8

OPERATING INSTRUCTIONS

Power-Up & Pre-Heat

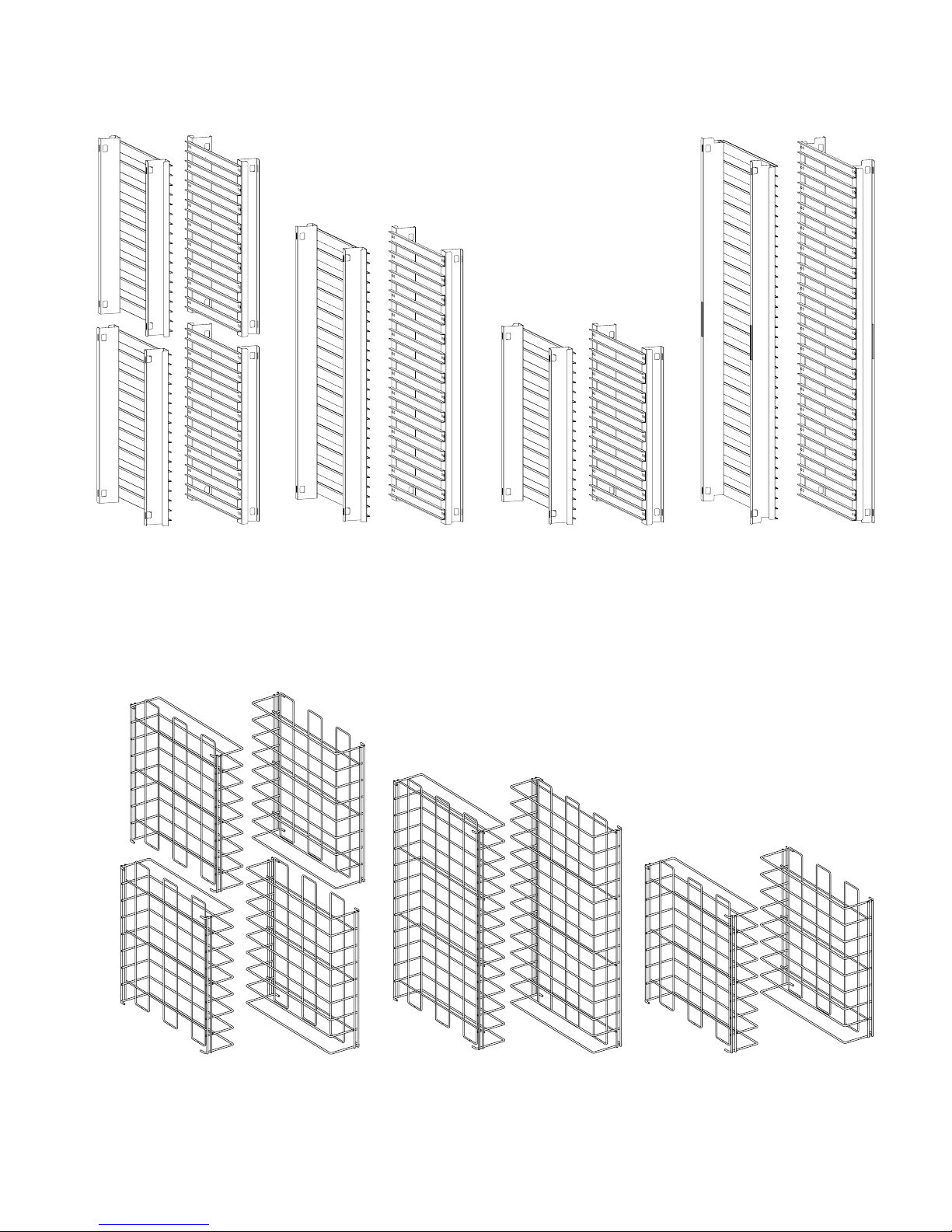

