MICRO-AIR OM 3510 User manual

Model OM 3510

OWNER’S MANUAL

CAUTION

Read complete instructions before operating.

Please file for future reference.

AIR CLEANERS

2

OM3510

INSTALLATION INSTRUCTIONS

A. WALL MOUNT

1. Removefour5/16”boltsfromsidesofcabinetneartopand

bottomofunit.

2. UseboltsremovedinStep1tosecurewallmountbracketstounit

as shown in FIG. 1.

FIG.1

FIG.2

MODEL OM 3510 SPECIFICATIONS

Inputvolts: 120/208-230/460/575v,60Hz

Maxcurrent: 20Amps(at120V,1 ½HP,singlephase)

5.2amps (at208-230V,1½HP,3phase)

2.6amps(at 460V, 1½ HP, 3phase)

6.8Amps(at208-230V2HP,3phase)

3.4Amps(at460V, 2 HP,3 phase)

9.6Amps(at208-230V, 3HP,3phase)

4.8Amps (at460V, 3HP,3 phase)

3.9Amps (at575V, 3HP,3 phase)

Motor: 1 ½ HP TEFC

2 HP TEFC

3 HP TEFC

Dimensions: 81” h X 26”w X 26”l

102” h X 26”w X 26”l W/ Stand

ShippingWt: 340lbs

ActualWt: 310lb*

*Add35lb.percharcoalmoduleasoption

PACKAGE CONTENTS

1 Ea. OM3510 Unit

1 Ea. Owner’sManual

PRE-OPERATING INSTRUCTIONS

1. Cutbandingmaterialandremovecardboardandplasticfromunit. Remove

unitfromshippingskid.

2. Inspectunitforshippingdamageandreportanydamagetofreightcompany.

3. Locateaninstallationsitethatwillprovideforthefollowing:

l Asolidstructure,capableofsupportingtheweightoftheunit.

l Threefeetofunobstructedexhaustspacefromtheoutletoftheunit.

l Easyaccesstoservicepanelsandunitinlet. Asnearaspossibletothe

sourceofoilmistunittobecaptured.

4. Marklocationofmountingholesonthesurfacetowhichunitistobe

mounted. SeeFIG. 2forholepattern. Drillholesthataresized

correctlyforholepatterninmountinghardware.

5. PositiontheOM3510wallmountbracketholesovertheholes

locatedonthestructureinStep4. Use3/8”x2”lagboltsor3/8”

boltsandnutstosecureOM3510tostructure.

CAUTION: The size and weight of the OM 3510 requires two persons or

mechanical means to lift and hold during mounting.

6. Connectunittooilmistsourceusingaducthavingthesame

diameterastheinletoftheunit. Theductmaybeflexiblehoseor

formedsheet metal. Maximumflowwillbeobtainedwithminimum

bendsinduct. Tocontainoilthatwillcollectontheinsideoftheduct,

theductmustbesealed. SlopingtheducttowardtheOM3510will

assistflow. Usehoseclampsofsheetmetalscrewstoattachductto

unit.

NOTE: Optionalhoseadaptersareavailableforconnectionto6”and8”

diameterhose. UsePartNo.34096-01for6”dia..AndPartNo.34096-02

for8”dia. Attachadaptertoplenumcollarwithsheetmetalscrewsand

sealwithRTVsealant.

C. FLOOR MOUNT

NOTE: Theoptionalbaseassembly(PartNo.38046-02)isrequiredfor

floormountinstallation.

1. locateaninstallationsiteonalevelsurfacethatwillmeetthe

requirementslistedinStep3ofthewallmountinginstructions.

2. Setthebaseinplaceandlifttheunitontothebase.

CAUTION: The size and weight of the OM 3510 requires two persons and/or

mechanical means to lift and hold during mounting.

NOTE: Youmaywanttoboltthebasetothefloor.

3. ConnecttheunittotheoilmistsourceasexplainedinStep6ofthe

wallmountinginstructions.

D. CEILING MOUNTING

NOTE: Theoptionalceilingmountingkit(PartNo.38049-02)isrequired

forceilingmountinstallation.

1. Removethetwo5/16”boltsfromthesideofthecabinetattheoutlet

end.

2. UsetheboltsremovedinStep1tosecuretheceilingmountbrackets

totheunitasshowninFIG. 3.

3

OM3510

FIG.3

3. Locateaninstallationsitethatwillmeettherequirementslistedin

Step3ofthewallmountinginstruction.

4. Firmlysecurefourlengthsof3/8”threadedrodtoafirmstructural

support. Spacerodstomatchpatternmadebyholesintopof

ceilingmountbrackets.

5. Threadonenutontoeachrod.

CAUTION: The size and weight of the OM 3510 requires two persons or

mechanical means to lift and hold during mounting.

6. Raiseunituptothreadedrodsandinsertrodsthroughceiling

mountbrackets. Threadasecondnutontoeachrodfrombelow

bracket.

7. Levelunitbytighteningnutsagainstceilingmountbracket.

8. Threadathirdnutontoeachrodandtightenagainstsecondnutto

preventlooseningofnutsduetoVibration.

9. ConnecttheunittotheoilmistsourceasexplainedinStep6of

thewallmountinginstructions.

OIL DRAINAGE

NOTE: Should captured oil be disposed of, make sure to follow local

codes.

Provisionfordrainingoilfromunitisprovidedforbya1”N.P.T.pipe

couplingonthebottomoftheunit. Drainagecanbepipedtoacentralcollection

systemorcollectedinabucketplacedundertheunit. Inallcasesashut-off

valveordraintrapisrequiredtopreventairbypassthroughthedrainopening.

OneofthedrainsystemsshowninFIG. 4shouldbeused. Drainconnections

andlinesarenotprovided.

NOTE: Ifashutoffvalveisinstalledinthedrainsystem,theunitmustbe

emptiedregularlytopreventoilfromoverflowingintotheintakeduct.

