metso automation ND800PA Operating and maintenance manual

VALVE CONTROLLER

ND800PA

Rev. 1.0

Installation, Maintenance and

Operating Instructions

7 ND 72 en

4/2001

Table of Contents

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . 3

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Principle of operation . . . . . . . . . . . . . . . . . . . . 3

1.3 Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Technical specifications . . . . . . . . . . . . . . . . . . . 3

1.5 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . 5

2 MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Mounting on Metso Automation actuators

with VDI/VDE mounting face (S1) . . . . . . . . . 5

2.3 Mounting on Metso Automation actuators

with old mounting face (S2). . . . . . . . . . . . . . . 5

2.4 Mounting on linear actuators withMetso

Automation or IEC 60534 mounting face . . . 6

2.5 Piping of supply air. . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Electrical connections . . . . . . . . . . . . . . . . . . . . 7

3 USER INTERFACE . . . . . . . . . . . . . . . . . . . . 9

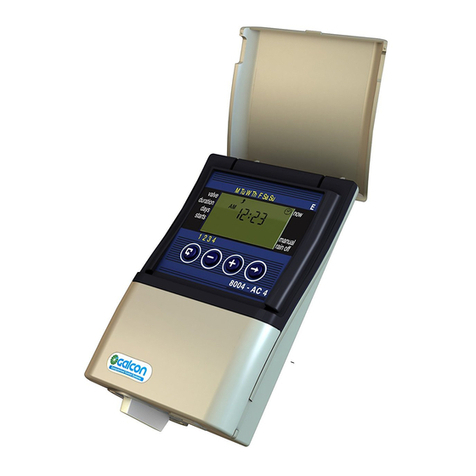

3.1 Keyboard and display . . . . . . . . . . . . . . . . . . . . 9

3.2 Keyboard functions . . . . . . . . . . . . . . . . . . . . . . 9

3.3 HW write protection . . . . . . . . . . . . . . . . . . . . 9

4 CONFIGURATION. . . . . . . . . . . . . . . . . . . 11

4.1 Zero and range . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Position control . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Control valve related settings. . . . . . . . . . . . . 12

5 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . 13

5.1 Prestage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Spool valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Circuit board pack . . . . . . . . . . . . . . . . . . . . . . 14

5.4 Position sensor. . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . 15

6 ERROR MESSAGES. . . . . . . . . . . . . . . . . . . 16

7 TROUBLE SHOOTING . . . . . . . . . . . . . . . 17

8 TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

9 ORDERING SPARE PARTS . . . . . . . . . . . . 17

10 ND800/K00 (WITH LIMIT SWITCHES) . 18

10.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.1.1 General description . . . . . . . . . 18

10.1.2 Markings . . . . . . . . . . . . . . . 18

10.1.3 Technical specifications . . . . . . . 18

10.1.4 Safety precautions . . . . . . . . . . 18

10.2 Installing ND800/K00 on a valve controller . 19

10.3 Electrical connections. . . . . . . . . . . . . . . . . . . . 19

10.4 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.5 Removal of the limit switch ND800/K00

for accessing the valve controller . . . . . . . . . . 19

10.6 Circuit diagrams . . . . . . . . . . . . . . . . . . . . . . . . 19

10.7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10.8 Ordering spare parts . . . . . . . . . . . . . . . . . . . . 19

11 DRAWINGS AND PARTS LISTS . . . . . . . 20

11.1 Exploded view and parts list . . . . . . . . . . . . . . 20

11.2 Mounting parts for B1C/B1J 6-20 actuators . 21

11.3 Mounting parts for B1C/B1J 25-50,

B1C 502 and B1J322 actuators. . . . . . . . . . . . 21

11.4 Mounting parts for Quadra-Powr®, ST,

SP and Valv-Powr®actuators. . . . . . . . . . . . . 22

11.5 Mounting parts for D/R linear actuators . . . . 23

11.6 Mounting parts for linear actuators

with IEC 60534 mounting face . . . . . . . . . . . . 24

11.7 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.7.1 Connection diagram for ND800/K05

and ND800/K06 . . . . . . . . . . . 25

11.7.2 Device gland receptacles . . . . . . 26

12 DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . 27

12.1 ND800/K00. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

13 TYPE CODING . . . . . . . . . . . . . . . . . . . . . . 29

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the valve controller

If you require additional assistance, please contact the manufacturer or manufacturer’s representative.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

2

1INTRODUCTION

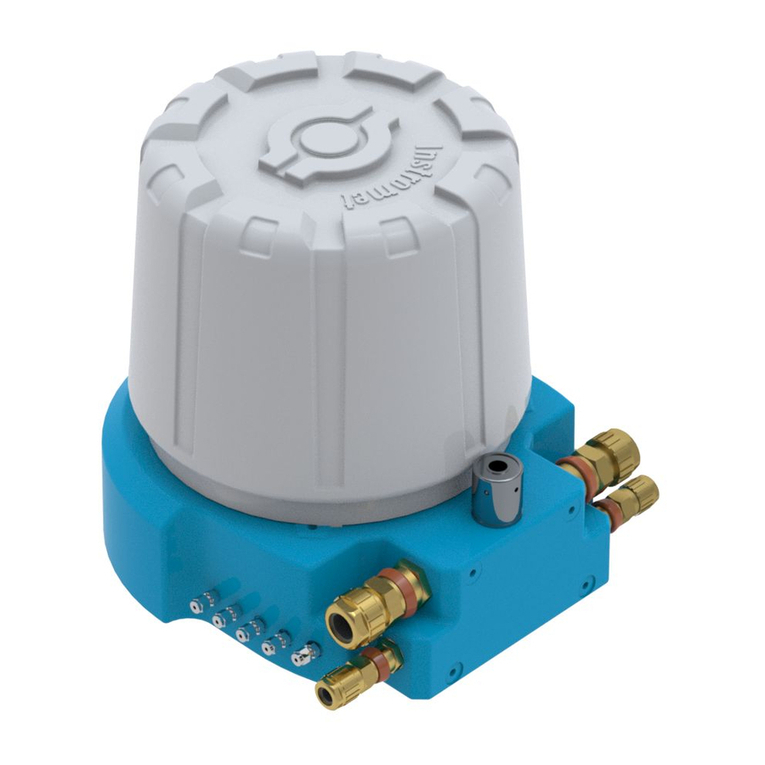

1.1 General

These instructions describe the digital Metso Automation

ND800PA valve position controller. The ND800PA can be used

with either cylinder or diaphragm type pneumatic actuators for

rotary or linear valves.

1.2 Principle of operation

The ND800PA is a fieldbus powered microcontroller-based valve

controller. The ND800PA configuration can be done either using

local push buttons, Simatic PDM (Process Device Manager) or some

other suitable Profibus PA configurator.

