Metronix DIS-2 310/2 FB FS STO User manual

Metronix Meßgeräte und Elektronik GmbH Phone: +49-(0)531-8668-0

Kocherstraße 3 Telefax: +49-(0)531-8668-555

38120 Braunschweig E-Mail: [email protected]

Germany http://www.metronix.de

Product Manual

Servo drive DIS-2 310/2 FB FS STO

Page 2

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

Translation of the original instructions

Copyrights

2018 Metronix Meßgeräte und Elektronik GmbH. All rights reserved.

The information and data in this document have been composed to the best of our knowledge.

However, deviations between the document and the product cannot be excluded entirely. For the

devices and the corresponding software in the version handed out to the customer, Metronix

guarantees the contractual use in accordance with the user documentation. In the case of serious

deviations from the user documentation, Metronix has the right and the obligation to repair, unless it

would involve an unreasonable effort. A possible liability does not include deficiencies caused by

deviations from the operating conditions intended for the device and described in the user

documentation.

Metronix does not guarantee that the products meet the buyer’s demands and purposes or that they

work together with other products selected by the buyer. Metronix does not assume any liability for

damages resulting from the combined use of its products with other products or resulting from

improper handling of machines or systems.

Metronix Meßgeräte und Elektronik GmbH reserves the right to modify, amend, or improve the

document or the product without prior notification.

This document may, neither entirely nor in part, be reproduced, translated into any other natural or

machine-readable language nor transferred to electronic, mechanical, optical or any other kind of data

media, without expressive authorisation by the author.

Trademarks

Any product names in this document may be registered trademarks. The sole purpose of any

trademarks in this document is the identification of the corresponding products.

ServoCommander™ is a registered trademark of Metronix Meßgeräte und Elektronik GmbH.

Page 3

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

Revision Information

Author:

Metronix Meßgeräte und Elektronik GmbH

Manual title:

Product Manual “Servo drive DIS-2 310/2 FB FS STO”

File name:

P-HB_DIS-2_310_2_FB-FS-STO_4p0_EN.docx

Version 4.0

November 2018

Page 4

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

TABLE OF CONTENTS:

1GENERAL.........................................................................................................12

1.1 Documentation........................................................................................12

1.2 Scope of supply......................................................................................13

2SAFETY NOTES FOR ELECTRICAL DRIVES AND CONTROLLERS............16

2.1 Used symbols .........................................................................................16

2.2 General notes..........................................................................................17

2.3 Danger resulting from misuse...............................................................19

2.4 Safety notes ............................................................................................20

2.4.1 General safety notes..................................................................20

2.4.2 Safety notes for assembly and maintenance.............................22

2.4.3 Protection against contact with electrical parts..........................24

2.4.4 Protection against electrical shock by means of protective

extra-low voltage (PELV) ...........................................................25

