MICRO-AIR OM 500 User manual

Model OM 500

OWNER’S MANUAL

CAUTION

Read complete instructions before operating.

Please file for future reference.

AIR CLEANERS ®

MODEL OM 500 SPECIFICATIONS

Input Volts: 120VAC,60Hz,SinglePhase

208-230/460 VAC, 3-Phase (Optional)

Max.Current: 120VAC 10.4Amps

208-230VAC 3.2Amps

460VAC 1.6Amps

Motor: 3/4 HP TEAO

1HPTEAO3-Phase(Optional)

AirFlow*: 6”Inlet 665 CFM (3387 FPM)

8”Inlet 800 CFM (2292 FPM)

Dimensions: 49”Hx26”W x 14” D (withoutwallbrackets)

ShippingWeight: 175lbs.

Actual Weight: 155lbs.

*Allair flows are tunnel tested readings.

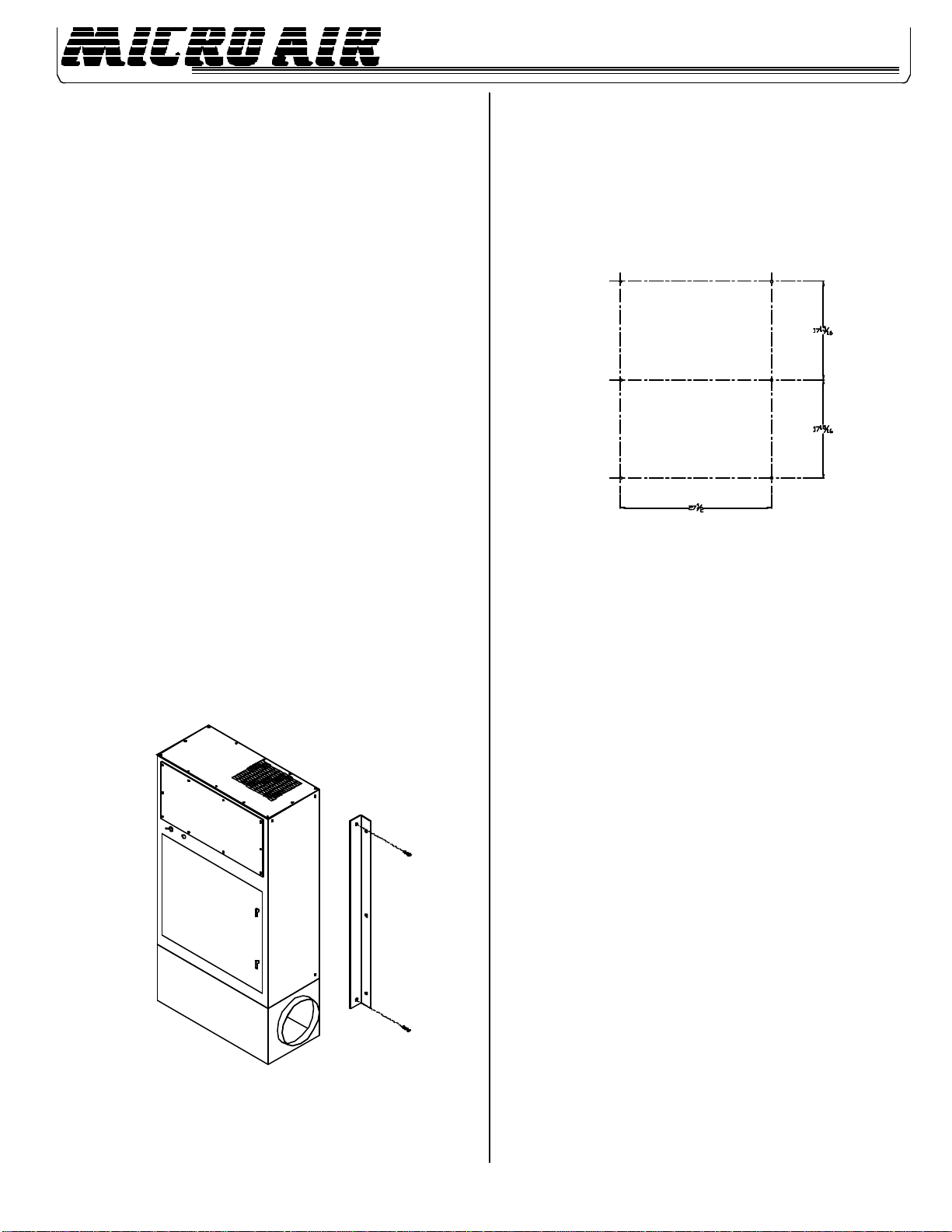

PACKAGE CONTENTS

1ea. OM 500 Unit

2ea. Wall Mount Brackets

1ea. Owner’sManual

PRE-OPERATING INSTRUCTIONS

1. Cutbandingmaterialandremovecardboardandplasticfromunit. Removeunit

fromshippingskid.