FIG.4

AIR FLOW ADJUSTMENT

The OM 3510 is equipped with variable diameter pulleys on the motor and blower

to allow the air flow to be adjusted to the installation requirements. The pulleys are set

for maximum air flow at the factory. The air flow rate can be reduced as follows:

1. Remove motor compartment access cover. Be careful to avoid tearing gasket

material between door and cabinet.

2. Remove belt.

3. Loosen pulley adjustment set screw on motor pulley and screw adjustable shive

out away from fixed shive. Tighten set screw onto flat of fixed screw (see FIG.

5).

4. Adjusting the motor pulley may require a size larger or smaller belt, depending on

the application.

5. Replace belt and check belt tension. Proper tension should be between ½” and

¾” deflection when belt is squeezed with normal pressure between fingers.

6. Replace motor compartment access cover.

7. Recheck for correct current draw of motor

NOTE: All filters and panels must be on unit and door closed for current

measurements of motor.

FIG.5

ELECTRICAL CONNECTIONS

1. Conduit electrical connections should be made by a qualified electrician, and

must comply with local electrical codes.

CAUTION: Be sure that the designated circuit breaker is off until all wiring

has been completed.

NOTE: It is recommended that a properly sized motor starter / protector be used in the

supply circuit for 208-240V/460V/575V units. 120V units have thermally protected

motors with on/off switches.

2. Make electrical connections as shown in wiring diagram to the wires protruding

from the conduit on the side of the unit.

3. Check blower for proper rotation direction. Blower should rotate clockwise when

viewed from the pulley end. If the blower rotates backwards, interchange two of

the motor supply connections.

4. Check current draw of motor. Do not exceed AMPs specified.

PRE-OPERATION CHECKLIST

Before placing unit in service, check the following items:

lCheck blower drive belt for proper tension. (Belt should deflect approximately

3/4” when firm pressure is applied midway between the pulleys.)

lCheck that motor, blower, and drive pulleys are mounted securely.

lMake sure that both corners of every pocket in the filter bag is supported by the

filter support rods and that filter support rods are fully engaged in their support

brackets.

lAir flow direction arrows on the oil impingers / pre-filters must point toward the

blower.

lCheck that air intake and oil drain connections are air or oil tight.

lMake sure that all access panels, removed during installation, are replaced and

the filter access door is closed.

Unit is now ready to be placed in service.

4

OM3510

OPERATION

A. PRESSURE SWITCH ADJUSTMENTS

1. The pressure switch is preset at the factory to indicate (light on)

dirty filters, but may need readjustment due to a desire for earlier

orlaterfilterchanges,adifferentcombinationoffilters,orbecause

thesetpointshiftedduringshipping. Thepressureswitchisalso

orientationsensitive. Toreadjusttheswitch,removethehole

pluginthesideoftheunitforaccesstotheadjustmentscrew.

Makesurefiltersandpre-filtersareinstalledinunit. Turntheunit

onandplaceapieceofcardboardovertheintakecoveringabout

80to85%oftheintakearea. Ona3-inletsystem,cover

entirelytwoinletsandalittlemorethanhalfoftheareaofthethird

inlet. Withastandardscrewdriver,turntheadjustmentscrew

clockwiseuntilthelightgoesoff,orcounterclockwiseuntilthe

lightcomeson.

2. Formoretimebetweenfilterchanges(lessairflow),cover

slightlymoreoftheopening,andforlesstimebetweenfilter

changes(moreairflow),coverlessoftheopening.

B. GENERAL MAINTENANCE

1. Occasionallychecktheconditionofthedrivebeltfortightness

andwear.

2. Checktheblowerbearingsforunusualwearandtheblower

wheelfordebrisanddirt. Cleanwhennecessary.

3. Checkthewiringforlooseconnectionsorcrackedinsulation.

4. Nolubricationisrequiredforthemotorbecauseitisapermanent

pre-lubedesign. Excessivedirt/oilshouldbeperiodically

removed.

5. Makesureoilisdrainingeasilythroughdrainpipe.

C. CHANGING FILTER

CAUTION: Always make sure that the unit is turned off before

changing filters or servicing the unit.

1. TheOM3510isequippedwithafilterchangelight,or(optional)

MagnahelicGauge,whichindicateswhenafilterneedstobe

replaced. Ifthedifferentialpressurehasbeensetproperly,the

light,orgaugesignalstheneedforexaminationofthefilters.

2. Whenthelightcomeson,orgaugereadshighdifferential

pressure, turntheunitoffandremovetheimpingerandmesh

pre-filterfromtheunit. Washthesepre-filtersinadetergent

solutiontoremovedirtandoilresidue.

3. Rinsethepre-filtersthoroughlywithwater, shakedryand

replaceintheunitwithairflowdirectionpointingtotheblower

(replacepleatedpre-filtersifinuse).

4. Ifthefilterchangelightfailstogoout,orthegaugecontinuesto

readhighdifferentialpressure,afterreplacingthepre-filter,then

theoilbagfiltermayalsoneedtobereplaced.

5. Visuallyinspectthebagfilter. Ifthepocketsareloadedwithoil

anddirt,thenremovethefilterfromthechannelandinsertanew

filter.

6. Starttheunit.Thefilterchangelightshouldbeoff,orthegauge

readslowdifferentialpressureandtheunitshouldbeoperating

properly.

