Introduction

ICA250i-IN2EN1.pdf2012-12-19

Introduction

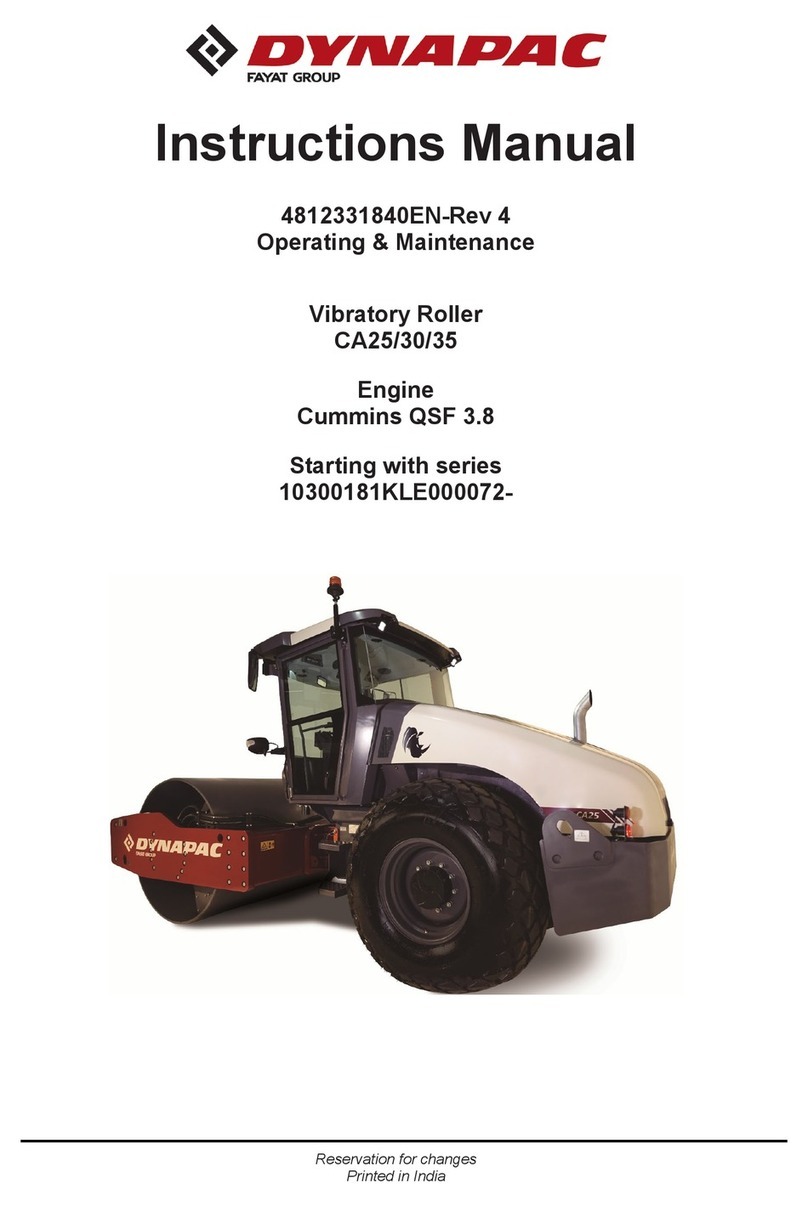

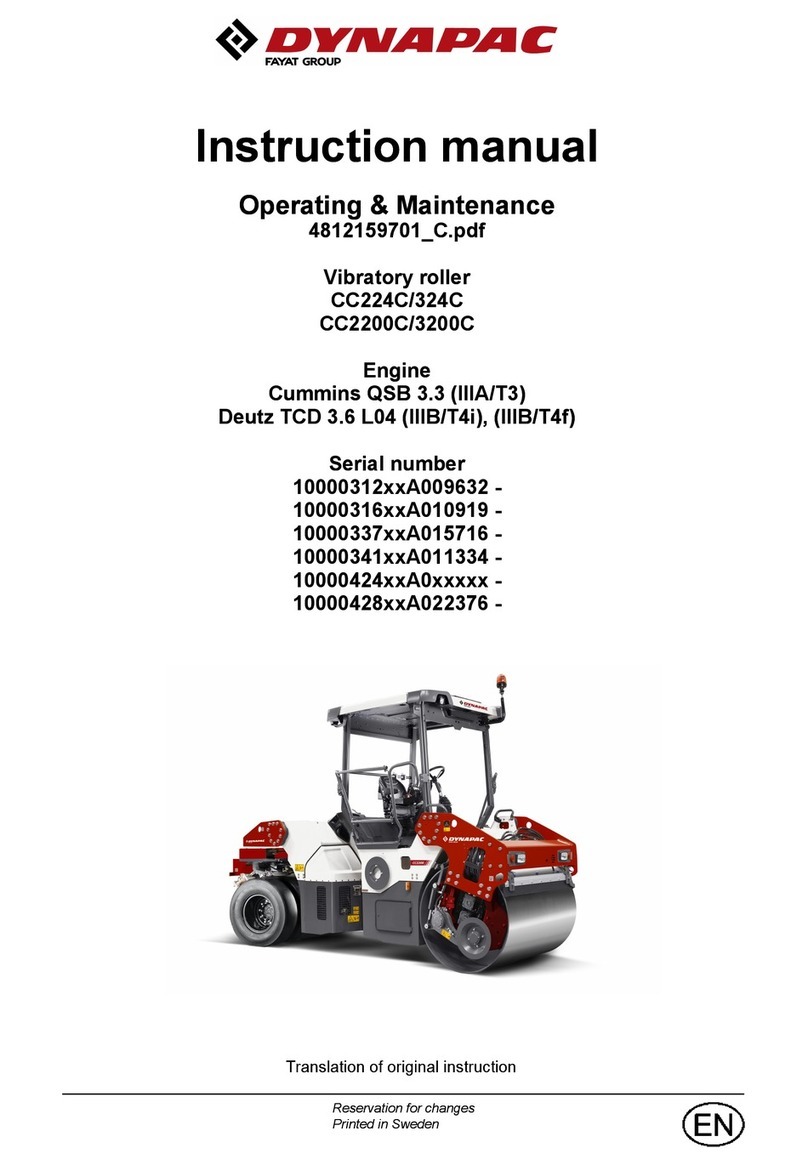

The machine

CA250i is one of Dynapac's medium-heavy soil

compaction rollers. It is available in STD and D

versions.

Intended use

All types of base courses and subbase courses can be

compacted deeper and the interchangeable drums, D

to PD, and vice versa, facilitate even greater variety in

the range of application.

The cab and safety-related accessories are described

in this manual. Other accessories, such as compaction

meter, tachograph and field computer, are described

in separate instructions.

Warning symbols

WARNING ! Marks a danger or a hazardous

procedure that can result in life threatening or

serious injury if the warning is ignored.

WARNING ! Marks a danger or a hazardous

procedure that can result in life threatening or

serious injury if the warning is ignored.

CAUTION ! Marks a danger or hazardous

procedure that can result in damage to the

machine or property if the warning is ignored.

CAUTION ! Marks a danger or hazardous

procedure that can result in damage to the

machine or property if the warning is ignored.

Safety information

It is recommended to at least train operators in

handling and daily maintenance of the machine

in accordance with the instruction manual.

It is recommended to at least train operators in

handling and daily maintenance of the machine

in accordance with the instruction manual.

Passengers are not allowed on the machine, and

you must sit in the seat when operating the

machine.

Passengers are not allowed on the machine, and

you must sit in the seat when operating the

machine.

The safety manual supplied with the machine

must be read by all roller operators. Always

follow the safety instructions. Do not remove

the manual from the machine.

The safety manual supplied with the machine

must be read by all roller operators. Always

follow the safety instructions. Do not remove

the manual from the machine.

We recommend that the operator reads the

safety instructions in this manual carefully.

Always follow the safety instructions. Ensure

that this manual is always easily accessible.

We recommend that the operator reads the

safety instructions in this manual carefully.

Always follow the safety instructions. Ensure

that this manual is always easily accessible.

1