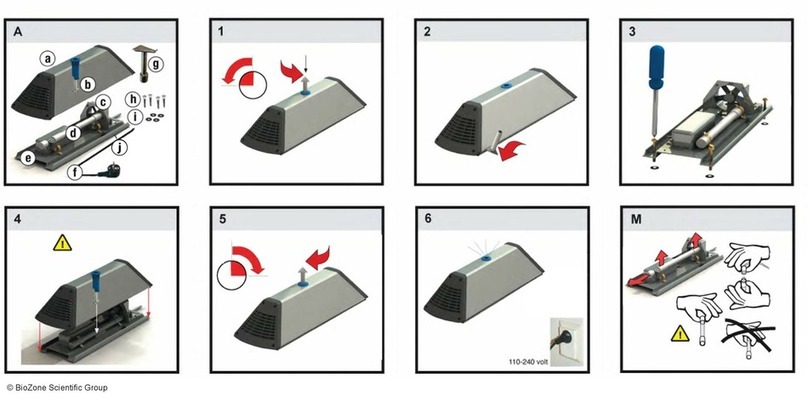

3

FIG.3

4. Firmly secure four lengths of 3/8” threaded rod to a

firm structural support. Space rods to match pattern

made by holes in top of mounting brackets.

5. Thread one nut onto each rod.

CAUTION: The size and weight of the OM550DD requires

two persons or mechanical means to lift and hold during

mounting.

6. Raise the unit up to threaded rods and insert rods

through mounting brackets. Thread a second nut onto

each rod from below bracket.

7. Level unit by tightening the nuts against the mounting

bracket.

8. Thread a third nut onto each rod and tighten against

the second nut to prevent loosening of nuts due to

vibration.

9. Connect the unit to the oil mist source as explained in

Step 6 of the machine mounting instructions.

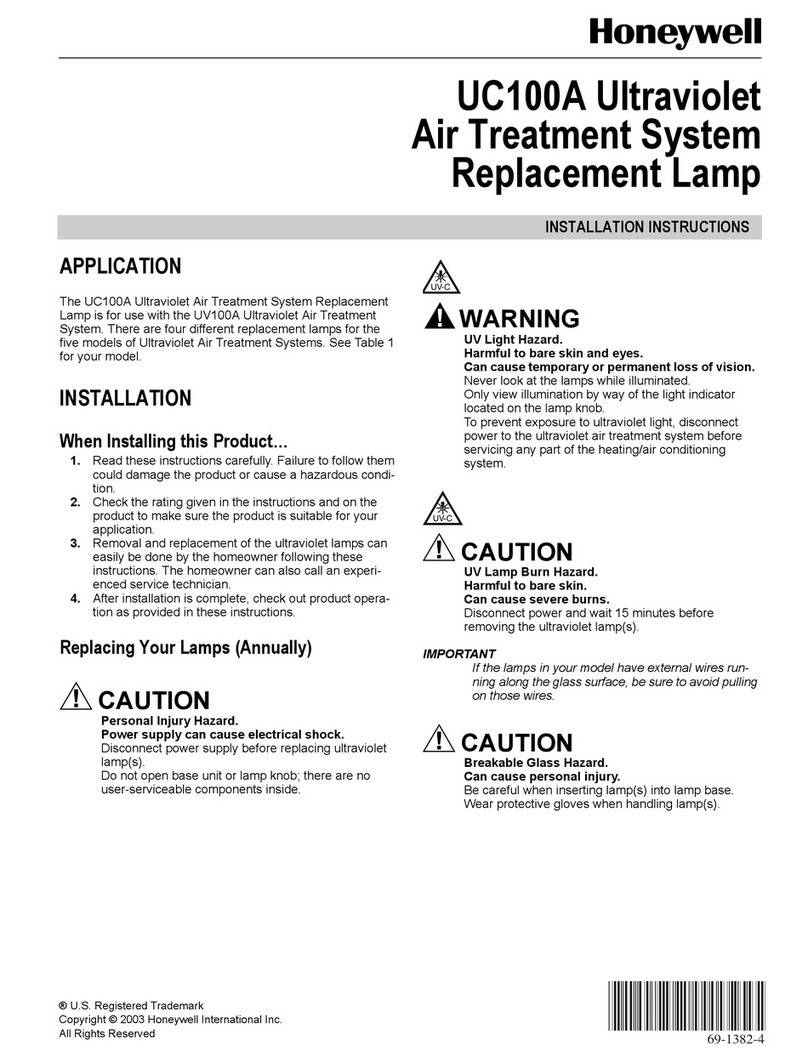

OIL DRAINAGE

NOTE: Should captured oil be disposed of, make sure to follow

local codes.

Provision for draining oil from unit is provided for by a 1” NPT

pipe coupling on the bottom of the unit. Drainage should be

piped to a central collection system. A shut-off valve or drain

trap is required to prevent air bypass through the drain

opening. The drain system shown in FIG.4 should be used.

Drain connections and lines are not provided.

NOTE: If a shut-off valve is installed in the drain system, the

unit must be emptied regularly to prevent oil from overflowing

into the intake duct.

ELECTRICAL CONNECTIONS

A. SINGLE PHASE 120 VOLT

Be certain that the system ON/OFF switch is in the OFF

position. Plug the power cord into the nearest outlet rated

for 120 volts.

FIG.4

B. THREE PHASE 208-230/460 VOLT

1. Conduit electrical connections should be made by a

qualified electrician, and must comply with local

electrical codes.

CAUTION: Be sure that the designated circuit breaker is

off until all wiring has been completed.

NOTE: It is recommended that a motor starter/protector be

used in the supply circuit to this unit. See Wiring Diagram

FIG.5.

2. Make electrical connections to the input wires as

shown in Wiring diagram FIG.5 for three phase wire

connections.

3. Check blower motor for proper rotation direction. The

blower should rotate clockwise when viewed from the

motor side. If the blower rotates backwards,

interchange two of the power connection wires (L1 &

L2).

4. Confirm proper rotation.

NOTE: 3PH Motor supplied with unit is not thermally protected.

A motor starter is recommended for proper installation. Prior to

running measure motor current and verity that it does not

exceed F.L.A rating of motor.

PRE-OPERATION CHECKLIST

Before placing unit in service, check the following items:

Check that motor and blower are mounted securely.

Make sure that both corners of every pocket in the filter

bag are supported by the filter support rod and that the

filter support rods are fully engaged in their support

brackets.

Airflow direction arrows on the oil impinge must point

toward the blower.

Check that air intake and oil drain connections are air and

oil tight.

Make sure that the filter access door is closed into proper

position and that door seals are compressed.

Check oil drain connections to unit and reservoir (Not

included).

Unit is now ready to be placed in service.