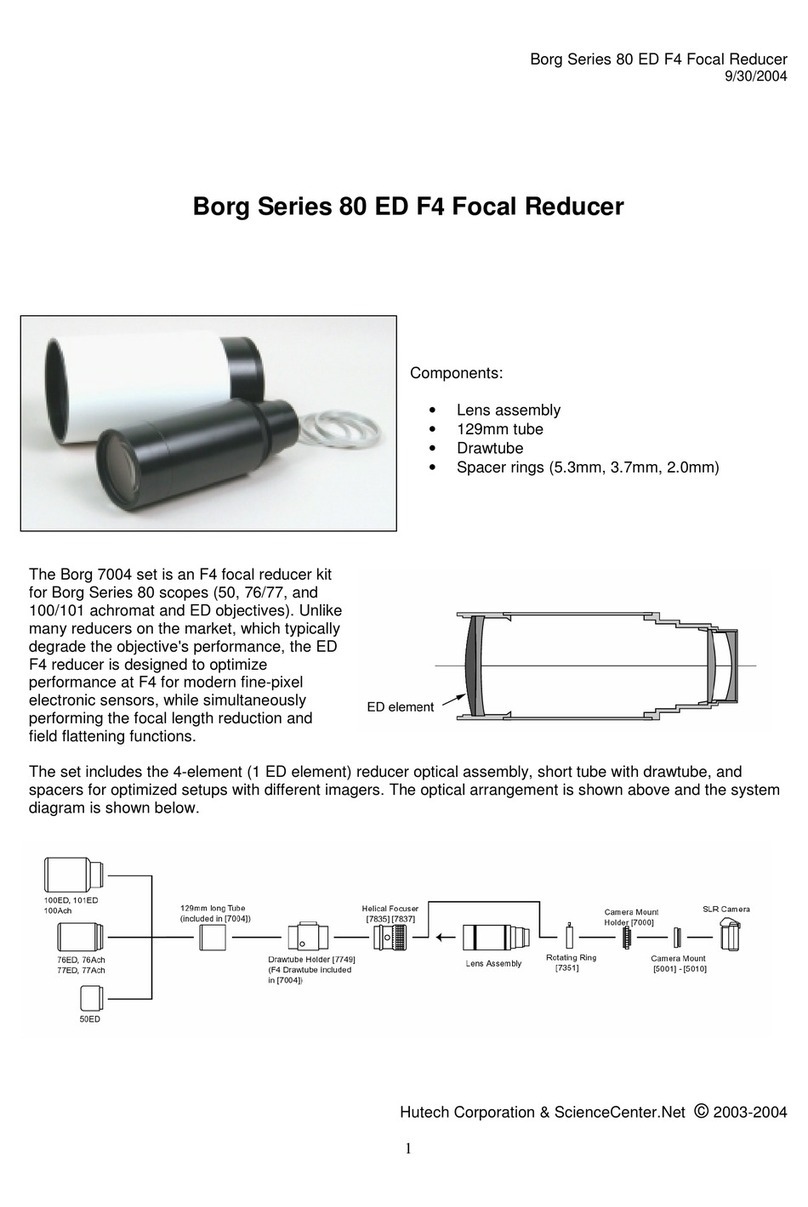

STEREO CABLE

Ground

Data output

Power

Figure 3 Connection types

ELECTRICAL AND TIMING CHARACTERISTICS

4

SAFETY PRECAUTIONS

METER sensors are built to the highest standards, but misuse, improper protection, or improper installation

may damage the sensor and possibly void the warranty. Before integrating sensors into a sensor network,

followthe recommended installation instructions and implement safeguards to protect the sensor from

damaging interference.

SURGE CONDITIONS

Sensors have built-in circuitry that protects them against common surge conditions. Installations in

lightning-prone areas, however, require special precautions, especially when sensors are connected to a

well-grounded third-party logger.

Visit metergroup.com for articles containing more information.

POWER AND GROUNDING

Ensure there is sufficient power to simultaneously support the maximum sensor current drain for all the

sensors on the bus. The sensor protection circuitry may be insufficient if the data logger is improperly

powered or grounded. Refer to the data logger’s installation instructions. Improper grounding may affect the

sensor output as well as sensor performance.

