MEWOI MEWOI9000G User manual

Leakage Current Monitoring Recorder

MEWOI9000G, MEWOI9000GB

User Manual

www.mewoi.com

CONTENT

Warning................................................................................................ 1

I.Brief Introduction ............................................................................. 3

II.Electrical Symbol............................................................................ 4

III.Series Model.................................................................................. 4

IV. Technical Specifications.................................................................. 4

V. Instrument Structure......................................................................... 7

VI. Instrument Operation...................................................................... 8

1 Turning on and off...................................................................... 8

2. Language Selection.................................................................. 8

3. Change Display Modes............................................................. 8

4. Selecting Power-saving Mode.................................................. 8

5. Setting Time.............................................................................. 9

6. Data Inquiry............................................................................. 10

7. Deleting Data ...........................................................................11

8. Leakage/current measurement................................................11

9.Real Time Monitoring............................................................ 13

10.Data Download.................................................................... 14

ⅦMonitoring Software Operation..................................................... 14

ⅧBattery replacement..................................................................... 15

ⅨPacking List................................................................................... 16

-1-

- 2-

Warning

Thank you for buying MEWOI9000G,MEWOI9000GB Leakage/Current

Monitoring Recorder manufactured by our company. Please keep to the

following requirements in order to use the product properly:

——Read the User Manual carefully.

——keep to the safety rules and precaution given in the manual strictly.

Pay special attention to safety when using this instrument in any case.

Observe the text and symbols attached to the front and rear panels of the

instrument.

Please replace the battery when the battery voltage low and the LCD display

is dim.

This instrument can not be turned off automatically. Please turn off it after

use.

Don not use the instrument to measure a line with a voltage higher than

600V.

It is forbidden to use the instrument when neither rear cover of the instrument

nor the battery cover is in place.

Never use the instrument when the instrument case or measuring wire is

broken and therefore any metallic part is exposed.

Don not place the instrument at a environment with high temperature, high

humidity, condensation and direct sunshine for a long time

It is necessary to maintain the instrument and clamp periodically to keep

them clean. Don not wipe the clamp by using corrosive medium or abrasive

object.

Avoid flexible bending of the clamp, so as not to cause break to the coil.

Please observe the correct polarity when replacing the battery. Remove the

battery from the instrument if you expect not to use the instrument for a long

time.

-2-

Operation, disassembly and maintenance of the instrument must be carried

out only by a authorized and qualified person.

When there is an instrument fault, never use it because continual use may

result in danger. In this case, isolate the instrument immediately and

delivered to an authorized agency for dealing with it.

The user must follow the safety instructions preceded by “ ”warning symbol

on the instrument and manual.

The user must strictly follow the instructions preceded by “ ”danger symbol

on the instrument and manual.

-3-

I.Brief Introduction

MEWOI9000G/9000GB Current/Leakage Monitoring Recorder is well

designed and manufactured for online measurement, monitoring and recording of

AC leakage / current. It is composed of a tester, monitoring software, current

clamp and communication cable, etc. This instrument has been widely applied in

many fields, such as electrical power, telecommunication, meteorology, railway, oil

fields, construction, metering, research agencies, universities, mines and

enterprises.

Both Chinese and English MMI is built in the instrument. Therefore, it is

suitable for use by engineers and technicians of different counties. The instrument

has a large LCD display with blue background and a large storage space. 4200

sets of data can be stored in the instrument. In addition, the instrument can

automatically store data at an interval, which is adjustable from 1 to 60 min.

MEWOI leakage/current monitor software provides online and real-time

monitoring and historical data inquiry. With the software developed by our

technical department, the instrument can display leakage current dynamically,

display current waveform, maximum value, minimum value and average value.

The users can preset the alarm limit. The instrument will generate an alarm when

the measured current exceeds the limit. In addition, the users can read, inquire,

store, analyze, process, sequence historical data and generate and print a fitting

curve and report.

