2 BO 70 en 3

1GENERAL

1.1 Safety precautions

1.2 Product & function description

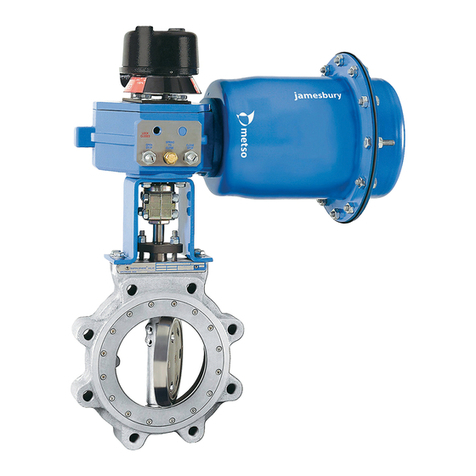

High Performance Butterfly Valve Type BO; a single eccen-

tric disc to shut off pipes and regulate the flow; soft-seated.

Type of body:

□Type wafer

Nominal size:

□DN 200 - DN 900

□NPS 8 - NPS 36

Pressure rating:

□PN 10

□CL 150

□Operation pressure: max. 2bar

Temperature range for standard valves:

□Operating temperature-10 °C - +130 °C

□Store temperature -20 °C - +80 °C

Function description:

The High Performance Butterfly Valve Type BO has been

designed especially for deployment in pressure-changing

systems for oxygen production, where it is required to oper-

ate under extreme demanding conditions due to the high

cycle-related peak tightness requirements. The shut-off disc

is made of aluminium to minimize the disc inertia and give

the valve extremely short opening and closing times. An

elastic sealing ring has been chosen as the sealing element.

The actuator force will be transmitted to the drive shaft as

well as to the disc, by means of fatigue-resistant feather key

connections.

The valve is closed when the disk is in a rectangular position

to the flow direction. The passage between OPEN and

CLOSED amounts (90°) and the disk is driven by an actuator

(manual, electric, pneumatic or hydraulic). There is a mark-

ing on the drive shaft as well as on the body. The valve is

closed when the two markings are aligned.

The notch on the actuator shaft indicates the current posi-

tion of the shut-off disc in the valve. The valve closes clock-

wise.

1.3 Intended use

The delivered valve has been designed especially in accord-

ance with the requirements noted in the order-related

specification.

This especially applies to the operation parameter pressure,

temperature medium and cycle rates.

If the process parameter is exceeded, it can lead to damage

of the valve.

The damaged parts have to be changed immediately.

The pipeline and used medium must be free of dirt, other-

wise the tightness of the valve may be affected.

It is part of the intended use of the valve that the operating,

mounting and maintenance personnel have read and

understood this IMO manual.

CAUTION:

Do not exceed the valve performance limitations!

Exceeding the limitations marked on the valve may cause

damage and lead to uncontrolled pressure release.

Damage or personal injury may result.

CAUTION:

Do not dismantle the valve or remove it from the pipe-

line while the valve is pressurized!

Dismantling or removing a pressurized valve will result in

uncontrolled pressure release. Always isolate the relevant

part of the pipeline, release the pressure from the valve

and remove the medium before dismantling the valve. Be

aware of the type of medium involved. Protect people and

the environment from any harmful or poisonous sub-

stances. Make sure that no medium can enter the pipeline

during valve maintenance.

Failure to do this may result in damage or personal injury.

CAUTION:

Beware of the discs’ cutting movement!

Keep hands, other parts of the body, tools and other

objects out of the open flow port. Leave no foreign

objects inside the pipeline.

When the valve is actuated, the disc functions as a cutting

device. The position of the disc can also be changed

when moving the valve.

Close and detach the actuator pressure supply pipeline

for valve maintenance.

Failure to do this may result in damage or personal injury.

CAUTION:

Beware of noise emissions!

The valve may produce noise in the pipeline. The noise

level depends on the application. It can be measured or

calculated using Metso Nelprof valve-sizing software.

Observe the relevant work environment regulations on

noise emissions.

CAUTION:

Beware of a very cold or hot valve!

The valve body may be very cold or very hot during use.

Protect yourself against cold injuries or burns.

CAUTION:

When handling the valve or the valve package, bear in

mind its weight!

Never lift the valve or valve package by the actuator, posi-

tioner, limit switch or their piping.

Valve sizes DN 400 and over are equipped with lifting eye

bolts.

Place the lifting ropes securely around the valve body.

Advise caution when lifting because the disc may turn.

Damage or personal injury may result from falling parts.

NOTE:

Do not turn the disc more than 90° as this could damage

the seat. The valve is constructed so that the disc operates

only between 0°-90°.