Using push buttons or PDM the configuration parameters can be

set according to the actuator and valve in question. Then auto-cali-

bration can be started via push buttons or PDM.A three-digit display

with text labels describes the operation.

In control service the microcontroller (µC) reads data from the input

signal (Profibus PA), position sensor (α) and pressure sensor (p). A

change in input signal will be detected by control algorithm inside

the µC. The microcontroller will change the pilot current to one of

the prestage (PR) coils. A prestage valve lowers the pilot pressure

at the end of the spool valve (SV). The spool moves in the direction

of low pressure to open the flow in to the top of the actuator

cylinder and out from the other side of the piston. The increasing

pressure difference over the piston moves the piston and rotates

the feedback shaft. A position sensor ( a) measures the rotation for

the µC. Using a control algorithm the microcontroller adjusts the

pilot current until a new position of the actuator proportional to the

input signal is reached. In the steady state, the spool valve (SV) and

prestage (PR) valves are closed.

1.3 Markings

The valve controller is equipped with an identification plate

sticker (Fig. 2). Identification plate markings from top to bottom are:

Type designation of the valve controller

Revision number

Enclosure class

Input signal

Maximum supply voltage

Supply pressure range

Operational temperature

Manufacturing series number

CE mark

Alternative markings on the optional plate (Fig. 3):

Filter-regulator (-K)

Operational temperature of regulator

Conduit entries (-L, -I or -NJ)

1.4 Technical specifications

General

The ND800PA valve controller is suitable for rotary and slid-

ing stem valves.

Actuator connection In accordance with VDI/VDE 3845

standard (S1) or as an option

compatibility with other NE-series (S2).

To replace an existing NE/NP positioner,

specify existing valve assembly

Action: Double or single acting

Turning angle: min 45°, max 95°

Environmental influence

Operational temp.: -20 - +85 °C (-4 - +185 °F)

option -40 - +85 °C (-40 - +185 °F)

Influence of temperature on valve position

< 0.05%/°C

Influence of vibration on valve position

< 1% under 2g 5-150 Hz and

1g 150-300 Hz

0.5g 300-2000 Hz

C

SV

C2

C1

PR

Profibus PA

14

3

2

P

α

µ

S

Fig. 1. Schematic diagram

Fig. 2. Identification plate

Fig. 3. Optional plate

3

Enclosure

Material: Anodized aluminium alloy

Protection class: IP65, NEMA 4 and 4X

Mechanical position

indicator: on cover

Pneumatics ports: 1/4 NPT

Electrical connection: Screw terminals internals for 2.5 mm2

and 1 PG 13.5 conduit entry

(1/2 NPT, M20x1.5 and R 1/2 as option,

see optional plate)

Weight: 2.1 kg (4.6 lbs)

Pneumatics

Supply pressure: 2.5-8 bar (36-115 psi)

Effect of supply

pressure: < 0.2 %/10 kPa (0.14%/psi)

Air quality: As defined by ISA S7.3 standard

Capacity: Max 30 Nm3/h (18 scfm)

at 4 bar (60 psi) supply

Consumption: 0.4 Nm3/h (0.24 scfm)

at 4 bar (60 psi) supply

Electronics

Power supply: Taken from bus

Bus voltage: 9 to 32 VDC

Reverse polarity protection permits

connection of the bus cables in any order

Power consumption: 23 mA

Electronic current limitation:

Imax ≤24 mA in case of fault

Performance with moderate constant load actuators

Hysteresis + dead band:< 1 %

Linearity error: < 2%

Local keypad functions

Calibration: Automatic / Manual

Control feedback: 0.0-3.0 (d and b)

Gain configuration: 0.1-3.0 (gain)

Mode Selection: Auto/Man/Off

Positioner Fail Action, PFA:

- close (default)

- open

Position Sensor Rotation, ROT:

- clockwise (default)

- counterclockwise

Dead Angle Compensation, A0:

acc. to valve (0 % default)

Valve Type Selection, TYP:

- rot (rotary valve), default

- lin (linear valve)

Setpoint Cut-off CLOSE, CLO:

- 0-100 % (2 % default)

Setpoint Cut-off OPEN, CHI:

- 0-100 % (100 % default)

Lower Limit Valve Position, RLO:

- 0-100 % (0 % default)

Upper Limit Valve Position, RHI:

- 0-100 % (100 % default)

Profibus slave address, ADR:

- 0-126, default 126

Electrical connections

Input signal: Profibus PA

according to IEC 61158-2

Approvals

Temp. ≤ +75 °C (+67 °F):

Cenelec EEx ia IIC T5/T6 (pending),

Temp. ≤+50 °C (+122 °F):

CSA Class I, Division 2, Groups A, B, C

and D (pending)

Sensors

Position sensor

linear range: 110 °

Actuator pressure

sensor linear range: 7 bar (100 psi) (differential pressure)

User interfaces

Local: 3 keys + LCD display

Simatic PDM functions:

Flow characterization: Linear, equal percentage, quick opening,

custom

Identification information:

HW/SW rev., serial numbers, actuator type etc.

Monitoring: Valve travel setpoint, actual travel,

actuator pressure and device temperature

Diagnostics: Travel deviation, travel duration, load factor,

operation time, valve/actuator travel counters,

failure information

Testing: Step response, hysteresis loop

Module calibration: Position sensor, pressure sensor, tempera-

ture measurement

Electromagnetic protection

Protection standards: EN50081-1 and EN50082-2

IEC 801-2 ESD, level 4,

IEC 801-3 Electro Magnetic Field, level 3

IEC 801-4 Fast Transients, level 4

CE marking

Electromagnetic

compatibility: 89/336/EEC

4

1.5 Safety precautions

CAUTION:

Do not exceed the permitted values!

Exceeding the permitted values marked on the valve control-

ler may cause damage to the controller and to equipment

attached to the controller and could lead to uncontrolled

pressure release in the worst case.

Damage to the equipment and personal injury may result.

CAUTION:

Do not remove or dismantle a pressurized controller!

Removing or dismantling a pressurized prestage, spool valve

or pressure sensor of an ND800PA leads to uncontrolled

pressure release. Always shut off the supply air and release

the pressure from the pipelines and equipment before re-

moving or dismantling the controller.

Otherwise personal injury and damage to equipment may result.

CAUTION:

During automatic or manual calibration the valve oper-

ates between open and closed positions. Make sure that

the operation does not endanger people or processes!

NOTE:

Avoid earthing a welding machine in close proximity to an

ND800PA valve controller.

Damage to the equipment may result.

