Metronix ARS 2100 SE User guide

Other manuals for ARS 2100 SE

1

This manual suits for next models

4

Table of contents

Other Metronix Servo Drive manuals

Metronix

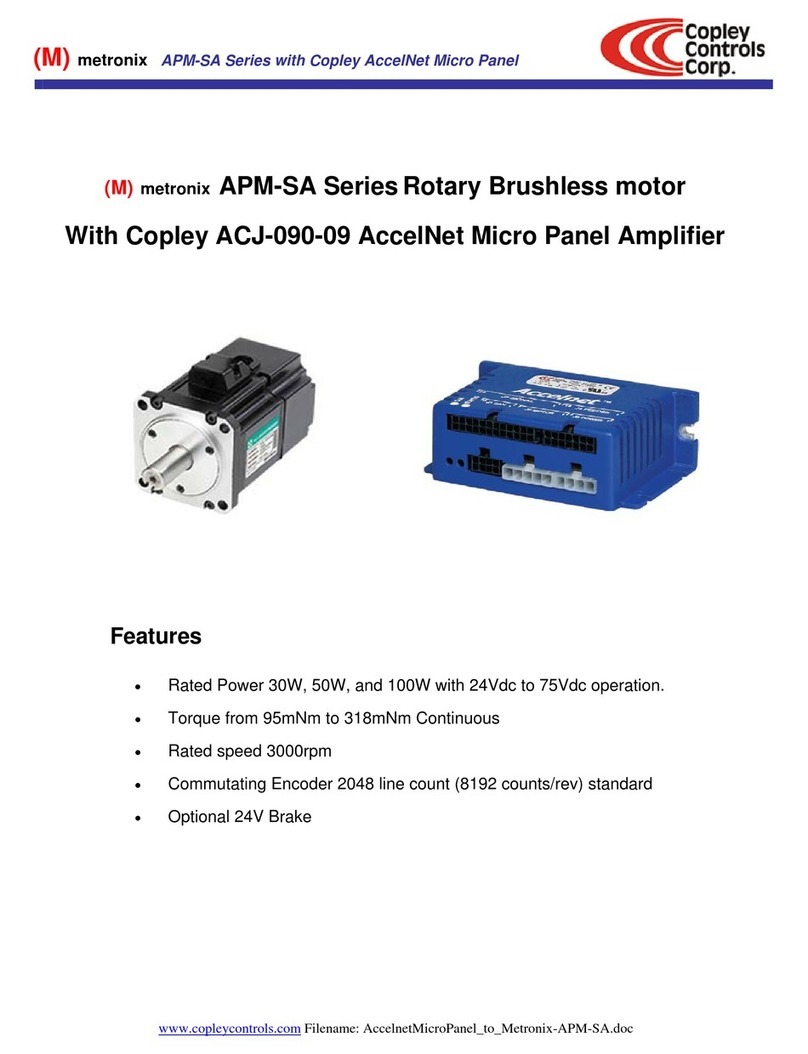

Metronix APM-SA Series User manual

Metronix

Metronix smartServo BL 4000-D Series User manual

Metronix

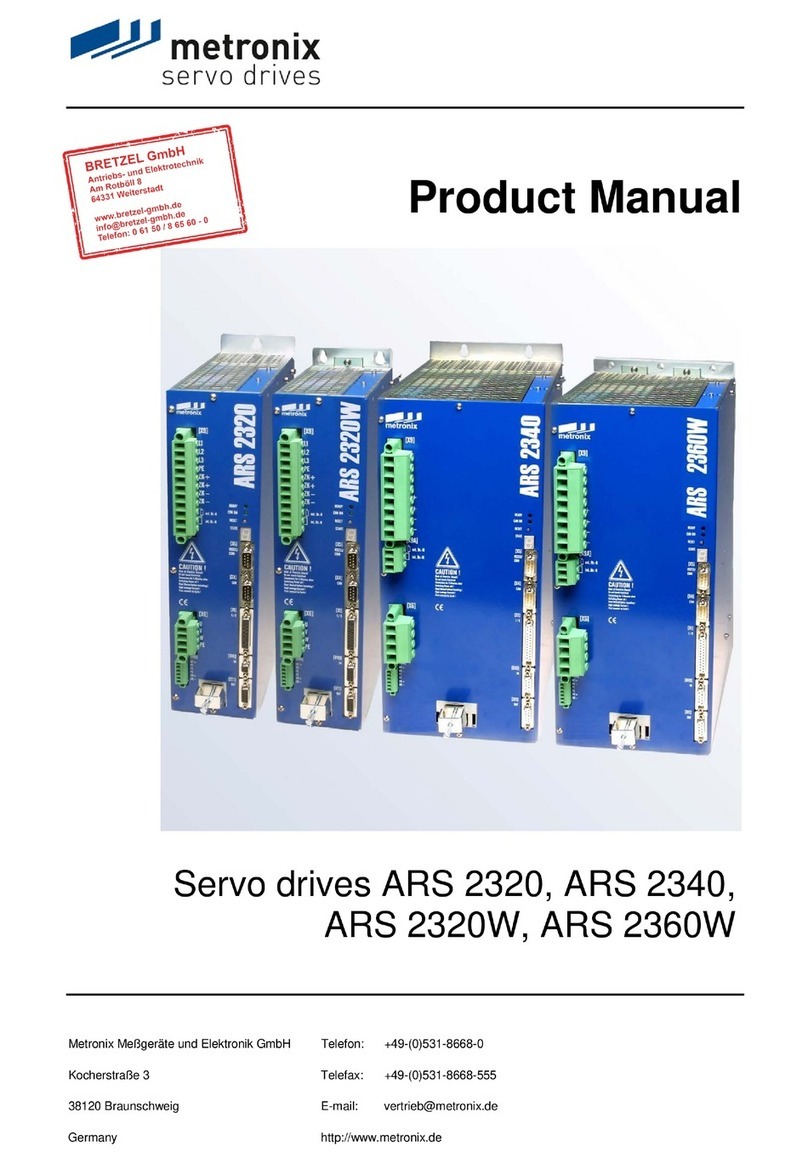

Metronix ARS 2320 FS User manual

Metronix

Metronix smartServo BL 4000-C Series User manual

Metronix

Metronix ARS 2100 SE User manual

Metronix

Metronix smartServo BL 4000-C Series User manual

Metronix

Metronix DIS-2 48/10 FB FS STO User manual