2. Inspect unit for shipping damage and report any damage to freight carrier.

INSTALLATION INSTRUCTIONS

A. WALLMOUNT

1. Removefour5/16”boltsfromsidesof cabinet near top and bottom of unit.

2. Useboltsremoved in Step 1 to secure wall mount brackets to unit

as shown in FIG.1.

3. Locateaninstallationsitethatwillprovide for the following:

•Asolid structure, capable of supporting the weightof the unit.

•Three feet of unobstructed exhaust space from the outlet of the unit.

•Easyaccessto servicepanelsandunitinlet.

•Asnear as possible to the sourceof oil mist unit to becaptured.

FIG. 1

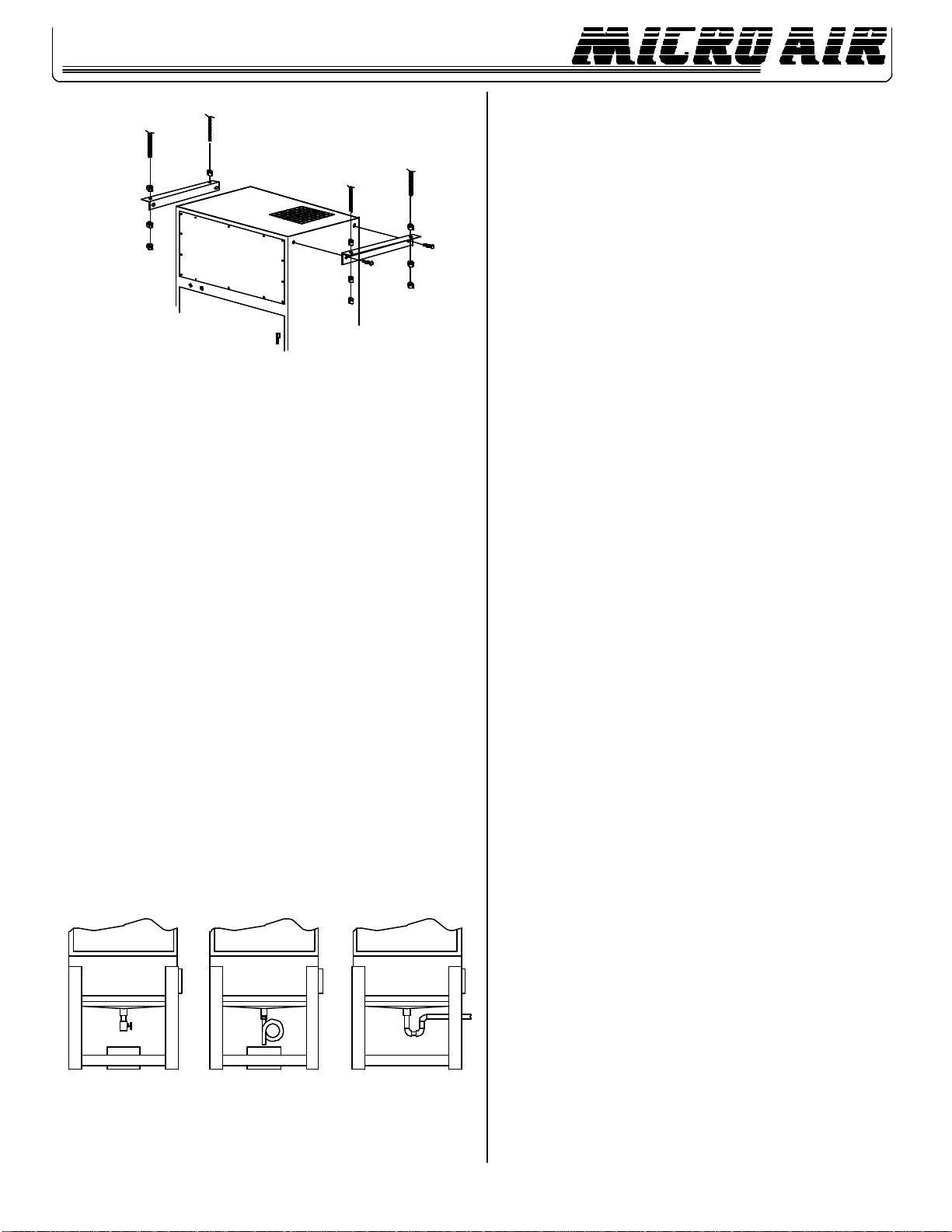

FIG. 2

4. Marklocationof mountingholesonthesurface towhichunitis to bemounted

(see Figure2 for hole pattern). Drill holes that are sized correctly for the

holepatterninmountinghardware.

