Microdyn Nadir MICRODYN BIO-CEL XS-1 User manual

Headquarters

MICRODYN-NADIR GmbH

Building D512

Kasteler Straße 45

65203 Wiesbaden

Germany

info@microdyn-nadir.de

www.microdyn-nadir.de

USA Office

MICRODYN-NADIR US, Inc.

93 South La Patera Lane

Goleta, CA 93117

USA

info@microdyn-nadir.com

www.microdyn-nadir.com/en

www.microdyn-nadir.com/trisep

China Office

MICRODYN-NADIR (Xiamen) Co. Ltd.

No. 66 Jinting North Road Xinglin

Xiamen, China 361022

infochi[email protected]om

Singapore Office

MICRODYN-NADIR Singapore Pte. Ltd.

18 Tuas Avenue 8

Singapore 639233

info@microdyn-nadir.com

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Technical Manual

MICRODYN-NADIR

MICRODYN BIO-CEL®XS-1 Pilot Plant

Manual

Table of Contents

2 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Table of Contents

1About this Document ...............................................................................................4

2Safety & Warning......................................................................................................5

Safety Guidelines.......................................................................................................5

DOs & DON’Ts...........................................................................................................6

General Operational Safety ........................................................................................7

Interim Storage...........................................................................................................7

Transport & Handling..................................................................................................8

Modifications..............................................................................................................9

Commissioning...........................................................................................................9

Operation...................................................................................................................9

Cleaning & Storage Chemicals...................................................................................9

3Product Description MICRODYN BIO-CEL®XS-1..................................................10

Membrane................................................................................................................10

Laminate..................................................................................................................10

Module.....................................................................................................................11

4MICRODYN BIO-CEL®XS-1 Pilot Plant..................................................................12

Equipment................................................................................................................12

Functional Description..............................................................................................13

Connections and Interfaces......................................................................................14

4.3.1 Waste water/ sludge supply..........................................................................14

4.3.2 Clean water supply.......................................................................................14

4.3.3 Permeate discharge.....................................................................................14

4.3.4 Filtration tank overflow .................................................................................14

4.3.5 Surplus sludge.............................................................................................14

4.3.6 Power supply/emergency shutdown .............................................................14

5Installation..............................................................................................................15

6Commissioning ......................................................................................................16

Start-up....................................................................................................................16

Start-up with clean water..........................................................................................16

Start-up with aerated sludge.....................................................................................16

7Operation................................................................................................................17

Operational Sequence and PLC Settings..................................................................17

Cleaning...................................................................................................................22

8Shut-Down and Transport......................................................................................24

Table of Contents

3 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Figure Index

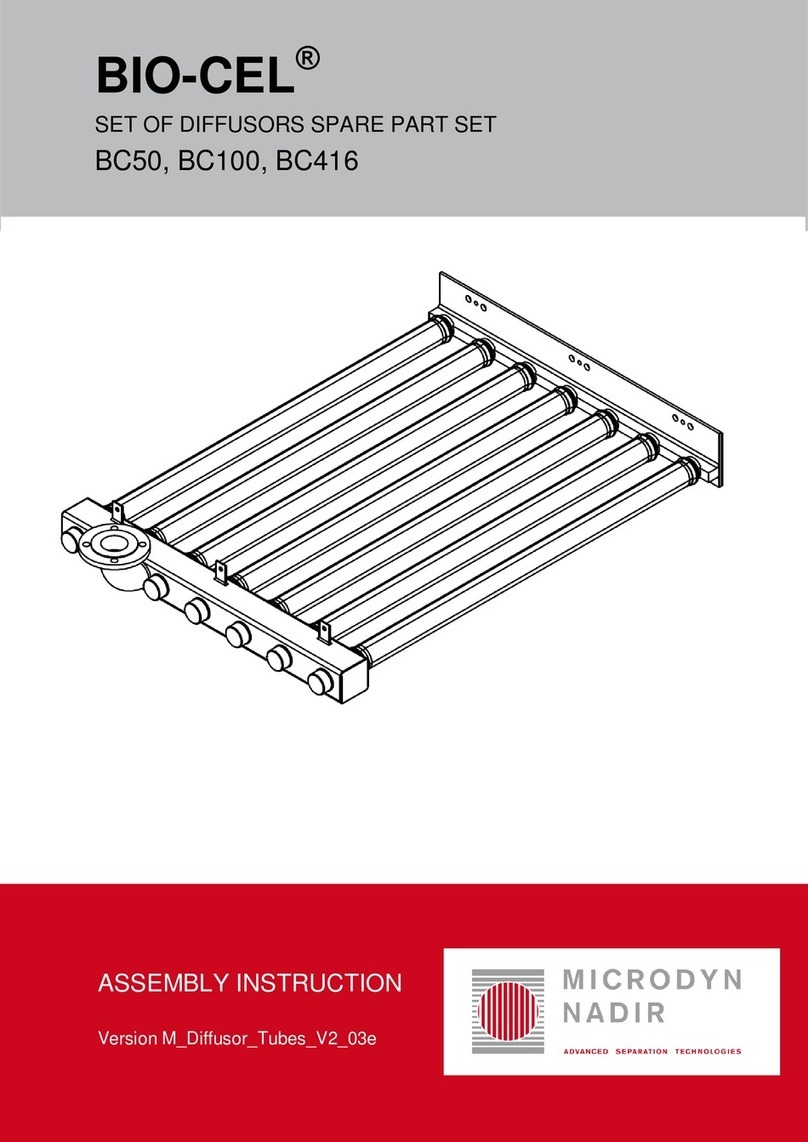

Figure 1. BIO-CEL XS-1 module............................................................................................10

