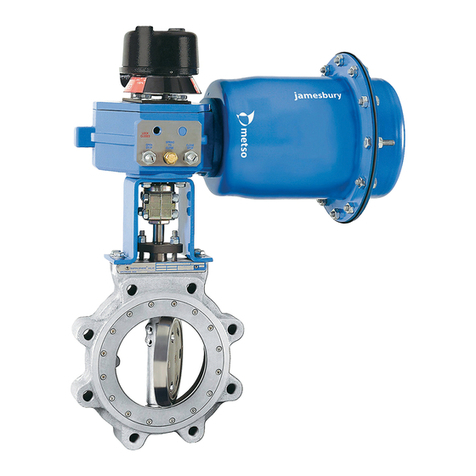

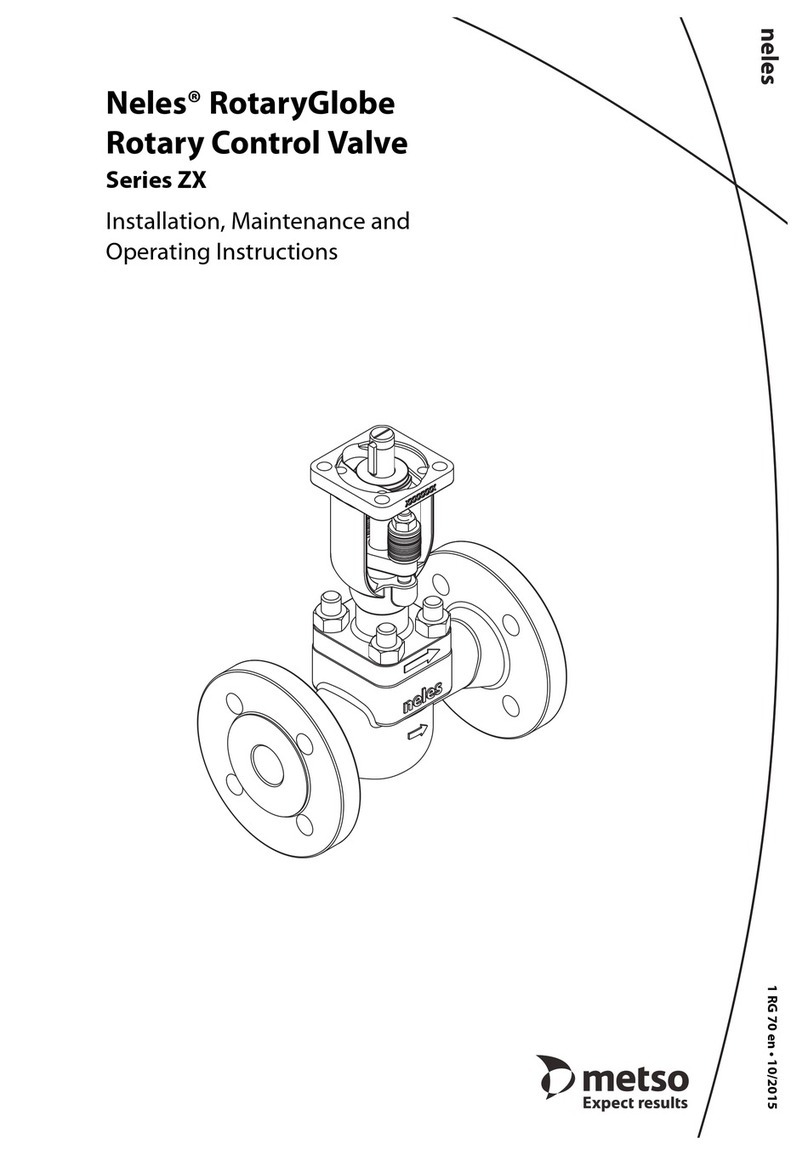

Metso Neles RotaryGlobe ZX Series Operating and maintenance manual

Other manuals for Neles RotaryGlobe ZX Series

1

This manual suits for next models

6

Table of contents

Other Metso Control Unit manuals

Metso

Metso Jamesbury 5000 series User manual

Metso

Metso GW Series Operating and maintenance manual