NOTE:

The display may become unreadable in ambient temperatures

below -20 °C/-4 °F.

Warming up the display, for instance with thumb, may be

necessary in such conditions.

2MOUNTING

2.1 General

If the ND800PA is supplied with valve and actuator the tubes are

mounted and the ND800PA adjusted in accordance with the

customer’s specificatons. If the controller is ordered separately, the

mounting parts for the assembly must be ordered at the same time.

Sample order: (B1C13)-Z-ND826/S1.

The controller is equipped with both the new Metso Automation

mounting face, for connection according to VDI/VDE 3845 (S1),

and the old Metso Automation mounting face (S2).

Shaft alternatives for the controller for Metso Automation rotary

actuators are shown in Fig. 4.

For mounting parts for Metso Automation actuators, see Sections

10.2-10.6.

2.2 Mounting on Metso Automation actuators

with VDI/VDE mounting face (S1)

See Sections 10.2, 10.4

Run the actuator until the piston is in the top position

(spring return actuators in the position determined by the

spring).

Set the direction arrow in the direction of the valve closure

member and attach the draught piece (2) to the indicator

cover in the position shown in Fig. 4. Secure the screw of

the draught piece e.g. with Loctite and tighten it sufficiently.

Attach the bracket (1) to the ND800PA.

Attach the bracket (1) to the actuator. The shaft (40) of

the ND800PA must fit into the draught piece (2) shown

in Fig. 5. See also drawings in Section 10.2.

Note the differences in installation between the B1C, B1J and B1JA

actuators.

2.3 Mounting on Metso Automation actuators

with old mounting face (S2)

See Sections 10.2, 10.3

Run the actuator until the piston is in the top position (spring

return actuators in the position determined by the spring).

Set the direction arrow in the direction of the valve closure

member and attach the draught piece (2) to the indicator

cover in the position shown in Fig. 5. Secure the screw of

the draught piece e.g. with Loctite and tighten it sufficiently.

Attach the bracket (1) to the ND800PA.

Attach the bracket (1) to the actuator. The shaft (40) of

the ND800PA must fit into the draught piece (2) shown

in Fig. 5. See also drawings in Sections 10.2 and 10.3.

Note the differences in installation between the B1C, B1J and B1JA

actuators.

C2

S

C1

The mark on the shaft must

stay in this sector

Fig. 4. Mounting on Metso Automation actuator with

VDI/VDE mounting face

draught piece (2)

coupling

coupling

bracket (1)

bracket (1)

B1C, B1J

B1JA

Fig. 5. Mounting on Metso Automation actuator with old

mounting face

40

40

mark

Shaft alternatives

mark = yellow dot

S2

S1

5

2.4 Mounting on linear actuators withMetso

Automation or IEC 60534 mounting face

See Sections 10.5, 10.6.

Connect an airset directly to the actuator and position the

actuator at its mid-stroke position (see serial plate for

actuator stroke length).

Attach the feedback arm on to the controller input shaft.

Make sure the lettering on the feedback arm faces up,

toward the controller.

Attach the controller mounting bracket loosely on to the

slotted leg of the actuator. Make sure the marks on the

shaft and feedback arm operate in the quadrant shown.

Measure the distance from the centre of the feedback

lever shaft to the slot on the feedback lever and mark this

distance with a pencil or other marking instrument. Use

the dimensions given in Sections 10.5 and 10.6.

Mount the controller loosely onto the controller mounting

bracket.

Adjust the controller mounting bracket and the controller

so that the controller is at 90°to the centre line of the

actuator and the controller feedback lever is horizontal

and at 90°to the centre line of the actuator.

Tighten the controller mounting bracket screws.

Adjust the controller on the controller mounting bracket so

that the measured distance is maintained between the centre

of the feedback lever shaft and the actuator pin (pre-meas-

ured mark on the feedback lever). Note the controller must

still conform to the specifications in previous steps.

Tighten all the mounting bolts and then re-check that the

controller complies with previous steps. Check that the

actuator pin does not touch the controller case through-

out the entire stroke of the actuator. If the actuator pin is

too long it may be trimmed to length. (The pin must be

trimmed on stroke of 1.125" or less.)

Actuator Piping Spool

valve

Plastic/Cu/SS (") Plastic/Cu/SS (mm)

B1C Stroke vol.

dm3/in3NPT 1/4 3/8 1/2 6/4 10/8 12/10

6 0.3/18 1/4 x x 2

9 0.6/37 1/4 x x 2

11 1.1/67 3/8 x x 2

13 2.3/140 3/8 x x 6

17

20

4.3/262

5.4/330

1/2 x

x

x

x

6

6

25

32

10.5/610

21/1282

1/2

3/4

x

x

(x)

(x)

x

x

(x)

(x)

6

6

40

50

43/2624

84/5126

3/4

1

(x)

(x)

x

x

x

x

6

6

502 195/11900 1 x x 6

B1J

B1JA

Stroke vol.

dm3/in3NPT 1/4 3/8 1/2 6/4 10/8 12/10 Spool

valve

8

10

0.9/55

1.8/110

3/8 x

x

x

x

21

61

12

16

3.6/220

6.7/409

1/2 x

x

x

x

61

61

20

25

13/793

27/1648

3/4 x

x

(x)

(x)

x

x

(x)

(x)

61

61

32

322

53/3234

106/6468

1(x)x

x

x

x

61

61

QP Stroke vol.

dm3/in3NPT 1/4 3/8 1/2 6/4 10/8 12/10 Spool

valve

1 0.62/37 3/8 x x 21

2 1.08/66 3/8 x x 21

3 2.18/133 3/8 x x 61

4 4.34/265 3/8 x x 61

58.7/5313/8 x x 61

6 17.5/1068 3/4 x x 61

Table 1. Piping

6

Attach the spring on to the feedback arm as shown.

Apply grease (Molykote or equivalent) to the contact

surfaces of the actuator pin and the feedback lever to

reduce wear.

Increase and/or decrease air pressure to the actuator to

stroke the actuator full stroke to check that nothing is

binding and that the rotation of the feedback lever is 70°

for a 1"-5" stroke and 60°for a 3⁄4" stroke. See Sections

10.5 and 10.6.

2.5 Piping of supply air

CAUTION:

Do not exceed the permitted supply pressure

of the ND800PA!

Table 1 provides the recommended tube sizes in accordance with

actuator sizes. Tube sizes are the minimum values allowed. For

supply air choose a tube one size bigger. Operating times can be

tested by the PDM.

Connect the air supply to S (1/4 NPT).

Connect C1 and C2 (1/4 NPT) to the actuator.

For the pipe threads liquid sealants, such as Loctite 577, are

recommended.

NOTE:

Too much sealant may cause faulty operation of the controller.