Visit metergroup.com for articles containing more information.

CABLES

Improperly protected cables can lead to severed cables or disconnected sensors. Cabling issues can be

caused by many factors, including rodent damage, driving over sensor cables, tripping over the cable, not

leaving enough cable slack during installation, or poor sensor wiring connections. To relieve strain on the

connections and prevent loose cabling from being inadvertently snagged, gather and secure the cable

travelling between the TEROS 11/12 and the data acquisition device to the mounting mast in one or more

places. Install cables in conduit or plastic cladding when near the ground to avoid rodent damage. Tie excess

cable to the data logger mast to ensure cable weight does not cause sensor to unplug.

SENSOR COMMUNICATIONS

METER digital sensors feature a serial interface with shared receive and transmit signals for communicating

sensor measurements on the data wire (Figure 3). The sensor supports two different protocols: SDI-12 and DDI

serial. Each protocol has implementation advantages and challenges. Please contact Customer Support if the

protocol choice for the desired application is not obvious.

SDI-12 INTRODUCTION

SDI-12 is a standards-based protocol for interfacing sensors to data loggers and data acquisition equipment.

Multiple sensors with unique addresses can share a common 3-wire bus (power, ground, and data). Two-way

communication between the sensor and logger is possible by sharing the data line for transmit and receive

as defined by the standard. Sensor measurements are triggered by protocol command. The SDI-12 protocol

requires a unique alphanumeric sensor address for each sensor on the bus so that a data logger can send

commands to and receive readings from specific sensors.

Download the SDI-12 Specification v1.3 to learn more about the SDI-12 protocol.

DDI SERIAL INTRODUCTION

The DDI serial protocol is the method used by the METER data loggers for collecting data from the sensor. This

protocol uses the data line configured to transmit data from the sensor to the receiver only (simplex). Typically,

the receive side is a microprocessor UART or a general-purpose I/O pin using a bitbang method to receive data.

Sensor measurements are triggered by applying power to the sensor.

INTERFACING THE SENSOR TO A COMPUTER

The serial signals and protocols supported by the sensor require some type of interface hardware to be

compatible with the serial port found on most computers (or USB-to-serial adapters). There are several

SDI-12 interface adapters available in the marketplace; however, METER has not tested any of these

5

interfaces and cannot make a recommendation as to which adapters work with METER sensors. METER

data loggers and the ProCheck hand-held device can operate as a computer-to-sensor interface for

making on-demand sensor measurements. For more information, please contact Customer Support.

METER SDI-12 IMPLEMENTATION

METER sensors use a low-impedance variant of the SDI-12 standard sensor circuit (Figure 2). During the

power-up time, sensors output some sensor diagnostic information and should not be communicated with

until the power-up time has passed. After the power up time, the sensors are compatible with all commands

listed in the SDI-12 Specification v1.3 except for the continuous measurement commands (aR0–aR9 and

aRC0–aRC9) and the concurrent measurement commands (aC–aC9 and aCC0–aCC9). M, R, and Ccommand

implementations are found on pages 8–9. The aR3 and aR4 commands are used by METER systems and

as a result use space delimination, instead of the sign delimination required by the SDI-12 standard.

Out of the factory, all METER sensors start with SDI-12 address 0and print out the DDI serial startup string

during the power-up time. This can be interpreted by non-METER SDI-12 sensors as a pseudo-break condition

followed by a random series of bits.

The TEROS 11/12 will omit the DDI serial startup string (sensor identification) when the SDI-12 address is

nonzero. Changing the address to a nonzero address is recommended for this reason.

SENSOR BUS CONSIDERATIONS

SDI-12 sensor buses require regular checking, sensor upkeep, and sensor troubleshooting. If one sensor goes

down, that may take down the whole bus even if the remaining sensors are functioning normally. Power cycling

the SDI-12 bus when a sensor is failing is acceptable, but METER does not recommend scheduling power cycling

events on an SDI-12 bus more than once or twice per day. Many factors influence the effectiveness of the bus

configuration. Visit metergroup.com for articles and virtual seminars containing more information.

