MICRO-AIR MAE2200 User manual

AIR CLEANERS

MAE2200

OWNER’S MANUAL

CAUTION

READ COMPLETE INSTRUCTIONS BEFORE OPERATING.

PLEASE FILE FOR FUTURE REFERENCE.

®

2

MAE2200

®

MODEL MAE2200 SPECIFICATIONS

Input Volts: 208-230/460 VAC 60Hz, 3-phase

Max. Current:208-230 VAC - 7.2 amps

460 VAC - 3.6 amps

Motor: 2 HP 3-phase TEFC Motor

Dimensions: 22"H. x 26"W. x 78"L. (cabinet and plenum)

Shipping WT:375 lbs. without arms

Actual WT: 325 lbs. without arms

ARM SPECIFICATIONS

Arm Length (Horizontal Reach): 14' - 8" dia.

10' - 8" dia.

8' - 8" dia.

Actuator:1/8 HP totally enclosed motor, 12" stroke at 35 in/min.

Input Volts: 120 VAC 60 Hz

Current: 2.1 amps

Control Circuit: 24 VAC

Hood Lamp: 12 VAC halogen at 4 amps

Weights: 8" dia. - 14' = 48 lbs

8" dia. - 10' = 40 lbs

8" dia. - 8' = 35 lbs

PACKAGE CONTENT

1 ea. MAE2200 with Plenum

1 ea. *Arm Assembly

1 ea. Owners Manual

1 ea. Arm Installation Kit

*Dual Arm units will contain two each of this item.

UNCARTONING INSTRUCTIONS

1. The MAE2200 is packaged in two cartons. Carton one

has the MAE2200 with plenum and base collars banded

to the wooden skid. Carton two contains the arm

assembly(s).

2. Cut the metal banding that secures the unit to the skid and

remove all cartoning, plastic wrap and padding.

3. Remove blower access panel. Inspect blower, motor, belt

tension and power leads for damage. Replace blower

access panel after inspection is complete. Report any

shipping damage to freight line carrier.

4. Open large door on the side of cabinet. Lift handles

outward and rotate to open door. Remove the plastic bag

from the filter and cut the paper band that is holding the

filter pockets in place. Reinstall the bag filter.

5. Open carton two and remove arm. Remove packaging

supports from arm assembly. Be careful not to damage the

steel tubes on the arm during unpackaging.

6. Inspect the arm for damage that may have been caused

during shipping. Immediately report any such damage to

the shipping carrier.

7. Examine the arm and compare it to the parts list

description to verify that all components have been

received. If a component is missing from the assembly,

contact your Micro Air Representative.

INSTALLATION INSTRUCTIONS

CAUTION: THIS UNIT WITHOUT THE ARMS WEIGHS

APPROXIMATELY 325 POUNDS. THEREFORE,

APPROPRIATE MANPOWER OR EQUIPMENT IS

RECOMMENDED FOR SAFE INSTALLATION.

CAUTION: DO NOT ATTEMPT TO MOUNT UNIT USING

THE FOUR THREADED HOLES ON THE BOTTOM SIDE

OF CABINET.