2.4.5 Protection against dangerous movements.................................26

2.4.6 Protection against contact with hot parts ...................................27

2.4.7 Protection during handling and assembly..................................28

3PRODUCT DESCRIPTION...............................................................................29

3.1 General ....................................................................................................29

3.1.1 Basic information .......................................................................29

3.1.2 Area of application and intended use ........................................29

3.1.3 Performance characteristics of the DIS-2 310/2 FB FS STO.....30

3.2 Power supply ..........................................................................................32

3.2.1 Single-phase AC power supply..................................................32

3.2.2 Intermediate circuit link, DC supply............................................32

3.2.3 Mains fuse protection.................................................................32

3.3 Brake chopper ........................................................................................32

3.4 Communication interfaces.....................................................................33

3.4.1 RS232 interface.........................................................................33

3.4.2 CAN bus ....................................................................................33

3.4.3 PROFIBUS ................................................................................33

3.4.4 EtherCAT...................................................................................33

3.4.5 I/O functions and device control.................................................34

4TECHNICAL DATA...........................................................................................35

4.1 Ambient conditions and qualification...................................................35

4.2 Supply [X1]..............................................................................................36

Page 5

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

4.3 Motor connection [X6]............................................................................36

4.4 Angle encoder connector [X2]...............................................................37

4.5 Communication interfaces.....................................................................40

4.5.1 RS232 [X5] ................................................................................40

4.5.2 I/O interface [X1]........................................................................40

4.5.3 Incremental encoder input and output [X1]................................42

4.6 STO interface [X40] ................................................................................43

4.7 Fieldbus interfaces.................................................................................44

4.7.1 CAN-Bus [X401] / [402]..............................................................44

4.7.2 PROFIBUS [X401] / [402]..........................................................44

4.7.3 EtherCAT [X401] / [402].............................................................44

5FUNCTION OVERVIEW ...................................................................................45

5.1 Motors......................................................................................................45

5.1.1 Synchronous servomotors.........................................................45

5.2 Current and speed control.....................................................................45

5.3 Positioning mode....................................................................................48

5.3.1 Homing ......................................................................................49

5.3.2 Relative positioning....................................................................50

5.3.3 Absolute positioning...................................................................50

5.3.4 Motion profile generator.............................................................50

5.3.5 Positioning sequences...............................................................51

5.3.6 Software limit switches...............................................................52

5.3.7 Brake management ...................................................................52

5.4 Synchronisation, electronic gear unit...................................................52

5.4.1 Pulse-direction interface ............................................................52

5.5 Use of digital and analogue inputs and outputs..................................52

5.6 Jogging and teaching.............................................................................52

6FUNCTIONAL SAFETY TECHNOLOGY..........................................................53

6.1 General, intended use............................................................................53

6.2Integrated "Safe Torque Off (STO)" function .......................................54

6.2.1 General information concerning the STO function.....................54

6.2.2 Description of the STO safety function ......................................55

6.2.3 Control inputs STO1, STO2 [X40]..............................................57

6.2.4 Feedback contacts REL1, REL2 [X40] ......................................58

6.2.5 Auxiliary supply +24V, GND [X40] .............................................58

6.3 Functionalities in the DIS-2 310/2 FB FS STO basic device................59

Page 6

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

6.4 Time behaviour.......................................................................................60

6.4.1 STO basic time behaviour..........................................................60

6.4.2 Time behaviour for activating STO during an operation with

restart.........................................................................................61

6.4.3 Time behaviour for activating SS1 during operation

with restart .................................................................................63

6.5 Circuit examples.....................................................................................65

6.5.1 "Safe Torque Off" (STO)............................................................65

6.5.2 Delays and safe torque switch-off (SS1, "Safe Stop 1") ............67

6.6 Parameterisation with the DIS-2 ServoCommanderTM.........................69

6.6.1 Servo drive type indication.........................................................69

6.6.2 Status indication of the state machine.......................................69

6.6.3 "Safety module - Status" window...............................................70

6.6.4 "Safety module –Parameters" window......................................72

6.7 Functional test, validation .....................................................................73

7MECHANICAL INSTALLATION .......................................................................75

7.1 Important notes.......................................................................................75

7.2 Position and alignment of the connectors...........................................75

7.2.1 Connectors on the main board ..................................................76

7.2.2 Connectors for the fieldbus interfaces and RS232 interface

(CANopen, PROFIBUS or EtherCAT)........................................76

7.3 Dimensions of the housing....................................................................77

7.4 Mounting .................................................................................................78

8ELECTRICAL INSTALLATION.........................................................................82

8.1Connection to power supply, control and motor.................................82