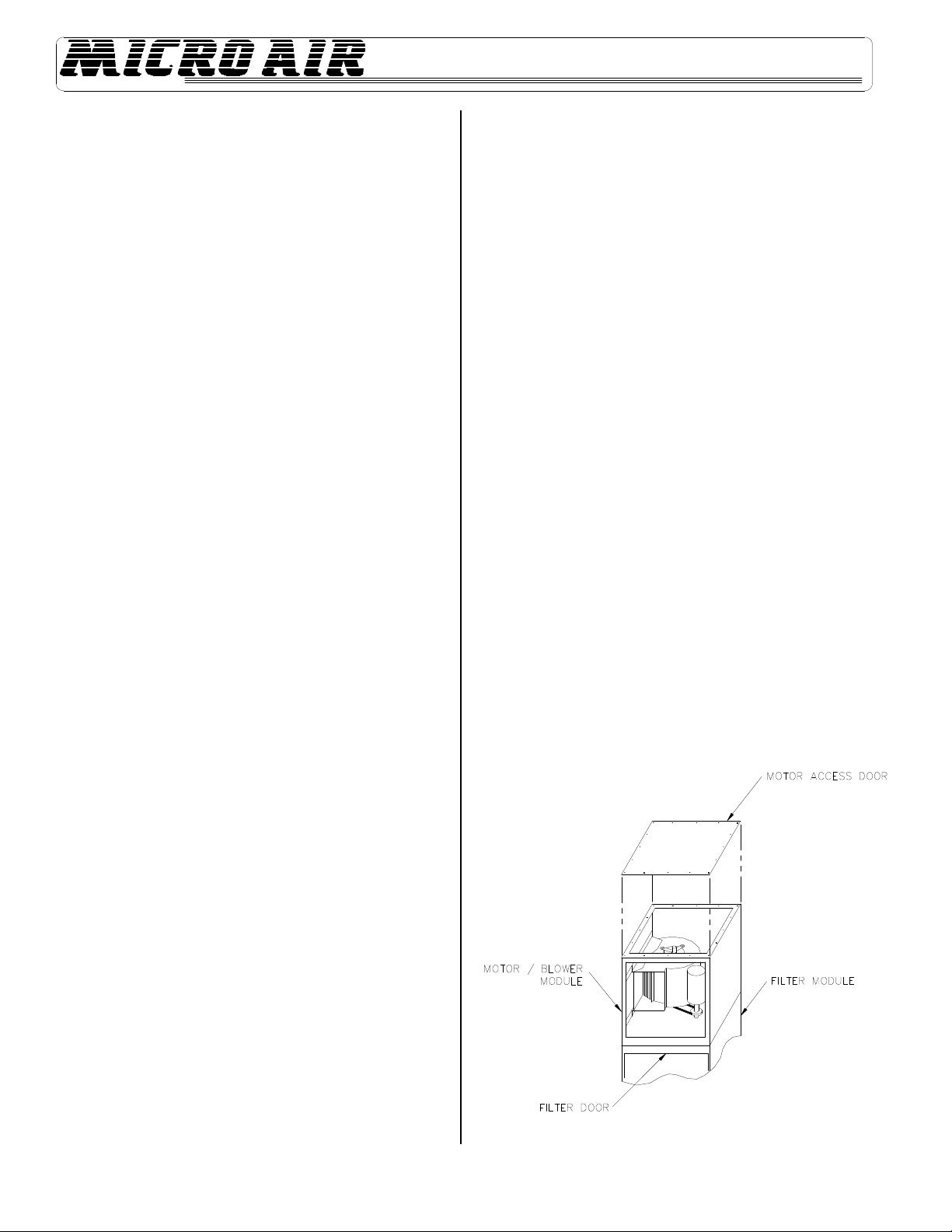

INSTRUCTIONS FOR SIDE DISCHARGE

BLOWER EXHAUST ON OM 3510

CAUTION: Read instructions completely before making changes.

1. TheOM3510motor/blowermodulecanberotatedsothatexhaustair

exitsfromthesideoftheunit. Beforerotatingmotor/blowermodulebe

surethatallinputpowerisdisconnectedandunitisturnedoff.

2. Removemotoraccessdoorandexhaustgrille.

NOTE: Careisrequiredwhenremovingthepaneltoprotectthebloweroutlet

gasket.

3. Remove5/16”hexboltsandwashersthatsecuremotor/blowermodule

tofiltermodule.

4. Rotatemotor/blowermodule90°asshownInfigure 6.

5. Using5/16”hexboltsandwashersre-securemotor/blowermodule

withfiltermodule.

CAUTION: Due to relocation of internal components, some wiring

may be loose. Be sure to retain wires so they will not become loose in

air stream of blower inlet.

6. Reinstallmotoraccessdoorandexhaustgrille.

NOTE: Careisrequiredtoprotectbloweroutletgasket.

7. Reconnectinputpowerandturnuniton. Checkforproperairflowand

blowerrotations.