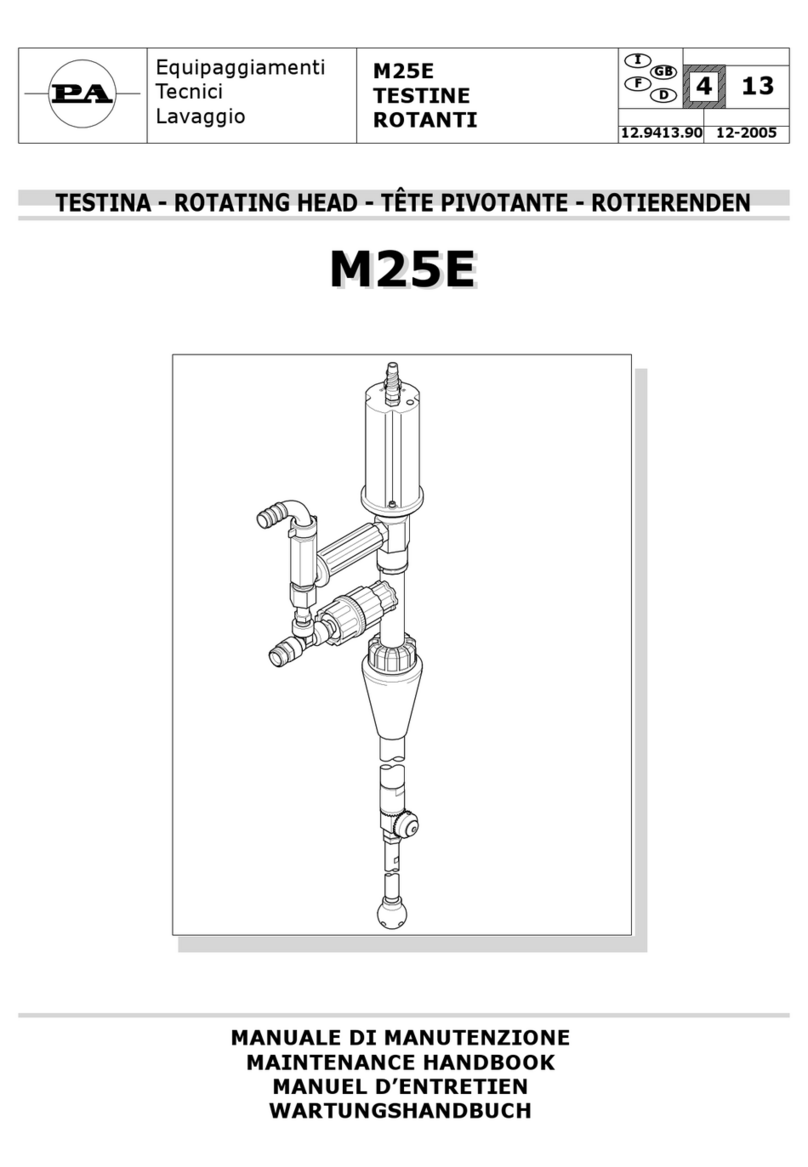

Figure 2. BIO-CEL Laminate..................................................................................................11

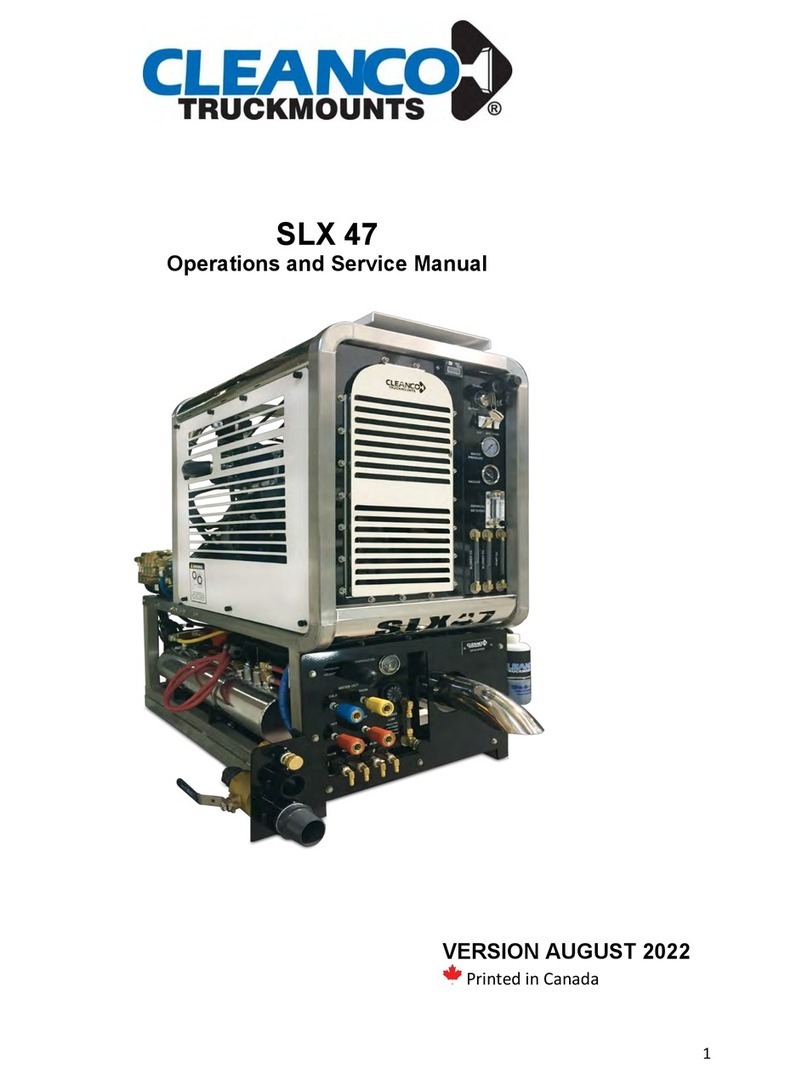

Figure 3. drawing (left) and photo (right) of the pilot plant.......................................................12

Figure 4. Pilot plant and auxiliary equipment..........................................................................13