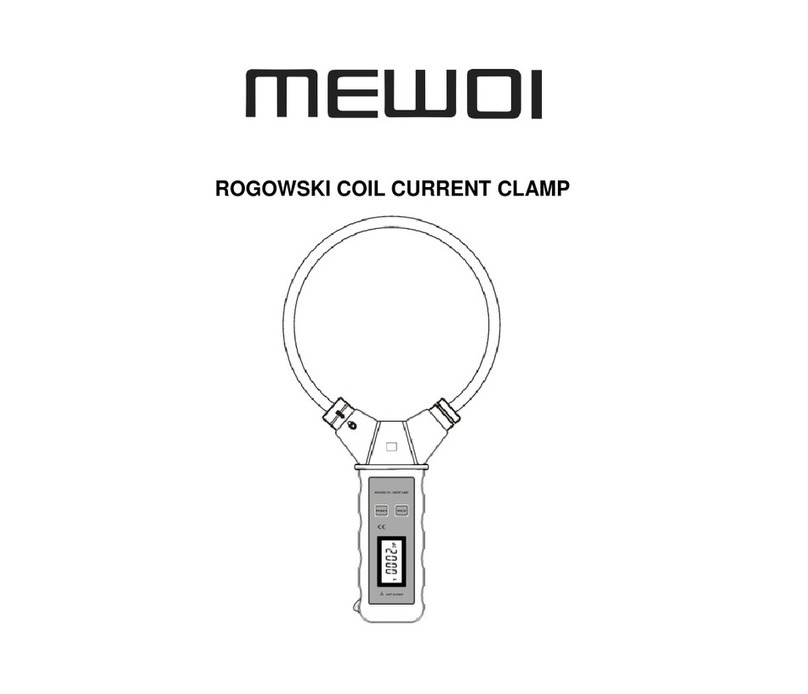

The flexible current clamp, using the advanced Rockwell coil (or Rogowski

coil) technology, is a circular coil that is uniformly twisted on non-ferromagnetic

materials. There is no hysteresis effect, almost zero phase error, no magnetic

saturation, high linearity and strong anti-interference ability. The output signal is

the differential of the current to the time. By integrating the output voltage signal,

the input current can be reduced and the current range can be measured from mA

to 20000A. The flexible current clamp coil has no bare metal conductor,

non-contact measurement, safe and fast, it is small in size, light in weight, delicate

in appearance, suitable for a place with narrow environment and dense line. The

user can customize the length of coil according to the requirement.

-4-

II.Electrical Symbol

Extremely dangerous!The operators must keep to the safety

rules strictly; otherwise, electric shock will result in death or injury.

Dangerous!The operators must keep to the safety rules strictly,

otherwise, electric shock will result in will result in death or injury.

Warning!The operators must keep to the safety rules strictly,

otherwise, personal injury or equipment damage will occur..

Double insulation

Alternating current (AC)

Direct current (DC)

III.Series Model

Model

Range

Coil Diameter

Coil Length

MEWOI9000G

AC 0.00A~

20000A

φ300mm(300G)

1000mm

MEWOI9000GB

AC 0.00A~

6000A

φ200mm(200G)

630mm

IV. Technical Specifications

Functions

Measuring AC leakage current and AC current, on-line

monitoring and recording, locating insulation faults and

repairing electrical lines.

Power source

DC6V, alkaline battery LR6 1.5V×4

Testing

Method

Flexible Coil CT, The output signal is the differential of

current to time. By integrating the output voltage signal,

the input current can be truly restored.

Coil Diameter

φ200mm/φ300mm(Can customize to other size)

Range

AC 0.00A~6000A/0.00A~20.00kA(Can customize)

Resolution

AC 10mA

-5-

Accuracy

±2%±3dgt(The tested wire is in the center of the

flexible coil, 23℃±2℃)

Coil Length

630/950mm(Can Customize)

Current

Frequency

50Hz/60Hz (automatic recognition)

Display

Method

LCD:128dots×64dots

Instrument

Dimension

Tester(L×W×H): 75mm ×170mm ×30mm

Current clamp(L×W×H): 170mm ×70mm ×38mm

Coils

φ7.5mm(suitable for narrow environment and crowded

places)

Weight

Tester: 240g (battery included)

Flexible Coil clamp: 130-150g

LCD

Dimension

Display field: 44mm×27mm

The electric

field

interference

Has no hysteresis effect and strong anti-interference

ability.