SDI-12 CONFIGURATION

Table1 lists the SDI-12 communication configuration.

Table1 SDI-12 communication configuration

Baud Rate 1200

Start Bits 1

Data Bits 7 (LSB first)

Parity Bits 1 (even)

Stop Bits 1

Logic Inverted (active low)

SDI-12 TIMING

All SDI-12 commands and responses must adhere to the format in Figure 4 on the data line. Both the

command and response are preceded by an address and terminated by a carriage return and line feed

combination (<CR><LF>) and follow the timing shown in Figure 5.

START STOPD0 D1 D2 D3 D4 D5 D6 EP

Figure 4 Example SDI-12 transmission of the character 1 (0x31)

6

Break

(at least 12 ms)

Marking

(at least 8.33 ms)

Marking

(at least 8.33 ms)

Comman

dR

esponse

SENSORDATA LOGGER

Maximum time*Sensor must respond

within 15 ms

*Maximum time is dependent upon the amount of data returned for the command sent.

Figure 5 Example data logger and sensor communication

COMMON SDI-12 COMMANDS

This section includes tables of common SDI-12 commands that are often used in an SDI-12 system and the

corresponding responses from METER sensors.

IDENTIFICATION COMMAND (aI!)

The Identification command can be used to obtain a variety of detailed information about the connected sensor.

An example of the TEROS 11 command and response is shown in Example 1 and the TEROS11 command and

response is shown in Example 2, where the command is in bold and the response follows the command.

Example 1 1I!113METER␣ ␣ ␣TER11␣107631800001 (TEROS 11)

Parameter

Fixed

Character

Length Description

1I! 3Data logger command.

Request to the sensor for information from sensor address 1.

11

Sensor address.

Prepended on all responses, this indicates which sensor on the bus is returning

the following information.

13 2 Indicates that the target sensor supports SDI-12 Specification v1.3.

METER␣ ␣ ␣ 8Vendor identification string.

(METER and three spaces ␣ ␣ ␣ for all METER sensors)

TER11␣6

Sensor model string.

This string is specific to the sensor type.

For the TEROS 11, the string is TER11.

107 3

Sensor version.

This number divided by 100 is the METER sensor version

(e.g., 107 is version 1.07).

631800001 ≤13,

variable

Sensor serial number.

This is a variable length field. It may be omitted for older sensors.

7

Example 2 1I!113METER␣ ␣ ␣TER12␣107631800001 (TEROS 12)

Parameter

Fixed

Character

Length Description

1I! 3Data logger command.

Request to the sensor for information from sensor address 1.

11

Sensor address.

Prepended on all responses, this indicates which sensor on the bus is returning

the following information.

13 2 Indicates that the target sensor supports SDI-12 Specification v1.3.

METER␣ ␣ ␣ 8Vendor identification string.

(METER and three spaces ␣ ␣ ␣ for all METER sensors)

TER12␣6

Sensor model string.

This string is specific to the sensor type.

For the TEROS 12, the string is TER12.

107 3

Sensor version.

This number divided by 100 is the METER sensor version

(e.g., 107 is version 1.07).

631800001 ≤13,

variable

Sensor serial number.

This is a variable length field. It may be omitted for older sensors.

CHANGE ADDRESS COMMAND (aAB!)

The Change Address command is used to change the sensor address to a new address. All other commands

support the wildcard character as the target sensor address except for this command. All METER sensors

have a default address of 0 (zero) out of the factory. Supported addresses are alphanumeric (i.e., a–z, A–Z, and

0–9). An example output from a METER sensor is shown in Example 3, where the command is in bold and the

response follows the command.

Example 3 1A0!0

Parameter

Fixed

Character

Length Description

1A0! 4Data logger command.

Request to the sensor to change its address from 1to a new address of 0.

01

New sensor address.

For all subsequent commands, this new address will be used by the

targetsensor.

ADDRESS QUERY COMMAND (?!)