Metso

Metso Neles RotaryGlobe ZX Series Operating and maintenance manual

Metso

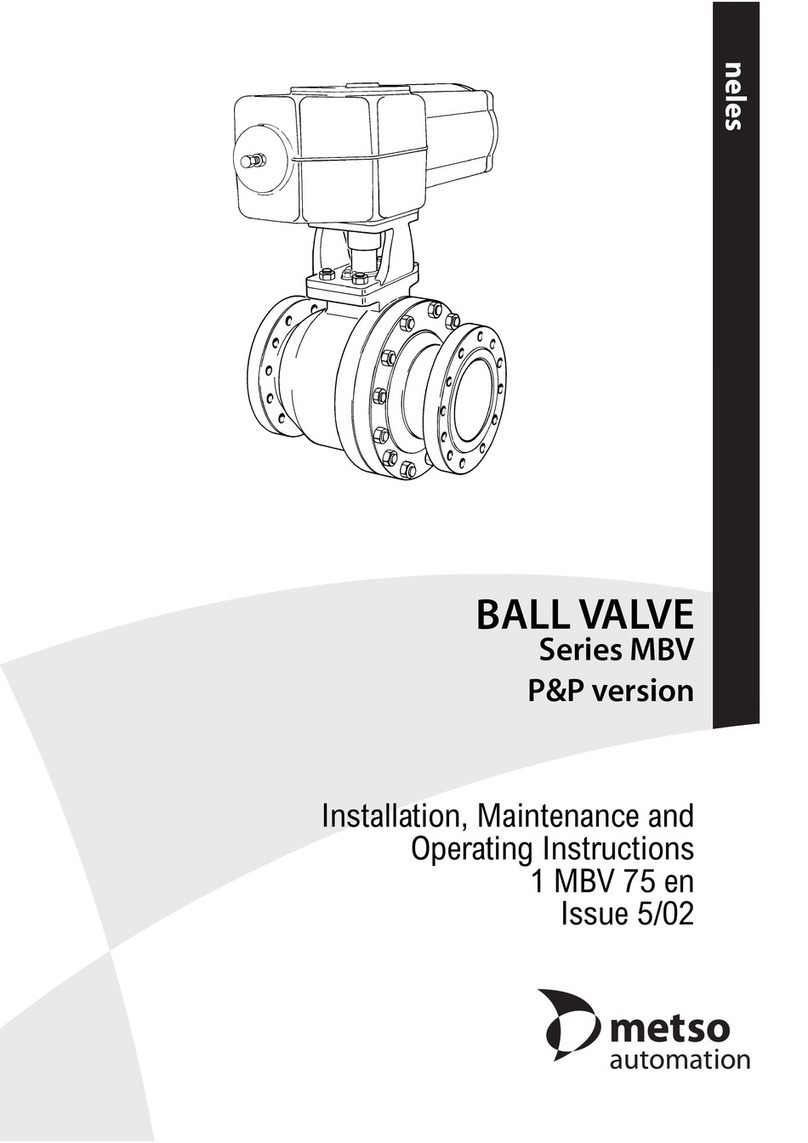

Metso MBV Series Operating and maintenance manual

Metso

Metso XT/XA Series Operating and maintenance manual

Metso

Metso Jamesbury 7000 Series Operating and maintenance manual

Metso

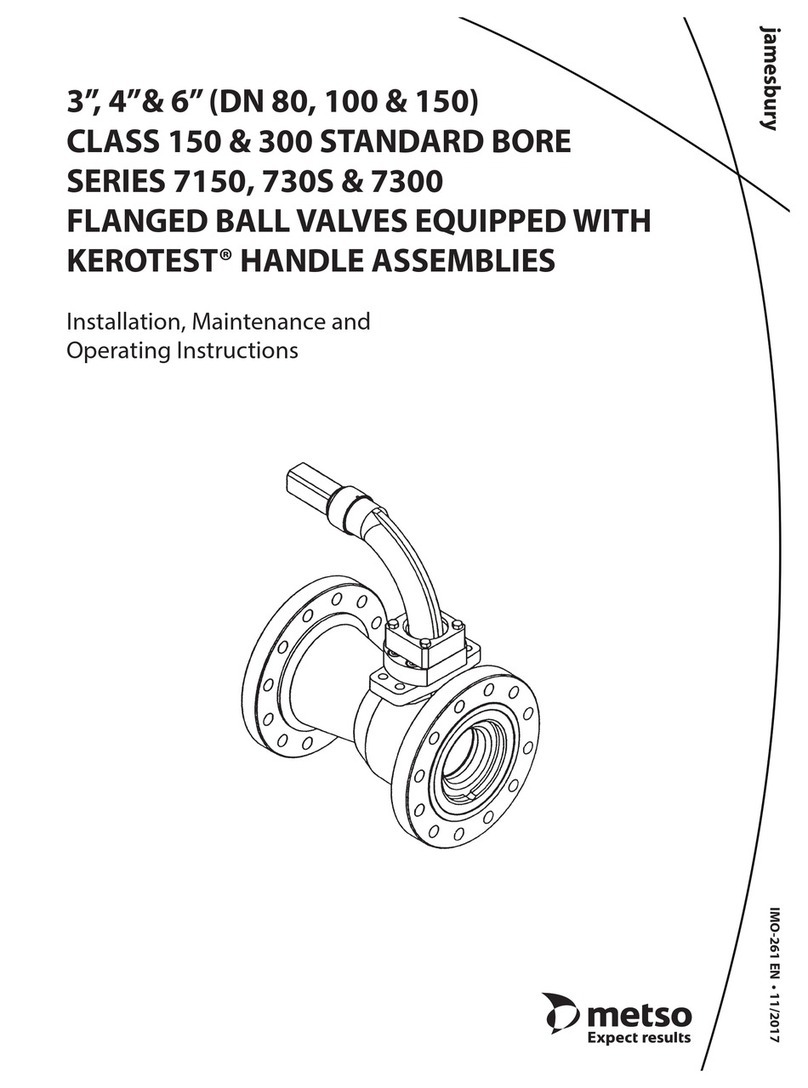

