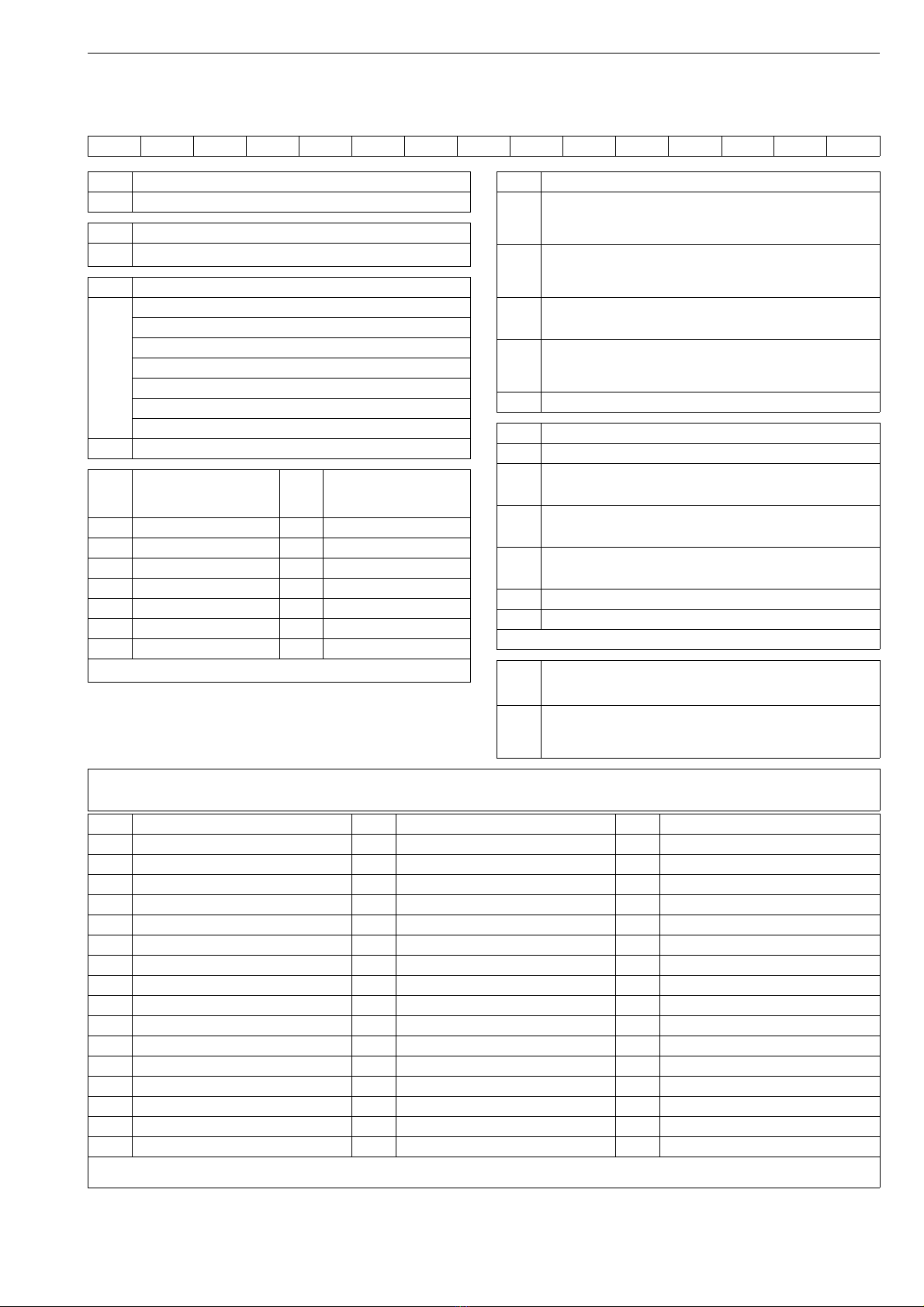

2 BW 70 en 19

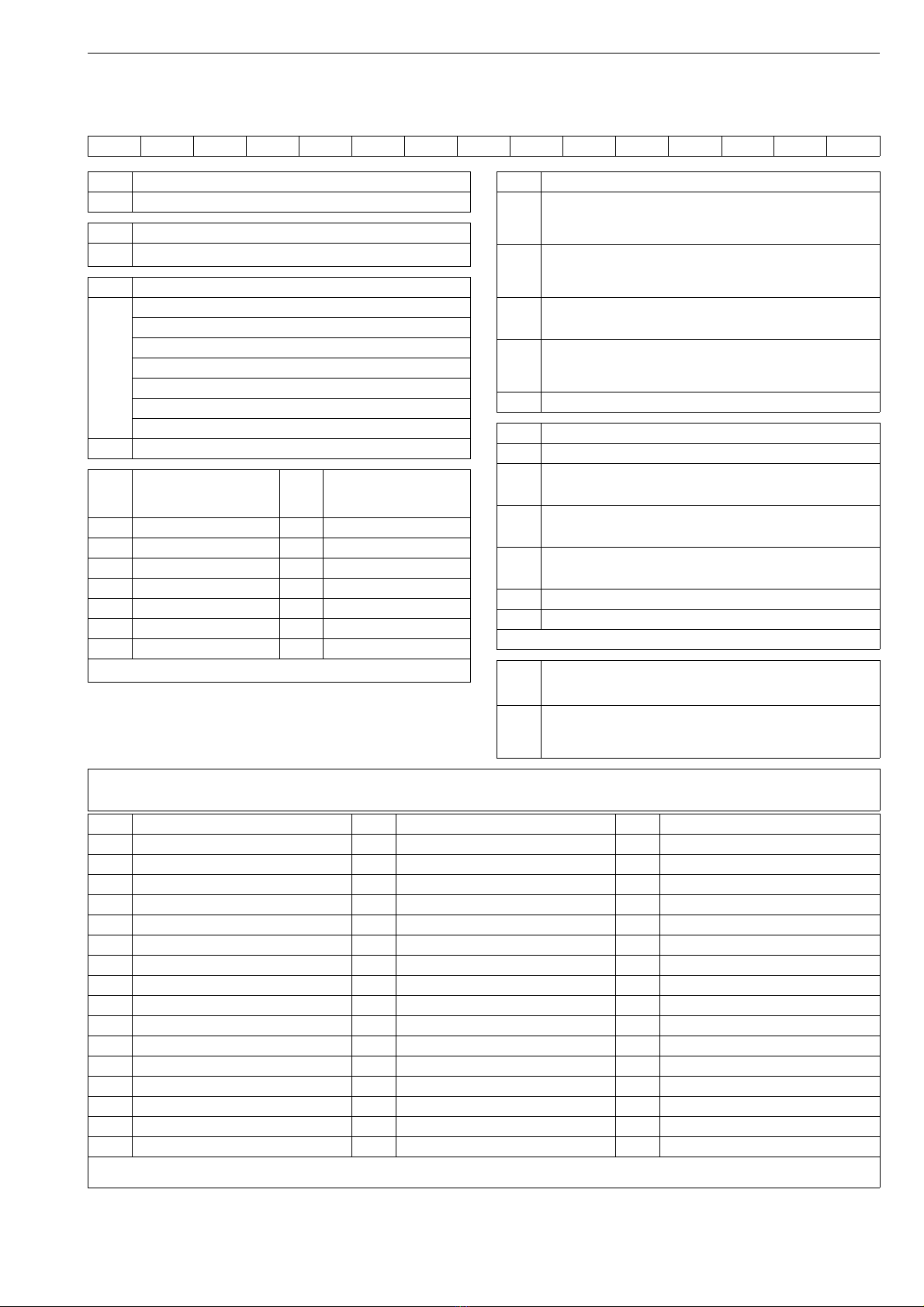

11 Type code

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. / / 13. 14.

BW 3 G/D 1 B 56 P N2N1N1G3

1. sign

–

2. sign PRODUCT SERIES / DESIGN

BW Metal seated butterfly valve, triple eccentric available as Double flanged,

Lug, Wafer or Butt weld end type.

3. sign BODY CONSTRUCTION

2Flanged, long pattern

3Flanged, short pattern

4Lug or Mono flange or single flange

6Wafer

7No Entry + Butt Weld ends

8Top entry, Side Access + Butt Weld ends

9Top entry, Top Access + Butt Weld ends

YSpecial, to be specified

4. sign

Body BODY PRESSURE RATING 4. sign

Trim

TRIM PRESSURE RATING

Use trim rating e.g. /C

if not full rated

C ASME class 150 /C ASME class 150

DASME class 300 /D ASME class 300

FASME class 600 /F ASME class 600

GASME class 900 /G ASME class 900

HASME class 1500 /C ASME class 150

HASME class 1500 /H ASME class 1500

IASME class 2500 /I ASME class 2500

BW1H/F...-> full rated body #1500, de-rated trim #600. Corresponding PN pressure

classes also avaiable.