8.2 Connectors on the basic device DIS-2 310/2 FB FS STO....................85

8.2.1 Connection: Power supply and I/O [X1].....................................85

8.2.2 Connection: Motor [X6]..............................................................87

8.2.3 Connection: Angle encoder [X2]................................................87

8.2.4 Connection: Holding brake [X3].................................................89

8.2.5 Connection: Brake resistor [X300] .............................................90

8.2.6 Connection: Extension port [X8] ................................................91

8.2.7 Connection: Safe Torque Off (STO) [X40] and [X40A]..............93

8.3 Connectors field bus modules DIS-2 310/2 FB FS STO ......................95

8.3.1 Connection: Serial interface [X5] ...............................................95

8.3.2 Connection: CANopen [X401] and [X402] .................................97

8.3.3 Connection: PROFIBUS [X401] and [X402]...............................98

Page 7

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

8.3.4 Connection: EtherCAT [X401] and [X402] .................................99

8.4 Notes concerning the safe and EMC-compliant installation.............100

8.4.1 Explanations and terminology..................................................100

8.4.2 General information concerning EMC......................................100

8.4.3 EMC ranges: First and second environment............................101

8.4.4 EMC-compliant cabling............................................................101

9START-UP......................................................................................................102

9.1 General connection notes....................................................................102

9.2 Tools/material .......................................................................................102

9.3 Connecting the DIS-2 310/2 FB FS STO servo drive to the motor....102

9.4 Connecting the DIS-2 310/2 FB FS STO servo drive to the power

supply and to the control panel or control unit .................................103

9.5 Connecting the PC................................................................................103

9.6 Checking whether the system is ready for operation........................104

10 SERVICE FUNCTIONS AND ERROR MESSAGES.......................................105

10.1 Protection and service functions........................................................105

10.1.1 Overview..................................................................................105

10.1.2 Overcurrent and short-circuit monitoring..................................106

10.1.3 Monitoring of the intermediate circuit voltage ..........................106

10.1.4 Logic supply monitoring ...........................................................106

10.1.5 Monitoring of the heat sink/housing temperature.....................106

10.1.6 Motor monitoring......................................................................107

10.1.7 Monitoring of the motion sequence..........................................107

10.1.8 Additional internal monitoring functions...................................107

10.1.9 Monitoring of the STO functionality..........................................108

10.1.10 Operating hour meter...............................................................108

10.2 Error messages ....................................................................................109

Page 8

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

Table of Figures:

Figure 1: Type key........................................................................................................................29

Figure 2: Controller cascade block diagram ................................................................................47

Figure 3: Positioning control block diagram .................................................................................48

Figure 4: Motion profiles of the DIS-2 310/2 FB FS STO.............................................................51

Figure 5: Path program ................................................................................................................51

Figure 6: Mode of operation in the case of the DIS-2 310/2 FB FS STO.....................................55

Figure 7: Basic time behaviour during the activation and deactivation of the STO safety function60

Figure 8: Time behaviour when activating the safety function STO with restart..........................61

Figure 9: Time behaviour when activating the safety function SS1 (external switching)

with restart.....................................................................................................................63

Figure 10: Circuit example "Safe Torque Off" (STO).....................................................................65

Figure 11: Circuit example "Delays and safe torque switch-off" (SS1, "Safe Stop 1")...................67

Figure 12: Indication of the type of servo drive and extended status window................................69

Figure 13: General "Status" window and "Safety module

–Status" window with the state "Normal operation" .....................................................70

Figure 14: General "Status" window, "Safety module

–Status" window, and "Error messages / warnings" window with the state "Error"......71

Figure 15: General "Status" window and "Safety module

–Status" window with the state "Safe state reached"...................................................72

Figure 16: "Safety module –Parameters" window.........................................................................72

Figure 17: Arrangement of the connectors DIS-2 310/2 FB FS STO

–Top view of the device ...............................................................................................75

Figure 18: Dimensions of the housing............................................................................................77

Figure 19: Mounting example without STO –synchronous servo motor, mounting plate

with brake resistor.........................................................................................................78

Figure 20: Mounting example without STO –servo drive, mounting plate, motor .........................78

Figure 21: DIS-2 310/2 FB FS STO mounting example with STO

–synchronous servo motor, mounting plate with brake resistor and servo drive.........79

Figure 22: DIS-2-FB FS STO Example of a mounting plate universal...........................................80