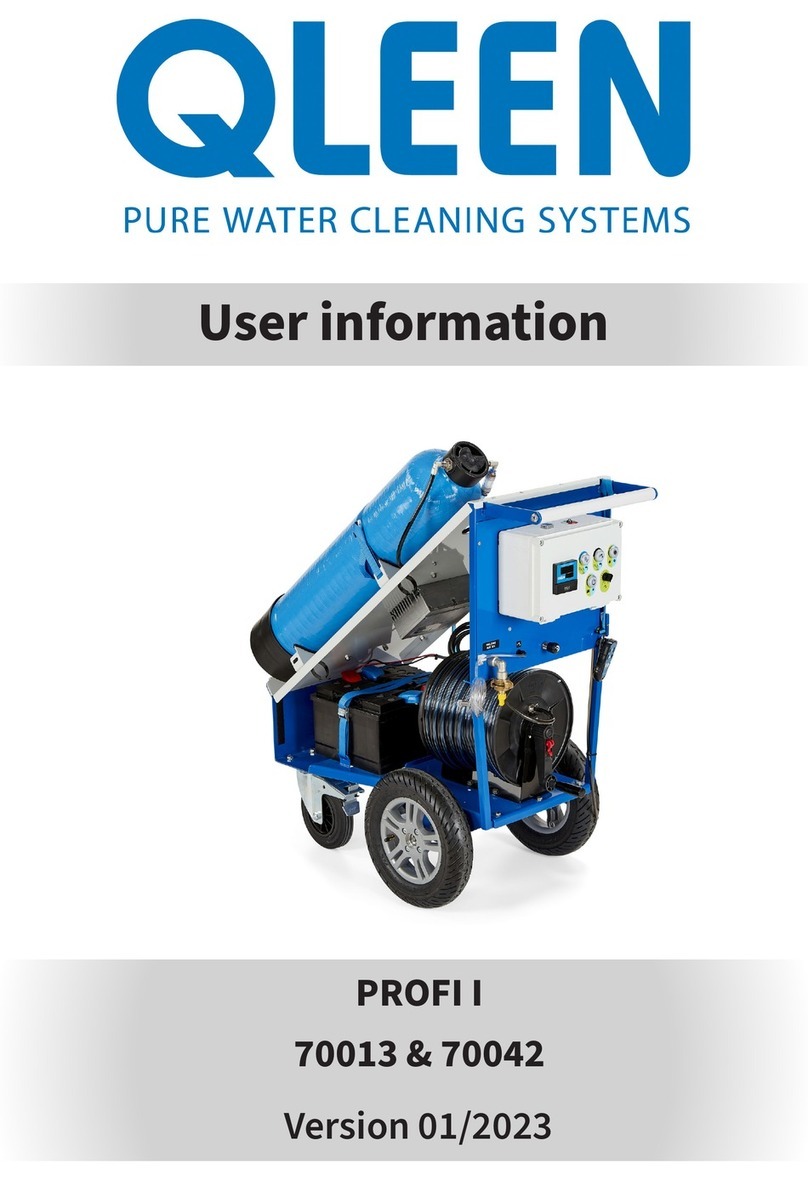

Figure 5. P&ID of the pilot plant.............................................................................................15

Figure 6: Control Panel –Overview.......................................................................................19

Figure 7: Control Panel - Plant...............................................................................................19

Figure 8: Control Panel –System Control..............................................................................20

Figure 9: Control Panel –Parameters 1.................................................................................20

Figure 10: Control Panel –Parameters 2...............................................................................21

Figure 11: Control Panel –Chart ...........................................................................................21

Table Index

Table 1: NADIR-UP150 properties .........................................................................................10

Table 2: BIO-CEL XS-1 module properties.............................................................................11

Table 3: Overview of equipment.............................................................................................12

Table 4: Overview of operation settings..................................................................................18

Table 5: Maintenance Cleaning procedure*............................................................................22

Table 6: Recovery Cleaning procedure*..................................................................................23

4 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

1 About this Document

This operating manual contains information about the MICRODYN BIO-CEL®XS-1 pilot plant.

The plant is constructed for mobile applications at changing locations. The following chapters

comprise descriptions of the general plant design and the test area aswell as importantoperating

information and safety instructions.

The suitability of the BIO-CEL modules installed in this plant for a special application depends on

the quality of the medium to be filtered, the applied biology and its quality. The suitability also

depends on keeping the directives for the process technology. In general, the BIO-CEL

instruction manual must be considered for the operation of BIO-CEL modules.

All information in this manual corresponds to the actual knowledge of MICRODYN-NADIR. It

should provide an overview of the most important data that are needed to operate the pilot plant.

Please make sure that you always use the up-to-date version of this manual.

MICRODYN-NADIR reserves the right to update data due to new developments. The data given

in this manualcannot betakento claim warranties. MICRODYN-NADIRdoesnot give guarantees

for the performance or life time of the product used in the pilot plant.

MICRODYN-NADIR refuses responsibility for any defects occurring directly and indirectly with

objects or persons if these defects are attributed to improper handling or to not complying with

safety and operating conditions as mentioned in this manual respectively.

The system is property of MICRODYN-NADIR. Improper handling can result in defects of parts

of the plant or the membrane module. Please check the system and the modules regularly by

appropriate tests and measuring. If the filtrate quality worsens, this may be due to several

reasons. Please insure just at the time of start-up that suitable measuring devices for the

detection and prevention of possible defects are available.

Warranty claims are refused for any defects due to improper handling of the modules (see BIO-

CEL manual) or to disregarding the operating parameters given in this operating manual or the

module data sheet.

The leaser takes care of the correct return of the system to MICRODYN-NADIR. At the time of

delivery, the pilot plant is cleaned, and it must be returned also clean. If the plant is not cleaned

before return, all the costs for cleaning will have to be paid by the leaser.

All the components inside the system must be fastened before the transport to prevent sliding or

falling. (Further instructions for the transport see chapter 0.)

Any defects at the pilot plant must be reported to MICRODYN-NADIR immediately. If defects are

not reported, and therefore further defects occur, the emerging costs must be paid by the leaser.

In the case of failure or operation disruption please immediately inform your contact partner or

MICRODYN-NADIR.

