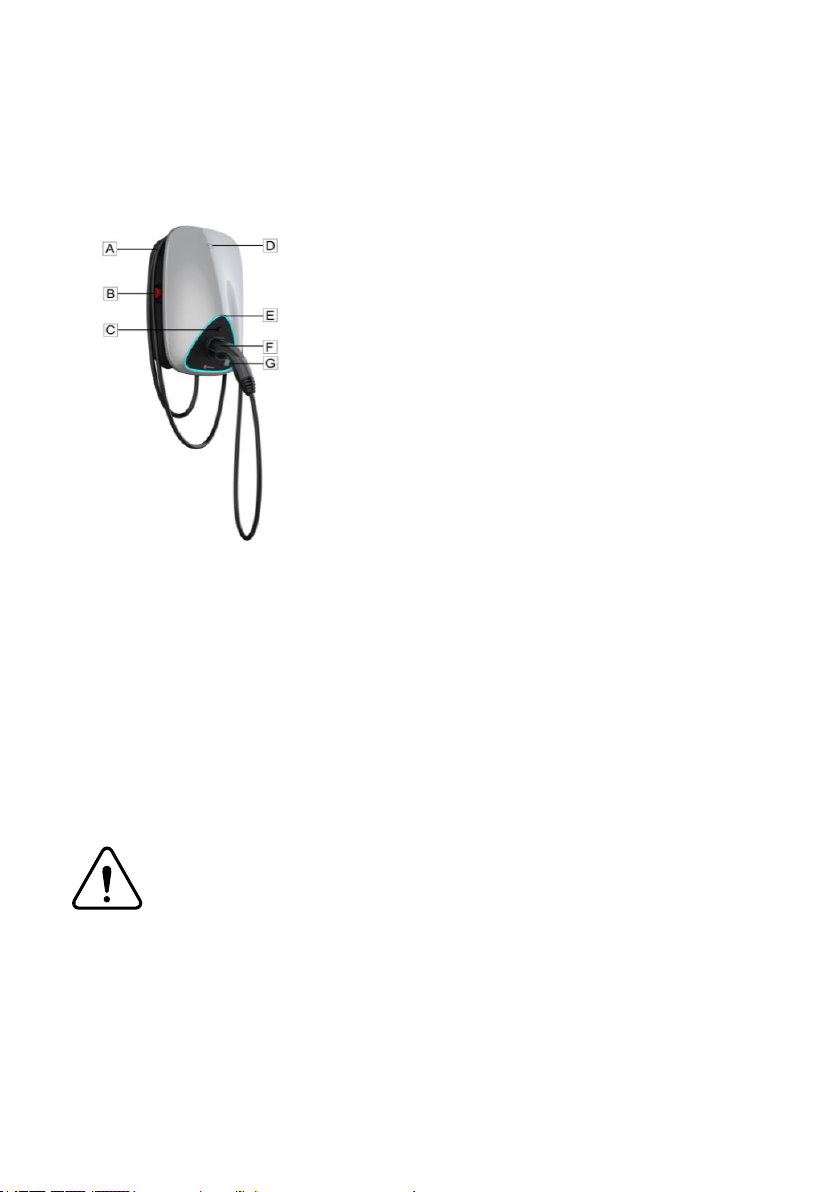

5MG MOTOR INSTRUCTION MANUAL

SYMBOL CONTENT

Failure to follow safety instructions can result in death, injury, and equipment

damage. Refuse to bear any claims arising from this.

• ELECTRICAL HAZARD

Only trained, qualied and authorized electrical professionals are responsible for

installation.

• The rst time to commission and maintain the charger, it should comply

with existing standards and installation regulations when performing the

aforementioned operations. See chapter “A Installation Instructions” for details.

• ELECTRICAL HAZARD / FIRE HAZARD

• Must regularly check the charging connector (including cable) in charger for

damage and check whether the case is damaged (visual inspection).

• If the charger is damaged, it must be turned off and replaced immediately.

• Do not perform the charger maintenance work without authorization. Only

the manufacturer can perform the operation (replace the charger).

• Do not modify or modify the charger.

• Never remove signs such as safety symbols, warnings, nameplates, signs or

pipeline markings.

• No extension cable shall be used when connecting the electric vehicle to the

electric vehicle power supply device.

• Only connect electric vehicles or their charging equipment.

Do not connect other loads (power tools, etc.).

• Hold the connector when pulling the charging connector, and do not pull the

cable.

• Do not bend, squeeze or tilt the charging connector so that it is mechanically

damaged.

• Do not touch the heat source, dirt or water on the contact surface.

• Some vehicles may generate toxic or explosive gases in the indoor area during

charging, so an external ventilation system must be provided.

• When using an integrated charger to charge your electric car, please read the

vehicle’s tips and instructions carefully.

CAUTION

• Damage hazard.

• Never use spray water to clean the charging point

(Hose for garden watering, high pressure cleaners, etc)

Instruction Manual