Figure 23: DIS-2-FB FS STO Example of a realised mounting plate.............................................81

Figure 24: Connection to power supply, control and motor............................................................82

Figure 25: Connection and pin numbering [X1]..............................................................................85

Figure 26: Position and connection motor cable............................................................................87

Figure 27: Position and connection angle encoder........................................................................87

Page 9

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

Figure 28: Position and connection holding brake .........................................................................89

Figure 29: Position and connection brake resistor.........................................................................90

Figure 30: Position and connection technology module interface..................................................91

Figure 31: Position and connection STO signals [X40] and [X40A]...............................................93

Figure 32: Position and connection RS232 interface.....................................................................95

Figure 33: Position and connection CAN interface ........................................................................97

Figure 34: Position and connection PROFIBUS interface..............................................................98

Figure 35: Position and connection EtherCAT interface ................................................................99

Page 10

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

Table of Tables:

Table 1: Scope of supply DIS-2 310/2 FB FS STO CANopen....................................................13

Table 2: Scope of supply DIS-2 310/2 FB FS STO PROFIBUS .................................................13

Table 3: Scope of supply DIS-2 310/2 FB FS STO EtherCAT....................................................13

Table 4: Accessories DIS-2 310/2 FB FS STO...........................................................................14

Table 5: Technical data: Ambient conditions and qualification...................................................35

Table 6: Technical data: Dimensions and weight .......................................................................35

Table 7: Technical data: Performance data power supply [X1] ..................................................36

Table 8: Technical data: Motor connection specifications [X6]...................................................36

Table 9: Technical data: Motor temperature monitoring [X2]......................................................37

Table 10: Technical data: Resolver evaluation [X2]......................................................................37

Table 11: Technical data: Evaluation of analogue Hall sensor signals [X2] .................................38

Table 12: Evaluation of Six-Step-Sensors (Hall) and block commutation mode [X2]...................38

Table 13: Technical data: Evaluation of Incremental encoder [X2] ..............................................38

Table 14: Technical data: Evaluation of HIPERFACE® Encoders [X2]........................................39

Table 15: Technical data: RS232 [X5] ..........................................................................................40

Table 16: Technical data: Digital inputs and outputs [X1].............................................................40

Table 17: Technical data: Analogue inputs and outputs [X1]........................................................41

Table 18: Technical data: Incremental encoder input [X1] (DIN4, DIN5, DIN6): ..........................42

Table 19: Technical data: Incremental encoder output [X1] (DOUT1, DOUT2): ..........................42

Table 20: Technical data: Control ports [X40] (STO1, STO2):.....................................................43

Table 21: Technical data: Feedback contact [X40] (REL1, REL2): ..............................................43

Table 22: Technical data: CAN-Bus [X401] / [X402].....................................................................44

Table 23: Technical data: PROFIBUS [X401] / [X402] .................................................................44

Table 24: Technical data: EtherCAT [X401] / [X402]....................................................................44

Table 25: Stop categories.............................................................................................................54

Table 26: STO signal plausibility table..........................................................................................56

Table 27: Time data concerning Figure 7.....................................................................................60

Table 28: Time data concerning Figure 8.....................................................................................62

Table 29: Time data concerning Figure 9.....................................................................................64

Table 30: Questions for a validation in accordance with EN ISO 13849-1 and -2 (example).......73

Table 31: Pin assignment [X1]......................................................................................................86

Table 32: Pin assignment [X6]......................................................................................................87

Page 11

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

Table 33: Pin assignment [X2]......................................................................................................88

Table 34: Pin assignment [X3]......................................................................................................89

Table 35: Pin assignment [X300]..................................................................................................90

Table 36: Pin assignment [X8]......................................................................................................91

Table 37: Pin assignment [X40]....................................................................................................94

Table 38: Pin assignment [X40A]..................................................................................................94

Table 39: Pin assignment [X5]......................................................................................................95

Table 40: Pin assignment to set up an RS232 adapter cable for connection to

a PC/notebook ..............................................................................................................96

Table 41: Pin assignment [X401] and [X402]................................................................................97

Table 42: Pin assignment [X401] and [X402]................................................................................98

Table 43: Pin assignment [X401] and [X402]................................................................................99

Table 44: Error overview.............................................................................................................110

General Page 12

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

1 General

1.1 Documentation

This manual serves the purpose of a safe use of the DIS-2 310/2 FB FS STO servo drive. It contains

safety notes, which must be complied with.

