5HY

5

*HQHUDO

1.1 Symbols used in the manual .......................................................................................... 7

1.2 Symbols used on the appliance ...................................................................................... 7

1.3 Checking the relation of the appliance and the manual ................................................. 7

6DIHW\

2.1 Safety instructions in case of malfunction ..................................................................... 8

2.2 Disposal of the appliance ............................................................................................... 8

2.3 Installation ..................................................................................................................... 8

2.4 Detergent and rinse aid .................................................................................................. 8

2.5 Washing and cleaning of the machine ........................................................................... 9

2.5.1 High pressure cleaning of the dishwasher ............................................................. 9

2.5.2 Inside of the machine ............................................................................................. 9

2.5.3 Outside of the machine .......................................................................................... 9

2.6 Floors ............................................................................................................................. 9

2.7 Repairs and maintenance of the machine ...................................................................... 9

)XQFWLRQDO'HVFULSWLRQ

3.1 Application of the appliance ........................................................................................ 10

3.1.1 Prohibited use/Use for other purposes ................................................................. 10

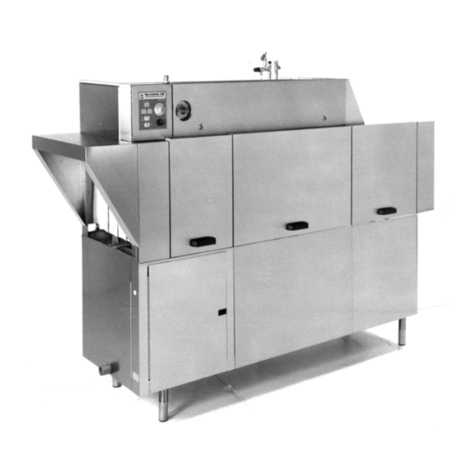

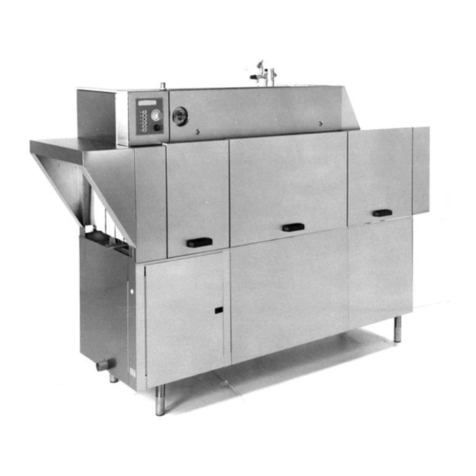

3.2 Construction ............................................................................................................... 11

2SHUDWLRQ

4.1 General ........................................................................................................................ 12

4.2 Operation procedures ................................................................................................... 12

4.2.1 To fill with water ................................................................................................ 12

4.2.2 Choice of wash programme ................................................................................ 12

4.2.3 Washing .............................................................................................................. 12

4.2.4 Hygiene warranty ................................................................................................ 13

4.3 After operation ............................................................................................................. 13

4.3.1 Emptying, internal machine rinse ....................................................................... 13

,QVWDOODWLRQ

5.1 General ........................................................................................................................ 14

5.2 Operating conditions ................................................................................................... 14

5.2.1 Lighting ................................................................................................................ 14

5.2.2 Ventilation ........................................................................................................... 14

5.3 Installation procedures ................................................................................................. 14

5.3.1 Electrical connections .......................................................................................... 14