Position error

The tested conductor should be at the center of the

flexible coil as far as possible, not near the opening. The

test error at the opening and closing points will be

increased by one time or more.

Sampling

Rate

2 samples/s

Data storage

4200 sets (data loss does not occur after power failure

or replacing the battery)

Time Setting

Recording internal adjustable from 1 to 60 min, If set to

0 min, the auto-store function is turned off

Recording

Time

Continuously operate for about 100hours at the

power-saving mode

-6-

Line Voltage

<AC600V

Overflow

Display

The “OL” symbol is displayed when a measured value is

beyond the measurement range

Battery

Voltage

A Low-Battery symbol is displayed and the user should

replace the battery with a new one when the battery

voltage drops to 4.6V to 4.8V. In this case, the

measured values are still accurate.

Rated Power

about 5mA at the power-saving mode, maximum current

consumption: 20mA

Lead Length

2 m

Temperature

and Humidity

Working: -10℃~40℃;below 80%rh

Storage: -10℃~60℃;below 70%rh

Insulation

Resistance

Higher than 100MΩ, 1000V

Safety Codes

IEC1010-1, IEC1010-2-032, Pollution Class 2, CAT

Ⅲ(600V), IEC61326(EMC standard)

-7-

V. Instrument Structure

1. Flexible Coil Current clamp interface

2. LCD(128dots×64dots, Chinese and English MMI)

3. Up, down, left, right keys and MEM control key

4. Instrument body

5. POWER key (for turning on and turning off the instrument)

6. USB data download interface

7. Flexible coil tap port A

8. Flexible coil tap port B

9. Lead shield layer

10. Audio plug

11. Output lead

12. Lock catch (Switch the arrow forward and backward to lock or open the

coil).

-8-

VI. Instrument Operation

1 Turning on and off

Turn on the instrument by pressing the POWER key. The LCD will light up.

The display on the LCD is as shown in the left figure. If the LCD display is

dim, the battery voltage may be low. If so, replace the battery with a new

one. Press the POWER key again to turn off the instrument. This

instrument can not be turned off automatically. Please turn off it after use.

2. Language Selection

Both Chinese and English MMI is built in the instrument to facilitate use by

engineers and technicians of different counties. After the instrument has

been turned on normally, select the language by pressing the LEFT and

RIGHT arrow keys, press the MEM key to confirm the selected language

and enter the measurement status.

3. Change Display Modes

After confirming the selected language and entering the measurement

status, press the LEFT and RIGHT arrow keys to change over between

measurement display modes. The measured values can be displayed in

two modes as shown in Figures A and B. Only the measured leakage

current is displayed in Fig. A. The measured leakage current, number of

stored data sets, date &time and preset storage interval are displayed in

detail in Fig. B. Press the RIGHT arrow key to change over to the display

mode as shown in Fig. B, and the LEFT arrow key to change over to the

display mode as shown in Fig.A.

4. Selecting Power-saving Mode

Press the DOWN arrow key at the measurement status to turn off the LCD

-9-

back-light and enter the power-saving mode. Press the UP arrow key to

turn on the backlight. The power consumption at the power-saving mode is

only 20 percent of the one at the common mode (the backlight is turned on).

It is recommended that the power-saving mode be adopted for long-time

online measurement and recording.

5. Setting Time

Press the MEM key at the measurement state to access the function menu,

press the UP or DOWN arrow keys to move the cursor to the Time Setting

item, and press the MEM key again to enter the date& time setting mode.

At the date& time setting mode, press the UP or DOWN arrow keys to

change values, press the LEFT or RIGHT keys to move the cursor, press

MEM key to Confirm or Cancel the setting.

After the recording interval has been set, return to the measurement state.

The instrument will automatically store the measured values at the set

interval. The instrument can store up to 4200 data sets. If the memory is

full, FULL will be displayed on the LCD. The instrument can store new data

only after some of stored data is deleted.