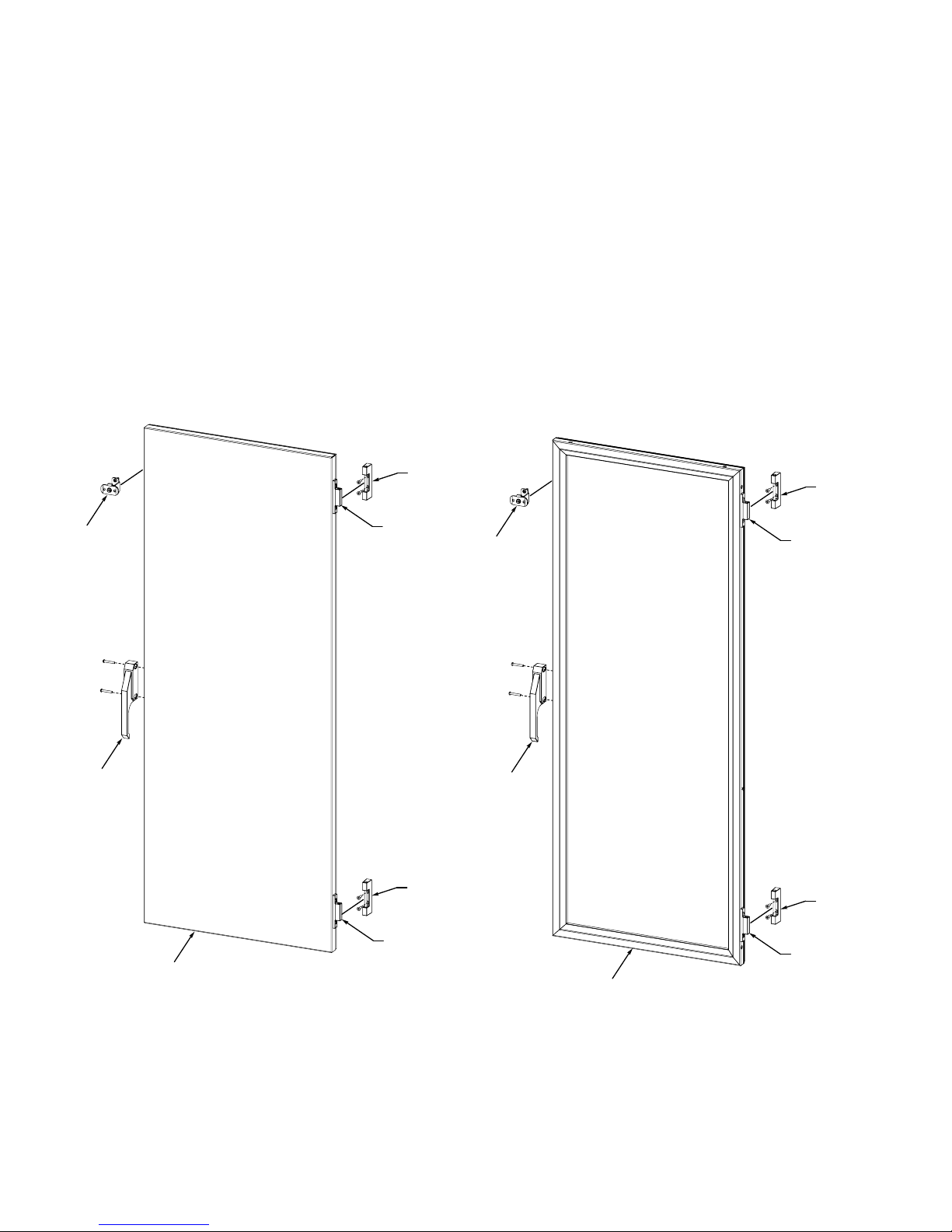

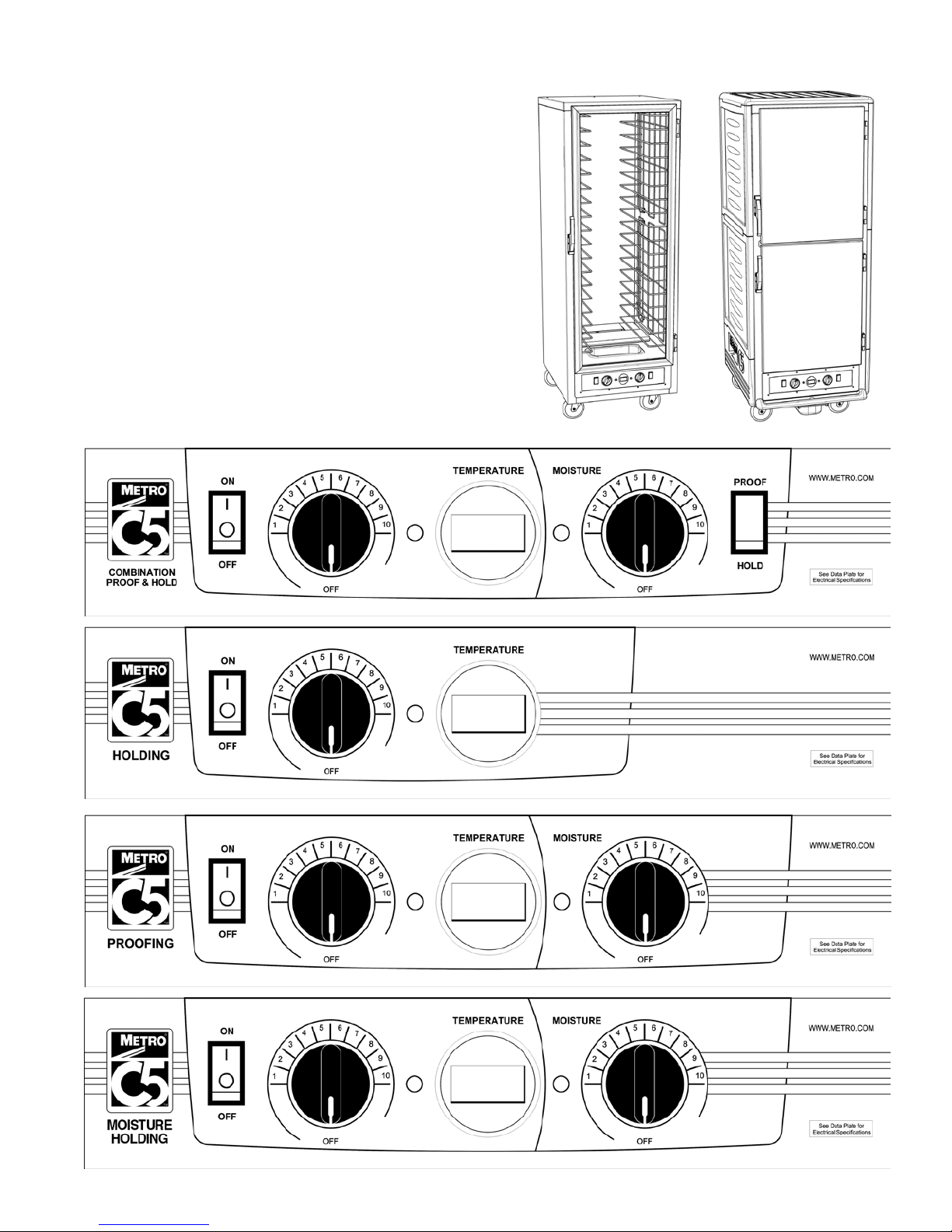

YOUR C5 1 SERIES OR 3 SERIES CABINET MAY BE EQUIPPED WITH SEVERAL DIFFERENT MODULES:

