10

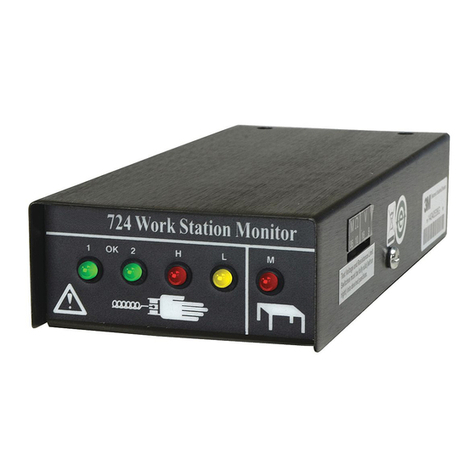

a. Red lamp(s) flashing with an audible alarm.

This alarm mode can be caused by two conditions and both are interrelated. If

either the voltage level on the operator is greater than the pre-selected internal

reference voltage or poor contact between the wrist band and the arm exist, the

alarm will activate.

If the 3M™Static Monitor 790’s alarm activates when the operator is not

moving (normally a non-charging situation), the cause is most likely due to

poor contact between the wrist band and the arm. The alarming period would

normally be long in duration (unless intermittent contact) during this type of

condition. Check contact between the wrist band and arm. Some operators

may have difficulty in providing sufficient contact to the wrist band because

of dry skin or arm hair. They may need to use an approved skin moisturizer or

reposition the wristband on the arm.

If the monitor’s alarm does not activate while the operator is not moving, then

the cause of the alarm was most likely due to a voltage being developed on the

operator. A high resistance between the operator and ground would allow the

operator to charge up as they moved about. The alarm period for this type of

fault would normally be short and coincide with their body movement.

Alarming can also be caused by an intermittent or high resistance in the wrist

strap’s dual conductor ground cord. Replace a suspect cord with a known good

ground cord or check the end to end resistance of the cord using an ohmmeter.

Approximately 1 megohm of resistance should exist between the tip to tip and

barrel to barrel contacts of the two plugs located on opposite ends of the cord.

Note: The operators may complain that the alarm is sounding too often until they learn to adjust the

wristband to fit securely or apply an approved skin moisturizer on a frequent basis. Please remember

that the monitor is informing you that the operator is exceeding the established static control

requirement for voltage to ground when wearing a static protective wrist strap assembly. These

alarms alert the operator when sensitive electronics are possibly being exposed to static electricity.

Prior to incorporating the static monitor into your static control process, the operator was unaware

of these events.

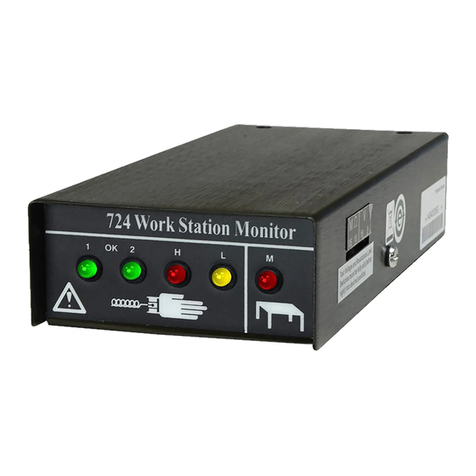

b. Two red lamps illuminated (continuously) with an audible alarm.

This indicates that a high resistance condition (greater than 10Ω) exists

between the Chassis/Ground Cord and ground. This will include the

equipment chassis ground if being monitored. Check the ground cords for

continuity and ground attachment points.