The instrument doesn’t have automatic clock function.

The date and time will reset to the default value (08.08 AM,

Aug 8, 2008) each time the instrument is turned on.

Press the MEM key to “Cancel” or maintain the previous

setting.

-10-

The storage interval is defaulted to “00” min each time the

instrument is turned on, that is to say, no measured value

is stored.

6. Data Inquiry

At the measurement state, press the MEM key to access the function

menu, press the UP or DOWN arrow keys to move the cursor to Data

Inquiry item, and press the MEM key to enter the inquiry submenu. Inside

the inquiry submenu, the first left line display the current page number and

total pages, the third line displays three sets of recorded values, and the

right side displays the page number increment. It is allowed to rapidly

navigate to the desired page number. Press the UP or DOWN arrow keys

to move the cursor and select the page number increment and then press

the MEM key to confirm the selection.

Press the MEM key with the cursor located at certain data set to display

the detailed information about this data set, including the set number

/stored data sets, current amplitude and recording time, etc.

Generally speaking, press the arrow keys to move the cursor and press

MEM key to confirm the selection under the inquiry submenu. The relevant

display is as shown in the following figure:

-11-

7. Deleting Data

At the measurement state, press the MEM key to access the function

menu, press the UP or DOWN arrow keys to move the cursor to “Deleting

Data” item, When press the MEM key again, a data deleting tips will pop

up. Press the MEM key with the cursor located at “OK” to delete the stored

data. Press the MEM key with the cursor at Cancel to cancel the deletion

and return to the main menu.

It is impossible to recover the deleted data. Take care to

delete any data.

The deletion operation will delete all of the stored data.

8. Leakage/current measurement

Electric shock, dangerous !The instrument can be

operated only by the trained and authorized person. The

operators must keep to the safety rules strictly;

otherwise, electric shock will result in personal injury or

damage to the equipment.

Don not use the instrument to measure the lines with a

voltage of higher than 600V, Otherwise, electric shock

will result in personal injury or damage to the

equipment.

1) Connect the flexible coil current clamp with the instrument body properly,

turn on the instrument and enter the measurement mode.

2) Clamp the measured conductor with the current clamp (ensure that the

clamp end should be fully closed, can be locked or opened by turning

the arrow in the direction of the arrow in the structure diagram). Observe

the reading. If an OL symbol is displayed on the instrument LCD, the

measured current exceeds the upper measurement limit of the

-12-

instrument.

The conductor to be tested should be in the center position of the

flexible coil (near point A), not near the opening and closing

mouth (C area). The test error at the opening and closing mouth is

about doubled or more, and the position error near point B is

increased by about 1%.

3) When the measured current is small, the test resolution can be

improved by repeatedly wrapping the flexible coil on the wire to be

tested and then closing it a plurality of turns. For example, the

measured current is 0.01A. After the flexible coil wraps around the

tested conductor for 3 turns, the test meter displays 0.03A, and

around 5 turns, it displays 0.05A, and so on. The actual current is

equal to the meter display value divided by the flexible coil. The

number of turns around. See the legend for the reference.

Detecting the

total electricity

safety status

Multi-turn

test

Grounding

Detecting hidden

dangers of buried

wall electricity

charges

Test

equipment

operation safety

status

Detecting

ground

leakage

-13-

The current of the line is measured by clamping the live

wire or the neutral wire separately (note that clamping 1

wire).

Clamp the live & neutral wires together to measure the

leakage current of the single phase (note that clamping 2

wires).

Clamp the ground wire to measure the leakage current of

the grounding wire of the electrical equipment (note that

clamping 1 wire).

Clamp the three-phase 3-wire together to measure the

leakage current of three-phase 3-wire (note that clamping 3

wires).

Clamp the three-phase 4-wire together to measure the

leakage current of three-phase four-wire (note that

clamping 4 wires).

Clamp the three-phase 5-wire together to measure the

leakage current of three-phase 5-wire (note that clamping 5

wires).