FIG.6

5

OM3510

FIG.7

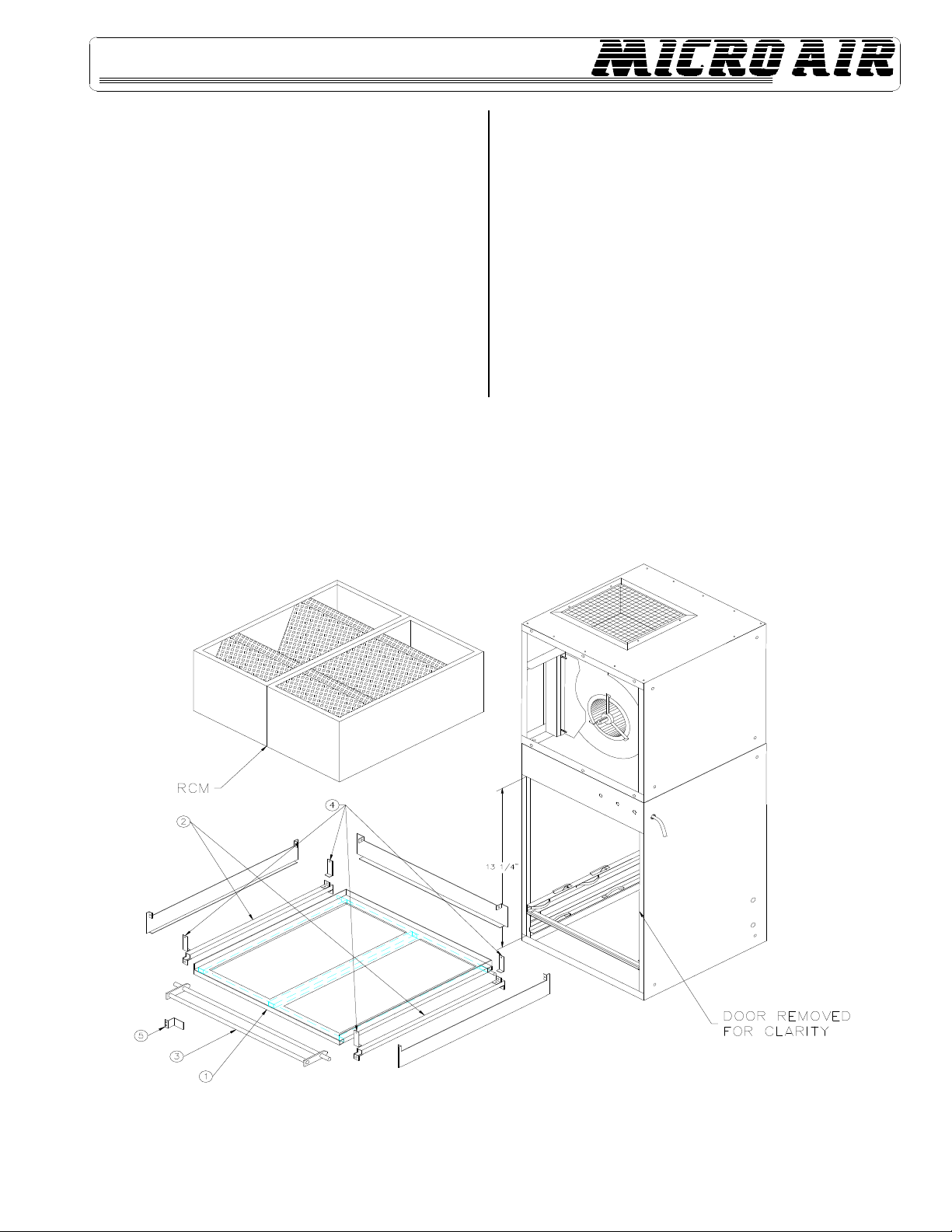

UNITS WITH HEPA OR CHARCOAL OP-

TIONS FOR OM 3510

1. OnunitswithoptionalHEPAorcharcoalfilters,anadjustablefiltertrackkitis

usedtocompletethesealofthesefilterstothefilterstop(seefigures 7 &8).

IftheunitwasorderedwitheitheraHEPAorcharcoalfilter,thisadjustable

filtertrackkitwasincludedwiththeunit. IfaHEPAorcharcoalfilteris

orderedasanaftermarketitem,theadjustablefilertrackkitshouldbeordered

aswell. OrderPartNo.38036-01.

2. Eachfiltertrackkitissuppliedwith:

(1) 1pc.Filtertrack

(1) 2pc.Supports

(2) 1pc.Handle

(3) 4pc.Retainingbrackets

(1) 1pc.Doorstopbracket

(2) 3pc.Horizontalsupport

(3) 16pc.#8-32selftappinghexscrews.

HEPA OR CHARCOAL AS SECOND MAIN FILTER

1. Placesupports(2)incabinetatadimensionof13¼”andsecurewithself

tappingscrew.

2. Placetrack(1)incabinetsoitrestsuponsupportsand½”diameterpinis

locatedbehindbracketsonsupports.

3. Placehandle(3)onsupportssothatitrestsinnotches.

4. Lock½”diameterrodsonhandleandtrackinplacewithbrackets(4)and

selftappingscrews.

5. Placehandlestopbracket(5)atadimensionof15½”andsecurewithself

tappingscrews. Thisistokeephandlefromrotatingpast90°andallowing

filtertoloosen.

