EN

page 5

INSTALLER SECTION

code 10799

image 1

WARNING: check very carefully if the “ground connection” of the machine, is

properly sized and fully effi

cient, and that not too many units are connected on

it. An undersized or poor “ground connection” might lead to corrosion and/or

pitting effect on the stainless steel plates, even to perforation.

On the back of the appliance there is a terminal marked with the symbol , which

is provided for equipotential connection between different appliances (see electrical

safety standards).

Feed cable: the retailer - importer - installer must ensure that the feed cable

complies with the cable insulation category of the workplace, in conformity with

current Technical Standards.

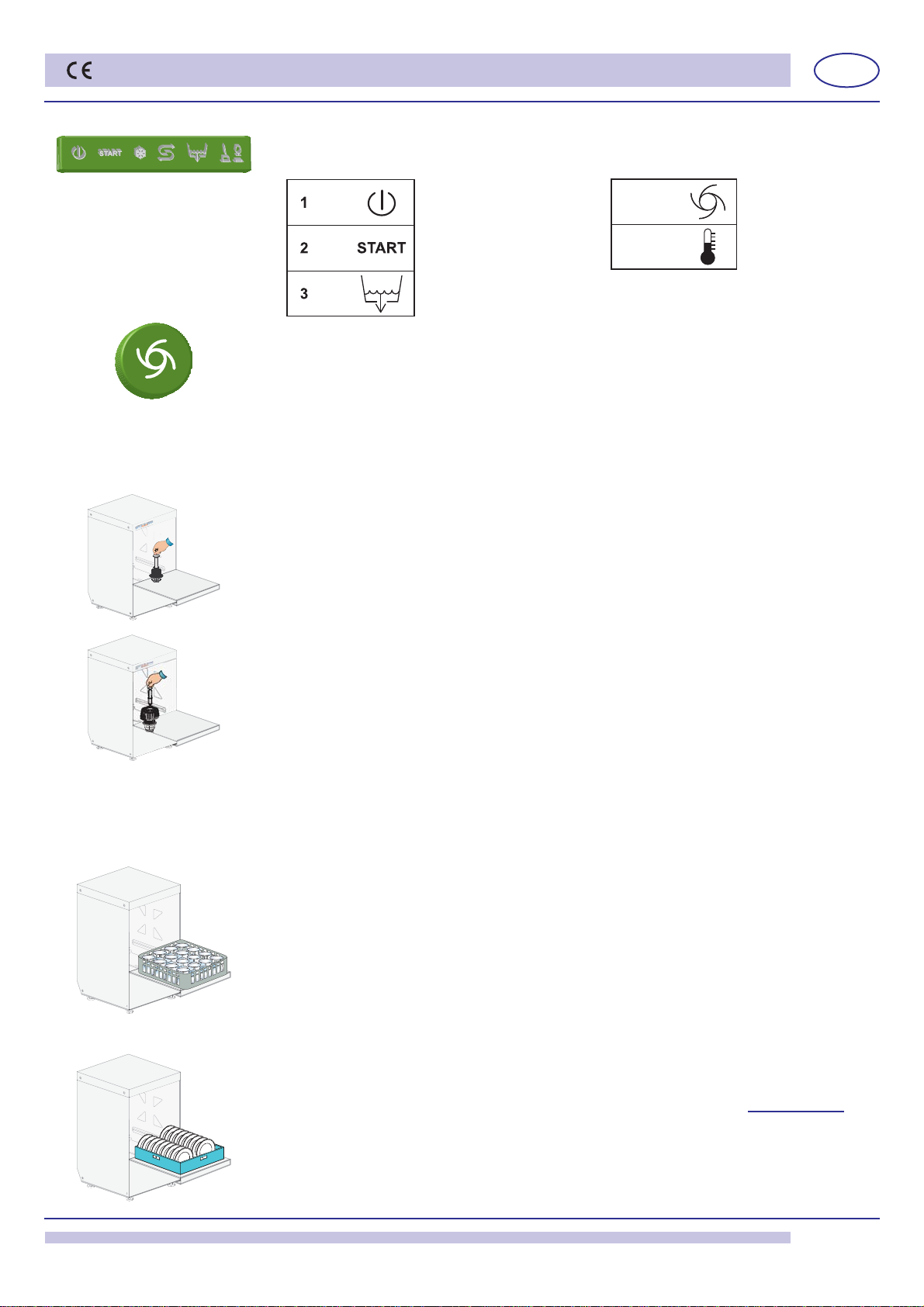

1.4 Temperature adjustment

If necessary, the water temperature of the wash and rinse cycles can be adjusted by means

of the fi ne-adjustment screws on the respective thermostats.

The recommended temperatures are 55°C for the wash cycle (tub) and 85 - 90°C for the

rinse cycle (boiler).

1.5 Rinse aid dispenser operation

Operation: It utilizes the difference in combined pressure caused by turning the washing

pump on and off, and the rinse pressure.

Water connection:

1) Connect the dispenser tube fi tting A to the pump, by means of the rubber tube installed

in the appliance (pump pressure).

2) Connect the small black rubber tube by the brass delivery fi tting B to the connection in

the boiler (injector).

3) Make sure that the green product suction tube is inserted on the special fi tting C and that

the small fi lter and the ballast are inserted in the rinse aid tub.

Priming: To prime the dispenser, turn on the appliance and carry out several complete

wash cycles.

Adjustment: With each rinse cycle, the dispenser draws an amount of rinse aid, adjustable

from 0 to 4 cc, equivalent to a length of 0 to 30 cm drawn into the suction tube.