For safety, when measuring high voltage and high current,

after confirming that the test has been performed correctly,

move the meter away from the conductor under test.

9.Real Time Monitoring

Open the host to enter the test state, connect the computer and the host

computer with a randomly configured USB communication cable, and run

the monitoring software installed in the computer. If the communication is

normal, the computer can monitor the online current in real time. If the

user fails to connect to the monitoring software, there may be a lack of

driver. Install the USB to serial port driver in the randomly configured CD

to use it normally.

-14-

10.Data Download

Connect the meter and computer with the randomly configured USB

communication cable, turn on the meter, run the monitoring software,

select the history to view, and then read the data. The more the data

storage, the longer the reading time. If the host storage is full, it takes

about 2 minutes.

ⅦMonitoring Software Operation

The monitoring software has online real-time monitoring, history query,

dynamic display, waveform indication; has maximum, minimum, and

average indication; has alarm value setting and alarm indication; has

historical data reading, reviewing, saving, sorting, generating curve,

printing and other functions. The introduction is as follows:

1. Homepage

After running the software to display the main interface, click the

“Enter” real-time monitoring interface.

The mouse cursor is in the waveform display area. Press and hold the

left mouse button to drag up or down to zoom in or out. The

monitoring data is refreshed every 0.5 seconds and monitoring can be

suspended at any time.

2. Alarm prompt

When the monitored current value is greater than the alarm set value,

the red alarm indicator flashes and the alarm set value can also be

cancelled.

-15-

3. Save waveform

Waveforms can be saved during real-time monitoring and saved in

BMP image format.

4. Historical review interface

Historical review includes: reading, saving, emptying, generating

curves, printing, ascending, descending, restoring, page turning and

other functions.

5. Historical data reading

The more historical data records, the longer the read time, and there

is a real progress indication.

6. Ascending Sequence of Historical Data

The historical leakage record values are arranged from small to large,

and if the values are the same, they are arranged in chronological

order.

7. Descending Sequence of Historical Data

The historical leakage record values are arranged from large to small,

and if the values are the same, they are arranged in chronological

order.

8. History saving

Historical data is saved in pages in TXT text format.

ⅧBattery replacement

Pay attention to the polarity of the battery, otherwise

the instrument will be damaged.

The battery is low, please replace it in time.

Cannot mix old and new batteries.

1) When the battery voltage drops to 4.8V±0.1V, the meter displays a

low battery voltage symbol, indicating that the battery is low. Please

replace the battery.

2) Press the POWER button to turn off the power, confirm that the

meter is off, open the battery cover, replace it with a new qualified

battery, pay special attention to the polarity of the battery

specification, cover the battery cover, and then turn on the power to

confirm whether the replacement is complete.

-16-

ⅨPacking List

Host

1PCS

Flexible current clamp

1PCS

RS232 Communication line

1PCS

Monitoring software (CD)

1PCS

Meter package

1PCS

User manual, warranty card, certificate

1PCS

This manual suits for next models

1

Table of contents

Other MEWOI Measuring Instrument manuals

MEWOI

MEWOI MEWOI-HY128 Series User manual

MEWOI

MEWOI MEWOI9000 User manual

MEWOI

MEWOI MEWOI1200 User manual

MEWOI

MEWOI 7800 User manual

MEWOI

MEWOI MEWOI7300E User manual

MEWOI

MEWOI MEWOI1330B User manual

MEWOI

MEWOI MEWOI8100E User manual

MEWOI

MEWOI MEWOI400 User manual

MEWOI

MEWOI MEWOI-JY218 User manual

MEWOI

MEWOI MEWOI1000 User manual

Popular Measuring Instrument manuals by other brands

Hanna Instruments

Hanna Instruments HI 93717 instruction manual

SCS

SCS Static Monitor 790 Installation, operation and maintenance

Nivel System

Nivel System M100 DIGITAL manual

Fleck

Fleck 3200ET Service manual

Badger Meter

Badger Meter ModMAG M2000 Installation and operation manual

CST/BERGER

CST/BERGER LD90 Original instructions