Sealing tape is not recommended.

Ensure the cleaniness of the air piping.

The supply air must be clean, dry and oil-free instrument air, e.g.

according to standard ISA S7.3-81.

2.6 Electrical connections

The bus cable is led through a PG13,5 cable gland. Connect the

conductors to the terminal strip according to Fig. 6.

Reverse polarity protection permits connection of the bus cables in

any order.

Depending on the plant grounding policy, wheter Equipotential

Bonding or Capacitive grounding can be used. See "PROFIBUS - PA

User and Installation Guideline". In the case of Equipotential Bonding,

connect the cable shield to earth connection screw. In the case of

Capacitive grounding, connect the cable shield to terminal strip 1. "

Profibus PA

Earth connection

Fig. 6. Terminals

Actuator type Spring rate (bar/psi)

B1JK

B1JSTD

B1JV

QPB

QPC

QPD

3/43

4.2/61

5.5/80

3/43

4.3/62

5.6/81

Adjust regulator pressure to a level which is max 1 bar (14.5

psi) + spring rate. If spring rate is less than 3 bar (43 psi)

then supply pressure 4 bar (58 psi) is recommended.

Table 2. Spring rates

7

SINGLE-ACTING ACTUATOR (SPRINGTO OPEN)

SINGLE-ACTING ACTUATOR (SPRINGTO CLOSE)

DOUBLE-ACTING ACTUATOR

1. Self closing.

Default setting:

PFA = CLO

ROT = cC ( lose valve to lockwise)

A0 = % (acc. to valve type)

cLo = 2 %

c c

3. Self closing.

Spring to close valve.

Default setting:

PFA = CLO

ROT = cC ( lose valve to lockwise)

A0 = % (acc. to valve type)

cLo = 2 %

c c

5. Self opening.

Spring to open valve.

Setting:

PFA = OPE

ROT = cC ( lose valve to lockwise)

A0 = % (acc. to valve type)

cLo = 2 %

c c

4. Self opening

Spring to open valve.

Setting:

PFA = OPE

ROT = ccC ( lose valve to ounter lockwise)

A0 = % (acc. to valve type)

cLo = 2 %

c c c

CAUTION: Valve closes exceptionally counterclockwise.

Unsuitable for Q-, R-, T5-, F- and L-series valves.

2. Self opening.

Setting:

PFA = OPE

ROT = cC ( lose valve to lockwise)

A0 = % (acc. to valve type)

cLo = 2 %

c c

C1

C2

S

C1

C2

S

C1

C2

S

C1

C2

S

C1

C2

S

After self-tuning the default parameters are as follows: Gain = 1.0 (for enhanced control use Gain=1.2)

d = 0.0 for double acting actuators (factory set)

d = 1.0 for single acting actuators (factory set)

b=1.0

In order to achieve symmetrical operation, always use filter regulator in connection with spring return actuators. See Table 2.

RA and DA actuators: use spool 21A. RB, RC, RD, RE and DB, DC, DE actuators: use spool 61A.

NOTE: Use QP values for diapharagm-pneumatic linear actuators.

Use B1J values for spring-return cylinder actuators. Use B1C values for double-acting cylinder actuators

If operational conditions change considerably, perform self-tuning for optimum performance.

Fig. 7. Operation directions and air connections

8

3 USER INTERFACE

3.1 Keyboard and display

The keyboard and the display of the ND800PA are shown in Fig.

8. Only applicable information is shown on the display in each mode.

Operations and display are controlled by +, -and rkeys.

Four setting functions are available: m, g, dor

c. Each of these names refers to the function to be adjusted

or changed.

In aor Mmode the display indicates 0-100 % as the valve

travel. In omode the display shows two dashes (--) instead of

digits. By pressing the rkey the display shows the input signal in mA

within about 5 seconds. In other situations the display indicates the

adjustable parameter value selected.

3.2 Keyboard functions

See keyboard operations (Fig. 11).

The keyboard setting state is initiated by pressing the +and -keys

for 5 seconds. The blinking text item mand one of the

previously selected operation modes, a, Mor o, will

be shown on the display. If you want to change the operation mode,

press rfirst. a, Mor owill start to blink showing that

the mode-changing function is enabled. Choose the desired mode,

a, Mor owith the +or - key. After the mode has

been selected, press the rkey.

The mfunction provides three alternative ND800PA opera-

tion modes:

a:

During amode the ND800PA controls the valve position

according to the analog output block (AO) output signal. This mode

is used during normal process control service.

M:

During this mode the valve position can be manually controlled from

the keyboard +or -keys. The position of the manually driven valve

is not saved in the non-volatile memory of the ND800PA, i.e. the

valve does not return to the same position after power failure.

However, the valve can be driven back into position after power

failure by the +and -keys.

o:

When the omode is activated the ND800PA closes the valve

and does not respond to incoming signal.

Accept the selected mode by pressing the rkey which returns you

automatically to the setting state.

Move to the next setting by pressing the +key. gstarts to

flash. The positioner gain required for different size of actuators is

set with the gparameter. gis set automatically by

self-tuning procedure during a/ Mcalibration. Pressing the

rkey allows you to change the gain value shown on the display with

the +and -keys. Accept a changed value with rkey, which returns

you automatically to the setting state.

dincludes positioner feedback parameters dand b. By pressing

the rkey you can select one of the above parameters with the +

and -keys. Confirm your choice with the rkey and change values

with +and -keys. Confirm the value with r. Default values are

listed in Fig. 7.

The next setting to move to with the +key is c. By pressing

the rkey you can start zero and travel range calibration and

self-tuning. More detailed information about cis given in

Section 4.1.

Within different options you can move forward with the +key and

with the -key backward.

In addition, there are nine control valve related configuration

parameters: FA. rot, A0, t4P, cLO, chi , rLo, rhi and Adr which are

explained in Section 4.3

You can return to the operation state from any setting by pressing

+and -keys simultaneously for less than 1 second, repeating if

necessary.

3.3 HW write protection

The ND800PA is delivered from the factory with HW write

protection OFF as the default setting. Reading and changing parame-

ters is thus allowed. Write protection can be enabled with a switch

(DIP2) located on the circuit board (Fig. 9). DIP1 is not in use.

Write protection protects all acyclic write access to all writeable

parameters of the device. Changing the parameters from the local

keyboard or PDM is thus not allowed.

