1 E2 70 en 7

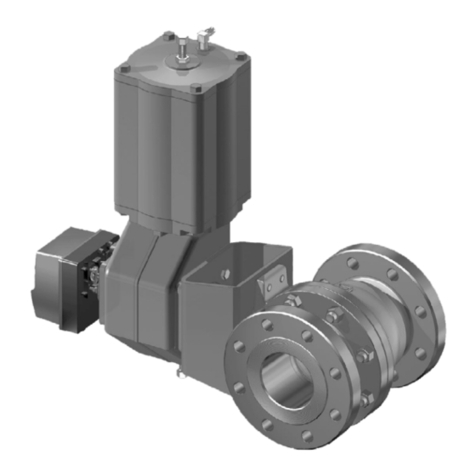

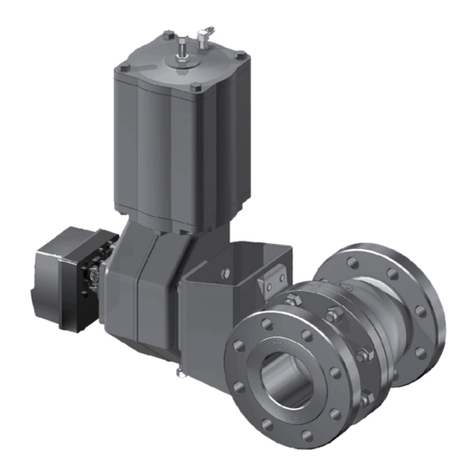

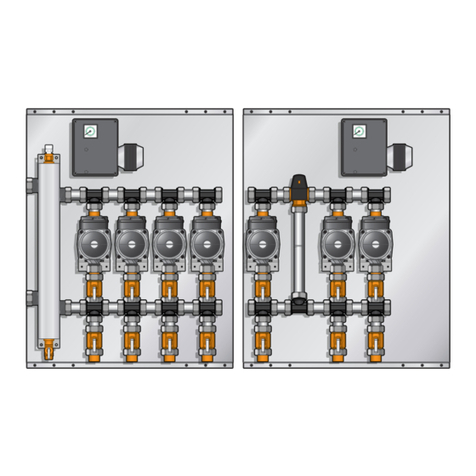

4.2.1 Disassembly

1. Detach the air supply conduit from the actuator. Also

detach any cables preventing the removal of the actuator.

2. Remove the actuator from the bracket (5) by

unscrewing the fixing screws. Pull the actuator from

the shaft (4). Detaching the actuator is described in

more detail in Section 4.7.1.

3. Detach the key (20) from the shaft.

4. Detach the bracket (5) from the body (1) by opening

the screws (13) M12 or M16.

5. Detach the bearing (8), the axial bearing (7) and the

lock ring (19).

6. Loosen the strain ring (9) with a special tool, see

Table 4.

7. Pull the shaft (4), and lift it and gland bushing (10)

and parts (11, 12, 17) out of the valve body.

8. Pull the gland bushing off the shaft while rotating.

Now the gland packing may be disassembled.

9. Remove the gasket (16) between the gland bushing

and the body from the valve body.

4.2.2 Replacing parts

The gland packing set includes the V-ring set (11) and

the spring (12). Replace both parts at the same time.

The O-ring (17) should be replaced if it is damaged.

The main purpose of the O-ring is to protect the shaft

from erosive media, such as sludge, and it therefore

does not need to be changed regularly.

4.2.3 Assembly

1. Apply silicon grease to the O-ring (17) and install it

into the gland bushing (10) cavity.

2. Slip the gland bushing (10) onto the shaft (4).

3. Install the spring (12) into the bottom of the gland

bushing (10). Before installation, the spiral should

be completely compressed once, for example in a

vice. This will make installation of the strain ring eas-

ier, since the working height of the spiral is roughly

0.6 x the free height of the spring.

4. Once the spiral is in place, slip the sheet ring (15)

into position. After this, install the V-ring (11) onto the

shaft, one by one.