5. PositiontheOM 500 wallmountbracketholes over theholeslocatedonthe

structureinStep4. Use3/8”x2” lag bolts or 3/8” bolts and nuts to secure

theOM500tostructure.

CAUTION:Thesize and weight of theOM500 requires two persons or

mechanicalmeanstoliftandholdduringmounting.

6. Connectunittooilmistsourceusingaducthaving the same diameter as

theinletoftheunit. The duct may be flexible hose or formed sheet metal.

Maximumflowwill be obtainedwithminimumbends in duct. Tocontainoil

that will collect on the inside of the duct, the duct must be sealed. Sloping

the duct toward the OM 500 will assist flow. Use hose clamps or sheet

metal screws to attach duct to unit.

NOTE: Optionalhoseadaptersareavailableforconnectionto6”and8”

diameterhose. UsePart No. 34145-01for6”diameter hose, andPartNo.

34145-02for8”diameterhose. Attachadaptertoplenumcollarwithsheet

metalscrewsand seal with RTVsealant.

B. FLOORMOUNT

NOTE: The optional base assembly (Part No. 38162-01) is required for floor

mountinstallation.

1. Locateaninstallation site on alevelsurfacethat will meet therequirements

listed in Step 3 of the wall mounting instructions.

2. Set the base in place and lift the unit onto the base.

CAUTION: Thesizeand weightof the OM500 requires twopersons

ormechanicalmeans to liftandhold during mounting.

NOTE: Youmay want to bolt the base tothe floor.

3. Connect the unit to the oil mist source as explained in Step 6 of the wall

mountinginstructions.

C. CEILINGMOUNTING

NOTE: Theoptional ceilingmountingkit (PartNo.38088-02) isrequiredfor ceiling

mountinstallation.

1. Remove the two (2) 5/16” bolts from the side of the cabinet at

2. Usethebolts removed in Step 1 to secure the ceilingmountbrackets to the

unitasshowninFIG.3.

2

OM500

3. Locateaninstallationsitethatwillmeettherequirementslisted in Step 3 of

the wall mounting instruction.

4. Firmlysecurefour lengths of 3/8”threadedrodto a firm structuralsupport.

Spacerodsto match patternmadebyholes in topofceilingmountbrackets.

5. Thread one nut onto each rod.

CAUTION: Thesizeand weightof the OM500 requires twopersons

or mechanicalmeans tolift andhold duringmounting.

6. Raise the unit up to threaded rods and insert rods through ceiling mount

brackets. Threadasecondnut onto each rod from below bracket.

7. Level unit by tightening the nuts against the ceiling mount bracket.

8. Thread a third nut onto each rod and tighten against the second nut to

preventlooseningof nuts due tovibration.

9. Connecttheunittothe oil mist source as explained in Step 6 of the wall

mountinginstructions.