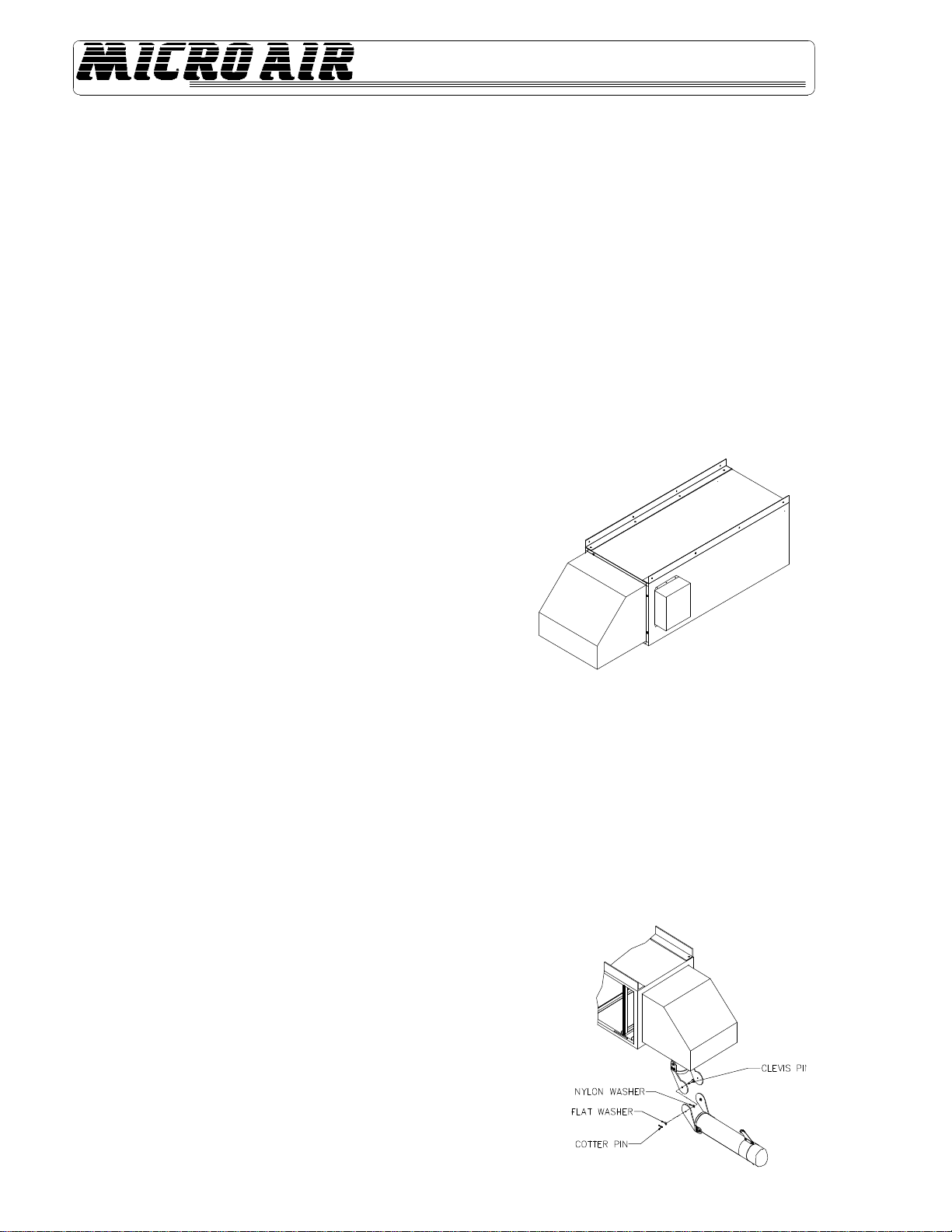

1. Install unit from solid structural support. Unit may then be

suspended with a rigid hanger assembly having sufficient

strength to support cabinet and the additional uneven load

of arm assembly(s) fully extended. (See FIG. 1.)

WARNING: DO NOT ATTEMPT TO INSTALL BY

SUSPENDING WITH CHAINS. ALL THREAD, ANGLE IRON,

OR OTHER FIXED SUPPORTS ARE REQUIRED.

ARM INSTALLATION INSTRUCTIONS

NOTE: Due to the numerous system combinations available,

some of the following installation steps may not be applicable.

Follow steps that directly address the specific system being

installed.

1. Assemble the arm(s) to the base collar using the hardware

preassembled to the arm as shown in FIG. 2.

FIG. 1

FIG. 2

3

MAE2200 ®

NOTE: During the step, it is recommended that two people be

used: one to support the arm assembly, while the other

attaches hardware to clamp arm assembly onto base collar.

2. Once the arm assembly is attached to the base collar,

raise the arm to a horizontal position (arm parallel to floor).

Using the hardware provided, attach the rigid pipe section

as shown in FIG. 3.

3. If vertical adjustment of the arm is required, adjustment

can be made by repositioning the clamp band along the

pipesection.

4. To reposition the clamp band, loosen the 1/4" bolts on

clamp band so that the clamp band can be moved for arm

adjustment.

NOTE: This is for fixed arm models only. If your arm has a

linear actuator proceed to Step 5.