6. Horizontal support (6) is not used in this case.

6

OM3510

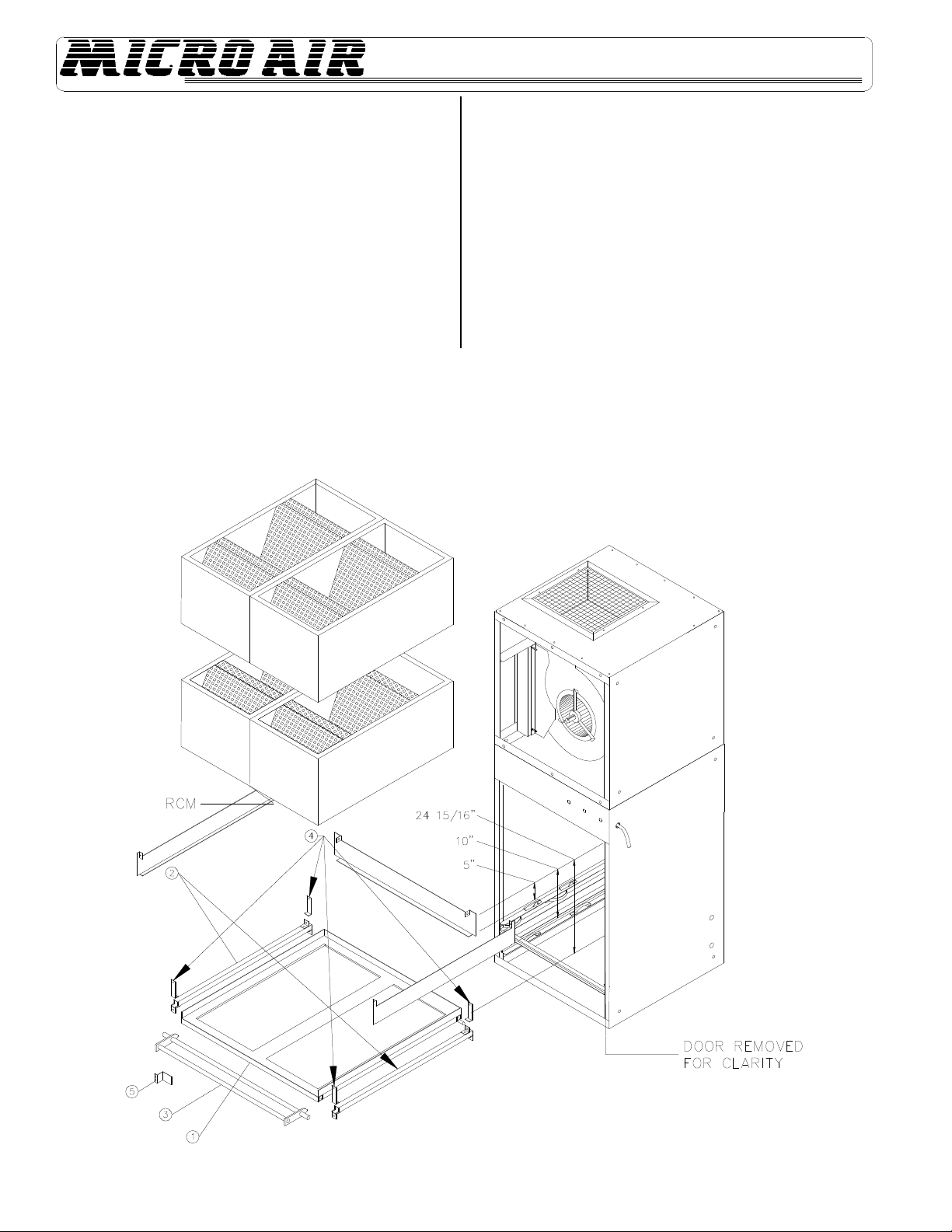

HEPA OR CHARCOAL AS FIRST AND SECOND MAIN FILTERS

1. Place supports (2) in cabinet at a dimension of 24 15/16” and

secure with self tapping screws.

2. Place track (1) in cabinet so it rests upon supports and ½”

diameterpinislocatedbehindbracketsonsupports.

3. Placehandle(3)onsupportssothatitrestsinnotches.

4. Lock½”diameterrodsonhandleandtrackinplacewithbrackets(4)and

selftappingscrews.

5. Placehandlestopbracket(5)at dimensionof27”andsecurewithself

tappingscrews. Thisistokeephandlefromrotatingpast90deg.and

allowingfiltertoloosen.

6. PlaceHorizontalSupports(6)2pc.onsidesofthecabinetatadimensions

of10”and(6)1pc.onrearofcabinetat5”andsecurewithselftapping

screws.

FIG.8

7

OM3510

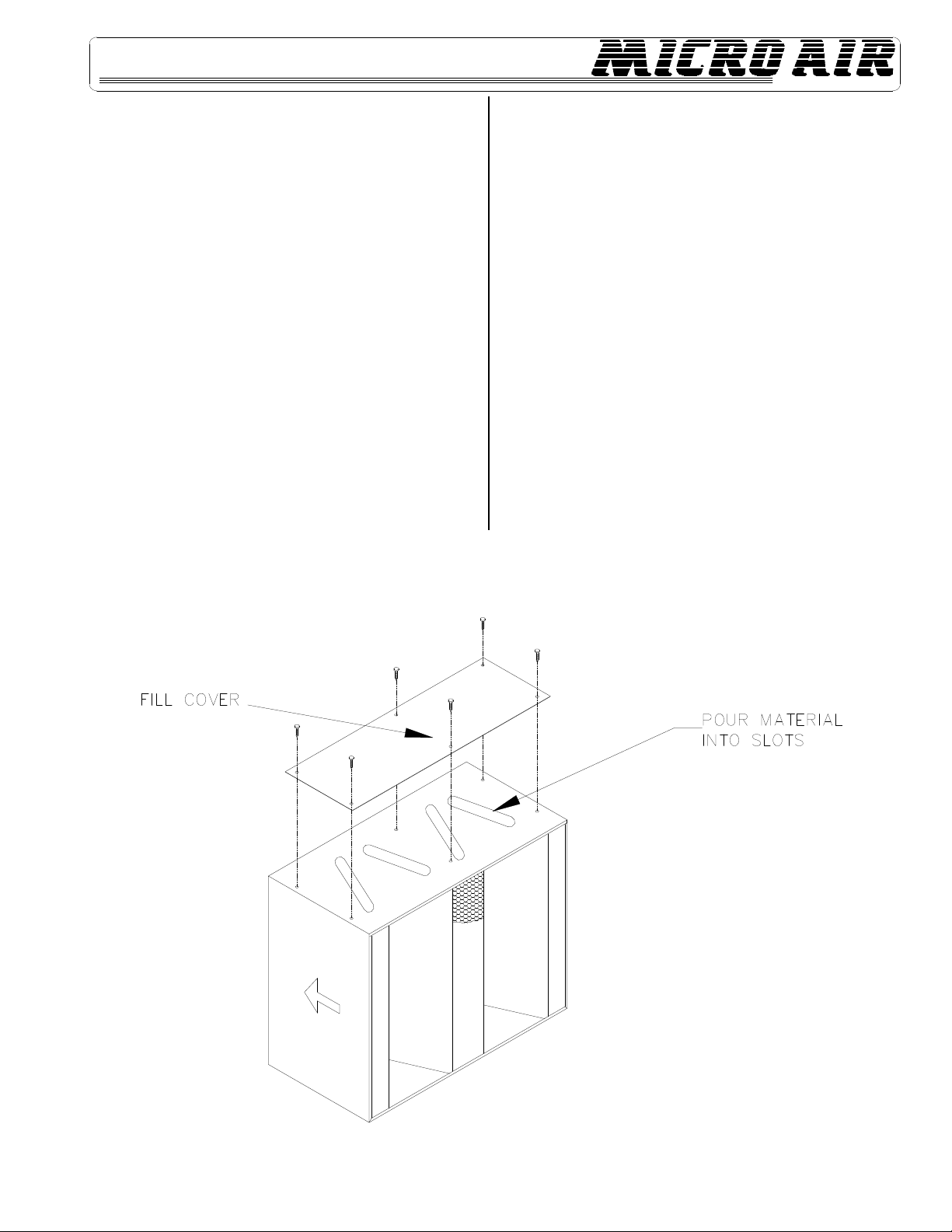

FILLING OF RCM MODULES

1. Removebulkcharcoalorpurasorbfromshippingcartonbyremovingplastic

bagswithincarton.