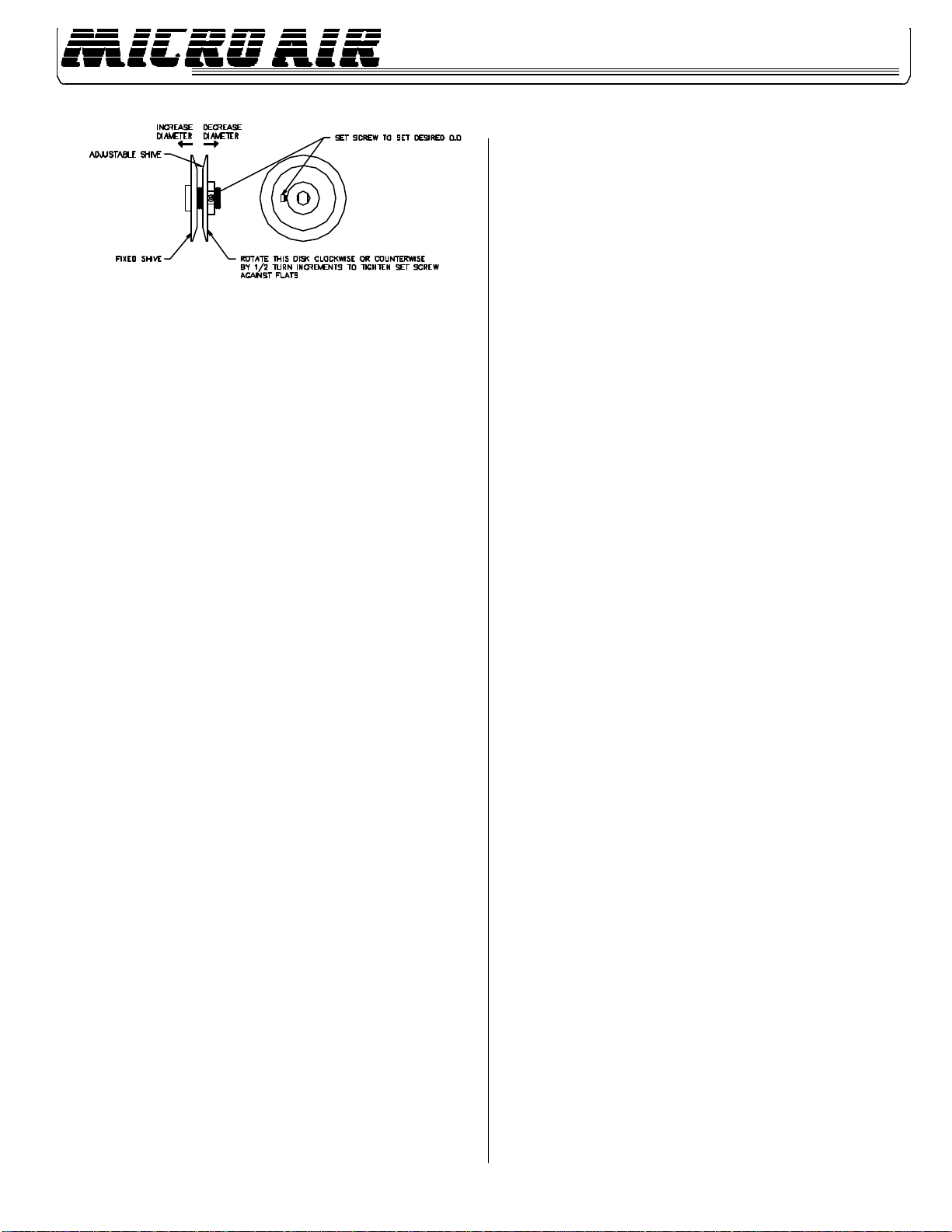

OIL DRAINAGE

NOTE: Shouldcapturedoil be disposed of,makesure to follow local codes.

Provision for draining oil from unit is provided for by a 1” NPT pipe coupling on the

bottomoftheunit. Drainagecanbepipedtoacentralcollectionsystemorcollectedin

abucketplaced under the unit. In all cases a shut-off valve or drain trapisrequired to

preventairbypassthroughthe drain opening. One of thedrainsystemsshowninFig.

4 shouldbeused. Drainconnectionand lines are not provided.

NOTE: Shutoffvalve isinstalledin thedrainsystem,theunitmustbeemptied regularly

topreventoilfromoverflowingintotheintakeduct.