Metso 7150 Operating and maintenance manual

Metso

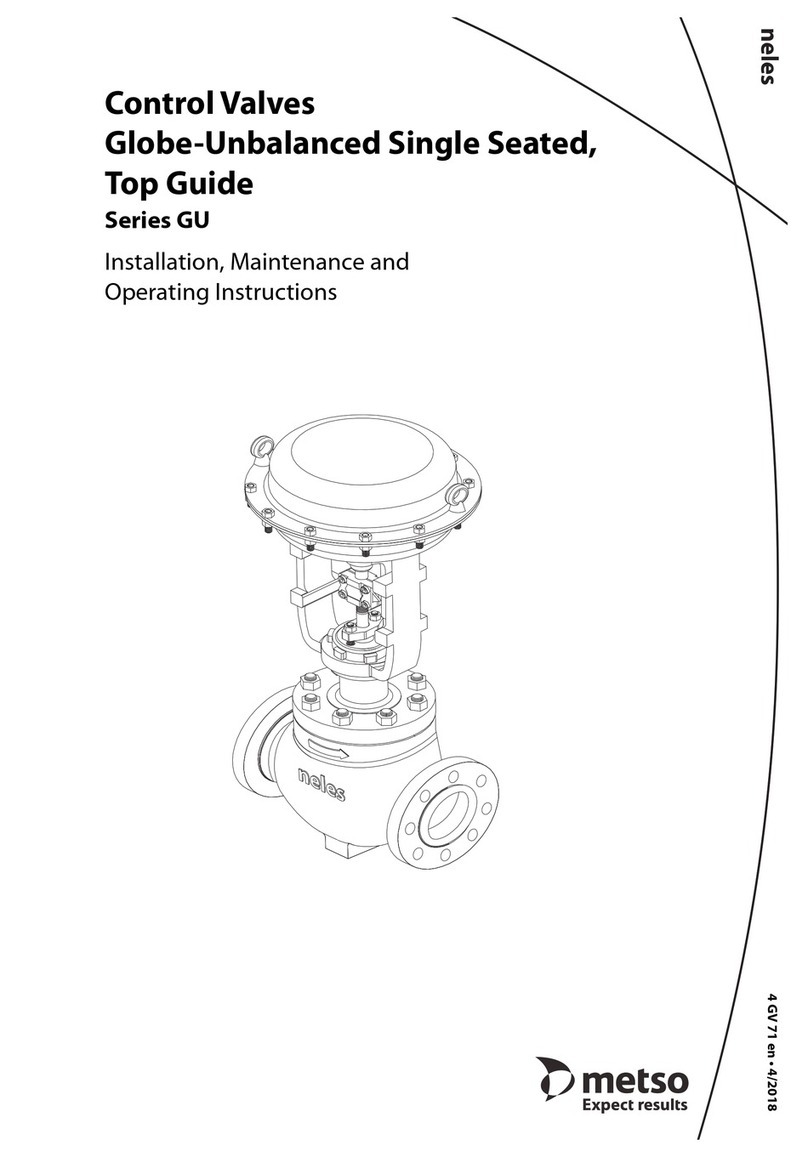

Metso GU series User manual

Metso

Metso Top 5 Series Operating and maintenance manual

Metso

Metso JAMESBURY EASYFLOW SC Series Operating and maintenance manual

Metso

Metso Jamesbury Wafer-Sphere K815W Operating and maintenance manual

Metso

Metso Neles BW Series Operating and maintenance manual

Metso