While disconnected from a bus, the Address Query command can be used to determine which sensors are

currently being communicated with. Sending this command over a bus will cause a bus contention where all

the sensors will respond simultaneously and corrupt the data line. This command is helpful when trying to

isolate a failed sensor. Example 4 shows an example of the command and response, where the command is in

bold and the response follows the command. The question mark (?) is a wildcard character that can be used in

place of the address with any command except the Change Address command.

Example 4 ?!0

Parameter

Fixed

Character

Length Description

?! 2Data logger command.

Request for a response from any sensor listening on the data line.

01Sensor address.

Returns the sensor address to the currently connected sensor.

COMMAND IMPLEMENTATION

The following tables list the relevant Measurement (M), Continuous (R), and Concurrent (C) commands and

subsequent Data (D) commands when necessary.

8

MEASUREMENT COMMANDS IMPLEMENTATION

Measurement (M) commands are sent to a single sensor on the SDI-12 bus and require that subsequent Data

(D) commands are sent to that sensor to retrieve the sensor output data before initiating communication with

another sensor on the bus.

Please refer to Table2 and for an explanation of the command sequence and see Table7 for an explanation of

response parameters.

Table2 aM! command sequence

Command Response

This command reports instantaneous values.

aM! atttn

aD0! a+<calibratedCountsVWC>±<temperature>+<electricalConductivity>

NOTES: <electricalConductivity> is only output on the TEROS 12.

The measurement and corresponding data commands are intended to be used back to back. After a measurement command is processed

by the sensor, a service request a <CR><LF> is sent from the sensor signaling the measurement is ready. Either wait until ttt seconds have

passed or wait until the service request is received before sending the data commands.See the SDI-12 Specifications v1.3 document for

more information.

CONCURRENT MEASUREMENT COMMANDS IMPLEMENTATION

Concurrent (C) measurement commands are typically used with sensors connected to a bus. Concurrent (C)

commands for this sensor deviate from the standard Ccommand implementation. First, send the Ccommand,

wait the specified amount of time detailed in the Ccommand response, and then use Dcommands to read its

response prior to communicating with another sensor.

Please refer to Table3 for an explanation of the command sequence and see Table7 for an explanation of

response parameters.

Table3 aC! measurement command sequence

Command Response

This command reports instantaneous values.

aC! atttnn

aD0! a+<calibratedCountsVWC>±<temperature>+<electricalConductivity>

NOTES: <electricalConductivity> is only output on the TEROS 12.

This command does not adhere to the SDI-12 concurrent command requirements. See METER SDI-12 Implementation for more information.

The measurement and corresponding data commands are intended to be used back to back. After a measurement command is processed

by the sensor, a service request a <CR><LF> is sent from the sensor signaling the measurement is ready. Either wait until ttt seconds have

passed or wait until the service request is received before sending the data commands.See the SDI-12 Specifications v1.3 document for

more information.

CONTINUOUS MEASUREMENT COMMANDS IMPLEMENTATION

Continuous (R) measurement commands trigger a sensor measurement and return the data automatically

after the readings are completed without needing to send a Dcommand.

Please refer to Table4 through Table6 for an explanation of the command sequence and see Table7 for an

explanation of response parameters.

Table4 aR0! measurement command sequence

Command Response

This command reports instantaneous values.

aR0! a+<calibratedCountsVWC>±<temperature>+<electricalConductivity>

NOTES: <electricalConductivity> is only output on the TEROS 12.

This command does not adhere to the SDI-12 response timing. See METER SDI-12 Implementation for moreinformation.

9

Table5 aR3! measurement command sequence

Command Response

This command reports instantaneous values.

aR3! a<TAB><calibratedCountsVWC> <temperature> <electricalConductivity><CR><sensorType><Checksum><CRC>

NOTES: <electricalConductivity> is only output on the TEROS 12.

This command does not adhere to the SDI-12 response format or timing. See METER SDI-12 Implementation for more information.

Table6 aR4! measurement command sequence

Command Response

This command reports instantaneous values.

aR4! a<TAB><calibratedCountsVWC> <temperature> <electricalConductivity><CR><sensorType><Checksum><CRC>

NOTES: <electricalConductivity> is only output on the TEROS 12.

This command does not adhere to the SDI-12 response format or timing. See METER SDI-12 Implementation for more information.