2. setmoduleonlevelsurface. Removefillcoverbyremovingsix10-32

phillipsheadscrews,thatsecurecover. Setcoveraside(seefigure 9).

3. Opentheplasticbagbyremovingthetape,holdingclose. Pourthematerial

fromtheplasticbagintothemodulethroughtheslots. Itmaybenecessary

toslightlyshakethemoduletoassureanevenfill. Excessmaterialmaybe

savedbyresealingtheplasticbag.

NOTE: Slowpouringwillminimizedustthatwillbepresentduringpouring.

4. Afterfillingmodule,discardplasticbagandreinstallfillcoverremovedin

step2.

NOTE: TheOM3510requirestwomoduleswhenusedasasecondmainfilter

andfourmoduleswhenusedasafirstandsecondmainfilter.

5. WithFiltertrackinplaceandhandlepulledoutawayfromcabinetloadRCM

/HEPA modulesintotrack.

NOTE: Makesuremodulesareseatedproperlyintotrackandstackedevenly.

6. Withfiltersinplacerotatehandle90°andlockfiltermodulesinplace.

FIG.9

8

OM3510

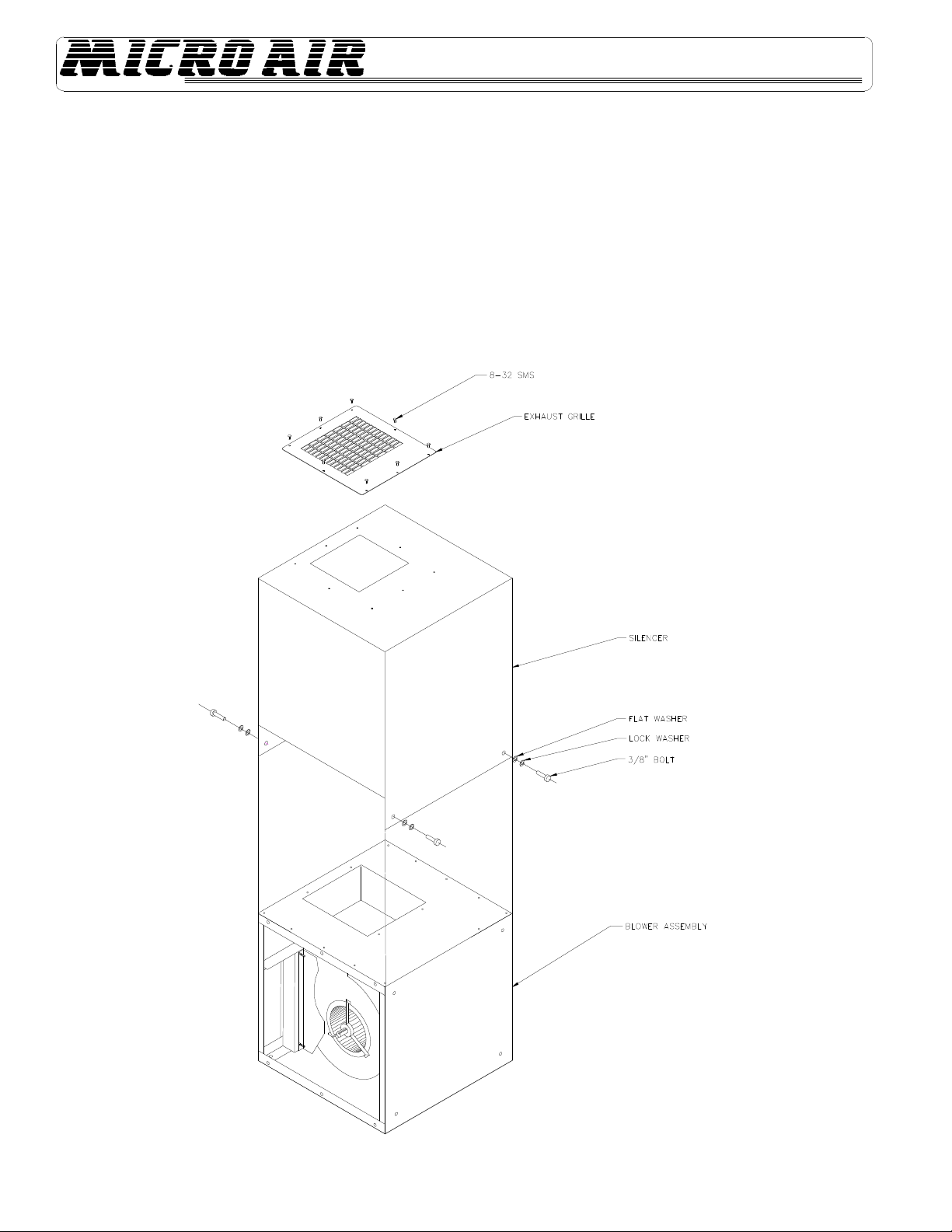

OPTIONAL SILENCER INSTALLATION

1. RemoveExhaustGrillefromunitasshowninFIG. 10.

2. SlideSilencer overBlowerAssembly.

3. AlignholesfromSilencerwiththoselocatedonsidesoftheBlowerAssembly.

4. AttachSilencertoBlowerAssemblyusing3/8”bolt,lockwasher,&flatwasher.

5. CenterExhaustGrilleoverholeinSilencer&attachusing8-32selftappingmachinescrews.

FIG. 10

9

OM3510

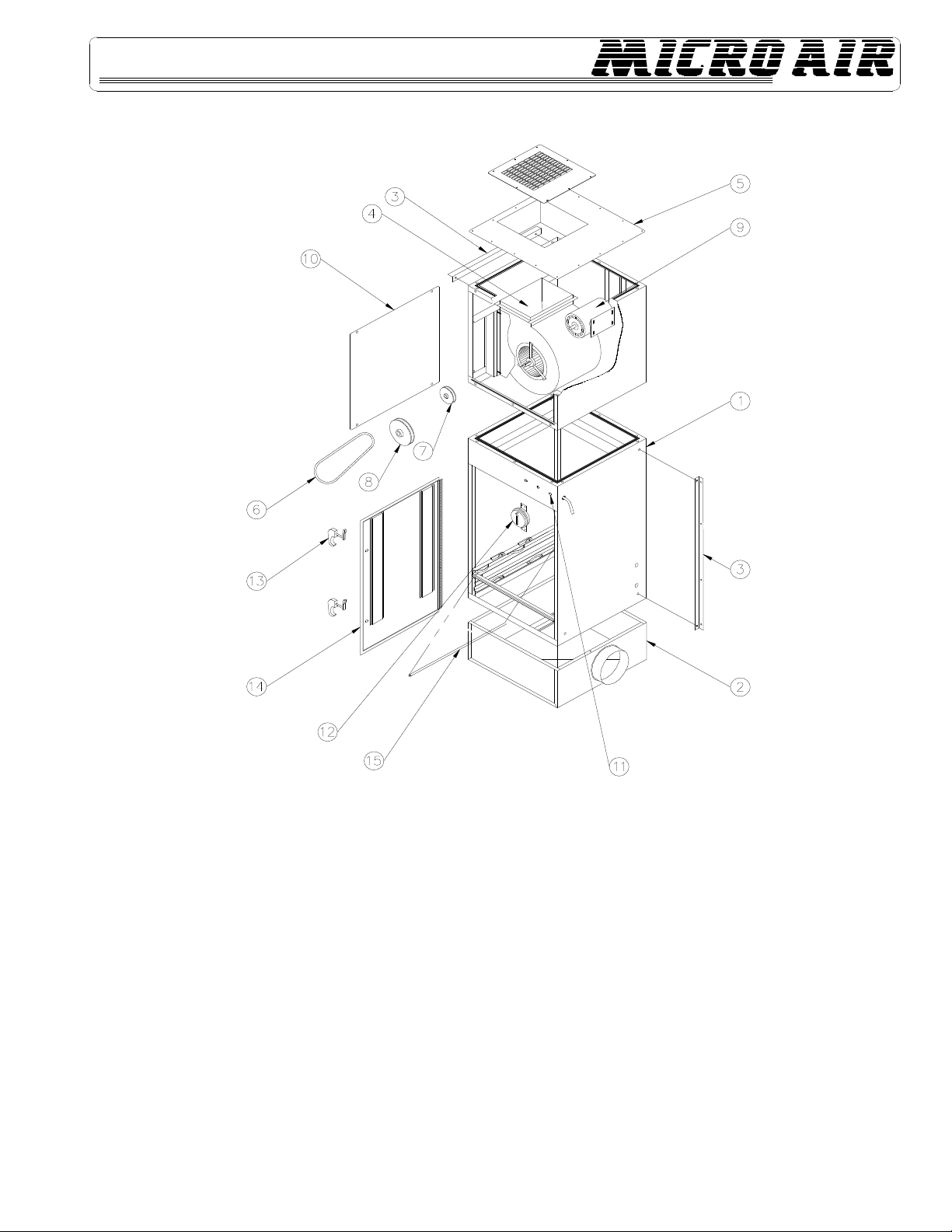

ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION

1. 38071-01 Cabinet Weldment 8. P1710 4.95" Blower Pulley NOT SHOWN 38046-01 Optional Floor Stand

2. 38024-01 Inlet Plenum P1974 5.93" Blower Pulley NOT SHOWN 38050-01 Silencer

3. 38049-01 Wall Bracket (2 ea. required) P1711 6.93" Blower Pulley NOT SHOWN P1585 70% Washable Pre-Filter

38049-02 Ceiling Bracket (2 ea. required) P3218 7.95" Blower Pulley NOT SHOWN P1586 96% Washable Pre-Filer