5. For models that use a motorized base joint, assemble the

linear actuator to the base collar with hardware provided.

Then assemble other end to the clamp band, similar to

that of the fixed joint assembly. (See FIG. 4.)

WARNING: FOR MODELS WITH A LINEAR ACTUATOR

DO NOT RELOCATE CLAMP BAND IN SUCH A WAY THAT

LINEAR ACTUATOR COULD COME IN CONTACT WITH

MAE2200 PLENUM OR OTHER OBJECT WHEN

ACTUATOR IS FULLY RETRACTED.

ELECTRICAL INSTALLATION

CAUTION: INSTALLATION CAN CAUSE EXPOSURE TO

LIVE COMPONENTS. DISCONNECT ELECTRICAL POWER

BEFORE PROCEEDING WITH INSTALLATION.

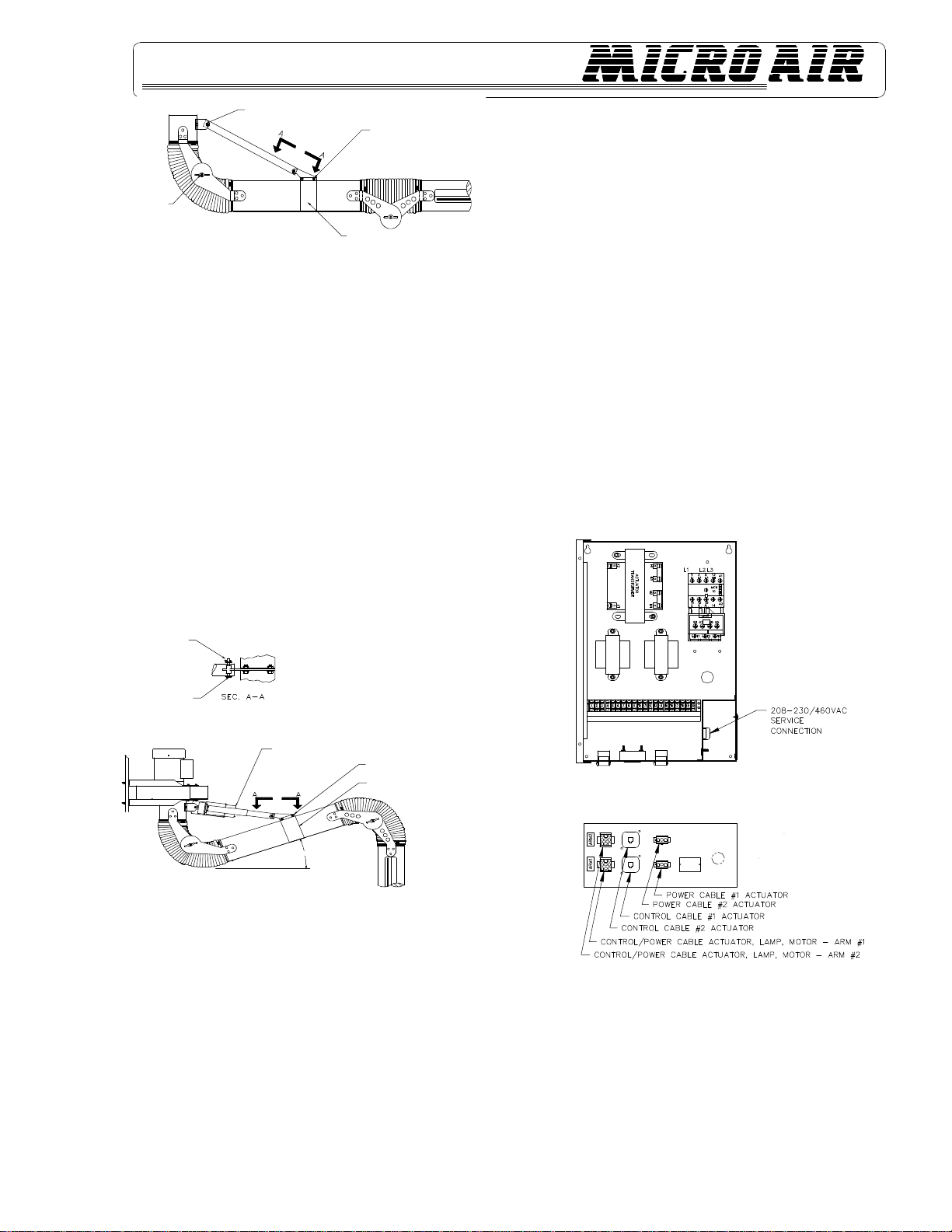

1. LINEAR ACTUATOR INSTALLATION:

The linear actuator is supplied with a 3-conductor input

power cable and a phone-type control cable.