FIG. 3

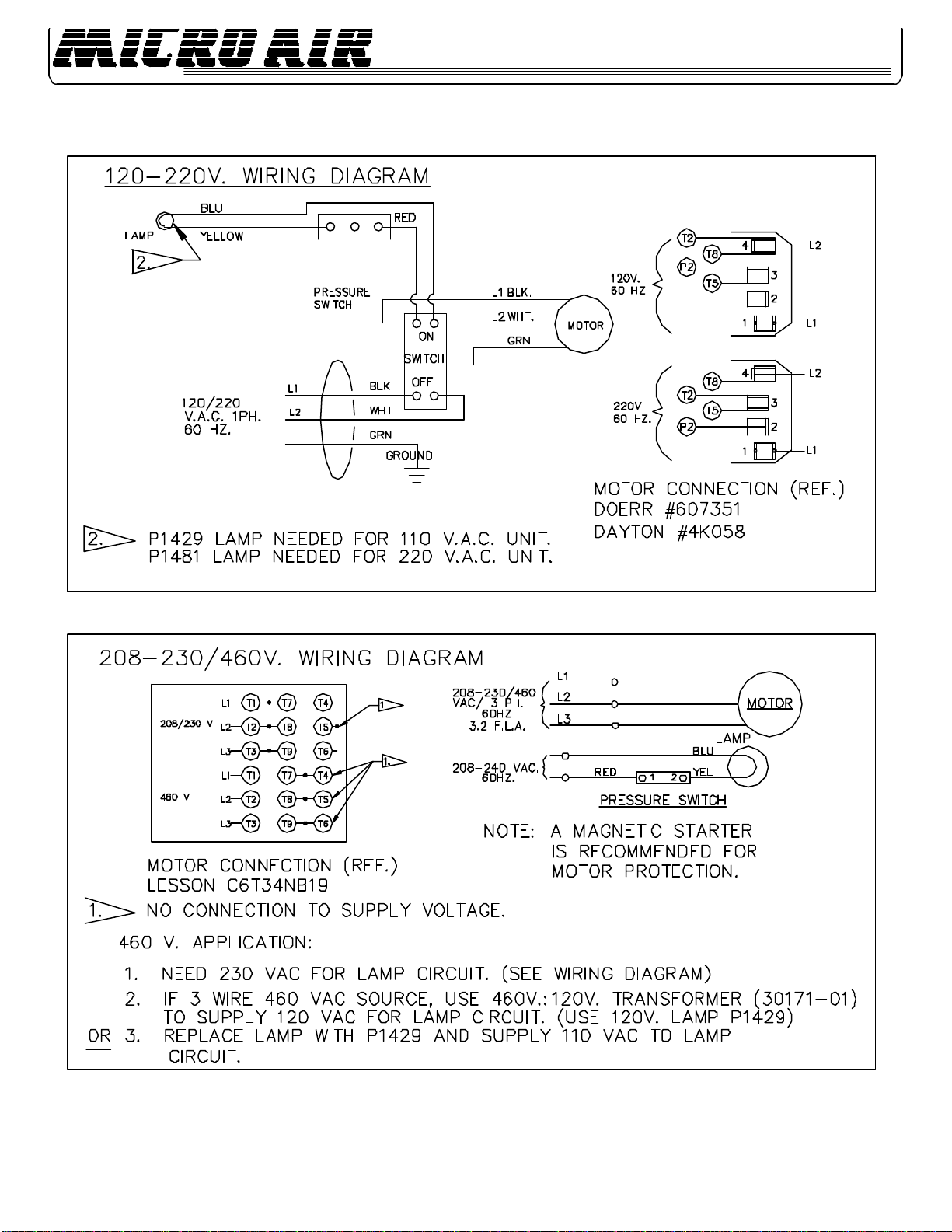

ELECTRICAL CONNECTIONS

A. SINGLEPHASE 120VOLT

Becertainthat thesystemON/OFFswitchis intheOFFposition. Plug thepower

cordintothenearestoutletratedfor120volts.

B. THREE PHASE 208-230/460 VOLT

1. Conduit electrical connections should be made by a qualified electrician,

and must comply with local electrical codes.

CAUTION: Besurethat thedesignated circuit breakeris off untilall

wiringhasbeencompleted.

NOTE: Itis recommended that a 1 HPmotor starter/protector be used in

the supply circuit to this unit. See Wiring Diagram (FIG.6).

2. Remove the front motor compartment access cover.

3. Removetheelectricalwiringboxcover.

4. Makeelectricalconnectionsto the input wires as shown in Wiring Diagram

(FIG. 6)forthreephasewireconnections.

NOTE: The filter change indicator light circuit must be supplied with no

morethan270V. If a 460V,3-wiresourceis used, a transformerreplacement

kit(PartNo.30171-01)mustbeinstalledtoprovidepropervoltagetothe

indicatorlight.

5. Afterwireconnectionsarecompleted,affixconduittosideof unit via the 7/

8”diameterholethatisprovided.

6. Check blower for proper rotation direction. The blower should rotate

clockwisewhenviewedfrom the pulley end.Iftheblowerrotates backwards,

interchangetwoof the motor connectionwires.

PRE-OPERATION CHECKLIST

Beforeplacingunitinservice,checkthefollowingitems:

•Checkblowerdrivebelt for proper tension. (Belt should deflect approximately

1/2”whenfirmpressureisappliedmidway between the pulleys.)

•Checkthatmotor,blower,anddrivepulleys are mounted securely.

•Makesurethatbothcornersofeverypocketinthe filter bag are supported

bythefilter support rod and that the filter support rodsarefully engaged in

their support brackets.

•Airflowdirection arrows on theoilimpingermust point toward theblower.

•Checkthatairintakeandoildrainconnectionsareairoroiltight.

•Makesurethatallaccess panels, removed during installation,arereplaced,

and the filter access door is closed.

Unitisnowreadytobeplacedinservice.