4. P3498 Blower (Standard) P3183 9.95" Blower Pulley NOT SHOWN P1461 Pleated Pre-Filter

5. 38010-01 BlowerAccessPanel P3540 12.00" Blower Pulley NOT SHOWN P1475 AluminumMeshPre-Filter

6. P1495 42" Belt 9. P3545 1 1/2 HP 115V Single Phase NOT SHOWN P1799 Baffle Impinger

P3207 43" Belt P3546 1 1/2 HP 208-230/460V. 3 Phase NOT SHOWN P1411 Pleated Pre-Filter 4"

P3182 44" Belt P1966 2 HP 208-230/460v. 3 Phase NOT SHOWN P1455 95% HEPA Filter

P3198 45" Belt P3495 3 HP 208-230/460v. NOT SHOWN P2101 99.97% HEPA Filter

P3213 46" Belt P2813 3 HP 575V. 3 Phase NOT SHOWN P1439 55% Long Bag

P3195 47" Belt 10. 38011-02 MotorAccessPanel NOT SHOWN P1442 95% Long Bag

P3548 48" Belt 11. P1429 Light (120V) NOT SHOWN P2179 95% Oil Mist Bag

P3550 49" Belt P1481 Light (208-230V, 460V, 575V) NOT SHOWN P2104 55% Duo Cube

P3549 52" Belt 12. P3505 PressureSwitch NOT SHOWN P2116 95% Duo Cube

7. P2105 1 1/2 HP, 5/8" Shaft, Motor Pulley 13. P1372 Door Latch (2 ea. required) NOT SHOWN P1460 95% short Bag

P3578 2 HP, 5/8" Shaft, Motor Pulley 14. 38022-01 Filter Door NOT SHOWN P2817 95% Short Oil Mist Bag

P3579 2 HP, 7/8" Shaft, Motor Pulley 15. P3214 Gasket Material (Specify Length) NOT SHOWN P3002 MaxGridPanelFilter

P2140 3 HP, 7/8" Shaft, Motor Pulley NOT SHOWN P2250 Magnahelic Gauge NOT SHOWN P3008 4” Mist-xfilter (Chevron)

NOT SHOWN 33740-00 RCM Module

10

OM3510

OM 3510 Wiring Diagram

11

OM3510

NOTES:

12

OM3510

TROUBLESHOOTING CHART

CAUTION:

Before disassembling the unit or doing any inspection of the parts, make certain that the power has been cut off and the

blower has come to a complete stop. Never run the unit with the access door open or removed.