Metso Ball Valves Operating and maintenance manual

Metso

Metso ND9200H Operating and maintenance manual

Metso

Metso Neldisc L1 Series User manual

Metso

Metso Mapag BAR Series Operating and maintenance manual

Metso

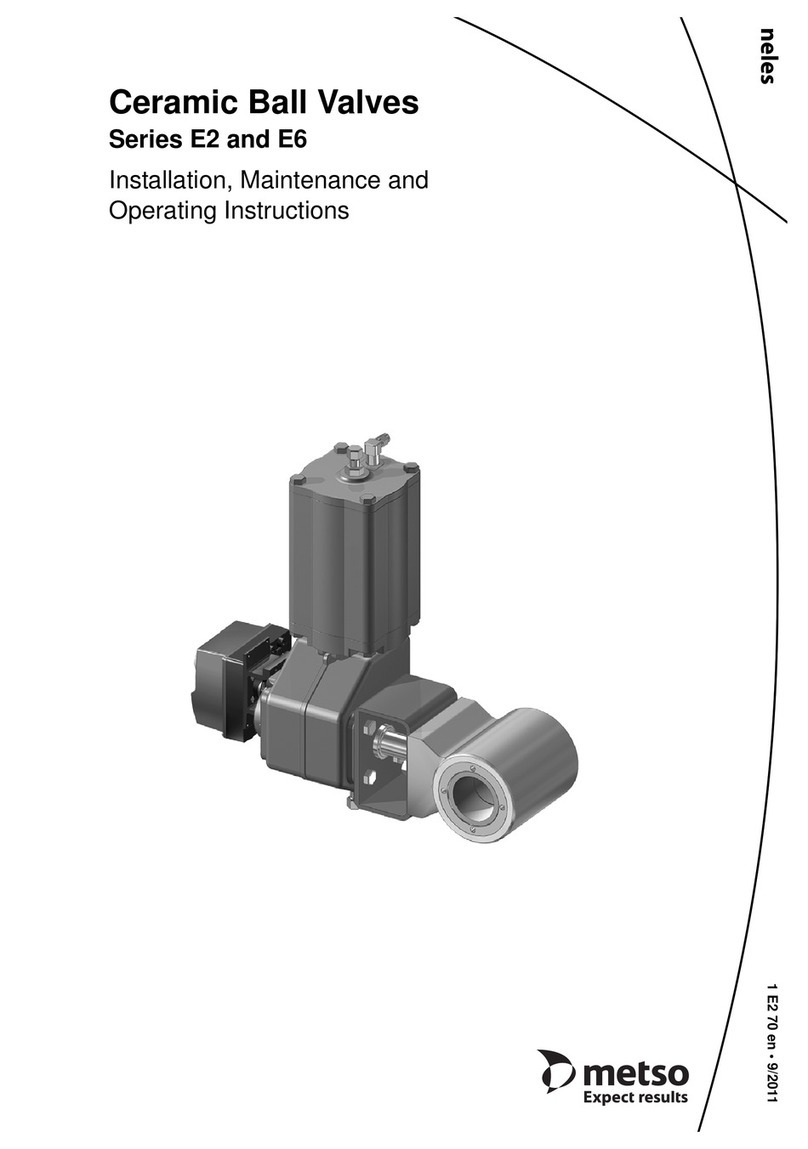

Metso E2 Series Operating and maintenance manual

Metso

Metso L12 Series Operating and maintenance manual

Metso