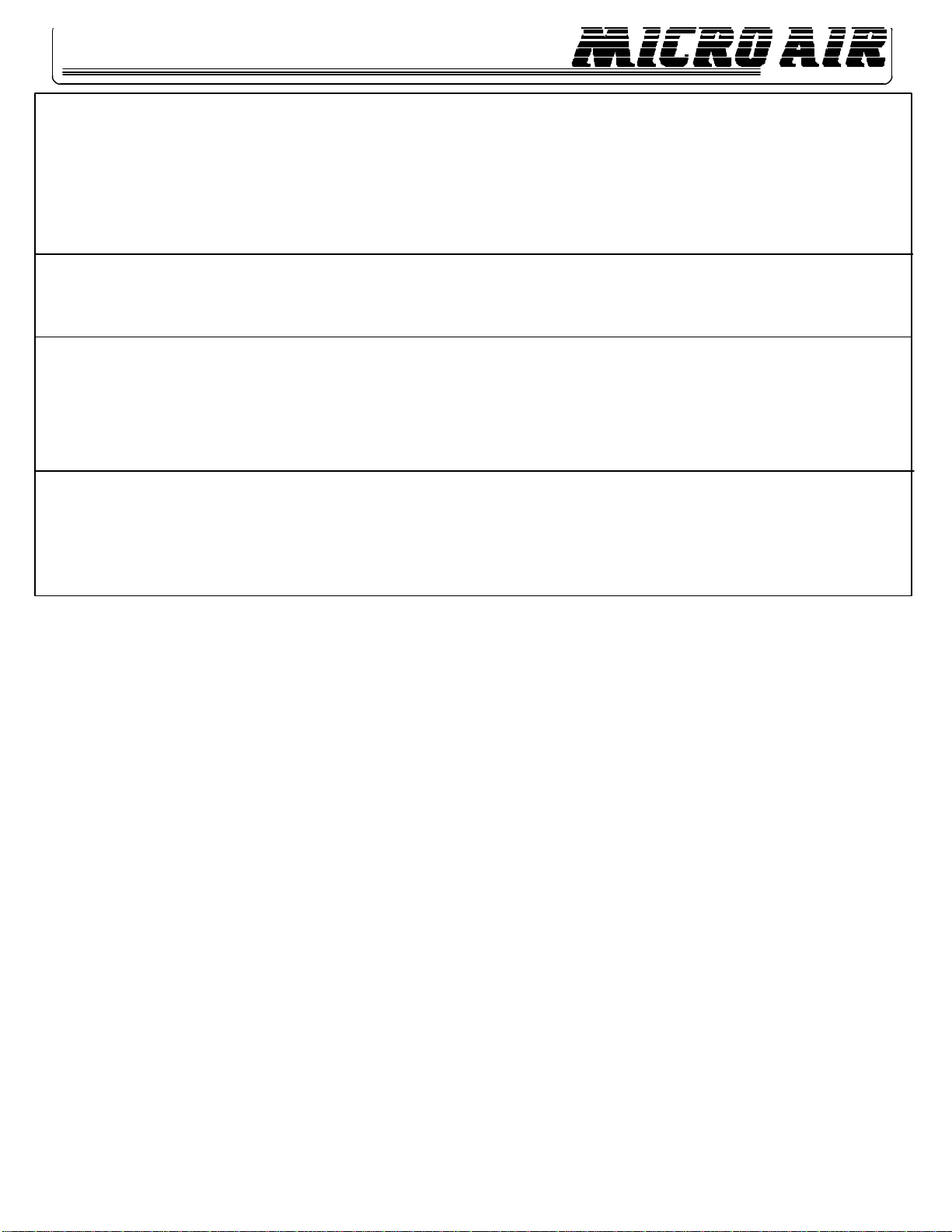

AIR FLOW ADJUSTMENT

The OM 500 is equipped with variable diameter pulleys on the motor and blower to

allowtheairflow to be adjustedtotheinstallationrequirements. Thepulleys are set for

maximumairflowatthe factory. The air flow rate can be reduced as follows:

1. Removemotorcompartmentaccess cover. Be careful to avoid tearing gasket

material between the door and the cabinet.

2. Removebeltfrommotorpulley.

3. Loosenmotorpulleyadjustment set screw andscrewadjustableshiveout away

fromfixedshive. Each turn will reduce the air flow by approximately50CFM.

Tighten set screw onto flat (see FIG.5).

3

OM500

FIG.4

4. Replacebeltandcheck for belt tension.Propertensionshouldbe approximately

1/2”deflectionwhenthebeltissqueezedtogetherwithnormalpressurebetween

fingers.

5. Iftensionistooloose, slide the motor awayfromtheblowershaftviathe slotted

holes located on the motor mount base.

6. Replacemotorcompartmentaccesscover.

7. FormultipleinletapplicationpleaserefertoMicroAir®airflowbalancingprocedure

(FormL1141).

NOTE: All filters and panels must be on the unit and door is closed for current

measurementsofmotor.

OPERATION

1. The pressure switch is preset at the factory to indicate (light on) dirty filters, but

mayneedreadjustment due to a desire for earlier or laterfilterchanges, a different

combination of filters, or because the set point shifted during shipping. The

pressureswitchisalsoorientation sensitive. Toreadjustthe switch,removethe

hole plug in the side of the unit for access to the adjustment screw. Make sure

filters and pre-filters are installed in unit. Turn the unit on and place a piece of

cardboardovertheintakecoveringabout80to85%oftheintakearea. Ona3-

inletsystem,coverentirely two inlets andalittlemorethanhalf of the areaofthe

thirdinlet. Withastandard screwdriver, turn the adjustment screw clockwise

untilthelightgoes off, or counterclockwise until the light comes on.

2. Formore time between filter changes (lessair flow), cover slightly more ofthe

opening,and for less time between filterchanges (more air flow), cover lessof

theopening.