MODE:

GAIN

DB

CALIB

AUTOMANOFF

Fig. 8. LCD-display and keyboard

DIP 1

OFF

12

ON

12

ON

DIP 2

ON

Fig. 9. DIP switch

9

&

%

> 5 s > 5 s

&

&(FACTORY = 90˚)

PREVIOUS SETTING

> 5 s

= Analog output block output signal (%)

KEYSTROKES

= Escape < 1 s

Operation

state

Setting state

&& &&&

Fig. 10. Keyboard operations

10

4 CONFIGURATION

4.1 Zero and range

The ND800PA position sensor operational range is factory adjusted

to suit Metso Automation actuators. If the ND800PA is to be fitted

into another manufacturer’s actuator, the sensor may need to be

readjusted as explained in Section 5.4.

Connect the air supply and fieldbus cable.

Select the cfunction from the keyboard according to 3.2.

Now you can select the aor Mcalibration mode

from the display by pressing the +or -key.

CAUTION:

Automatic calibration drives the valve against the

mechanical open and closed travel limits of the

valve-actuator assembly and a self-tuning proce-

dure is performed. Make sure that these proce-

dures can be safely executed.

Self-tuning procedure:

This is performed automatically during aor M

calibration.

As a result of self-tuning the gis set = 1 and bis set = 1.

dis originally factory set as explained in Fig. 7.

acalibration function:

For safety reasons the rkey needs to be pressed for 5

seconds to activate the acalibration function. During

calibration the display shows the text CAL. After calibration

the ND800PA returns automatically to the setting function.

A self-tuning procedure is performed.

At any time you may interrupt the calibration sequences

by pressing the +and -keys simultaneously.

After the acalibration sequence is finished press the

+and -keys simultaneously to get back to the operation

state. If this sequence has ended and an error message Err

appears on the display, see Chapter 6.

Now the ND800PA will work with basic settings including 2 ±0.5 %

signal cutoff margins to secure full closing of the valve.

If you cannot drive the valve into a fully open position or if there is

no mechanical limit stop, proceed as follows:

Mcalibration function:

After selecting the Mcalibration function from the

display press the rkey to activate the procedure.

With the +or -keys drive the valve manually to the

closed (0 %) position and then press the rkey.

If you cannot drive the valve into the open position, you

may skip this sequence by pressing the +and -keys

simultaneously. Now the ND800PA assumes that the

maximum valve opening is the latest calibrated value. The

factory setting is 90°.

Drive the valve into the desired maximum opening posi-

tion (100 %) with the +and -keys and press the rkey.

A self-tuning procedure is performed.

If an error message Err appears on the display, see

Chapter 7.

Press the +and -keys simultaneously to return to the

operation state.

Now the valve controller will work with basic settings including

2 ±0.5 % signal cutoff margins.

4.2 Position control

gis the gain parameter, dis the actuator pressure feedback

parameter and bis the valve velocity feedback parameter. The

default values after self-tuning are given in Fig. 7. Values are defined

for the control valve in question during self-tuning. However,

because of the large range of pressure drop and temperature for

the different processes, variations in supply air pressure and the great

variety of valve constructions, actuator load may differ considerably

from the default value. For this reason g, dand bmay have to

be adjusted to ensure optimum control performance for special

cases. Use the following guidelines to adjust g, dand b.

Check that dvalue is according to Fig. 7.

Perform aor Mcalibration.

For enhanced control increase the gto value 1.2

If the valve is unstable, lower guntil the valve is stable

at a constant input signal. If higher gis needed, increase

dto dampen instability with spring-return actuators.

If the valve is slow, increase g. If the valve is over-

shooting, decrease g. Adjust gfor slight over-

shooting and then increase bto dampen it.

If the deviation between input signal and actual valve

position is high, increase gto decrease deviation.

However, avoid unstable operation.

gsetting:

Select the gfunction from the keyboard according

to Section 3.2.

Now the display should indicate the current parameter

value. If you want to change it, press the rkey.

Increase the parameter value by pressing the +key or

decrease its value by pressing the -key.

Press the rkey when the desired value appears on the display.

Press the +and -keys simultaneously to return to the

operation state.

dsetting:

The dparameters can be adjusted in the same manner.

(See Fig. 10).

The ND800PA stays in the selected operation mode during the

gand dsettings.

11

4.3 Control valve related settings

The basic factory settings of the ND800PA assume a positioner fail

action to be closing the valve and a clockwise closing direction for

the position sensor. The setpoint cut-off CLOSE is set to 2 ±0.5 %

to guarantee full closing of the valve against mechanical travel stops.

Following parameters are possible to change during setting state by

pressing +or -keys until the parameter in question appears on

the display.

Valve package fail action (PFA)

Configuration of the action taken during the loss of the power

(supply pressure is available). This action takes place also when the

positioner software notices a fatal device failure. In these both cases

the spool valve feeds C1 and releases C2 pressure, see Fig. 7.

When the letters FA appear on the display you may read the

current value by first pressing the rkey and then selecting either

the CLO or OPE values by pressing the +and -keys.

To conclude press the rkey when the desired value is

shown on the display. See default values in Fig. 7 and

functions in Fig. 10.

Position sensor rotation (rot)

The next application-specific parameter rot defines the relationship

between position sensor rotation and valve action.

Once rot is displayed press the rkey and the current

parameter value will be shown on the display. Now you

may select between two values by pressing the +or -

key. The value cC means clockwise rotation for closing the

valve and ccC means counterclockwise to close.

After the desired value is displayed, press the key rto

conclude the operation. See default values and tubing sizes

in Fig. 7 and functions in Fig. 10.

α0setting (dead angle, A0)

The α0setting is made for Metso Automation segment and ball

valves. This setting takes into account the “dead angle”α0of the

ball valves. The entire signal range is then used for effective valve

opening 90°- α0(Figure 12 and Table 3). Use 0 % as the “dead

angle”for the valves not mentioned in Table 3.

After selecting A0 on the display, press the rkey and the

parameter value currently selected appears as a percent-

age (%) on the display.

Modify the parameter value by pressing +or -keys

alternately until the desired value appears on the display.

Press the rkey to finalize your selection and return to the

setting state. See Fig. 10 for functions.

Valve type selection (t4P)

To compensate for nonlinearity of the position feedback caused by

the actuator linkage mechanism of a linear control valve, the

appropriate selection must be made at the t4P display.

After selecting t4P on the display, press the rkey and select

between two values rot and Li n using the +and -keys.

The value rot indicates a rotary valve and Li n a linear valve.

To conclude press the rkey when the desired value is

shown on the display.

