1 RG 70 en 7

Make sure the pin (21) is in the hole between the

cage (7) and the body before mounting the bon-

net seal.

Mount the new bonnet seal.

Push the shaft through the bonnet halfway to the

yoke and check the keyway edges so as not to

scratch the packing rings.

Mount the sheet ring (70) and support ring (23) with

the bearing strip (71) on the shaft. Mount the net

side of the sheet ring and bearing strip against the

thrust bearing. Hold the thrust bearing halves onto

the groove of the shaft and slide the support ring

onto the thrust bearing to lock it. Push the shaft to

the upper position. Make sure the pin (6) head of the

plug is in the recess of the bonnet.

Fasten the gland (9) with the nuts (18) and tighten

them according to the Table 1.

Mount the bonnet with the shaft and plug to the

body, plug in closed position, so the arrows on the

body and on the bonnet point to the same direction.

Tighten the nuts (17) in a cross-tightening manner

according to the Table 1.

Tap the key (10) to the keyway.

5 TESTING THE VALVE

We recommend that the valve body is pressure-tested after

the valve has been assembled.

The pressure test should be carried out in accordance with

an applicable standard for the pressure rating. The valve

must be in the open position during the test.

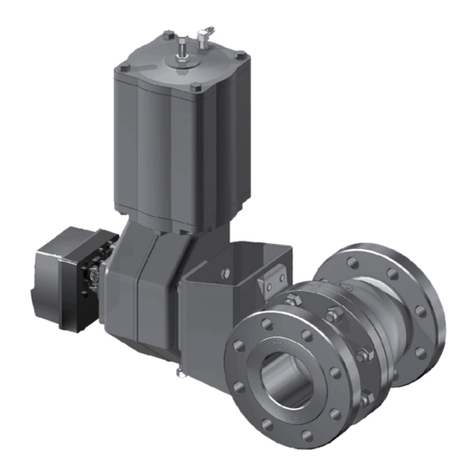

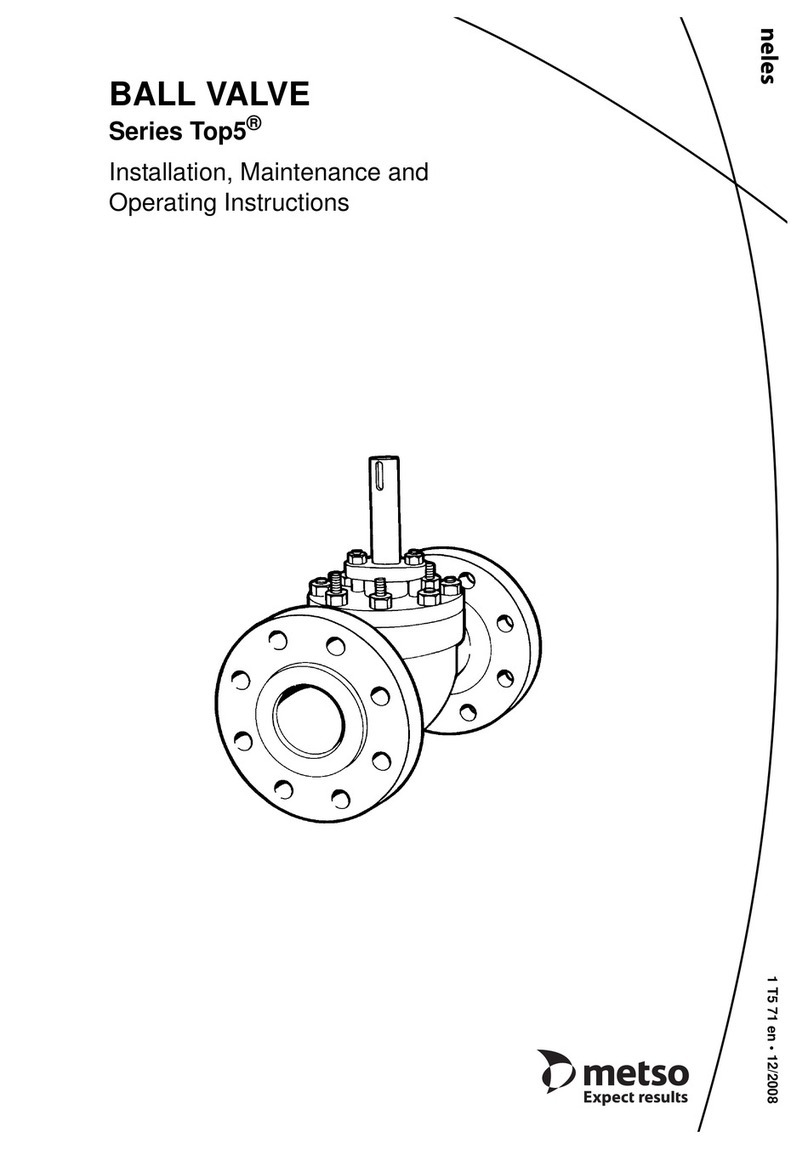

6 MOUNTING THE ACTUATOR

The actuator is attached to the valve via an ISO 5211 stand-

ard mounting interface. Several types of Metso actuators

can be used with suitable couplings. Refer to the individual

manuals for further information on their installation, main-

tenance and operation.

Push the actuator carefully onto the valve shaft.

Avoid forcing it, since this may damage the plug and

cage. Tighten the screws of the interface, see Table 1.

The cone coupling has an axial tightening screw in E-

series actuators. Make sure it is tightened according

to the instructions.

Adjust the closed position of the trim by means of

the actuator stop screw, see actuator instructions.

The valve has an internal limit stop to find the closed

position of the valve. Unscrew the closed position

stop screw of the actuator until the rotation of the

valve shaft stops or if the valve shaft does not rotate

turn in the opposite direction until the shaft starts to

rotate. Then adjust the stop screw by one half turn so

the valve rotates in the open direction slightly. Lock

the stop screw.

Adjust the open position of the trim by means of the

actuator stop screw. Drive the actuator 90 degrees

from the closed position. Turn the stop screw to the

contact and lock the stop screw.

The stop screw threads through the cylinder heads

of the actuator must be sealed using an appropriate

non-hardening sealant, e.g. Loctite 225.

7 TOOLS

Removal of the actuator

In addition to standard tools, the following special tools

might facilitate some phases of the work.

Extractor. (ID-code table in actuator's IMO)

cage removal tool, see Table 1.

Table 1 Cage removal tools series ZX

Tools can be ordered from the manufacturer.

8 ORDERING SPARE PARTS

When ordering spare parts, always include the following

information:

type code, sales order number, serial number

number of the parts list, part number, name of the

part and quantity required

This information can be found from the identification plate

or documents.

CAUTION:

Pressure testing should be carried out using equip-

ment conforming to the correct pressure class!

CAUTION:

Beware of the plug movement!

NOTE:

The B1J actuator (spring-to-close) may not be driven

against the internal stop screw with the full spring torque.

Adjust the limit by lowering the actuator pressure slowly.

The counterpressure in the actuator limits the spring tor-

que. Operate the B1JA (spring-to-open) actuator, or the

double-acting B1C actuator with the lowest possible

pressure against the internal stop. Excessive torque may

damage the valve.

Product: ID:

DN 0H-02 (12 mm - 50 mm) H083121

DN 03 (80 mm) H137439

DN 04 (100 mm) H137435

NOTE:

Always use original spare parts to make sure that the valve

functions as intended.