Further information can be found in the following manuals of the DIS-2 product range:

Mounting Instructions “Servo drive DIS-2 310/2 FB FS STO”: Instructions on the installation of

the DIS-2 310/2 FB FS STO servo drive (English version).

CANopen Manual “Servo drive DIS-2”: Description of the implemented CANopen protocol as

per DSP402.

PROFIBUS Manual “Servo drive DIS-2”: Description of the implemented PROFIBUS-DP

protocol.

EtherCAT Manual “Servo drive DIS-2”: Description of the implemented EtherCAT protocol

(German version).

User Manual “DIS-2 48/10, DIS-2 48/10 IC, DIS-2 48/10 FB”: Description of the device

functionality and the software functionalities of the firmware including the RS232 communication.

Description of the parameterisation program DIS-2 ServoCommanderTM with instructions for the

commissioning of a DIS-2 series servo drive.

You can find all these documents on our homepage at the download area (http://www.metronix.de).

Furthermore, the manuals are part of the CD-ROM DIS-2 ServoCommander™.

Certificates and declarations of conformity for the products described in this manual can be found at

http://www.metronix.de.

The functions described in this product manual refer to the firmware version 3.4.

General Page 13

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

1.2 Scope of supply

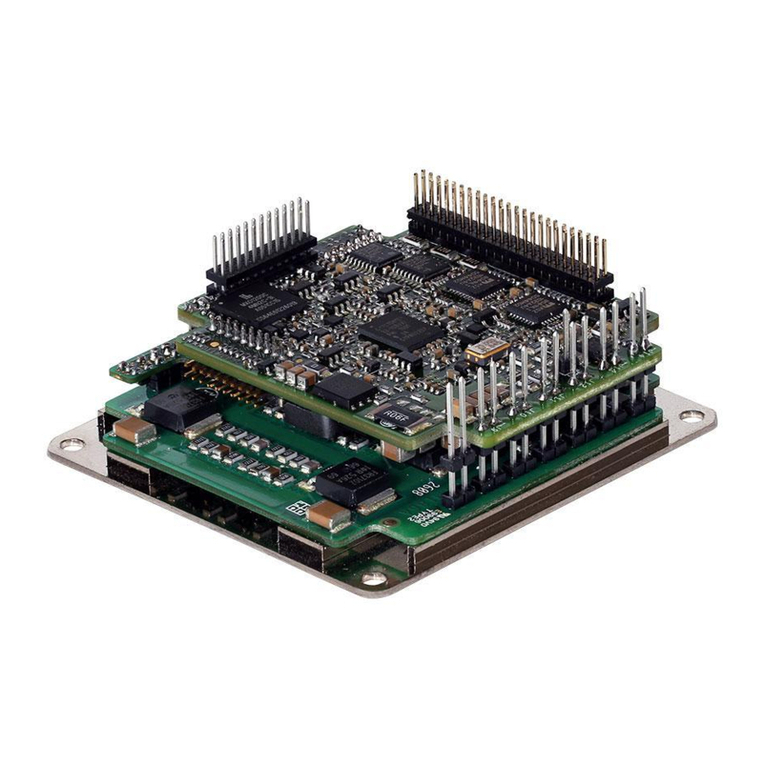

The DIS-2 310/2 FB FS STO servo drive is available in the following three versions. The corresponding

technology modules (CAN, PROFIBUS, EtherCAT) are factory-integrated and are not designed for an

exchange by the user.