Valve size

Valve series

MBV, D,

QMBV,

QD

T5, T25,

QT5,

QT25

R, QR

mm in Dead angle as %

25

40

50

65

80

100

125

150

200

250

300

350

400

450

500-800

900-1000

1

1 1⁄2

2

2 1⁄2

3

4

5

6

8

10

12

14

16

18

20-32

36-40

18

18

18

16

14

14

14

12

10

9

9

9

9

9

8

6

21

21

21

-

15

15

15

14

11

11

11

11

11

11

-

-

15

12

17

13

9

8

8

8

7

7

6

5

5

-

-

-

Table 3. Dead angle as percentage

0% 100%

100%

Dead Angle

Compensation

Setpoint Cut-Off CLOSE

Upper Limit Valve Position

Setpoint Cut-Off OPEN

INPUT

OUTPUT

Lower Limit Valve Position

Fig. 11. The input signal modifications accomplished using

Dead Angle compensation, Cut-Off and Limit func-

tions

α0= dead angle

Fig. 12. Dead angle

12

Setpoint cut-off CLOSE (cLo)

When cLo appears on the display, press the rkey and the

current default value as a percentage (%) appears on the

display. The Metso Automation’standard default value is

2 % (2.0). Now modify this value to the desired number

and press the rkey to return to the setting state. See Fig.

10 for functions.

When input signal goes below the defined value, the valve

is driven to the CLOSED position, see Fig. 11.

Setpoint cut-off OPEN (chi )

When chi appears on the display, press the rkey and the

current default value as a percentage (%) appears on the

display. The Metso Automation’s standard default value is

100 % (100). Now modify this value to the desired number

and press the rkey to return to the setting state. See Fig.

10 for functions.

When input signal goes above the defined value, the valve

is driven to the OPEN position, see Fig. 11.

Lower limit valve position (rLo)

When rLo appears on the display, press the rkey and the

current default value as a percentage (%) appears on the

display. The Metso Automation’s standard default value is

0 % (0.0). Now modify this value to the desired number

and press the rkey to return to the setting state. See Fig.

10 for functions.

Valve position is never allowed to go below this value.

The only exception is fail-safe situation. See Fig. 11.

Upper limit valve position (rhi )

When rhi appears on the display, press the rkey and the

current default value as a percentage (%) appears on the

display. The Metso Automation’s standard default value is

100 % (100). Now modify this value to the desired number

and press the rkey to return to the setting state. See Fig.

10 for functions.

Valve position is never allowed to go above this value.

The only exception is fail-safe situation. See Fig. 11.

NOTE:

The setpoint cut-off function overrides the limit function. If

setpoint cut-off CLOSE is greater than 0 %, the lower limit

Valve position is not applied (has value 0 %). Correspondingly,

if setpoint cut-off OPEN is smaller than 100 %, the upper limit

valve position is not applied (has value of 100 %).

Profibus slave address, (Adr)

When Adr appears on the display, press rkey and the

current value appears on the display. The default is 126.

Now modify this value to desired number and press rkey

to return the setting state. see Fig. 10 for instructions.

When all the control valve-related parameters are cor-

rectly set, return to operation state by pressing the +and

-key simultaneously for a short time.

5 MAINTENANCE

The maintenance requirements of the ND800PA valve controller

depend on the service conditions, for instance, the quality of instrument

air. In normal service conditions no regular maintenance is required.

The best reliability is achieved by following these instructions.

In the following text the numbers in parenthesis ( ) correspond to

the part numbers on the expoded view in Chapter 11, unless

otherwise stated.

The ND800PA valve controller includes the following interchange-

able modules: prestage (3), spool valve (4), circuit board pack (5),

position sensor (6), and differential pressure sensor (7).

The modules are located underneath a protective cover (46) which

is attached with M3-screws (48, 4 pcs.). If a module fails it must be

changed. The module retrofit must be made in a clean, dry

environment. After replacement apply thread-locking compound

(for instance, Loctite 243) and tighten the screws firmly.

5.1 Prestage

NOTE:

The prestage must be handled very carefully. In particular the moving

parts on both ends of the prestage should not be touched when

the prestage is functioning and the protective cover is not in place.

Disassembly

Unplug the prestage (3) wire connectors from the circuit

board (5). Unscrew the M4 screws (92, 2 pcs.) and

remove the prestage module.

Reassembly

Place the O-rings (91) in the respective grooves and press

the prestage into place. Make sure that the nozzles are

properly guided on top of the O-rings. The screws guide

the prestage body into the correct position.

Push the prestage 2-pole wire connectors into the sockets on

the circuit board. Make sure that the wires do not cross each

other. The wire connectorscan only be fitted in the correct way.

Tighten the screws (92) evenly with a torque of approx.

0.8 Nm (0.6 ft.lb).

Set the protective cover (46) carefully in place and tighten

the screws (48).

13

5.2 Spool valve

Before removing the spool valve (4) the prestage (3) must be taken

off. (See Section 5.1)

Disassembly

Unscrew the M4 screws (99, 4 pcs.) and remove the spool

valve assembly.

The spool valve can be cleaned by following especially clean and

careful procedures. The seal (106), filter (105), restriction (104)

and spring (100) are located at the ends of the spool valve (102,

103). The spool (97) can also be removed for cleaning.

NOTE:

Each spool valve body has an individual matching spool which

cannot be replaced by any other spool. Never change the orien-

tation of the spool or the location of the individual spool springs.

Reassembly

Place a new gasket (98) in the location determined by the fitting

screw holes. Fit the spool valve into its corresponding position

on top of the seal and tighten the M4 screws (99) evenly.

The O-rings must be mounted first in their grooves located in

the spool valve unit. During mounting the O-rings must be

compressed because the sealing is done radially. Make sure that

the O-rings are evenly compressed and that they are fully inside

the grooves. The O-rings must be in perfect condition; no

defects are allowed. If a tool is used it must be blunt.

Mount the prestage unit directly onto the spool valve unit.

The ends of the nozzles will guide the prestage unit to the

right location. The prestage unit must fit by pushing gently

with no excessive force. Ensure that the spool valve unit

and the prestage unit have an even surface connection

before tightening the screws.

5.3 Circuit board pack

Disassembly

Loosen the M8 screw (66) and turn the position indica-

tor (65) outwards from the feedback shaft.

Unplug all wire connectors from the circuit board (5) and

the signal wires from the terminal block (35).

Remove the M3 screws (111, 5 pcs.).

NOTE:

Ground yourself on the body of the device before touching

the circuit board pack.

Take hold of the sides of circuit board and lift it directly

upwards and outwards. Handle the board carefully, touch-

ing only the sides.

Reassembly

Remount the circuit board pack carefully. Do not let the

feedback shaft touch the circuit board.

Locate the pins of the pressure sensor on the matching

connections on the board.

Tighten the M3 screws (111) evenly.

Push the rubber grommet into the slot located on the

intermediate wall of the body and connect the wires to

the terminal block as shown in Fig. 14. Plug the prestage

wire connectors into the board making sure that the wires

do not cross each other. Plug the position sensor (6) wire

connector into the board.