A. The input power cable is supplied with a 3-pin

quick-connect plug which plugs into the 3-pin

receptacle located below the electrical box.

B. The phone-type control cable is supplied with

two plugs that plug into the actuator on one end

and a phone jack receptacle located below the

electrical box.

2. LOW VOLTAGE CONTROL CABLE:

The low voltage control cable is a seven-conductor cable that

once connected allows the control switches located at the

nozzle to control the linear actuator, lamp, and motor/blower.

Connect the control cable to the 9-pin connector in the

electrical box bottom.

NOTE: When a single arm configuration is used, be certain to

connect all power and control cables to their respective

receptacles labeled ARM #1. (See FIG. 5.)

3. The MAE2200 is designed to operate from 208-230/460

VAC at 60 Hz, 3-phase. Takes input power cable through

the knockout hole in the power box bottom and connect

input power wiring to the designated wiring terminal strip.

Be sure to ground AC input per local electrical codes.

FIG. 5

NOTE: Once the input voltage is supplied to the electrical box,

control transformers become energized. It is recommended

that a disconnect switch or breaker box be installed in line with

the system to remove input power from system when not in

use.

BASE JOINT

ATTACHRIGIDPIPE SECTION

TOSWIVELBASEUSINGTHE

CLEVIS PIN PROVIDED 1/4"-20 HEXBOLT,FLAT

WASHER,1/4" -20 HEXNUT (2)PLCS.

CLAMPBAND

20° REFERENCE

ACTUATOR COMPLETELY

RETRACTED

CLEVIS PIN

FLAT WASHER

COTTER PIN

1/4" - 20 HEX BOLT, FLAT WASHER

1/4" 20 NUT (2) PLCS.

CLAMP BAND

TYP. CLEVIS PIN

CONFIGURATION

FIG.4

FIG.4

4

MAE2200

®

OPERATION:

CAUTION: ALWAYS MAKE SURE THAT ARM ASSEMBLY

IS FREE FROM OBSTRUCTIONS WHEN LIFTING OR

LOWERING MOTORIZED ARM.