3. Nolubrication isrequiredfor themotorbecause itisa permanentpre-lubedesign.

Excessivedirt/oilshouldbeperiodicallyremoved.

4. Makesureoilisdrainingeasilythroughdrainpipe.

FIG. 5

CHANGING FILTERS

CAUTION: Alwaysmake sure thatthe unitisturned offbeforechanging filtersor

servicing the unit.

1. The OM 500 is equipped with a filter change light, or an optional Magnehelic

Gauge, which indicates when a filter needs to be replaced. If the differential

pressurehasbeensetproperly,thelightsignalstheneed for examination of the

filters.

2. Whenthe light comes on, or thegauge reads high differential pressure, turnthe

unitoffandremovethe impinger pre-filter from the unit. Wash the pre-filter in a

detergentsolutionto remove dirt and oil residue.

3. Rinsethe pre-filter thoroughly with water, shakedry and replace it into theunit

withairflowdirection pointing to theblower.

4. Turnon the unit. If the filter change lightfails to go out, or the gauge continuesto

readhighdifferentialpressure,afterreplacingthepre-filter,thentheoilbagfilter

mayalsoneedtobe replaced.

5. Visually inspect the bag filter. If the pockets are loaded with oil and dirt, then

removethe filter from the channel and inserta new filter.

6. Starttheunit.Thefilterchangelightshouldbeoff,orthegaugereadslowdifferential

pressure,andtheunitoperating properly.

GENERAL MAINTENANCE

1. Occasionallychecktheconditionofthedrivebeltfortightnessandwear.

2. Checkthe blowerbearingsfor unusualwearand theblowerwheel fordebrisand

dirt. Clean when necessary.

3. Checkthewiringforlooseconnectionsorcrackedinsulation.

4. Nolubrication isrequiredfor themotorbecause itisa permanentpre-lubedesign.

Excessivedirt/oilshouldbeperiodicallyremoved.

5. Makesurethatoilisdrainingeasily through drain pipe.

4

OM500

TROUBLESHOOTINGCHART

CAUTION:Beforedisassemblingtheunitordoinganyinspectionoftheparts,makecertainthatthepowerhasbeencutoffand

theblowerhascometoacompletestop. Never runtheunitwiththeaccessdooropenorremoved.

PROBLEM POSSIBLE CAUSE REMEDY

Unit fails to start Deadpowerline Checkthecircuitandswitch

Blownfuse Replacefuse

Loosewireinterminalbox Reconnectwire

Burned out motor Replacemotor

Unitruns slowly or Wired for wrong voltage or Check input voltage

Inadequatecapturevelocity Improper rotation Check wiring diagram

Dirtyfilters Servicefilters

(see Changing Filters section)