Table 1: Scope of supply DIS-2 310/2 FB FS STO CANopen

1x

Servo drive DIS-2 310/2 FB FS STO CANopen

Metronix part number:

9019-3103-10

1x

STO connection cable pre-fabricated on both sides with the

device interface M12 (circular connector) for rear panel

installation

1x

Counterplug for the STO interface

Table 2: Scope of supply DIS-2 310/2 FB FS STO PROFIBUS

1x

Servo drive DIS-2 310/2 FB FS STO PROFIBUS

Metronix part number:

9019-3103-14

1x

STO connection cable pre-fabricated on both sides with the

device interface M12 (circular connector) for rear panel

installation

1x

Counterplug for the STO interface

Table 3: Scope of supply DIS-2 310/2 FB FS STO EtherCAT

1x

Servo drive DIS-2 310/2 FB FS STO EtherCAT

Metronix part number:

9019-3103-15

1x

STO connection cable pre-fabricated on both sides with the

device interface M12 (circular connector) for rear panel

installation

1x

Counterplug for the STO interface

General Page 14

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

Counterplugs, control panel, mains filter, communication cables, brake resistor and parameterisation

program are not part of the standard scope of supply. They can be ordered as accessories:

Table 4: Accessories DIS-2 310/2 FB FS STO

1x

Connector set for motor, encoder, holding brake:

Metronix part number:

9019-3120-02

Content:

1x

5-pole motor connector incl. crimp

contacts

1x

16-pole counterplug for angle

encoder, incl. crimp contacts

1x

2-pole counterplug for holding brake,

incl. crimp contacts

1x

Connector set for power supply and I/Os

1x 2-pole VARICON counterplug

(for DIS-2 48/10 FB FS STO)

1x 6-pole VARICON counterplug

(for DIS-2 310/2 FB FS STO)

2x 8-pole VARICON counterplug incl. sleeve frame,

sleeve housing and EMC cable gland

Metronix part number:

9019-3120-01

1x

Control panel DIS-2 310/2 FB FS STO

Metronix part number:

9019-0330-00

1x

Line filter Metronix END-230/4

Necessary to fulfil the EMC directive EN 61800-3,

conducted interference, 1st environment, category C1

Metronix part number:

9504-0005

1x

Line filter Epcos B84111-A-B110

Necessary to fulfil the EMC directive EN 61800-3,

conducted interference, 1st environment, category C2

Epcos order number:

B84111A0000B110

1x

RS232 connection cable for DIS-2 FB FS STO

Pre-fabricated connection cable for the servo drive

parameterisation, length approximately 150 cm, M8

circular connector for the connection to the servo

drive, 9-pole DSUB connector for the connection to the

COM-Port of the PC

Metronix part number:

9019-0221-00

General Page 15

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

1x

Brake resistor for DIS-2 310/2 FB FS STO

Plate resistor pre-fabricated, Metallux PLR 100.61.41,

100 10%, 30 W 100 W continuous power output,

dimensions 61 mm x 40,5 mm, height approx.

1,5 mm, in the area of the connecting cables height

approx. 4 mm, with strands l = 105 mm + connector by

JST (VHR-2N and contacts SVH-41T-P1.1)

Metronix part number:

9519-0002-00

1x

Parameterisation program DIS-2 ServoCommanderTM

Metronix part number:

9019-0900-00

Safety notes for electrical drives and controllers Page 16

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

2 Safety notes for electrical drives

and controllers

2.1 Used symbols

Information

Important information and notes.

Caution!

Nonobservance may result in severe property damages.

DANGER!

Nonobservance may result in property damages and in personal injuries.

Caution! Dangerous voltages.

The safety note indicates a possible perilous voltage.

Safety notes for electrical drives and controllers Page 17

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

2.2 General notes

In case of damage resulting from non-compliance with the safety notes in this manual, Metronix

Meßgeräte und Elektronik GmbH will not assume any liability.