5 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

2 Safety & Warning

This operations and maintenance (O&M) manual highlights certain potential hazards related to

handling, operation and maintenance of the equipment. The intent of this chapter is to

supplement any safety and health standards that are applicable to the facility in which the

equipment is being used. The manual does not cover the full spectrum of published safety and

health standards that are mandated by law. Consequently, users should not assume that they

are responsible only forthose standardsreferencedin this manual or thatthose standards quoted

are current. The user of this manual is responsible for ensuring that their own safety program and

operation and maintenance procedures comply with all applicable safety rules, regulations and

standards in accordance with prudent industry standards. In the event that the safety

recommendations in this manual conflict with local safety and health laws, regulations and/or

standards, the user is encouraged to follow the more stringent standard or law.

Safety Guidelines

It is highly recommended to follow the safety guidelines provided in this manual, to comply with

applicable local safety rules, regulationsand standards or to operate andmaintain the equipment

according to prudent industry practices. Failure to follow these safety guidelines, local safety

rules, regulations and standards may result in a potentially hazardous situation. The severity of

the potentially hazardous situations highlighted in this manual have been indicated using the

symbols listed below.

Symbol

Meaning

a

DANGER

DANGER indicates an imminently hazardous situation. If not avoided, it may

result in death, serious injury, or equipment damage.

WARNING

WARNING indicates a potentially hazardous situation. If not avoided, it may

result in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation. If not avoided, may

result in injury or equipment damage.

DANGER - PRESSURIZED DEVICE: Improper installation, operation or maintenance of the

equipment, including but not limited to the membrane units, electrical system and piping may

result in loss of life, severe bodily injury and/or propertydamage. Please read and understand all

equipment guidelines provided before attempting to open, operate or service the equipment.

Failure to follow these instructions and observe precautions may result in malfunction and

catastrophic failure. Misuse, incorrect assembly or use of damaged or corroded components may

result in serious injury.

WARNING: Certain operating situations require the use of chemicals and other hazardous

substances. Material safety data sheets (MSDS) should be provided by chemical suppliers and

all instructions therein should be adhered to. Safety briefings for the operating personnel should

be carried out by plant health and safety personnel. Always use caution and wear the correct

personal protective equipment (PPE) when handling chemicals.

WARNING: Comply with all pressure and temperaturelimits specified in the technical data sheet

when operating membrane products.

WARNING: The use of chemicals that are not approved or in concentrations higher than those

specified, may cause premature failure of the equipment, including the membrane products.

WARNING: Do not perform any equipment or membrane maintenance unless the system control

power is OFF, the pump starters are OFF, lock out/tag out procedures have been followed and

internal pressure has been relieved from the equipment. Failure to do so may result in serious

injury or death.

WARNING: Do not drink treated water. Treated water is not potable.

CAUTION: The membranes should not be allowed to dry out. The membranes must remain wet

at all times including when the equipment is shut down or for maintenance. Dried out membrane

may result in irreversible membrane damage.

6 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

CAUTION: No anti-foam agents of any kind are to be added into the equipment, without prior

review and written approval from MICRODYN-NADIR. If approved, the anti-foam agents should

only be used in accordance with the conditions specified by MICRODYN-NADIR.

CAUTION: Silicone-based materials, such as waterproofing sprays, lubricating or cutting fluids,

or greases, should not be used in or around the equipment. Using these materials may result in

complete and irreversible membrane fouling.

DOs & DON’Ts

DO –Conduct a site-specific safety review before installation and operation of the equipment.

DO –Install and operate the equipment following the recommendations within this manual.

DO –Familiarize yourself with this entire manual and the equipment, including the controls,

before attempting to operate or perform maintenance on the equipment.

DO –Follow equipment manufacturer recommendations for operation and maintenance.

DO –Wear the appropriate personnel protective equipment.

DO –Routinely inspect for wear and tear on equipment and perform maintenance when

necessary.

DO –Monitor the equipment’s performance and maintain log sheets.

DO –Contact MICRODYN-NADIR with any questions or concerns related to the equipment.

DO –Follow all applicable safety practices and precautions.

DON’T – Install or operate the equipment without knowledge of its operations.

DON’T – Allow unqualified personnel to operate or perform maintenance on the equipment.

DON’T – Allow unsafe conditions: such as water on the floor, worn equipment, exposed wires,

etc.

DON’T – Exceed the mentioned thresholds (i.e. for temperature, pressure, chemical limits) of

the membrane and/or equipment.

DON’T – Use chemicals without prior review and understanding of their MSDS information and

compliance with applicable safety precautions.

DON’T – Use chemicals which have not been approved by MICRODYN-NADIR in writing.

DON’T – Operate the system for purposes other than those described in this manual.

DON’T – Allow the biological processes to perform differently from their intended conditions.

7 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

General Operational Safety

Symbol

Instruction

Wear a safety helmet.

Wear safety shoes.

Read the manual before using the product.

Interim Storage

The membrane modules have a shelf life of 12 months when stored according to the conditions

below. More details regarding decommissioning and storage are given in Chapter 8.

Caution

INSTALL THE MEMBRANE MODULE INTO THE TANK DIRECTLY PRIOR TO

WATER COMMISSIONING.

Symbol

Instruction

Do not place the product under direct sunlight.

Do not exceed a humidity of 70 % during storage.

Do not place the product in rain. The membrane is preserved and after the

preservative is washed out, the membrane module should be kept wet at

all times to prevent irreversible damage from drying out.

Store within the following temperature range only: 5-40°C (41-104°F).

Note that this product is not frost-resistant.

8 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Symbol

Instruction

Always place the product upright unless stated differently in a specific

instruction document.

Handle the product with care. No direct contact with the membrane itself

should occur. Ensure that no damage occurs to the membrane during

transport, assembly and installation. Do not separate the membrane

sheets if they are attached to each other.

Do not damage the outer packaging at the top of the product with knives

or sharp tools. The product must be stored in the delivered packaging till

commissioning is performed.

Transport & Handling

Symbol

Instruction

Only use the eye bolts at the lifting points for elevating the product.

Do not step or stand under a suspended load.

Be cautious of forklift traffic.

The product is top-heavy.

Do not stack the product.

9 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Modifications

MICRODYN-NADIR must be notified of any modifications to the product or any provided parts.

Commissioning

The commissioning process should be performed by personnel trained by MICRODYN-NADIR

or under the supervision of MICRODYN-NADIR.