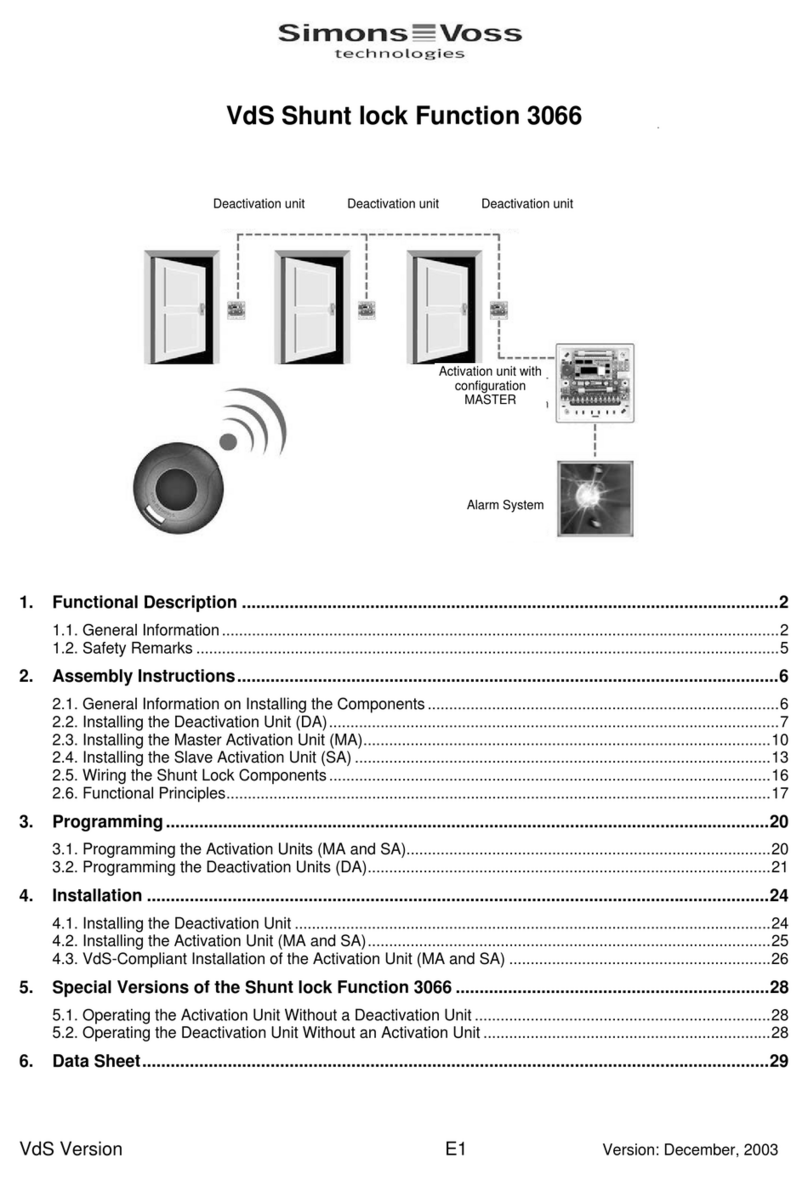

The order from bottom to top of the different rings is as

follows:

❑base ring

❑angle rings

❑saddle ring

5. Place the gasket (16) into the valve body.

6. Insert the shaft together with the gland bushing

back into the valve body.

7. The shaft joint on the ball has been shaped in such

a way that the shaft only fits seat when it is in the

correct position. Check the direction of the bore by

observing the indicator line at the top of the shaft,

and take the position of the keyway into account

when you install the actuator.

8. Lubricate the thread of the strain ring with, for exam-

ple, Molykote. Then fasten the strain ring (9). When

correctly fastened, the ring shoulder must be at least

on a level with the body, or 0.1 mm below it. The tight-

ening torques are given in Table 4. The shoulder of the

strain ring must not remain above the surface level of

the body.