Mount the protective cover (46).

Mount the position indicator (65) on the shaft and tighten

the M8 screw (66) temporarily. The final locking of the

position indicator occurs when the actuator is installed.

NOTE:

Changing a new circuit board pack requires updating the

module parameters using PDM communication. See the in-

structions provided with the new circuit board.

100

102 103

104

105

106 97

96

107101108 109

Fig. 13. Spool valve

circuit board pack grommet

Fig. 14. Circuit board pack

14

5.4 Position sensor

Before loosening the position sensor (6) first loosen the circuit board

according to 5.3.

The position sensor assembly (6) consists of the MR-sensor (114),

which is fixed to the housing, and the spiral (117), which is fixed to

the main shaft.

Disassembly

Loosen the M3 screws (116, 2 pcs.) and lift the sensor out

of the housing.

Remove the lock ring (119) from the shaft and open the

hexagonal socket screw (118, 2 pcs.). Mark the top of the

spiral before removing it. Slide the spiral out of the shaft.

Reassembly

Mount the new sensor and spiral together as a pair. Slide

the spiral back onto the shaft and replace the lock ring on

the shaft. Turn the spiral and the shaft to the position

shown in the Fig. 15, corresponding to a 45°valve opening.

Tighten the M3 screws.

Install a 0,1 mm (0.004 in) thick gauge strip between the

sensor and the spiral. Press the sensor against the spiral,

without using unnecessary force, and tighten the screws

(116) evenly. Remove the strip.

Mount the circuit board and the protective cover (46) as

directed in 5.3.

NOTE:

Changing the new position sensor requires updating of the

calibration values of the sensor using PDM. See the instructions

in the ND800PA User’s guide.

5.5 Pressure sensor

Before removing the pressure sensor (7) you must loosen the circuit

board according to 5.3.

Disassembly

Loosen the M3 screws (126, 2 pcs.) and lift out the

pressure sensor (7) holding it from the both ends.

Reassembly

Mount the O-rings (123, 2 pcs.) in their grooves in the

housing. Push the pressure sensor back into place, guided

by the O-rings. The final location is shown in Fig. 16.

Tighten the M3 screws evenly.

Replace the circuit board and the protective cover accord-

ing to 5.3.

NOTE:

Changing the pressure sensor requires updating of the calibration

values of the sensor using PDM communication. See the instruc-

tions in the ND800PA User’s guide.

119

118 117

116

114

40

40

40

45°

45°

mark to this

position

mark

mark

mark

Shaft alternatives

mark = yellow dot

yellow

yellow

Fig. 15. Position sensor

Fig. 16. Pressure sensor

15

6 ERROR MESSAGES

When the ND800PA detects serious device failure (analogue

inputs, analogue outputs or electronics) it enters fail-safe mode

which drives the control valve into the position defined in the

parameter positioner fail action (PFA). Fail-safe mode is indicated by

the LCD as message Exx, where xx is a number between 1-99, or

by the PDM. The error message is displayed until the cause of error

is eliminated and the ND800PA unit is cold-started, i.e. the fieldbus

is momentarily disconnected. Cold-start can also be done using

PDM.

When the ND800PA detects an error during travel calibration or

self-tuning, the error message Err is displayed. It disappears when

any key is pressed.

The ND800PA stores error messages in its non-volatile memory,

which saves the 20 most recent error codes. The memory can be

read out with PDM.

Table 4 lists the error messages shown on the LCD display and their

explanations.

Error message Reason Action

E41 Pneumatic prestage valve 1 (VA1) control

failure.

Check wires and connectors or change circuit board.

Resistance of the coil is approx. 100 Ω, measured from the prestage connectors.

E44 Pneumatic prestage valve 2 (VA2) control

failure.

Check wires and connectors or change circuit board.

Resistance of the coil is approx. 100 Ω, measured from the prestage connectors.

E51

Position feedback ADC low limit failure. Check the mounting of controller; the mark on the shaft must stay in the

right sector, see Fig. 4.

Check wires, connector and position sensor rotation range or

change circuit board.

Rotate the position feedback shaft 10 degrees counterclockwise and

cold-start the device.

E52

Position feedback ADC high limit failure. Check the mounting of controller; the mark on the shaft must stay in the

right sector, see Fig. 4.

Check wires, connector and position sensor rotation range or

change circuit board.

Rotate the position feedback shaft 10 degrees clockwise and

cold-start the device.

E61 Memory (EEPROM) failure. Change circuit board.

E65 Memory (EEPROM) failure. Change circuit board.

E81 Memory (RAM) failure. Change circuit board.

E82 Memory (ROM) failure. Change circuit board.

E91 Processor failure. Change circuit board.

Err

Zero and travel calibration or

self-tuning fails.

Check range of position sensor or mechanical limits of actuator.

Check wires and connectors.

Check leakage.

Check that spool valve does not stick.

Check that prestage is not defective.

ADC = analog/digital converter

Table 4. Error messages shown on LCD display

16

7 TROUBLE SHOOTING

Mechanical/electrical defects

1. A change in the valve position setpoint does not affect the

position of the actuator

supply pressure too low

spool valve sticks

tubes between controller and actuator are incorrect, see

Fig. 7

actuator and/or valve jammed

signal wires incorrectly connected, no value on display

circuit board is defective

calibration has not been carried out (aor M)

ND800PA is either in Mor omode

prestage is defective

position sensor is defective

2. The actuator goes to the final position with a small change of

input signal

tubes between controller and actuator are incorrect, see

Fig. 7

the parameter settings FA and rot are incorrectly selected.

See Figs. 7 and 10

3. Inaccurate positioning

spool valve dirty

dirt in the permanent magnet air gap

actuator too small

supply pressure too low

pressure sensor is defective

dand bparameters in the dmode do not comply with

recommendations shown in Fig. 7

gparameter is too small, perform a/ M

calibration acc. to Section 4.2

4. Overshooting or positioning too slow

gis too high or too low, see Fig. 7

spool valve dirty

supply air tube too small or supply air filter dirty

valve sticks

check leakages in tubes between controller and actuator

check leakages in mechanical stop screws

5. Err is shown during calibration

position sensor is out of range, see Section 5.4

mechanical actuator travel exceeds position sensor linear

travel, i.e. 110°. If it fails in fully closed position, turn the spiral

(117) counterclockwise in 5°steps. If it fails in the fully open

position, turn the spiral (117) clockwise in 5°steps.

the parameter settings PFA and rot are incorrectly se-

lected, see Section 4.3 and Fig. 7

the actuator did not move or was stuck during calibration

ND800PA/actuator mounting is incorrect, see Figs. 4, 5,

15 and Sections 10.2-10.6

spool valve sticks

prestage is defective

PDM trouble shooting is explained in the ND800PA User’s Guide.

