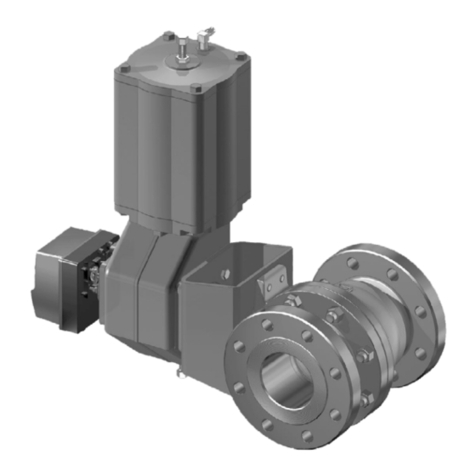

1. GENERAL

This instruction manual contains important information

regarding the installation, operation and trouble shooting

of the Jamesbury® 3” & 4”(DN 80 & 100) Series 5000 Flanged

Ball Valves. Please read these instructions carefully and save

them for further reference.

1.1 WARNING

FOR YOUR SAFETY AND PROTECTION, IT IS IMPORTANT THAT THE

FOLLOWING PRECAUTIONS BE TAKEN PRIOR TO REMOVING THE

VALVE FROM SERVICE OR BEFORE ANY DISASSEMBLY OF THE VALVE.

1. AT ALL TIMES DURING THIS ENTIRE PROCEDURE, KEEP HANDS

OUT OF THE VALVE,A REMOTELY ACTUATED VALVE COULD

CLOSE AT ANY TIME AND RESULT IN SERIOUS INJURY.

2. KNOW WHAT MEDIA IS IN THE LINE. IF THERE IS ANY DOUBT,

CHECK WITH THE PROPER AUTHORITY.

3. WEAR ANY PROTECTIVE CLOTHING OR EQUIPMENT NORMALLY

REQUIRED WHEN WORKING WITH THE MEDIA INVOLVED.

4. DEPRESSURIZE THE LINE AND VALVE AS FOLLOWS:

A. OPEN THE VALVE AND DRAIN THE LINE.

B. CLOSE AND OPEN THE VALVE TO RELIEVE ANY RESIDUAL

PRESSURE THAT MAY BE IN THE VALVE PRIOR TO REMOVING

THE VALVE FROM SERVICE. LEAVE THE VALVE IN THE OPEN

POSITION.

C. AFTER REMOVAL AND PRIOR TO ANY DISASSEMBLY, DRAIN

ANY REMAINING MEDIA BY PLACING THE VALVE IN THE

VERTICAL POSITION AND CAREFULLY OPEN AND CLOSE

THE VALVE SEVERAL TIMES.

5. SEAT AND BODY RATINGS THE PRACTICAL AND SAFE USE OF

THIS PRODUCT IS DETERMINED BY BOTH THE SEAT AND BODY

RATINGS. READ THE NAME TAG AND CHECK BOTH RATINGS.

THIS PRODUCT IS AVAILABLE WITH A VARIETY OF SEAT

MATERIALS. SOME OF THE SEAT MATERIALS HAVE PRESSURE

RATINGS THAT ARE LESS THAN THE BODY RATINGS. ALL OF

THE BODY AND SEAT RATINGS ARE DEPENDENT ON VALVE

TYPE AND SIZE, SEAT MATERIAL, BOLTING MATERIAL, AND

TEMPERATURE. DO NOT EXCEED THESE RATINGS.

2. INSTALLATION

1. Place the valve in the open position.

2. Flow through a Jamesbury valve can be in either

direction. However, it is recommended that the valve

be installed with the insert facing upstream. For dead

ended service 3” and 4” (DN 80 & 100) Series 5000

valves must be installed with the insert upstream.

3. Flow through this Jamesbury valve can be in either

direction. It is recommended, however, that the valve

be installed with the insert facing upstream.

IMPORTANT: The valve should be tightened between anges

using appropriate gaskets and fasteners for the service, in

compliance with applicable piping codes and standards.

4. If there is seepage past the packing upon installation,

the valve may have been subjected to wide

temperature variations in shipment. “Leak-tight”

performance will be restored by a packing adjustment

described in the MAINTENANCE Section.

3. MAINTENANCE

Although Metso’s Jamesbury valves are designed to work

under severe conditions, proper preventative maintenance

can signicantly help to prevent unplanned downtime and

in real terms reduce the total cost of ownership. Metso

recommends inspecting valves at least every ve (5) years.

The inspection and maintenance frequency depends on

the actual application and process condition.

1. Routine maintenance consists of tightening the

packing nut (15) periodically to compensate for stem

seal wear. This may be done as follows:

A. Manual Valves - Loosen the handle screw (18) and

tighten the packing nut (15) until snug, then tighten

an additional 1/4 turn. retighten the handle screw.

B. Actuated Valves - When the valve is connected to an

actuator by a no-play (clamped) type coupling, loosen

the coupling before tightening the packing nut.

2. Overhaul Maintenance consists of replacing seats

and seals. A standard repair kit consisting of these

parts may be obtained through your Metso Distributor

(See Table 1). Refer to the Disassembly and Assembly

sections below for details on installing the repair kits.

TABLE 1

Repair Kits

Valve Size 3” (DN 80)

5150, 530S, 5300

4” (DN 100)

5150

4” (DN 100)

530S, 5300

PTFE Seats RKN75TT RKN76TT RKN77TT

Filled PTFE Seats RKN75MT RKN76MT RKN77MT

PEEK® Seats RKN75LT RKN76LT RKN77LT

UHMW Seats RKN75UU RKN76UU RKN77UU

PFA Seats RKN75BT RKN76BT RKN77BT

PFA Seats &

Seals RKN75BP RKN76BP RKN77BP

Repair Kits contain one pair of seats, a body seal, upper stem seals, a lower stem

seal and maintenance instructions.

NOTE: Repair kits contain two #8 seals and one #24 seal set. Depending on valve

model, one #8 or one #24 will not be used. See note under parts list on page 4

3.1 Disassembly

Tools needed to disassemble Jamesbury valves, such as

the “breechlock eld wrench” mentioned in Step 5, may be

ordered as service parts from your local Metso Distributor.

NOTE: Replacement of seats and seals is recommended if

any disassembly becomes necessary.

1. Read the WARNING Section before performing any

work on the valve.

2. Open the valve.

3. Remove the cap screw (18) holding the handle to the stem.

4. Remove the handle (17).

5. The “breechlock” design requires that the insert be

compressed and rotated approximately 60 degrees

before removal. Use one of the following methods:

IMO 3/18

IMO-059 EN 3