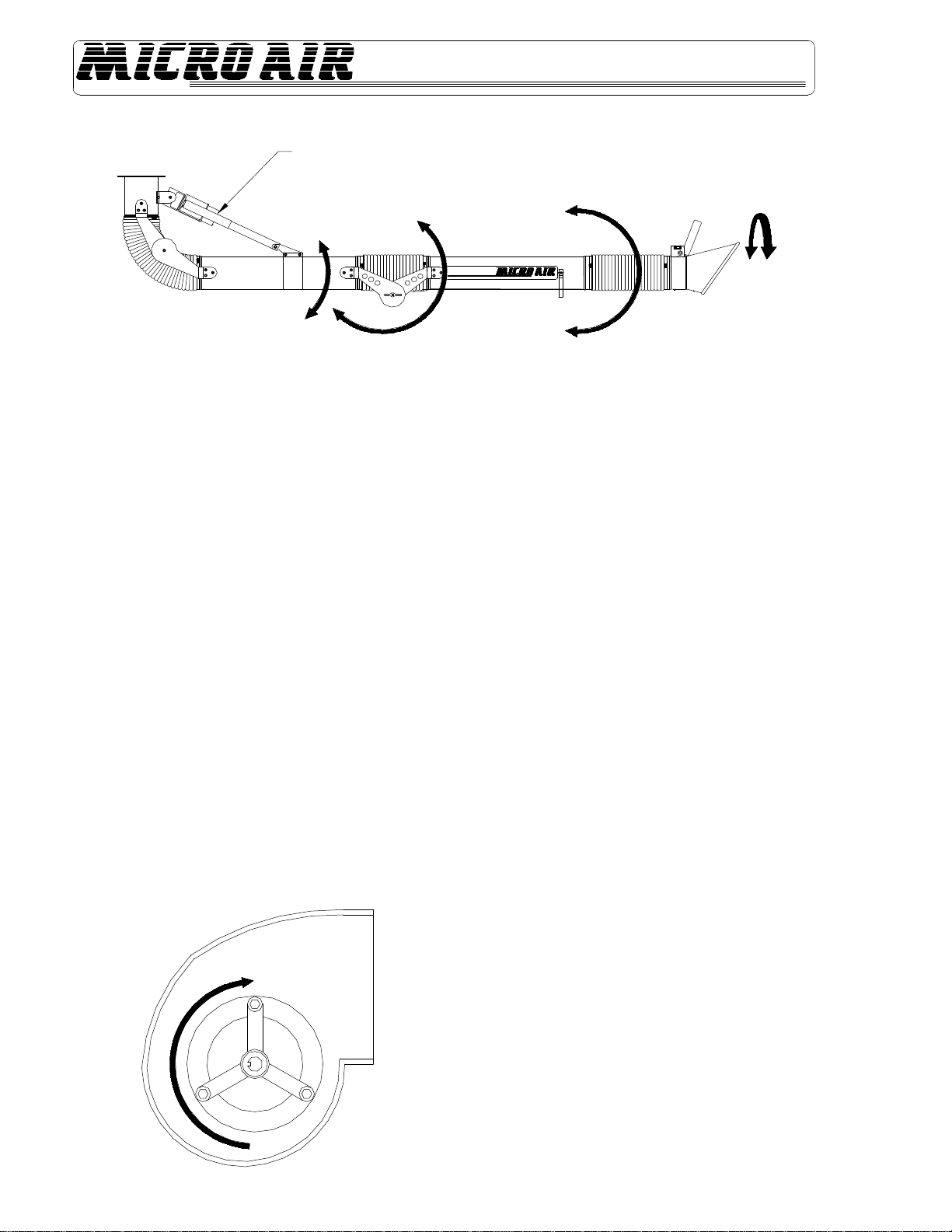

1. For motorized arm systems, the upper arm section can

be raised and lowered by depressing the toggle switch,

located on top of the remote switch control box, located

near the hood. The linear actuator has limit switches that

override the toggle switch when the arm exceeds the

retracted or extended length of the actuator.

2. Grasp the nozzle handle and lift the lower arm section up

and down. If the middle joint seems too tight, loosen the

two wingnuts that hold the joint together. If the arm has

trouble maintaining a position, hand tighten the wing nuts.

3. The nozzle-joint section can be manipulated up, down and

rotated. The joints are located inside the flexible hose

nearest the nozzle. If the joints are too loose or tight,

simply remove the hose clamp at the nozzle, gaining

access to the joints, and adjust as needed. (See FIG. 6.)

4. To operate blower, depress the fan switch located on the

remote switch control box to ON. The blower motor will

activate via a motor relay located inside the electrical

control box.

5. Be sure to check for proper blower rotation. If blower is

rotating backwards, interchange L1 and L2. (See FIG. 7.)

6. Activate the lamp located inside the nozzle by depressing

the lamp switch located on the remote switch control box.

ACTUATOR (OR RIGID PIPE)

90° UP

45° UP

20° UP

90° DOWN

45° DOWN

20° DOWN

7. The damper lever near the nozzle can be rotated 90° to

adjust inlet air velocity.

PRESSURE SWITCH ADJUSTMENTS

1. Make sure filters and pre-filters are installed in unit.

2. The pressure switch is preset at the factory to indicate

(light on) dirty filters, but may need readjustment due to a

desire for earlier or later filter changes, a different

combination of filters, or because the set point shifted

during shipping. To readjust the switch, remove the hole

plug in the side of the unit for access to the adjustment

screw. Turn the unit on and place a piece of cardboard

over the hood covering about 80-85% of the intake. With

a standard screwdriver, turn the adjustment screw

clockwise until the light goes off, or

counterclockwise until the light comes on.

3. For more time between filter changes (less airflow), cover

slightly more of the hood, and for less time between filter

changes (more airflow), cover less of the hood.