Problem Possible Cause Remedy

UnitFailstoStart Dead Power Line ChecktheCircuitandSwitch

BlownFuse ReplaceFuse

LooseWireinTerminalBox ReconnectWire

BurnedOutMotor ReplaceMotor

UnitRunsSlowlyor WiredforWrongVoltage CheckInputVoltage

InadequateCaptureVelocity orImproperRotation CheckWiringDiagram

DirtyFilters ServiceFilters

(SeeChangingFiltersSection)

ObstructioninHose/Arm ReachintoHoodand

Assembly RemoveObstruction

PulleysSetForStatic AdjustorChangePulleys

Vibration LooseMountingBolts TightenBolts

ForeignObjectsinBlower RemoveAccessDoorand

RemoveObjects

DirtyDisposableFilters ServiceFilters

ObstructioninHose/Arm ReachintoHoodand

Assembly RemoveObstruction

UnittrippingBreaker CurrentDrawofMotor AdjustorChangePulleys

ToHigh

AIR CLEANERS

Products of Metal_Fab. Inc.

P.O. Box 1138 • Wichtia, Ks 67201

(316) 943-2351 • FAX (316) 943-2717

© 1997 Metal-Fab, Inc. Form No. L1470 9/99

6169

Litho in U.S.A.

®

Table of contents

Other MICRO-AIR Air Cleaner manuals

MICRO-AIR

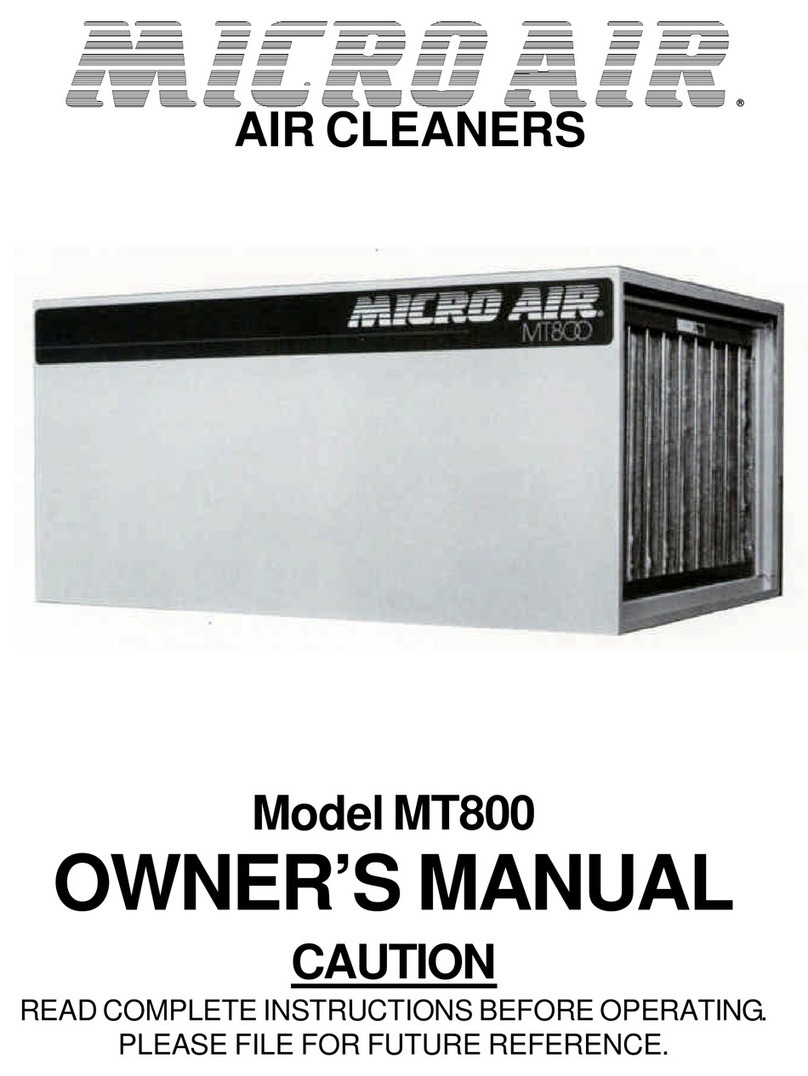

MICRO-AIR MT800 User manual

MICRO-AIR

MICRO-AIR MAE2200 User manual

MICRO-AIR

MICRO-AIR WM 500 User manual

MICRO-AIR

MICRO-AIR SC150 User manual

MICRO-AIR

MICRO-AIR WC2500 User manual

MICRO-AIR

MICRO-AIR MT1252 User manual

MICRO-AIR

MICRO-AIR MX3510 User manual

MICRO-AIR

MICRO-AIR OM 500 User manual

MICRO-AIR

MICRO-AIR OM550DD User manual

MICRO-AIR

MICRO-AIR XA34 Max User manual

Popular Air Cleaner manuals by other brands

Momax

Momax Ultra-Air Plus instruction manual

Honeywell

Honeywell 60001 - Enviracaire Grade Air Purifier owner's manual

TEFAL

TEFAL INTENSE PURE AIR CONNECT PU4085 Series manual

Ravanson

Ravanson MAC-12000 user manual

Sensede

Sensede SIGNATURE Series operating instructions

Clean Air Way

Clean Air Way R-CLEAN 200 quick start guide