Operation

Ensure the proper use of all equipment e.g. pumps, blowers. Contact the manufacturer of these

devices for handling instructions.

The membrane is preserved and after the preservative is washed out, the membrane module

should be kept wet at all times to prevent irreversible damage from drying out.

Cleaning & Storage Chemicals

To safely perform chemical cleanings and safely store chemicals, please follow the instructions

provided bythe chemical manufacturer. The pHrange and maximum concentrationforchemicals

used for cleaning purposes should not exceed the limits of the MICRODYN BIO-CEL®MBR

module as listed on the module data sheet. For further information, please contact the chemical

manufacturer.

10 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

3 Product Description MICRODYN BIO-CEL®XS-1

The MICRODYNBIO-CEL®XS-1 is avery compactmembrane module for pilot testing and small-

scale applications. It combines the membrane unit and the aeration system into one easy to

handle module.

Figure 1. BIO-CEL XS-1 module

Membrane

The membrane used is the NADIR®-UP150, a membrane specifically developed for MBR

applicationsThis membrane has been used for numerous MBR plants worldwide. The membrane

is characterized by an excellent chemical and mechanical durability. It is also hydrophilic, which

allows high flows with a low fouling potential.

Table 1: NADIR-UP150 properties

Material

Nominal pore size

Allowable pH range

Allowable temperature range

Preservative

polyethersulphone (PES)

0.04µm (150 kDa).

2-11

40 °C

Glycerine 20% / Sodium benzoate 3%

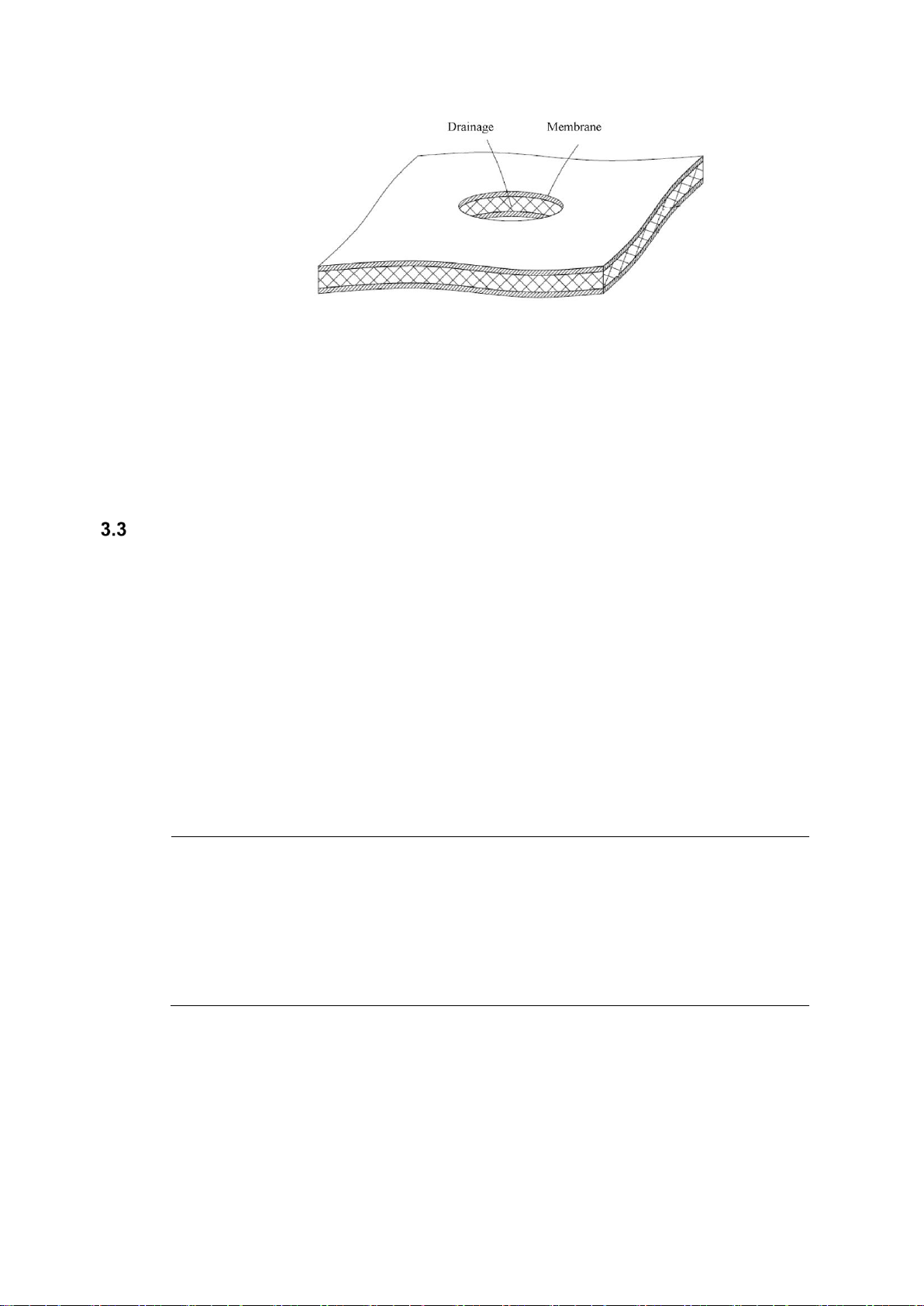

Laminate

The membrane is fused with a drainage layer (polyester) in a lamination process. A solid

connection and at the same time a high water permeability are realized with this process. This

compound creates a backwashable membrane laminate (

Figure 2). This self-supporting membrane laminate with only 2 mm thickness has a high packing

density and a low specific weight.

11 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Figure 2. BIO-CEL Laminate

Module

The single laminate sheets are combined inthe module. Themodule housing provides protection

for the membranes and mechanical stability. It also helps to direct the cross flow of air and

activated sludge through the laminate sheets.