CHANGING FILTERS

CAUTION: ALWAYS MAKE SURE THAT THE UNIT IS TURNED

OFF BEFORE CHANGING FILTERS OR SERVICING THE UNIT.

1. The MAE 2200 is equipped with a filter change light, which

indicates when a filter needs to be replaced. If the differential

pressure has been set properly, the light signals the need for

examination of the filters.

2. When the light comes on, turn the unit off and remove the

pre-filter only. Replace with a new pre-filter, making sure that

the air flow directional arrow is pointed toward the outlet end.

Turn the unit back on. If the filter change light is off, then the

unit is operating properly.

3. If the filter change light fails to go out after replacing the pre-

filter, then the media bag filter may also need to be replaced.

4. Visually inspect the bag filter. If the pockets are loaded with

dirt, then remove the filter from the channel and insert a new

filter.

5. Start the unit. The filter change light should be off and the unit

operating properly.

FIG. 7

5

MAE2200 ®

UNITS WITH HEPAOR CHARCOAL

OPTIONS

1. On units with optional Hepa or charcoal filters, an

adjustable filter track kit is used to complete the seal of

these filters to the filter stop, (see FIG. 8.) If the unit was

ordered with either a Hepa or charcoal filter, this adjustable

filter track kit was included with the unit. If a Hepa or

charcoal filter is ordered as an after market item, the

adjustable filter track kit should be ordered as well. Order

Part No. 30178-01 for each Hepa or charcoal filter initially

used.

2. Each filter track kit is supplied with two adjustable filter

tracks, four carriage bolts and four nuts. The corner

braces inside the MAE2200 unit are slotted. Position the

Hepa or charcoal filter in the unit up against the picture

frame filter stop at the blower end of the unit. Position the

adjustable filter track at the front (air inlet end) of the filter

in the inverted T position. (See FIG. 8.)

3. Install a carriage bolt in each of the two slots on either side

of the bottom of the unit. Push the carriage bolts towards

the front of the filter and through the holes provided in the

adjustable filter track.

4. Put a nut on each bolt, but do not tighten.

5. Repeat Steps 3 and 4 for the top adjustable filter track.

6. Use the two adjustable filter tracks to push the filter snugly

against the filter stop. Tighten the nuts on all four carriage

bolts.

7. If a second filter (Hepa or charcoal) is used in the unit,

repeat Steps 3, 4 and 5 for the leading filter. Push the

second filter snugly against the first using the adjustable

filter tracks and tighten the nuts. The second filter should

be resting on the adjustable filter track on both ends.

Because the bolts on the adjustable filter track between a

Hepa and charcoal filter combination may interfere with

the ends of the Hepa filter, the bolts for a middle filter track

may be omitted.

GENERAL MAINTENANCE-ARM(S)

1. Occasionally check the condition of the flexible hose for

any opening that will allow air to flow through. For

replacement, see Parts List.

2. Check the linear actuator for any debris that may have

settled along screw drive. Listen for any abnormal gear

noises during operation. No lubrication is required.

3. Periodically inspect the internal spring section at the

middle joint for debris or damage. Replace if needed.

4. Periodically inspect hardware for loose nuts and bolts

around the swivel base areas. Tighten if needed.

5. Periodically inspect all wiring for loose connections and

cracked or cut insulation. Replace as needed.

GENERAL MAINTENANCE –

MAE2200

1. Occasionally check the condition of the drive belt for

tightness and wear.

2. Check the blower bearings for unusual wear, and the

blower wheel for debris and dirt. Clean when necessary.

3. Check the wiring for loose connections or cracked

insulation.

4. If it should be necessary to replace the motor, it is much

easier to first remove the end panel of the unit for access

to the motor bolts.

5. No lubrication is required for the motor because it is a

permanent pre-lube design. Excessive dirt/oil should be

periodically removed.

FIG. 8

ADJUSTABLE FILTER TRACK

RCM FILTER KIT ASSY.