PARAMETERS

Table7 lists the parameters, unit measurement, and a description of the parameters returned in command

responses for TEROS 11/12.

Table7 Parameter Descriptions

Parameter Unit Description

±—Positive or negative sign denoting sign of the next value

a—SDI-12 address

n—Number of measurements (fixed width of 1)

nn —Number of measurements with leading zero if necessary (fixed width of 2)

ttt sMaximum time measurement will take (fixed width of 3)

<TAB> — Tab character

<CR> — Carriage return character

<LF> — Line feed character

<calibratedCountsVWC> — Calibrated ADC counts for volumetric water content

<temperature> °C Air temperature

<electricalConductivity> dS/m Bulk electrical conductivity normalized to 25 °C (TEROS 12 only)

<sensorType> —

ASCII character denoting the sensor type

For TEROS 11, the character is h

For TEROS 12, the character is g

<Checksum> —METER serial checksum

<CRC> —METER 6-bit CRC

DDI SERIAL COMMUNICATION

The DDI serial communications protocol is ideal for systems that have dedicated serial signaling lines for each

sensor or use a multiplexer to handle multiple sensors. The serial communications are compatible with many

TTL serial implementations that support active-high logic levels using 0 to 3.6 V signal levels. When the sensor

is first powered, it automatically makes measurements of the integrated transducers then outputs a response

over the data line. Systems using this protocol control the sensor excitation to initiate data transfers from

the sensor. This protocol is subject to change as METER improves and expands the line of digital sensors and

dataloggers. TEROS 11/12 will omit the DDI serial startup string when the SDI-12 address is nonzero.

NOTE: Out of the factory, all METER sensors start with SDI-12 address 0and print out the startup string when power cycled.

10

DDI SERIAL TIMING

Table8 lists the DDI serial communication configuration.

Table8 DDI serial communication configuration

Baud Rate 1200

Start Bits 1

Data Bits 8 (LSB first)

Parity Bits 0 (none)

Stop Bits 1

Logic Standard (active high)

At power up, the sensor will pull the data line high within 100 ms to indicate that the sensor is taking a reading

(Figure 6). When the reading is complete, the sensor begins sending the serial signal out the data line adhering

to the format shown in Figure 7. Once the data is transmitted, the sensor goes into SDI-12 communication

mode. To get another serial signal, the sensor must be power cycled.

NOTE: Sometimes the signaling from the sensor can confuse typical microprocessor UARTs. The sensor holds the data line low while

taking measurements.The sensor raises the line high to signal the logger that it will send a measurement.Then the sensor may take some

additional measurements before starting to clock out the first data byte starting with a typical start bit (low). Once the first start bit is sent,

typical serial timing is valid; however, the signal transitions before this point are not serial signaling and may be misinterpreted by theUART.

SDI-12 ready

DDI serial

Measurement

duration

Up to 100 ms

Power applied

Figure 6 Data line DDI serial timing

START STOP

D0 D1 D2 D3 D4 D5 D6 D7

Figure 7 Example DDI serial transmission of the character 9 (0x39)

DDI SERIAL RESPONSE

This section contains tables detailing the DDI serial response.

Table9 DDI serial response

COMMAND RESPONSE

NA <TAB><calibratedCountsVWC> <temperature> <electricalConductivity><CR><sensorType><Checksum><CRC>

NOTES: <electricalConductivity> is only output on the TEROS 12.

There is no actual command.The response is returned automatically upon power up.

11

DDI SERIAL CHECKSUM

These checksums are used in the continuous commands R3 and R4 as well as the DDI serial response. The

legacy checksum is computed from the start of the transmission to the sensor identification character,

excluding the sensor address.

TEROS 11 LEGACY CHECKSUM EXAMPLE

Legacy checksum example input is <TAB>1797.7 21.8<CR>h and the resulting checksum output is D.