Metso Jamesbury 4000 B Operating and maintenance manual

Metso

Metso Neles PZ Series Operating and maintenance manual

Popular Control Unit manuals by other brands

Pacific Recorders & Engineering Corporation

Pacific Recorders & Engineering Corporation LSM-10 Technical manual

Wigersma & Sikkema

Wigersma & Sikkema UNIGAS 300 Installation, operating and maintenance manual

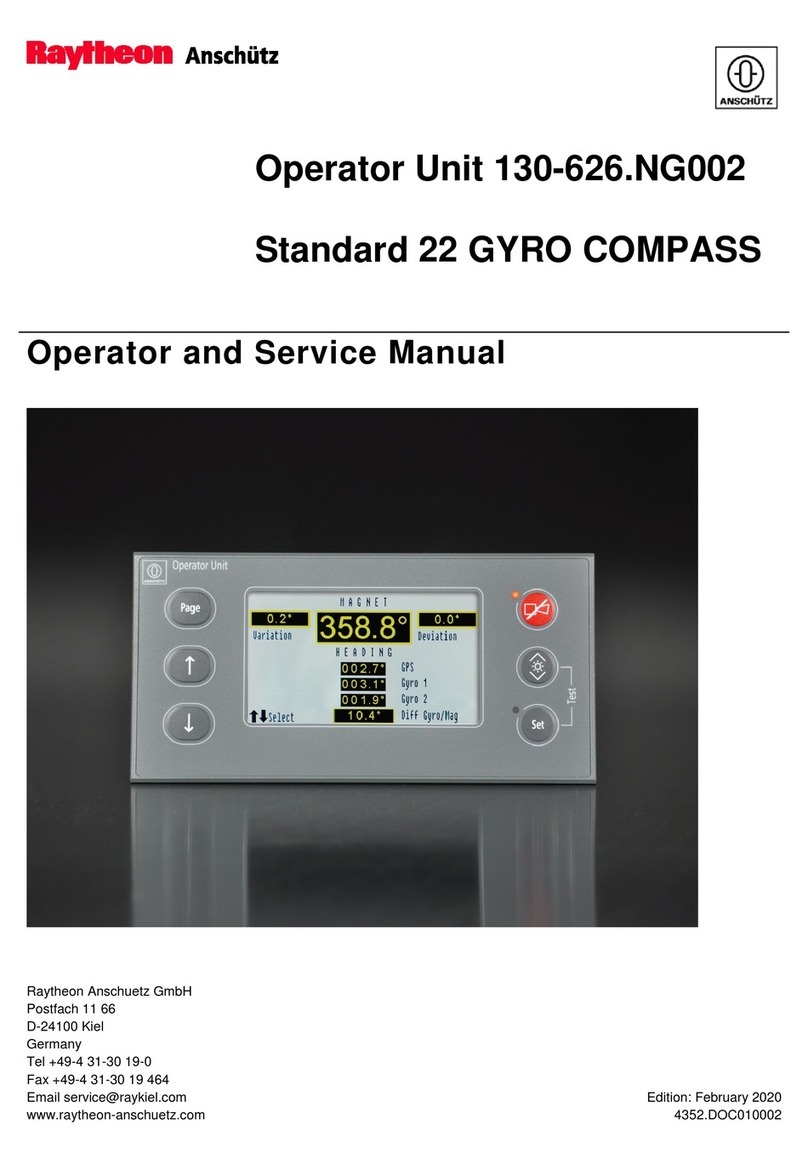

Raytheon Anschütz

Raytheon Anschütz Standard 22 GYRO COMPASS Operator's and service manual

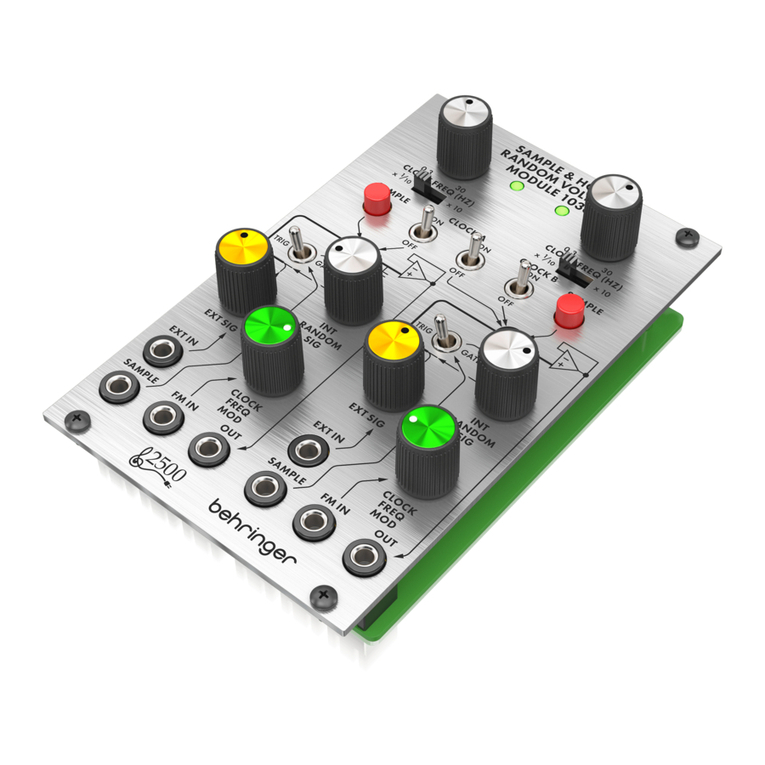

Behringer

Behringer 2500 Series quick start guide

Stahl

Stahl 9469/35 Series operating instructions

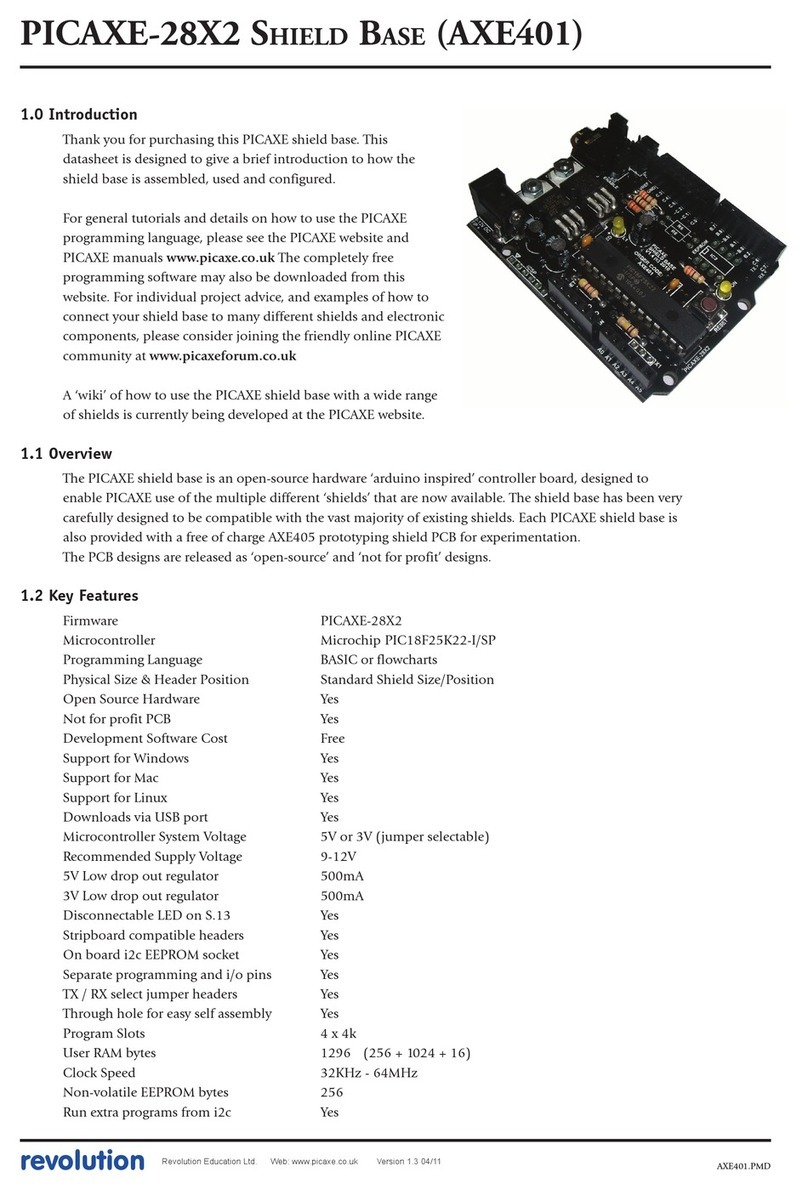

Picaxe

Picaxe AXE401 manual

Asco

Asco 290 Series Installation and maintenance instructions