The membrane modules of the MICRODYN BIO-CEL®XS-1 series are made of polyethylene

(frame), PVC (membrane cassettes and aeration system) and a few parts of stainless steel

(clamping elements). They areresistant to corrosion when used in activated sludge. The aeration

system is integrated in this module and is located at the base of the module. The air is required

in order to generate a small amount of cross flow in the module and on the membrane surface in

order to be able to discharge the sludge out of the module. The pressure differences and the

turbulences created by the air dissolve adhering particles from the membrane surface. The fine-

bubble aerators are made of polyurethane (PUR) with small slit openings to achieve the highest

possible oxygen yield and to prevent sludge penetration even when the modules are in stand-by.

Table 2: BIO-CEL XS-1 module properties

Housing material

Dry weight

Length

Width

Height

Diffuser Material

Nominal membrane area

Polyvinyl chlorides (PVC), Polyethylen (PE)

45kg (99lb)

280mm (0.9ft)

747mm (2.5ft)

1515mm (5.5ft)

Polyurethane (PUR), Polypropylene (PP)

10m² (108ft²)

12 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

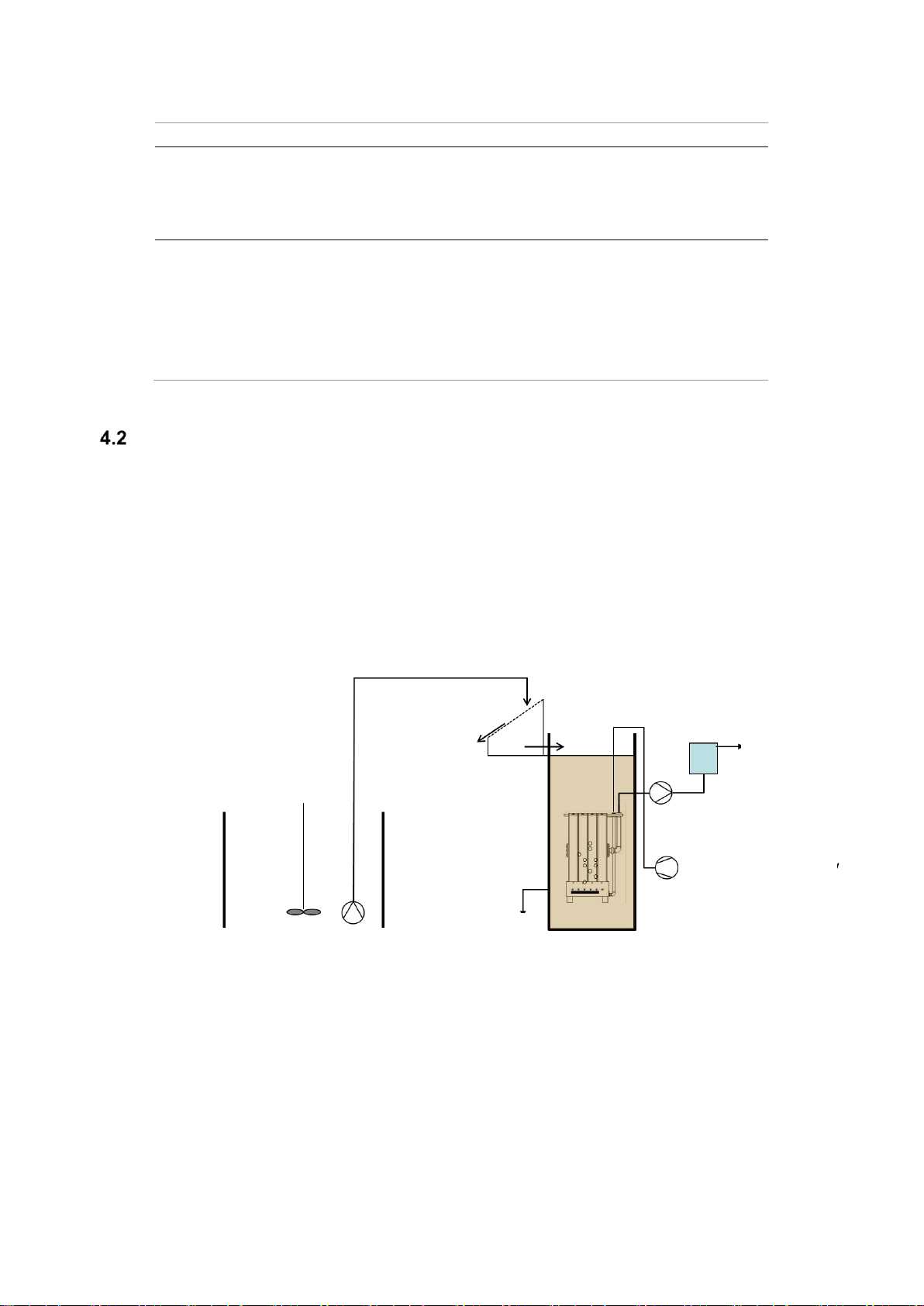

4 MICRODYN BIO-CEL®XS-1 Pilot Plant

The pilot plant solely contains the membrane filtration part for separating cleaned waste water

from activated sludge –the main pre-treatment steps (mechanical pre-treatment) is not part of

the pilot plant. You may use the integrated 1 mm inlet screen as a final step of the pre-treatment

or directly guide the pre-treated waste water to the filtration tank. Instructionsfor the construction

of the pre-treatment can be found in the MICRODYN BIO-CEL® Design Guidelines.

Figure 3. drawing (left) and photo (right) of the pilot plant

Equipment

The equipment installed in the pilot plant is listed below. The specifications are equal to the

specifications in the P&ID (Figure 5. P&ID of the pilot plant).