TEROS 12 LEGACY CHECKSUM EXAMPLE

Legacy checksum example input is <TAB>2749.0 23.8 660<CR>g and the resulting checksum output is 8.

uint8_t LegacyChecksum(const char * Response)

{

uint16_t length;

uint16_t i;

uint16_t sum = 0;

// Finding the length of the response string

length = strlen(response);

// Adding characters in the response together

for( i = 0; i < length; i++ )

{

sum += response[i];

if(response[i] == '\r')

{

// Found the beginning of the meta data section of the response

break;

}

}

// include the sensor type into the checksum

sum += response[++i];

// Convert checksum to a printable character

sum = sum % 64 + 32;

return sum;

}

12

TEROS 11 CRC6

The more robust CRC6, if available, utilizes the CRC-6-CDMA2000-A polynomial with the value 48 added to the

results to make this a printable character and is computed from the start of the transmission to the legacy

checksum character, excluding the sensor address.

CRC6 checksum example input is <TAB>1797.2 21.8<CR>hD and the resulting checksum output is 2.

TEROS 12 CRC6

The more robust CRC6, if available, utilizes the CRC-6-CDMA2000-A polynomial with the value 48 added to the

results to make this a printable character and is computed from the start of the transmission to the legacy

checksum character, excluding the sensor address.

CRC6 checksum example input is <TAB>2749.0 23.8 660<CR>g8 and the resulting checksum output is O

(uppercase o).

uint8_t CRC6_Offset(const char *buffer)

{

uint16_t byte;

uint16_t i;

uint16_t bytes;

uint8_t bit;

uint8_t crc = 0xfc; // Set upper 6 bits to 1’s

// Calculate total message length—updated once the meta data section is found

bytes = strien(buffer)

// Loop through all the bytes in the buffer

for(byte = 0; byte < bytes; byte++)

{

// Get the next byte in the buffer and XOR it with the crc

crc ^= buffer[byte];

// Loop through all the bits in the current byte

for(bit = 8; bit > 0; bit--)

{

// If the uppermost bit is a 1...

if(crc & 0x80)

{

// Shift to the next bit and XOR it with a polynomial

crc = (crc << 1) ^ 0x9c;

}

else

{

// Shift to the next bit

crc = crc << 1;

}

}

if(buffer[byte] == '\r')

{

// Found the beginning of the meta data section of the response

// both sensor type and legacy checksum are part of the crc6

// this requires only two more iterations of the loop so reset

"bytes"

// bytes is incremented at the beginning of the loop, so 3 is added

bytes = byte + 3;

}

}

// Shift upper 6 bits down for crc

crc = (crc >> 2);

// Add 48 to shift crc to printable character avoiding \r \n and !

return (crc + 48);

}

13

CUSTOMER SUPPORT

NORTH AMERICA

Customer service representatives are available for questions, problems, or feedback Monday through Friday,

7:00 am to 5:00 pm Pacific time.

Email: support.environment@metergroup.com

sales.environment@metergroup.com

Phone: +1.509.332.5600

Fax: +1.509.332.5158

Website: metergroup.com

EUROPE

Customer service representatives are available for questions, problems, or feedback Monday through Friday,

8:00 to 17:00 Central European time.

Email: support@metergroup.de

sales@metergroup.de

Phone: +49 89 12 66 52 47

Fax: +49 89 12 66 52 36

Website: metergroup.de

If contacting METER by email, please include the following information:

Name

Address

Phone number

Email address

Instrument serial number

Description of problem

NOTE: For products purchased through a distributor, please contact the distributor directly for assistance.

REVISION HISTORY

The following table lists document revisions.

Revision Date Compatible Firmware Description

02 2.15.2019 1.07 Add TEROS 11

01 4.30.2018 1.00 Correct specifications and measurement value

00 3.1.2018 1.00 Initial release

Other manuals for TEROS 11

2

This manual suits for next models

1

Table of contents

Other METER Accessories manuals

METER

METER TEROS 21 Assembly Instructions

METER

METER TEROS 10 User manual

METER

METER TEROS 54 User manual

METER

METER ATMOS 14 User manual

METER

METER HYDROS 21 GEN 1 User manual

METER

METER TEROS 12 User manual

METER

METER TEROS 11 User manual

METER

METER TEROS VERIFICATION CLIP User manual

METER

METER ATMOS 14 User manual

METER

METER ATMOS 14 User manual