NiceRF

NiceRF RF24L01F20 manual

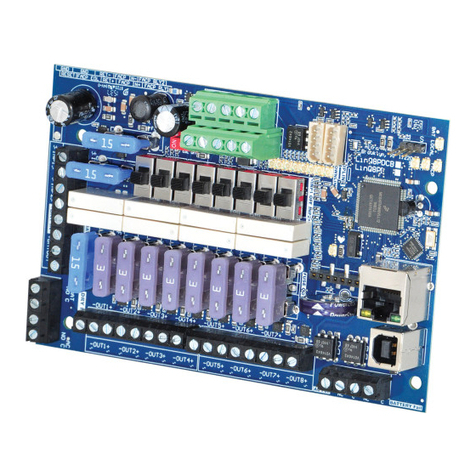

Altronix

Altronix LINQ8PD Installation and programming manual

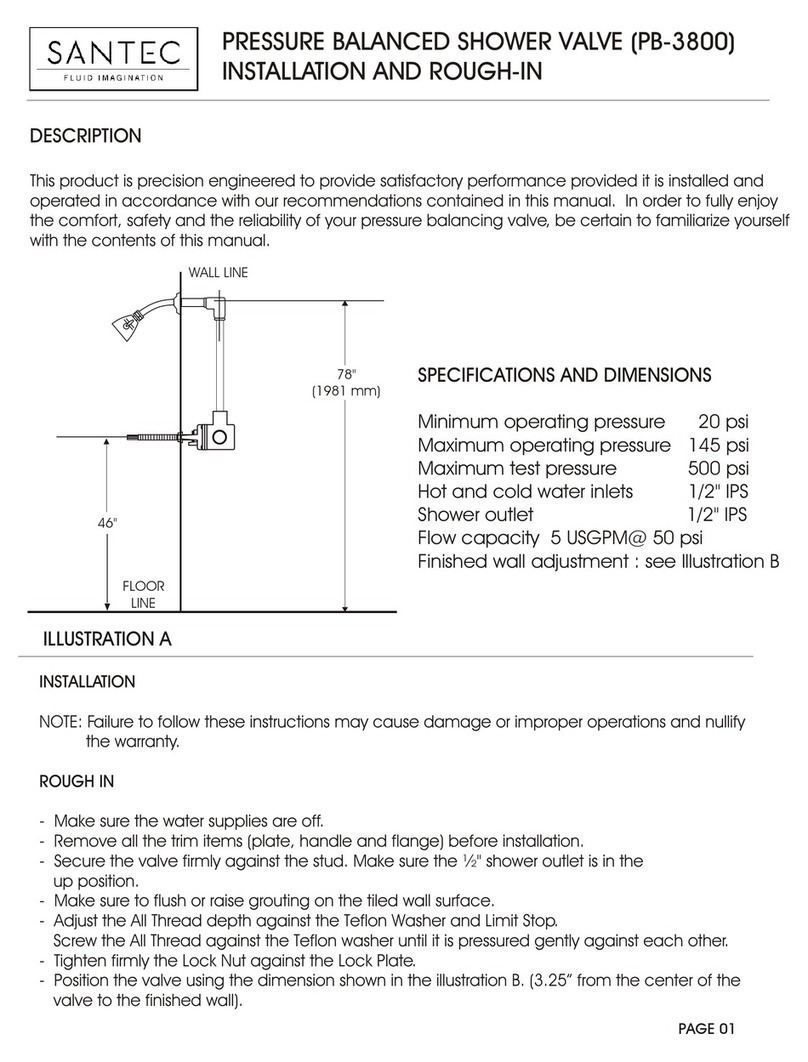

Santec

Santec Designer Series Installation and Rough-In

STIEBEL ELTRON

STIEBEL ELTRON FEB Operation and installation manual

Mitsubishi Electric

Mitsubishi Electric QJ71DN91 user manual