Metronix

Metronix smartServo BL 4000-C Series User manual

Metronix

Metronix DIS-2 310/2 FB FS STO User manual

Metronix

Metronix DIS-2 310/2 FB FS STO User manual

Popular Servo Drive manuals by other brands

Electro-Craft

Electro-Craft SCA-SE-30-06 user manual

Oriental motor

Oriental motor CSD2120-T Connection and Operation

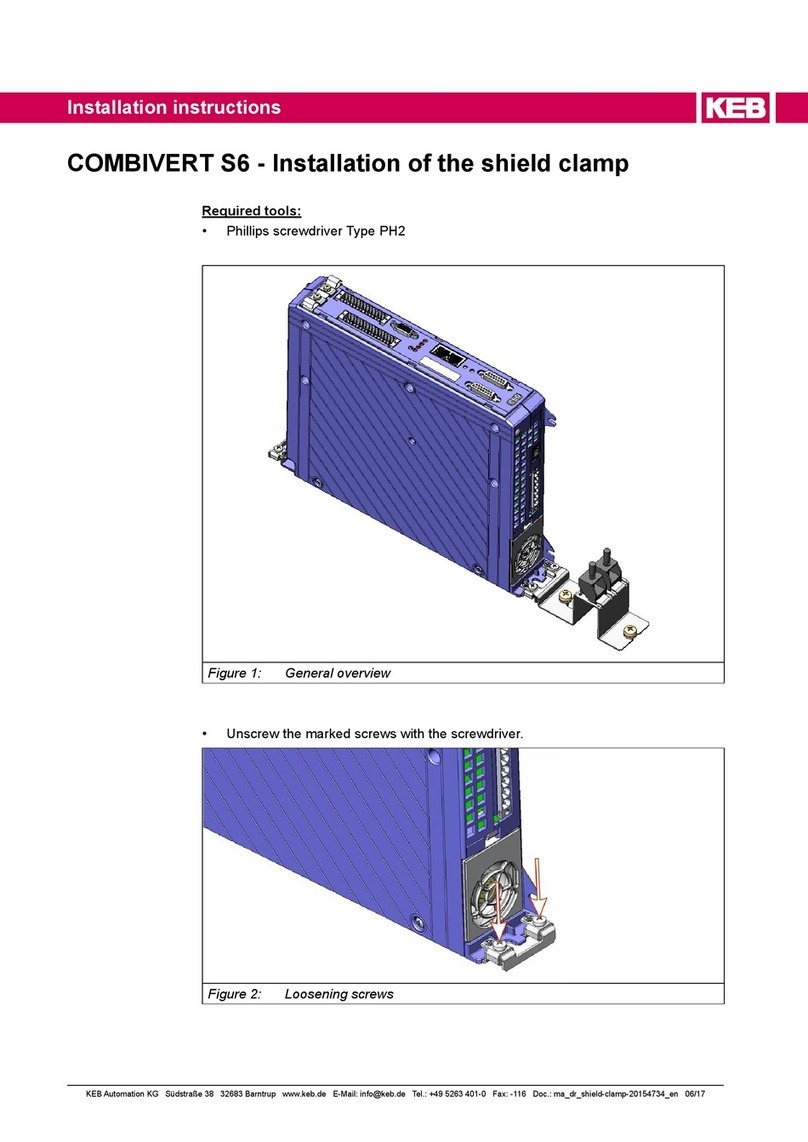

KEBCO

KEBCO COMBIVERT S6 Series installation instructions

LS ELECTRIC

LS ELECTRIC iX7NH Series quick start guide

Omron

Omron G manual

Nidec

Nidec Control Techniques Digitax-SF Series instruction manual