5. sign SEAT DESIGN

1

U-Type Metal seat with coating (sign 11).

Max tightness in preferred direction API 598 or FCI 70.2 cl V (std),

FCI 70.2 cl VI (optional), EN12266 Rate B.

Non-preferred direction, FCI 70.2 cl V (Air).

2

Double seat, metal + soft (Tmax limited by soft seat).

Max tightness in preferred direction, API 598, FCI 70.2 cl VI, EN12266 Rate A.

Non-preferred direction, FCI 70.2 cl VI (Air).

Max pressure 100 bar.

4

Double seat on valve body + leak off connection between the seat.

Max tightness in preferred direction, API 598.

Max tightness in non-preferred direction, FCI 70.2 cl VI (Air).

8

Solid proof.

One sealing ring on the disc + seat on the body.

Max tightness in preferred direction, API 598, FCI 70.2 cl V.

Max tightness in non-preferred direction, 100 x FCI 70.2 cl V (Air).

YSpecial construction.

6. sign BEARING AND BODY DESIGN

ASoft bearings, PTFE or eq. on metal net Tmax 250 °C, trim rating max #600.

B

Metallic or carbon bearings for high temperature.

(e.g. GGG-CrNi or stellite or high performance carbon bearings).

Tmax 500 °C.

H

Metallic or carbon bearings for high temperature.

(e.g. GGG-CrNi or stellite or high performance carbon bearings).

Temp: 500-850 °C.

HH

H + cooling ribbons.

(e.g. GGG-CrNi or stellite or high performance carbon bearings) cooling

ribbons. Temp: 850-1150 °C.

SConstruction B + Steam jacket.

YSpecial construction.

For NACE, add "N" to sign. 6 "B" -> "BN"

7.

sign

SIZE

Note: Pressure rating = ASME -> inch sizes

Pressure rating = PN --> metric sizes

BW

Inch: 04, 06, 08, 10, 12, 14, 16, 18, 20, 24, 28, 30, 32, 36, 38, 40, 42 48, 52,

54, 56, 60, 64, bigger sizes on request

Metric: 100, 150, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800, 900,

1000, 1200, 1400, 1500, 1600

NOTE:

- The factory will keep the right to change the material if the material is same e.g. from casting to forged

- With slash "/" the materials are double marked

8. sign BODY 9. sign DISC 10. sign SHAFT, PINS AND KEY

PASTM A216 WCB/ 1.0619 N2 ASTM A487 CA6NM (similar to 1.4317) N2 1.4021 (-10 °C to +400 °C)

FASTM A352 LCC G5 1.4931 N1 1.4923

NASTM A217 WC6 NASTM A217 WC6 CASTM SA564 Gr. 630(17-4PH)

UASTM A351 CK3MCuN (SM0254) UASTM A351 CK3MCuN (SM0254) UUNS31254 (SM0254)

U2 ASTM A890 4A (similar to 1.4517) U2 ASTM A890 4A (similar to 1.4517)

U3 ASTM A890 GR. 5A (similar to 1.4469) U3 ASTM A890 5A (similar to 1.4469)

G9 1.4923 K5 1.4462

G G 1.4313 (similar to A487 CA6NM)

NXM-19 (Nitronic 50 HS)

AASTM A351 CF8M / 1.4408 AASTM A351 CF8M eq.AISI 316/1.4408 C2 Gr. 660/1.4980 (pressure class 900 and above)

A2 ASTM A351 CF3M (AISI316L) A4 ASTM A351 CF8C eq. AISI 347/1.4552 C3 1.4980 (-200 °C to + 815 °C)

C2 ASTM A638 Gr. 660 (similar to 1.4980)

AF316

A2 ASTM A351 CF3M eq. AISI316L

HASTM A494 CW-6M (Hastelloy C) HASTM A494 CW-6M (Hastelloy C) H1 HAST C

TTitanium TTitanium TTitanium

NOTE: Check the recommend material combination from the Factory

NOTE: The list of materials have been shortened due to space limitations. Please consult Metso to find the availability of other materials.