AFTER-FILTER

6

MAE2200

®

TROUBLESHOOTING CHART

CAUTION: BEFORE DISASSEMBLING THE UNIT OR DOING ANY

INSPECTION OF THE PARTS, MAKE CERTAIN THATTHE POWER HAS BEEN

CUT OFF, AND THE BLOWER HAS COME TO ACOMPLETE STOP. NEVER

RUN THE UNIT WITH THE ACCESS DOOR OPENED OR REMOVED.

PROBLEM POSSIBLE CAUSE REMEDY

Unit Fails to Start Dead Power Line Check Circuit and Switch

Blown Fuse Replace Fuse

Loose Wire in Terminal Box Reconnect Wire

Burned Out Motor Replace Motor

Unit Runs Slowly or Inadequate Wired for Wrong Voltage Check Input Voltage

or Improper Rotation Check Wiring Diagram

Dirty Filters Replace Filters

(See Changing Filters Section.)

Obstruction in Hose/Arm Assembly Reach into Hood and Remove

Obstruction

Mist Coming from Exhaust Dirty Disposable Filters Replace Filters

or Torn Filters

Air Bypass Around Filters Add Foam Seal to Seal Gaps

Vibration Loose Mounting Bolts Tighten Bolts

Foreign Object in Blower Remove Access Door and

Remove Object

Dirty Disposable Filters Replace Filters

(See Maintenance Section.)