In order to regulate the dispenser to the minimum amount, turn the adjustment screw D

completely clockwise. For the maximum amount, turn the screw anticlockwise about 20

complete turns.

For the correct amount of rinse aid, see the paragraph 5.3 Use of rinse aid.

Note: for each turn of the screw the amount of the product drawn into the tube varies by 1.6

cm, equivalent to 0.2 cc/turn (about 0.21g/turn with a concentration of 1.05 g/cm³ of rinse

aid). The rinse aid cannot function properly if the difference in level between the bottom of

the machine and the container exceeds 80 cm.

THE DISPENSERS ARE PRE-SET TO A 5 CM OF TUBE (0,65 gr.) INTAKE OF PRODUCT

FOLLOWING A TEST PHASE SYSTEM CHECK. THIS MEASUREMENT SHOULD BE

ADJUSTED ACCORDING TO THE TYPE OF RINSE AID USED AND WATER HARDNESS.

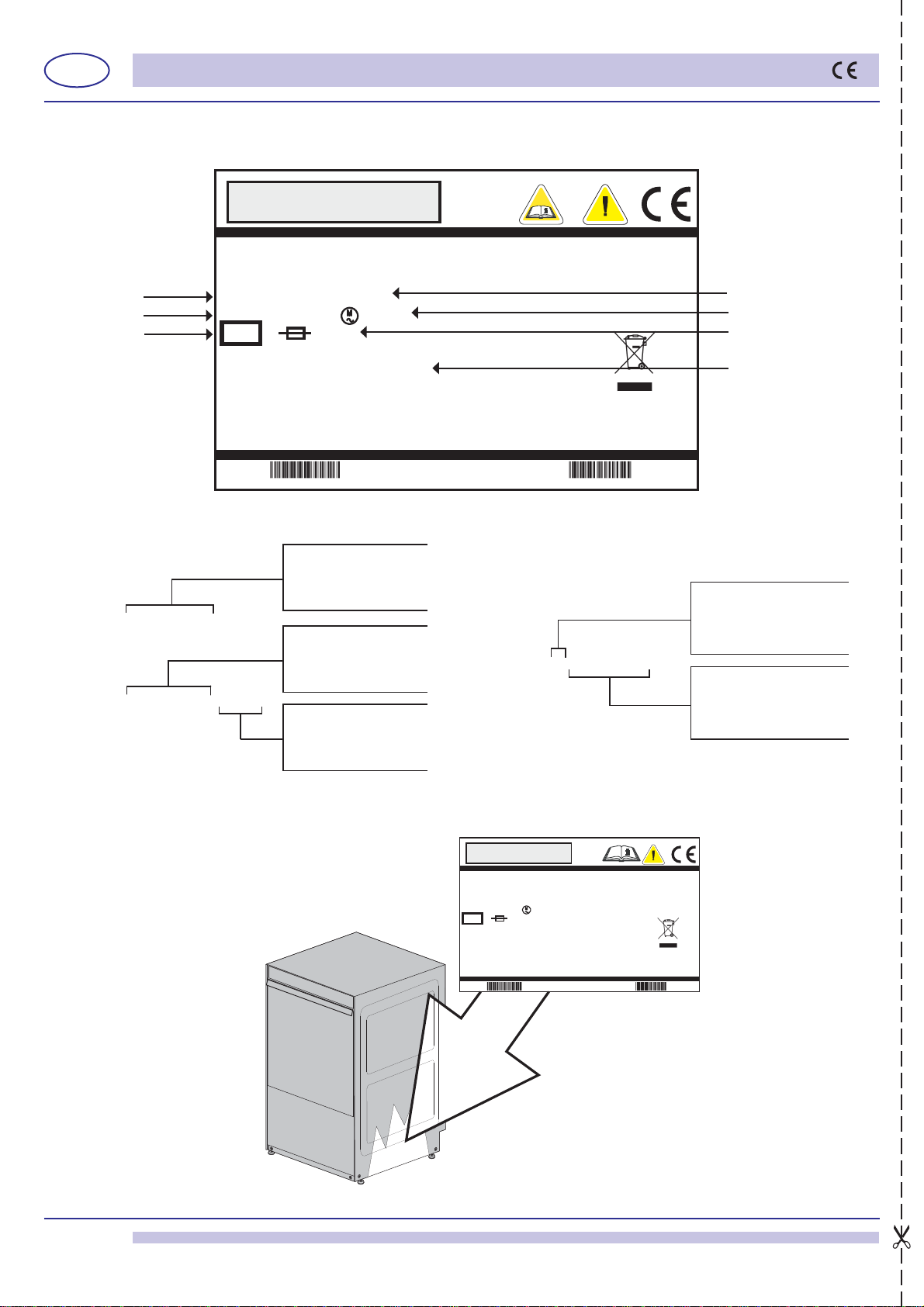

2. 2. DETERGENT DISPENSER RETROFIT

2.1 Electrical connection

Follow the wiring diagram attached to the machine.

2.2 Water connection

a) A Ø 12 hole must be made on the back of the appliance.

In some appliances the hole has already been made and is closed with a plastic cap.

Remove the cap from the hole and fi t the delivery connection.

b) Otherwise, drill one of the same diameter as the injector on the back part of the tub (see

image 3). This operation must be carried out by the Technical Service.

The hole must be made above the water level.

Important: make the hole in a position distant from the overfl ow tube, so that detergent

does not fl ow out immediately. Fix the dispenser in a vertical position with tube connectors

turned downwards, making sure not to place it on energized components.

Clean the inside of the machine from any drilling residual.

!

!

image 2

15185

Ø 10