MEWOI WBGT2019A User manual

This manual suits for next models

1

Table of contents

Other MEWOI Measuring Instrument manuals

MEWOI

MEWOI MEWOI1310B User manual

MEWOI

MEWOI MEWOI400 User manual

MEWOI

MEWOI MEWOI8000B User manual

MEWOI

MEWOI MEWOI1000 User manual

MEWOI

MEWOI MEWOI7300E User manual

MEWOI

MEWOI MEWOI-JY218 User manual

MEWOI

MEWOI 7800 User manual

MEWOI

MEWOI 8000 User manual

MEWOI

MEWOI MEWOI1200 User manual

MEWOI

MEWOI MEWOI8100E User manual

Popular Measuring Instrument manuals by other brands

Molecular Devices

Molecular Devices SPECTRAmax PLUS 384 Operator's manual

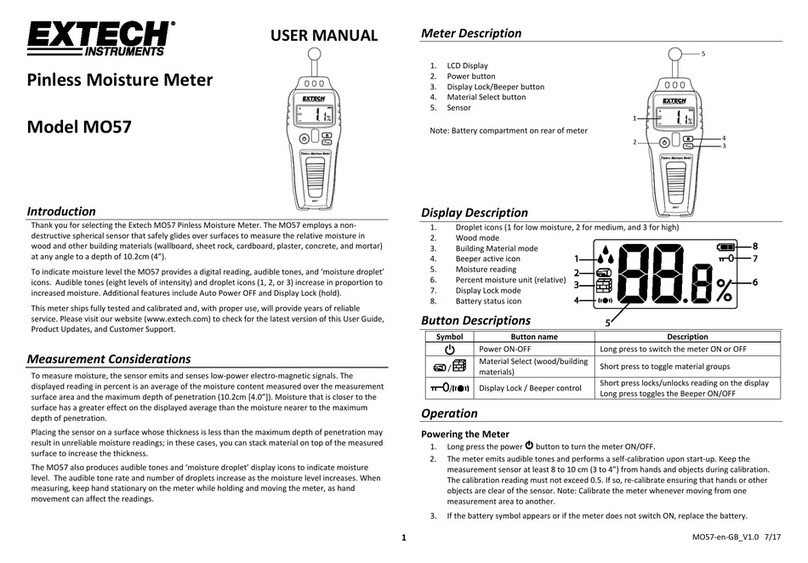

Extech Instruments

Extech Instruments MO57 user manual

SKF

SKF TKTL 31 Instructions for use

Sper scientific

Sper scientific 840012 instruction manual

Benning

Benning TA 6 operating manual

Veratron

Veratron OceanLink operating instructions

Bricon

Bricon SPEEDY manual

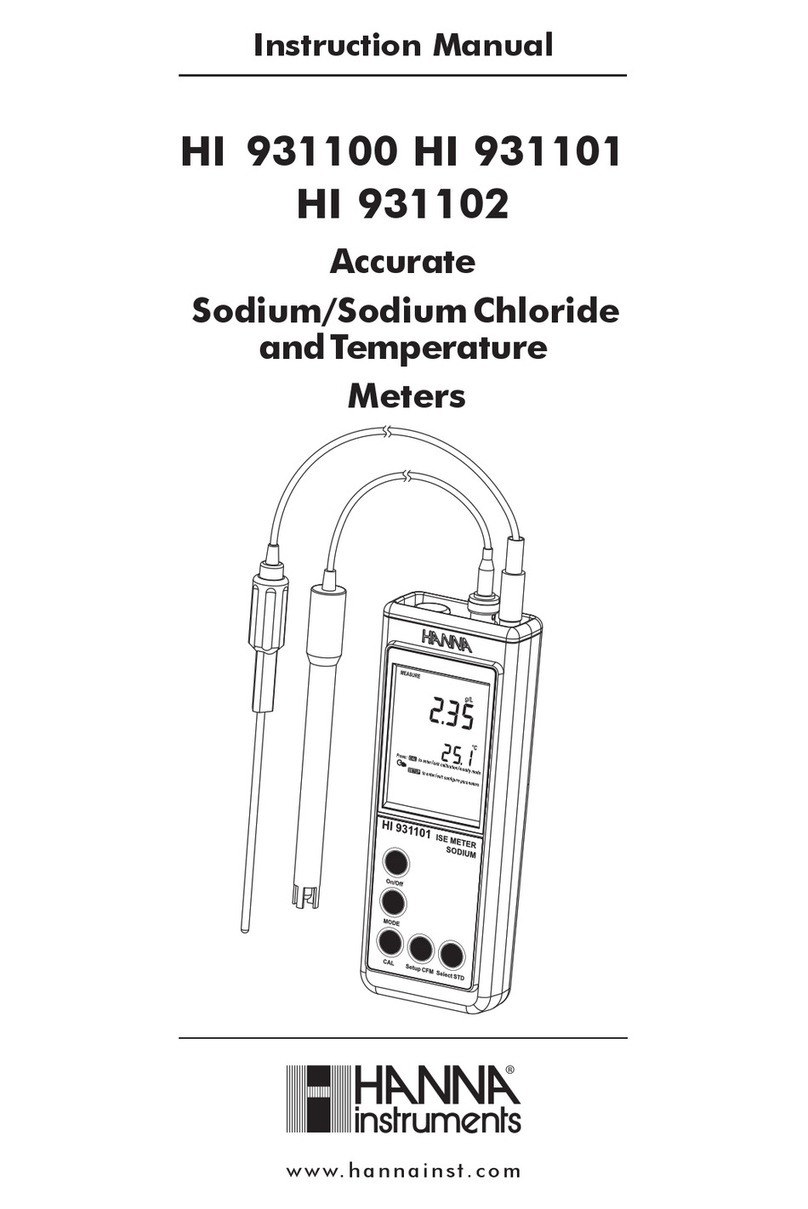

Hanna Instruments

Hanna Instruments HI 931100 instruction manual

Agilent Technologies

Agilent Technologies FieldFox MW N9913A Service guide

Stocks AG

Stocks AG MM 117A Installation, Calibration and Operation

Krone

Krone OPTISOUND 3030 C operating instructions

Worldcast Systems

Worldcast Systems ecreso NEXT FM user manual