Prior to the initial use you must read chapter 2Safety notes for electrical drives and

controllers and section 8.4 Notes concerning the safe and EMC-compliant installation

If the documentation in the language at hand is not understood accurately, please contact and inform

your supplier.

Sound and safe operation of the servo drive requires proper and professional transportation, storage,

assembly and installation as well as proper operation and maintenance.

Only trained and qualified personnel is authorised to handle electrical devices and systems:

TRAINED AND QUALIFIED PERSONNEL

in the sense of this product manual or the safety notes on the product itself are persons who are

sufficiently familiar with the project, the setup, assembly, commissioning and operation of the product

as well as all warnings and precautions as per the instructions in this manual and who are sufficiently

qualified in their field of expertise:

Education and instruction or authorisation to switch devices/systems on and off and to ground

them as per the standards of safety engineering and to efficiently label them as per the job

demands.

Education and instruction as per the standards of safety engineering regarding the maintenance

and use of adequate safety equipment.

First aid training.

The following notes must be read prior to the initial operation of the system to prevent personal injuries

and/or property damages:

These safety notes must be complied with at all times.

Do not try to install or commission the servo drive before carefully reading all safety notes

for electrical drives and controllers contained in this document. These safety instructions

and all other user notes must be read prior to any work with the servo drive.

In case you do not have any user notes for the servo drive, please contact your sales

representative. Immediately demand these documents to be sent to the person

responsible for the safe operation of the servo drive.

If you sell, rent and/or otherwise make this device available to others, these safety notes

must also be included.

Safety notes for electrical drives and controllers Page 18

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

The user must not open the servo drive for safety and warranty reasons.

Professional control process design is a prerequisite for sound functioning of the servo

drive!

DANGER!

Inappropriate handling of the servo drive and non-compliance with the warnings

as well as inappropriate intervention in the safety features may result in property

damage, personal injuries, electric shock or in extreme cases even death.

Safety notes for electrical drives and controllers Page 19

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

2.3 Danger resulting from misuse

DANGER!

High electrical voltages and high load currents!

Danger to life or serious personal injury from electrical shock!

DANGER!

High electrical voltage caused by wrong connections!

Danger to life or serious personal injury from electrical shock!

DANGER!

Surfaces of device housing may be hot!

Risk of injury! Risk of burning!

DANGER!

Dangerous movements!

Danger to life, serious personal injury or property damage due to unintentional

movements of the motors!

Safety notes for electrical drives and controllers Page 20

Product Manual “Servo drive DIS-2 310/2 FB FS STO“Version 4.0

2.4 Safety notes

2.4.1 General safety notes

The servo drive corresponds to IP54 degree of protection as well as pollution degree 2.

Make sure that the environment corresponds to this degree of protection and pollution

degree.

Only use replacement parts and accessories approved by the manufacturer.

The devices must be connected to the mains supply as per EN regulations and VDE

regulations, so that they can be cut off the mains supply by means of corresponding

separation devices (for example main switch, contactor, power switch).

The servo drive may be protected using an AC/DC sensitive 300 mA fault current

protection switch, type B (RCD = Residual Current protective Device).

Gold contacts or contacts with a high contact pressure should be used to switch the

control contacts.

Preventive interference rejection measures should be taken for control panels, such as

connecting contactors and relays using RC elements or diodes.

The safety rules and regulations of the country in which the device will be operated must

be complied with.

The environment conditions defined in the product documentation must be kept. Safety-

critical applications are not allowed, unless specifically approved by the manufacturer.

For notes on installation corresponding to EMC, please refer to section 8.4 Notes

concerning the safe and EMC-compliant installation. The compliance with the limits

required by national regulations is the responsibility of the manufacturer of the machine

or system.

The technical data and the connection and installation conditions for the servo drive are

to be found in this product manual and must be met.

DANGER!

The general setup and safety regulations for work on power installations (for example

DIN, VDE, EN, IEC or other national and international regulations) must be complied

with.