C5 1 SERIES C5 3 SERIES

COMBINATION PROOF & HOLD MODULE COMBINATION PROOF & HOLD MODULE

HOLDING MODULE HOLDING MODULE

PROOFING MODULE MOISTURE HOLDING MODULE

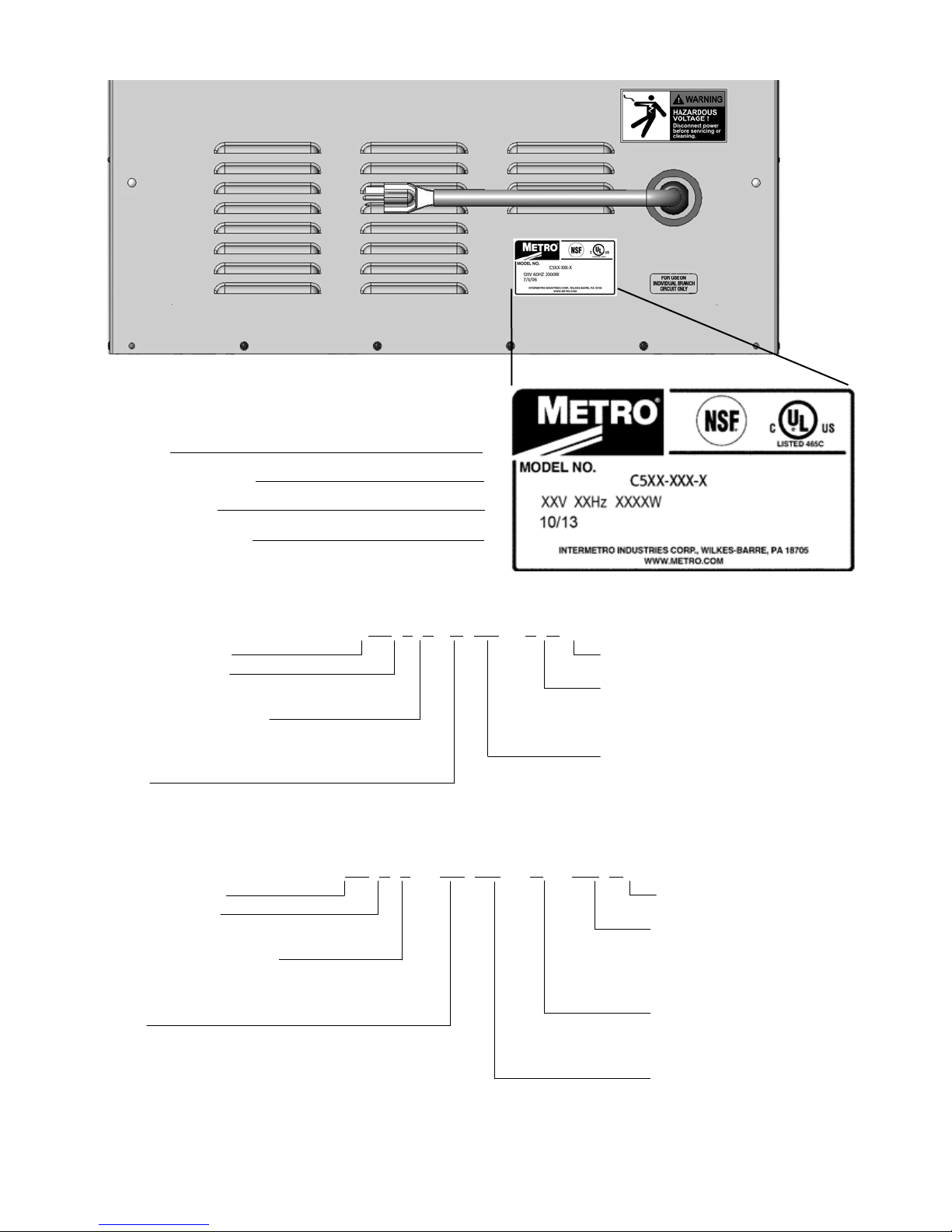

A. Refer to the data plate located near the power cord for the electrical specifications of cabinet as shown on page 3.

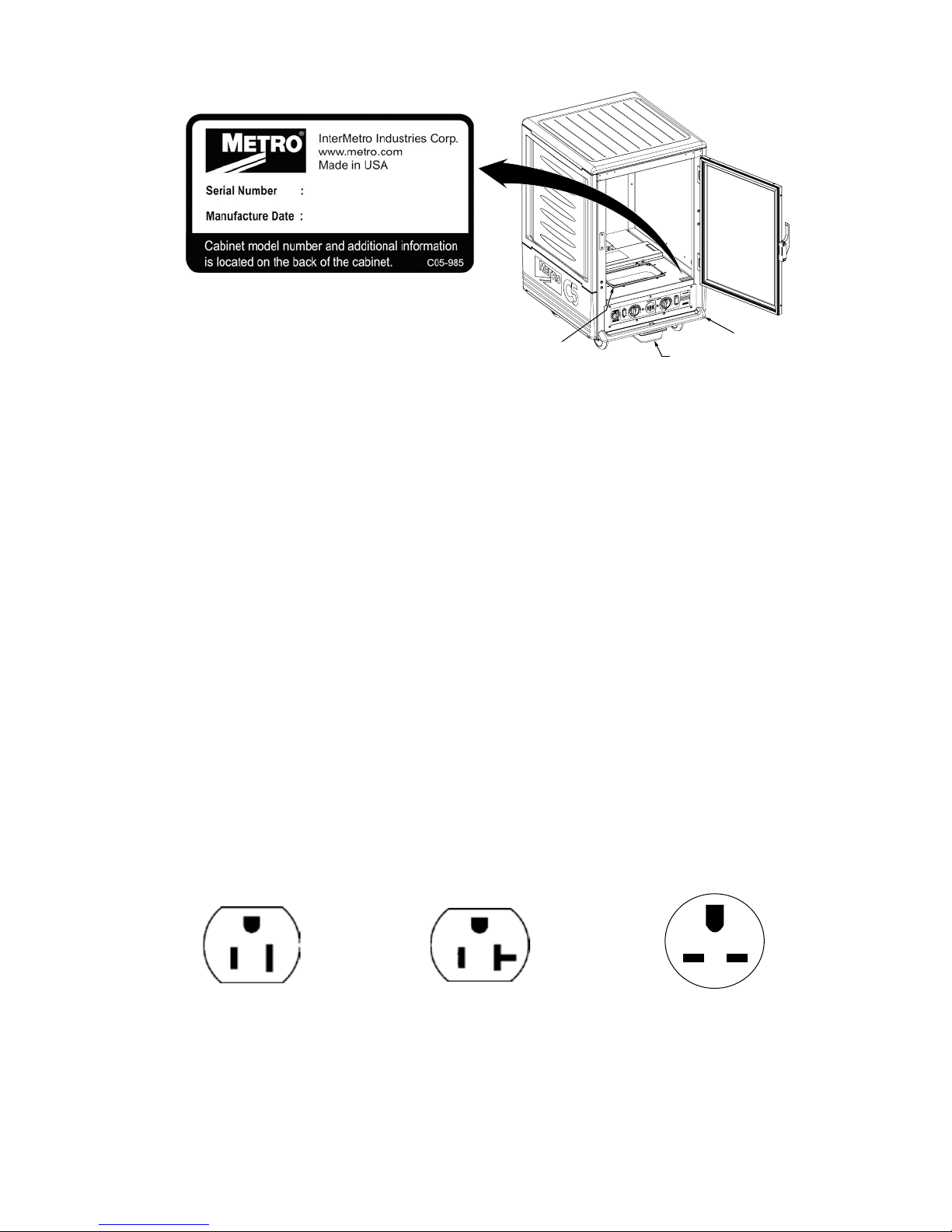

• With the the POWER switch OFF, plug the cord into the appropriate rated, grounded receptacle.

• Cabinets rated at 120V 1440W must be plugged into either a 15 amp or 20 amp 125VAC receptacle.

• Cabinets rated at 120V 2000W must be plugged into a 20 amp 125VAC receptacle.

• Cabinets rated at 220-240V must be plugged into a 15 amp 250VAC receptacle.

B. With POWER switch OFF, plug into a grounded receptacle.

C. Fill the stainless steel water pan to 1/2" from the top with clean HOT tap water for Proofing or if moisture is desired

for Holding. Check water level every 3 hours (2 hours when Proofing) and refill with clean HOT tap water as

necessary. Water pan does not have to be filled for Holding. Proofing and Moisture Holding Module require water

pan to be filled if moisture control is turned on.

