Operating instructions

WARNING

Risk of injury if maintenance work is done incorrectly!

Incorrect maintenance can lead to serious injury and considerable material damage.

Before the start of work, ensure there is sufficient room for doing the work.

Ensure the space around the work is tidy and clean! Parts and tools in loose piles or lying around

are hazard sources.

If parts have been removed, take care to assemble correctly and re-install all attachment items.

Before putting back into service, ensure:

All maintenance work has been carried out and completed.

There are no persons in the hazard area.

All covers and safety devices are installed and operating correctly.

CAUTION

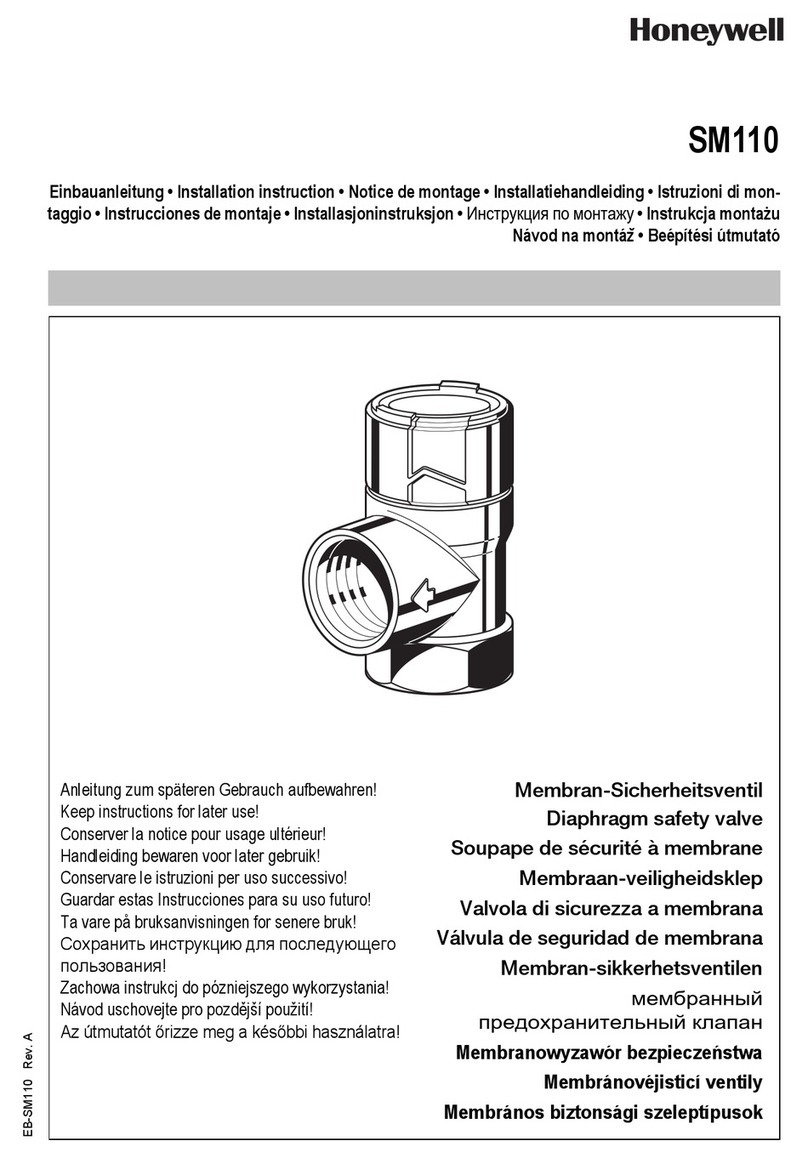

Cold/hot pipelines and/or check valves.

Risk of injury due to thermal influences!

Insulate the check valves.

Attach warning signs.

Medium escaping at high speed and high/low temperature.

Risk of injury!

Wear the prescribed protective equipment

NOTICE

Impermissible stresses arising from operating conditions and extensions / added structures.

Leakage or rupture of the check valve body!

Provide suitable support.

Additional loads, such as traffic, wind or earthquakes, are not explicitly taken into account by

default and require separate sizing.

Condensation in air conditioning, cooling and refrigeration plants.

Icing!

Blocking of the actuation mechanism!

Damage due to corrosion!

Insulate check valves with diffusion-tight material

Improper handling.

Leaking check valve or damage to the check valve!

Do not store tools and/or other objects on the check valve.

Painting of check valves and pipelines.

Functional impairment of the check valve / loss of information!

Protect stem, synthetic material parts and type plate against the application of paint.

Impermissible stress.

Damage to the control mechanism!

Do not use the check valve as a foothold.

Exceeding the maximum permissible operating conditions.

Damage to the check valve!

The maximum permissible operating pressure must not be exceeded, and the minimum and

maximum allowable working temperatures must be observed.

Create the welding/soldering seam stepwise so that the warming in the middle of the body does

not exceed the maximum permissible operating temperature.

Welding beads, scale and other contaminants.

Damage to the check valve!

Take appropriate measures against contamination.

Remove contaminants from the pipes.

Incorrect earthing during welding work in the pipeline.

Damage to the check valve (burned spots)!

Remove bonnet during welding.

When carrying out electric welding work, do not use functional parts of the check valves for

earthing.