Table 3: Overview of equipment

Specification

Abbreviation

Description

Remark

Membrane

module

1 x BIO-CEL XS-1

10m²

membrane

surface

Tanks

B1

Inlet tank screen

1mm bar screen

B2

Screenings tank

Not on P&ID

B3

Filtration tank

900 L

B4

Permeate tank

35 L

Pumps

P1

Feed pump

(not included in

delivery)

P2

Permeate pump

80 –250 L/h

Blower

G1

Blower for cross flow aeration

Sensors

PICR

Pressure sensor permeate

FICR

Flow meter permeate

LS

Level permeate tank

LSIC

Filling level membrane tank

Schaltschrank

Gebläse

Siebgutkasten

Zulauf-Bogensieb Permeatbehälter

Permeatpumpe

Inlet Screen

Control panel

Blower

Screenings

tank

Permeate

tank

Permeate

pump

13 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Specification

Abbreviation

Description

Remark

TIR

Temperature aeration tank

TI

Temperature air

PI

Pressure indicator air

FI

Flow indicator air

Valves

V6

Excess sludge outlet / drain

V7

Permeate pipe

V8

Permeate sampling

V9

Permeate pipe

V10

Air pipe

V11

Air pipe

Functional Description

The MICRODYN BIO-CEL®XS-1 pilot plant serves to separate the aerated sludge from cleaned

waste water by means of membrane filtration. The aeration tank of the pilot plant is fed with the

mechanically pre-treated waste water via flexible pipes. Before the effluent reaches the filtration

tank it is flowing through a 1mm bar screen to remove any coarse materials (optional). The

filtration tank is a round tank with an inner diamerter of 75cm and houses the membrane module.

It is possible to operate thefiltration tank with an intermittent denitrification,in this case a separate

anoxic tank for the denitrification is not required.

Figure 4. Pilot plant and auxiliary equipment

The raw waste water is transported into the plant by means of an external pump. Feed supply

and sludge discharge are not part of this plant. They must be provided by the leaser.

The membrane filtration process consists of the steps:

•filtration

•backwashing

•relaxation

•(de-aeration)

Feed line

Feed (aeration) tank

Permeate

tank

Permeate

overflow

Permeate pump

Blower for cross-

flow and aeration

Drain, excess

sludge outlet

Screenings

discharge

14 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

•cleaning

During filtration permeate is sucked through the membranes. After regular and well-defined

periods of time a so-called periodical backwashing is made to keep the membrane surface free

of deposits. In doing so, the permeate pump delivers permeate against the filtration direction.

There is always a relaxation period between the two modes of filtration and backwashing. This

period is called relaxation phase. Usually, in longer, regular time delays the permeate pipe is de-

aerated. Due to the arrangement of the permeate tank, de-aeration is not necessary in this

special case. Cleaning procedures are carried out after definite periods of times to maintain the

membrane permeability. The exact description and the operation principle of the MICRODYN

BIO-CEL®XS-1 modules are to be taken from the BIO-CEL operation and maintenance manual.

The plant is controlled via the integrated touch panel at the switch cabinet. A detailed description

is given in chapter 7.

Connections and Interfaces

4.3.1 Waste water/ sludge supply

The pilot plant may be operated with aerated sludge from a biological cleaning facility (e.g. a

waste water treatment plant) or with raw waste water (after mechanical pre-treatment).

The leaser/operator will use his own pump or feed supply (e.g. by means of controlling the valve

via level differences). The feed pipe from the feed source to the connector at the pilot plant is

supplied by the leaser/operator.

4.3.2 Clean water supply

The MBR pilot plant must be provided with clean water. The leaser/operator has to make sure

that clean water is supplied to the plant, because it is needed for intensive cleaning as well as

for the start-up and shut-down procedures.

4.3.3 Permeate discharge

The cleaned waste water (permeate) is discharged from the plant in free fall.

The drain pipe from its connection to the pilot plant to the suitable terminal reservoir is provided

by the leaser/operator. The proper and professional discharge and disposal has to be warranted

by the operating company.

4.3.4 Filtration tank overflow

The pilot plant is equipped with an emergency overflow of the filtration tank. This overflow must

be connected to the drain or to the waste water feed tank.

4.3.5 Surplus sludge

Surplus sludge is discharged by a manual valve (V6) near the bottom of the filtration tank. The

drain pipe from this connection to a suitable terminal reservoir is provided by the leaser/operator.

The proper and professional discharge and disposal has to be warranted by the operating

company.

4.3.6 Power supply/emergency shutdown

Electric power is supplied via a main high-voltage lead (16A), and an appropriate electrical

connection must be provided by the leaser/operator.