9. Make sure that the bracket (5) is not carrying the

weight of the valve because this would have an

immediate effect on the bearing clearance.

10.Install the lock ring (19), the axial bearing (7) and

the bearing (8) onto the shaft.

11.Attach the bracket to the valve body. While fastening

the screws, make sure that the hole in the bracket is

properly centered in relation to the shaft. For the

correct tightening torques, see Table 5.

12.Install the actuator. See Section 4.7.2.

CAUTION:

Do not detach or disassemble a pressurized valve!

This warning also applies to individual compo-

nents (13).

NOTE:

Replace the gasket (16) between the gland bushing (10)

and the body (1) whenever the strain ring has been loos-

ened. Leakage of the V-ring set (11) and leakage of the

gasket (16) may cause similar symptoms.

NOTE:

Make sure you do not damage the O-ring with the shaft

keyway and the shaft shoulder.

NOTE:

Make sure you do not damage the gland packing rings

with the shaft keyway or shaft shoulder.

Table 4 Tightening torques of strain ring

Nominal

size

DN Thread Torque

Nm Tool

DIN 1810A Special

tool

25/20 M39 x 1.5 190 34-36 F14096_01

40/32 M45 x 1.5 250 40-42 F14096_1H

50/40 M50 x 2 320 45-50 F14096_02

80/65 M64 x 2 340 58-62 F14096_03

100/80 M75 x 2 560 68-75 F14096_04

150/100 M95 x 2 1330 80-90 F14096_06

200 M95 x 2 1330 80-90 F14096_06

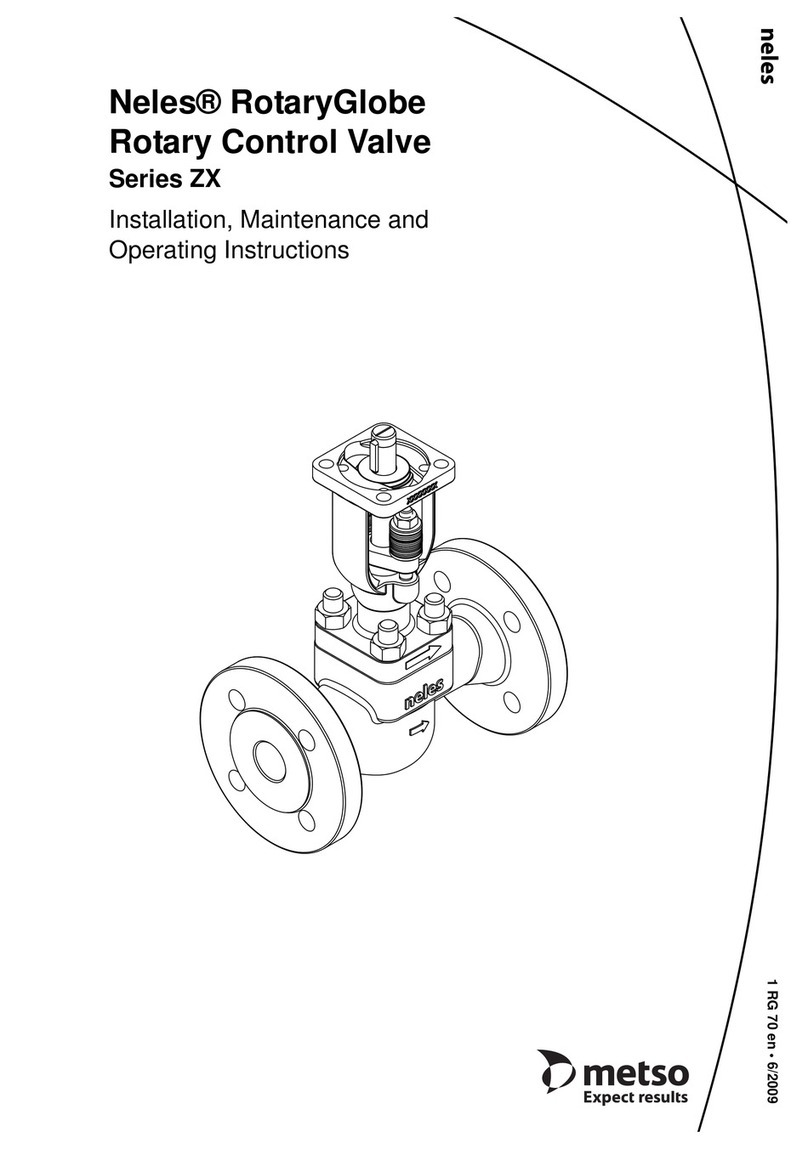

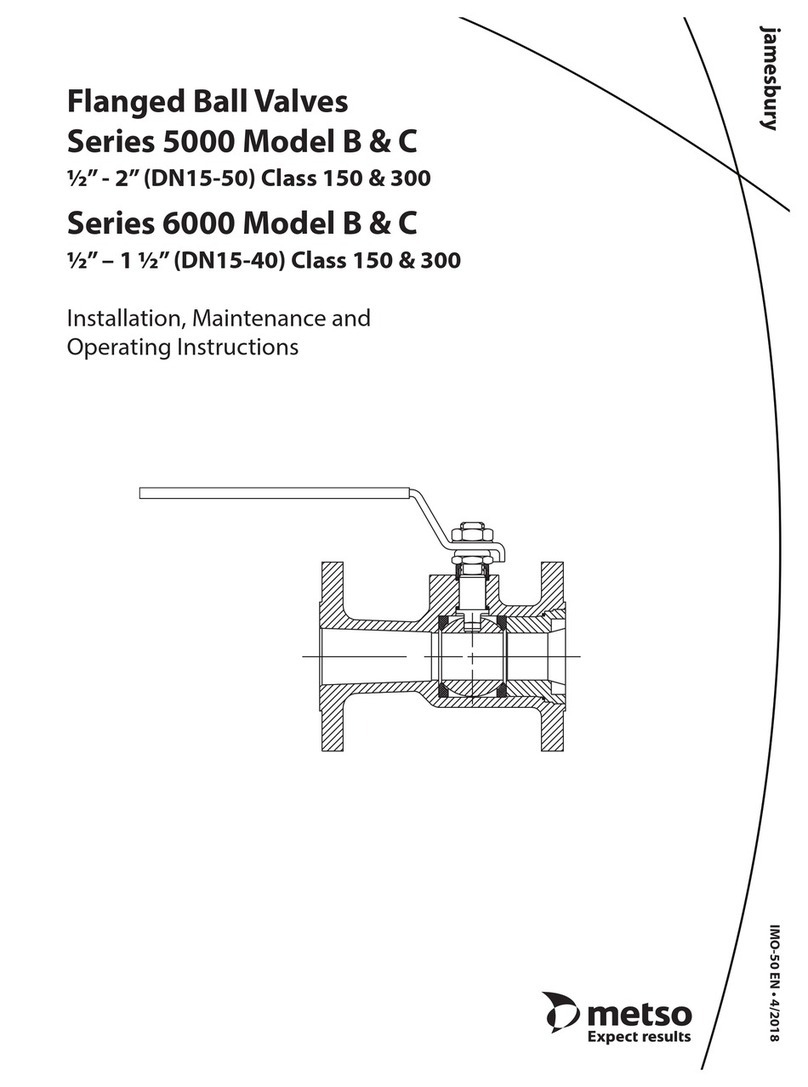

Fig. 7 Sealing of the shaft, A-construction

0...0,1 mm bellow the

top level of the bracket

bracket (5)

strain ring

(9)

saddle ring

(11)

angle ring

(11)

base rings

(11)

O-ring

(17)

sheet ring

(15)

spring

(12)

gland

bushing

(10)

gasket (16)shaft (4)