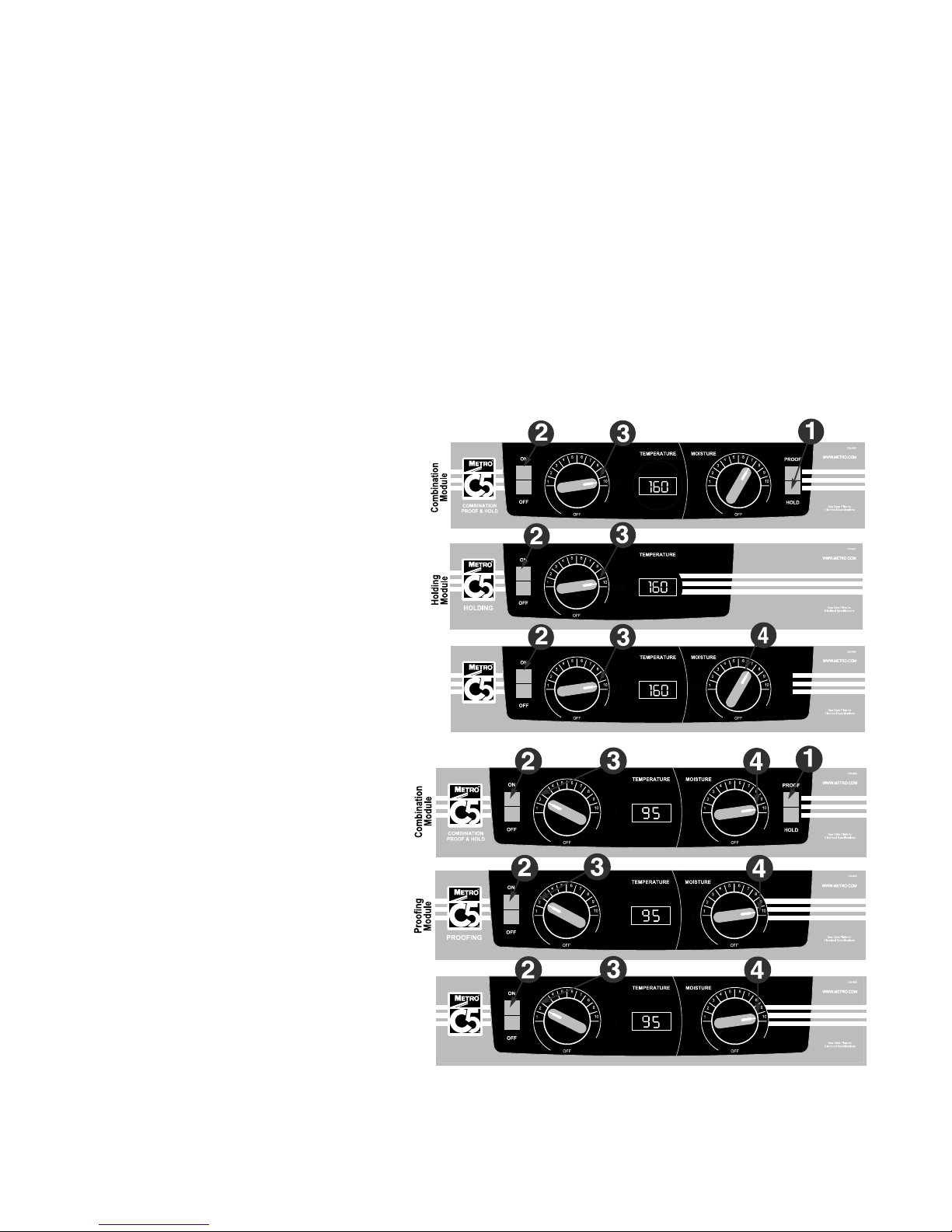

HOLDING INSTRUCTIONS (Combo, Holding & Moisture Holding)

1. Set Combination Module switch to HOLD.

2. Set POWER switch to the ON position.

3. Set TEMPERATURE control to 10.

4. On Moisture Holding only: Set MOISTURE

control to 10.

5. Pre-heat cabinet until desired temperature

is reached (typical heat-up time from 72°F (22°C)

ambient to 160°F (71°C) is approximately

45 minutes).

6. Re-set TEMPERATURE control and adjust as

necessary to reach the desired temperature

(setting 6-8 typical for 150°F (66°C) to 160°F

(71°C)). Power indicator light will turn on

and off as the heat thermostat cycles.

7. On Moisture Holding only: Adjust MOISTURE

control to desired level (10 being highest level,

1 lowest level, OFF being no heat to the water).

The indicator lights will turn on and off as the

heat and moisture thermostats cycle.

PROOFING INSTRUCTIONS (Combo & Proofing)

1. Set Combination Module switch to PROOF.

2. Set POWER switch to the ON position.

3. Set TEMPERATURE control to 2.

4. Set MOISTURE control to 10.

5. Pre-heat cabinet until desired temperature

and humidity is reached (typical heat-up time

from 72°F (22°C) ambient to 95°F (35°C) and

95% relative humidity is approximately

30 minutes).

6. Adjust settings as necessary to reach the

desired temperature and humidity levels.

Power indicator lights will turn on and off

as the heat and moisture thermostats cycle.

7. Adjust MOISTURE control to desired level

(10 being highest level, 1 lowest level, OFF

being no heat to the water). The indicator

lights will turn on and off as the heat and

moisture thermostats cycle.

When the power switch is on, the blower is always energized, circulating air, and the digital thermometer is always

displaying the cabinet temperature. When the thermostat senses heat is required, the appropriate indicator will light

and the heater element will begin to produce heat.

• At the end of the operating day, it is not necessary to disrupt the temperature setting to turn the cabinet off. By

switching the power switch off, the cabinet is no longer operating. When resuming operations, switch the power

on and the cabinet will attain the previous temperature and moisture levels.

Moisture Holding

Module

MOISTURE

HOLDING

MOISTURE

HOLDING

Moisture Holding

Module

Figures Shown in °F