Non-compliance may result in death, personal injury or serious property damages.

Other manuals for DIS-2 310/2 FB FS STO

3

Table of contents

Other Metronix Servo Drive manuals

Metronix

Metronix DIS-2 48/10 FB FS STO User manual

Metronix

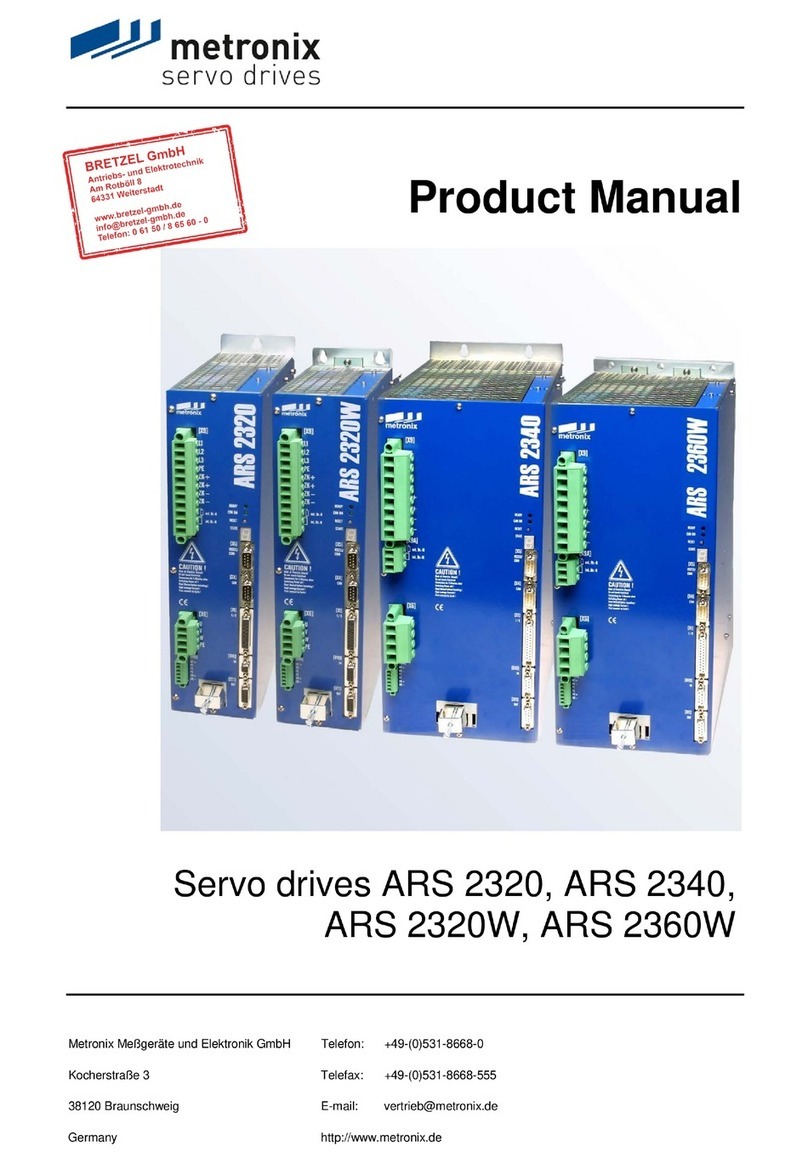

Metronix ARS 2320 User manual

Metronix

Metronix smartServo BL 4000-D Series User manual

Metronix

Metronix DIS-2 310/2 FB FS STO User manual

Metronix

Metronix ARS 2100 SE User manual

Metronix

Metronix APM-SA Series User manual

Metronix

Metronix smartServo BL 4000-C Series User manual

Metronix

Metronix DIS-2 48/10 FB FS STO User manual

Metronix

Metronix DIS-2 310/2 FB FS STO User manual

Metronix

Metronix smartServo BL 4000-C Series User manual