8 TOOLS

No special tools needed.

9 ORDERING SPARE PARTS

Spare parts are delivered as modules. Available modules are shown

in Sections 11.1 and 11.2.

When ordering spare parts, always include the following information:

controller type designation and serial number from the ID

plate

code of this manual, part number, part name and quantity

required

When ordering the circuit board, serial number of the

position sensor

17

10 ND800/K00 (WITH LIMIT SWITCHES)

10.1 Introduction

10.1.1 General description

ND800 can be equipped with limit switches. ND800/K00 has

2 microswitches.

Limit switches are used for electrical position indication of the valves

and other devices.

The switching points can be chosen freely.

10.1.2 Markings

The limit switch is provided with an identification plate sticker, see

Fig. 20. Identification plate markings from top to bottom are:

Type designation

Electrical values

Enclosure class

Temperature range

Conduit entry

Serial number

The type designation is described in Chapter 13.

10.1.3 Technical specifications

10.1.3.1 ND800/K00

Microswitch type: OMRON D2VW-5 (05)

OMRON D2VW-01 (06)

(gold plated contacts)

Protection class IP67

Resistive load: 3A: 250 V AC (05)

5A: 30 V DC

0.4A: 125 V DC

100 mA: 30 V DC/125 V AC (06)

Switch accuracy: < 2°

Number of switches: 2

Protection class

of cover: IP65 (DIN 40050, IEC 529)

Conduit entry: PG 13.5

1/2 NPT = -L

M20x1.5 = -I

R 1/2 = -NJ

Ambient temperature: -20 - +80 °C (-4 - +176 °F)

Weight: Approx. 0.8 kg (1.8 lbs) (limit switches only)

Materials:

Body: Aluminium alloy, epoxy-coated

Internal parts: Stainless steel and plastic

Sealing: Nitrile and neoprene rubber

10.1.4 Safety precautions

CAUTION:

Do not exceed the limit switch performance limitations!

Exceeding the limitations marked on the limit switch may

cause damage to the limit switch, actuator and valve. Damage

or personal injury may result.

CAUTION:

Observe caution with the live parts of the limit switch!

The limit switches are fed with a voltage that, depending on

the system, may be lethal.

Do not touch any uncovered parts of the wires. Always

disconnect the wires before dismantling the limit switch.

2 micro-

switches

2 cams

terminal

earth

connection

PG 13.5

Fig. 17. ND800/K00 layout

Fig. 18. Identification plate

18

10.2 InstallingND800/K00 on a valve controller

The limit switch can be installed on an existing valve controller.

NOTE:

Do not install a ND800/K00 limit switch on a ND800/X valve controller!

If the valve controller is already mounted on an actua-

tor/valve assembly, operate the actuator into the closed

or open position.

Remove the cover (2) and the pointer (65).

Turn the shaft (304) onto the shaft (40). Fasten the screw

(305) using a locking agent such as Loctite. Unfasten the

screws (331) in the cam discs (330).

Mount the housing (300) on the valve controller.

Turn the cam discs (330) to avoid contact with the

microswitches, if needed.

Mount the pointer (65) on the shaft (304).

Adjust the limit switch according to Section 10.4.

10.3 Electrical connections

Before connecting the power, make sure that the electrical specifi-

cations and the wiring meet the installation conditions. See the

diagrams in Section 11.7. See also the information on the identifica-

tion plate.

10.4 Adjustment

The pointer (65) need not be removed for adjustment.

When the limit switch is ordered together with the valve and the

actuator, the valve controller switches are factory-adjusted.

The limits can be adjusted by changing the position of the cam discs

(330) on the shaft. The lower switch is activated at the closed limit

and the upper switch at the open limit.

With the actuator in the open or closed position, find the switching

point by turning the cam disc so that the switch changes about 5°-6°

before the limit.

After re-installation of the actuator, first adjust its mechanical limits

according to the valve, then the valve controller, and finally the limit

switch.

When adjustment is completed, turn the pointer (65) so that

the yellow line is parallel with the valve closure member.

10.5 Removal of the limit switch ND800/K00

for accessing the valve controller

Before the protective cover (46) can be removed the limit switch

must be detached.

Remove the cover (2) and the pointer (65).

Loosen the screws (302) and remove the housing (300).

Detach the shaft (304) with cam discs (330).

Proceed with the valve controller as applicable.

Re-install the limit switch according to Section 10.2 and check the

adjustment according to Section 10.4.

10.6 Circuit diagrams

The internal circuitry of the limit switch is shown in the connection

diagrams in Section 11.8 and on the sticker inside the cover.

10.7 Maintenance

Regular maintenance of the limit switch is not necessary.

10.8 Ordering spare parts

NOTE:

Always use original spare parts to make sure that the limit

switch functions as intended.

When ordering spare parts, always include the following informa-

tion: limit switch type designation (from the name plate or

switch documents)

number of the spare parts list or number of this manual,

part number, part name and quantity required

16

15

13

12

K

A

ND800/K00B

LS2

LS1

Fig. 19. Limit switch adjustment, ND800/K00

19

11 DRAWINGS AND PARTS LISTS

11.1 Exploded view and parts list

66

48

111

65

46

5

119

116

118

6

126

7

123

107

103, 104, 105

100

98 102, 104, 105

106

109

91

99

3

92

31

32

44

40

54

52 51

2

35

1

96

64

97

4

101

108

Item Qty Description Recommended spare

11Housing

21Cover

3 1Prestageunit*

4 1 Spool valve assembly * x

5 1 Circuit board pack

6 1 Position sensor *

7 1 Differential pressure sensor *

31 1 Exhaust cover

32 2 Screw

35 4 Terminal block

40 1 Shaft assembly

44 1 Washer

46 1 Protective cover

48 4 Screw

51 1 Ear

52 1 Screw

54 1 Couplings jacket

64 4 Screw

65 1 Pointer

66 1 Screw

91 2 O-ring x

92 2 Screw

Item Qty Description Recommended spare

96 1 Spool valve body **

97 1 Spool **

98 1 Gasket x

99 4 Screw

100 2 Spring **

101 1 Back stop **

102 1 End piece I **

103 1 End piece II **

104 2 Restriction **

105 2 Filter **

106 2 Gasket **

107 4 Screw **

108 1 Adjustable back stop **

109 1 O-ring **

111 5 Screw

116 2 Screw

118 2 Screw

119 1 Lock ring

123 2 O-ring

126 2 Screw

*) delivered as a module

**) part of the spool valve assembly

20

Table of contents

Other metso automation Controllers manuals