Obstruction in hose/arm Reach into hood and

assembly removeobstruction

Pulleys set for static Adjust or change pulleys

Vibration Loose mounting bolts Tightenbolts

Foreign objects in blower Removeaccessdoorand

remove objects

Dirty disposable filters Servicefilters

Obstruction in hose/arm Reach into hood and

assembly removeobstruction

5

OM500

OM 500 - WIRING DIAGRAM

6

OM500

FIG.6

OM500-PARTSLIST

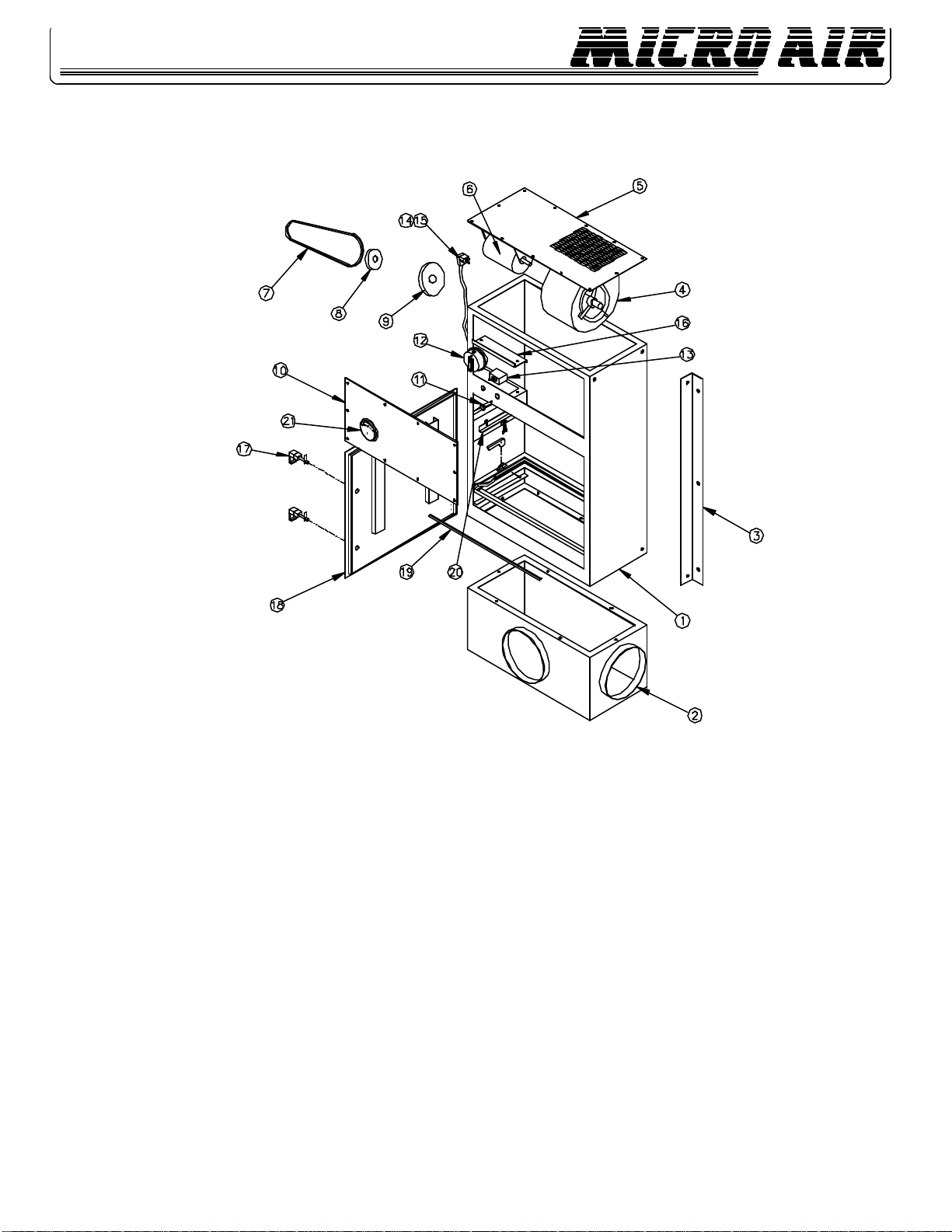

FIG. 7

ITEM PARTNO. DESCRIPTION ITEM PART NO. DESCRIPTION

1. 34126-01 Cabinet Weldment 15. P1954 Strain Relief (not shown)

2. 34142-03 Inlet Plenum (3”-8” collars) 16. 34150-01 ControlBox Cover

3. 34094-02 Wall Bracket (2 ea. required) 17. P1372 Door Latch (2 ea. required)

4. 34122-01 Blower/Rivnut Assembly (120 V & 220 V) 18. 34136-01 Filter Access Door

5. 34148-01 Exhaust Panel 19. P2126 Gasket (specify length required)

6. P1717 Motor (120 V) 20. 34161-01 Optional Hepa Kit

P1762 Motor (208-230/460 V) 21. P2250 Optional Magnehelic Gauge

7. P2064 Belt Not Shown P2061 Oil Impinger

8. P1789 Motor Pulley Not Shown P2062 Oil Bag Filter

9. P1710 Blower Pulley Not Shown P2072 Optional Hepa Filter

10. 34134-01 Front Access Panel Not Shown P2070 Optional Oil Bag Filter

11. P1429 Lamp (120 V) (used with Hepa Filter)

P1481 Lamp (220 V) Not Shown P3001 Optional 2” Max Grid Panel Filter

12. P1428 Pressure Switch Not Shown P3008 Optional 4”Mist-Xfilter (Chevron)

13. P1356 ON/OFF Switch Not Shown 34088-02 Optional Ceiling Bracket (2 ea. required)

14. P1363 Power Cord Not Shown 34162-01 Optional Base Assembly

Not Shown 34145-01 Optional 6” Diameter Collar Adapter

7

OM500

NOTES:

AIRCLEANERS

Products of Metal-Fab Inc.

P.O.BOX1138,WICHITA,KS67201

©1998 Metal-Fab, Inc. Form No. L1142 11/02

7051

Lithoin U.S.A.

8

OM500

®

Table of contents

Other MICRO-AIR Air Cleaner manuals

MICRO-AIR

MICRO-AIR MX3510 User manual

MICRO-AIR

MICRO-AIR SC150 User manual

MICRO-AIR

MICRO-AIR CLEAN AIR BOOTH User manual

MICRO-AIR

MICRO-AIR MT800 User manual

MICRO-AIR

MICRO-AIR MAE2200 User manual

MICRO-AIR

MICRO-AIR XA34 Max User manual

MICRO-AIR

MICRO-AIR SC 150 User manual

MICRO-AIR

MICRO-AIR WC2500 User manual

MICRO-AIR

MICRO-AIR WM 500 User manual

MICRO-AIR

MICRO-AIR M2150 User manual