Obstruction in Hose/Arm Assembly Reach into Hood and Remove

Obstruction

7

MAE2200 ®

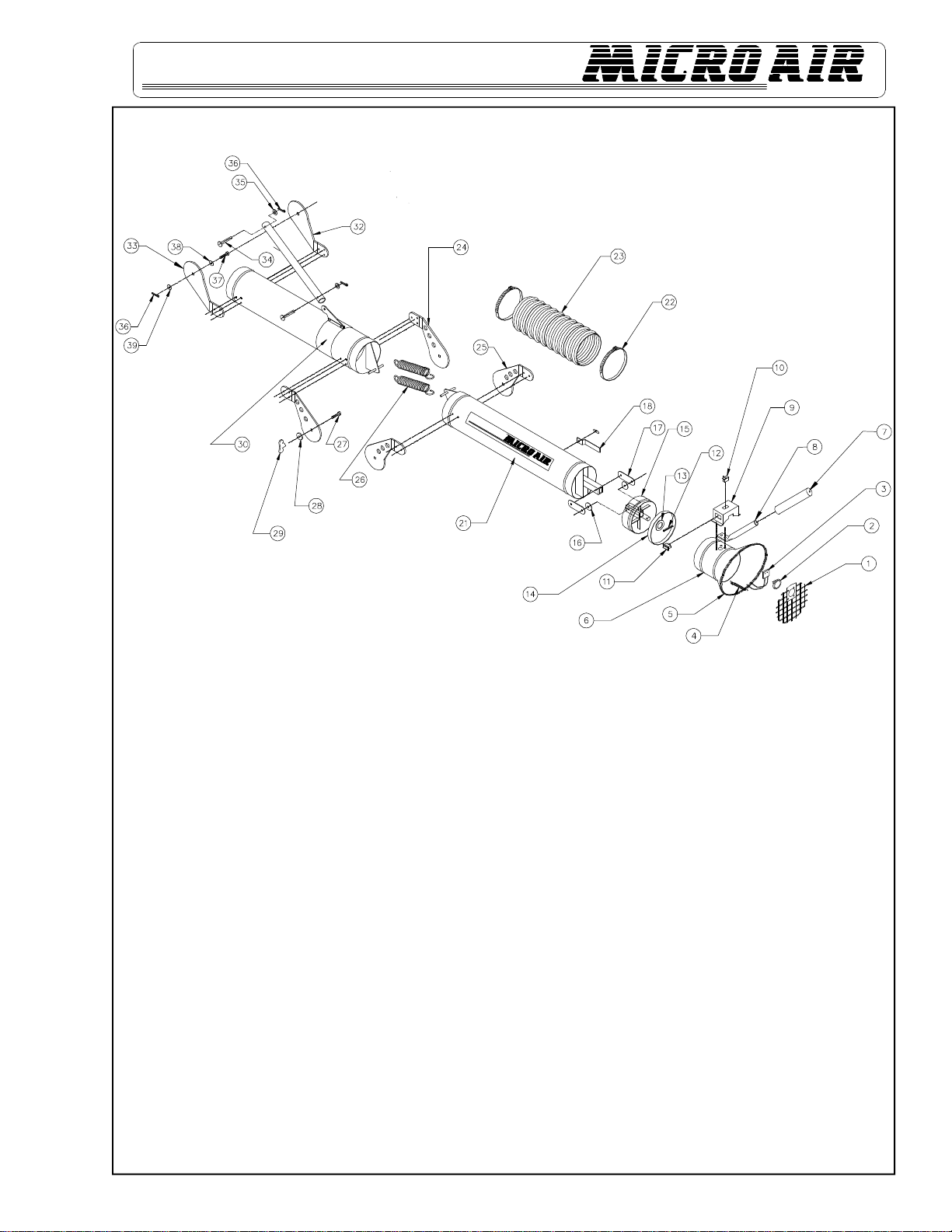

ITEM PART NO. DESCRIPTION

1. 36071-01 Arm Grille

2. P2170 Lamp

3. P2168 Lamp Holder

4. P2847 Spring

5. P1342 Edge Guard

6. 36533-02 Nozzle Assembly

7. P2237 Foam Grip

8. 36025-01 Handle

9. 37070-01 Switch Box

10. P2719 Actuator Box

11. P2219 Rocker Switch

12. P200 Cotter Pin

13. P125 Washer

14. P2933 Rubber Seal

15. 36532-02 Collar Assembly

16. 36030-02 Mini Joint Half

17. 36535-01 Mini Joint Half

18. 36044-01 Damper Handle

ITEM PART NO. DESCRIPTION

21. 36005-01 Steel Tube

22. P2232 Hose Clamp

23. P2617 Hose

24. 36020-01 Joint Half with Holes

25. 36020-02 Joint Half with Holes

26. P2615 Spring

27. P2673 Carriage Bolt

28. P2618 Thrust Bearing

29. P2619 Plastic Wing Nut

30. 36024-02 Adjustable Support Clamp

32. 36019-01 Joint Half

33. 36019-02 Joint Half

34. P2830 3/8” Clevis Pin

36. P2828 Cotter Pin

37. P2829 5/16” Clevis Pin

38. P2620 Nylon Washer

39. P233 5/16” Washer

MODEL MAE2200

PARTS LIST - ARM ONLY

MAE2200

Litho in U.S.A. 1997 Metal-Fab, Inc. Form No. L1241 10/99

6210

8

AIR CLEANERS

Products of Metal-Fab. Inc.

P.O. Box 1138

•

Wichita, KS. 67201

(316) 943 2351

•

FAX (316)943-2717

ITEM PART NO. DESCRIPTION

1. P1966 Motor

2. P1361 Blower

3. P1658 Blower Pulley

4. P1451 Belt

5. P2801 Motor Pulley

6. P1481 Lamp

7. P2800 Pressure Switch

8. 34083-01 Access Panel

9. 33287-06 Motor Access Panel

10. 33373-04 Filter Door

ITEM PART NO. DESCRIPTION

11. P1372 Latch - 2 ea.

12. 36038-02 Base Collar

13. 36019-01 Joint Half

14. 36019-02 Joint Half

15. 36031-01 Anchor Assembly

16. 36060-01 Nylon Ring

17. 36060-03 Mounting Ring

18. 36060-04 Nylon Ring

19. 36227-01 Plenum

MODEL MAE2200

PARTS LIST

®

®

Table of contents

Other MICRO-AIR Air Cleaner manuals

MICRO-AIR

MICRO-AIR OM 500 User manual

MICRO-AIR

MICRO-AIR WM 500 User manual

MICRO-AIR

MICRO-AIR M2150 User manual

MICRO-AIR

MICRO-AIR CLEAN AIR BOOTH User manual

MICRO-AIR

MICRO-AIR SC150 User manual

MICRO-AIR

MICRO-AIR XA34 Max User manual

MICRO-AIR

MICRO-AIR OM550DD User manual

MICRO-AIR

MICRO-AIR SC 150 User manual

MICRO-AIR

MICRO-AIR MT800 User manual

MICRO-AIR

MICRO-AIR MT1252 User manual