15 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

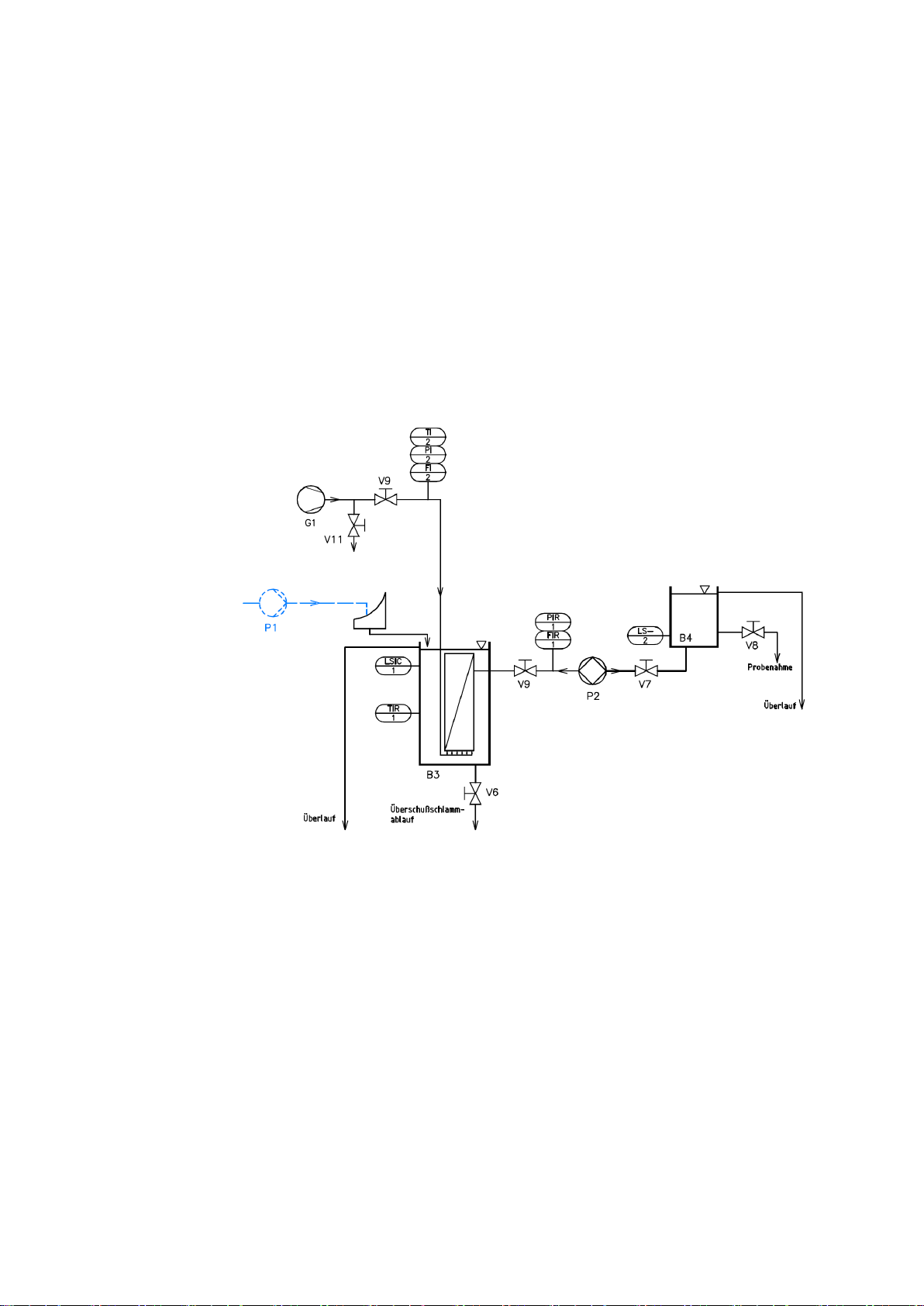

5 Installation

The installation and adjustment of technical componentsof the MICRODYN BIO-CEL®XS-1 pilot

plant must imperatively be done by expert staff. The pilot plant must be operated by personnel

trained by MICRODYN-NADIR. The operation of the pilot plant mustbe monitored byexpert staff.

The pilot plant must be installed horizontally on a plane surface.

Figure 3 shows a possible setup for system integration of the BIO-CEL XS-1 pilot plant. The

following works needed to be performed before commissioning date:

1. All tanks which are intended to be used for piloting must be cleaned.

2. Connect all auxiliary tanks and pipes according to chapter 4.3.1 - 4.3.5.

3. The membrane module is stored with a preservative solution. Avoid wetting the

membranes until the pilot plant is ready for commissioning. Once wet, the membranes

have to remain submerged in water at all times.

4. Prepare a recent water analysis of the feed water (including at least COD/BOD/NH4-N,

TP and TSS)

Figure 5.P&ID of the pilot plant

16 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

6 Commissioning

Before the start-up the instructions of the MICRODYN BIO CEL®Operation and Maintenance

manual are to be adhered imperatively. For start-up a supervisor of MICRODYN-NADIR is

recommended onsite.

Start-up

1. Connect electricity

2. Fasten all screw connections of pipes

3. Check, whether the hand valves are easy to move, and control the valve positions

Start-up with clean water

In starting-up with clean water all components are tested with respect to functionality. Leakages

must be eliminated, and program parameters may be corrected.

1. Fill clean water into the filtration tank up to the overflow (in ideal case let the water

overflow continuously).

2. Fill clean water into the permeate tank, permeate piping will be filled as well.

3. Open manual valves V7, V9, V10, V11

4. Switch on panel

5. All electronically controlled actuators/sensorshave to be checked inmanual operation

(see instruction manual for the plant control)

a) Check the pump performance (never run pump with closed V7 and/or V9)

b) Check the blower performance (adjust V10 and V11 in a way to achieve 5-6

Nm3/h air flow)

CAUTION

Air flow to diffuser must not exceed 6 Nm3/h. Too high air flow can cause

irrevocable damage of diffuser.

Notice: In the beginning increased foaming will be noticed, due to the stabilizing agent on the

membranes. Thus, during the start-up procedure, the filtration tank should once be emptied

completely and refilled with water to wash out the stabilizer.

Start-up with aerated sludge

Before the plant can be operated in the automatic mode, all fault messages and the

communication with external components (e.g. with a feed pump) must be checked.

Feed flow and effluent flow must be checked.

The permeate pipe must be de-aerated often during the first filtration cycles, until all air has

passed from the system.

At the beginning of the pilot phase the plant is operated with aerated sludge without sludge

discharge to achieve the designated TSS concentration of about 10-12 g/l as possible fast. The

age of the seed sludge should be at least 5 days.

17 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

7 Operation

TheMICRODYNBIO-CEL®XS-1 module is operated asdeadend filtration, but with air crossflow,

which is induced by a blower. The permeate pump is controlled by the given flow. The cycle of

filtration is:

•Filtration (510 s standard operation)

•Relax 1 (50 s standard operation)

•Back washing (30 s standard operation)

•Relax 2 (10 s standard operation)

The abovelisted intervals arefreely adjustable within acertain range, so that aflexible adaptation

to the operational conditions on site is possible. Plesae note, that usually a regular de-aeration

is necessary for propper function of the filtration stage. Due to the position of the permeate tank,

the permeate system de-aerates trough the tank automatically, so that no separate de-aeration

step is necessary.

For backwashing the conveying direction of the permeate pump is changed. Filtrate from the

permeate tank is pressed into the membrane pockets, reversing the flow and removing the filter

cake and all particles that have entered the membrane pores. In addition to the back washing,

the air crossflow remains on to clear the removed particles off the membrane surface. For this,

the permeate tank must always be filled. The allowable pressure during backwashing is limited

to avoid membrane damage.

An accumulation of air bubbles in the permeate line due to outgassing can occcur, especially

during high transmembrane pressures. To avoid this effect, the permeate tank is situated at the

highes point of the permeate line so the air can easily escape.

The pilot plant runs fully automated after the initial start up.

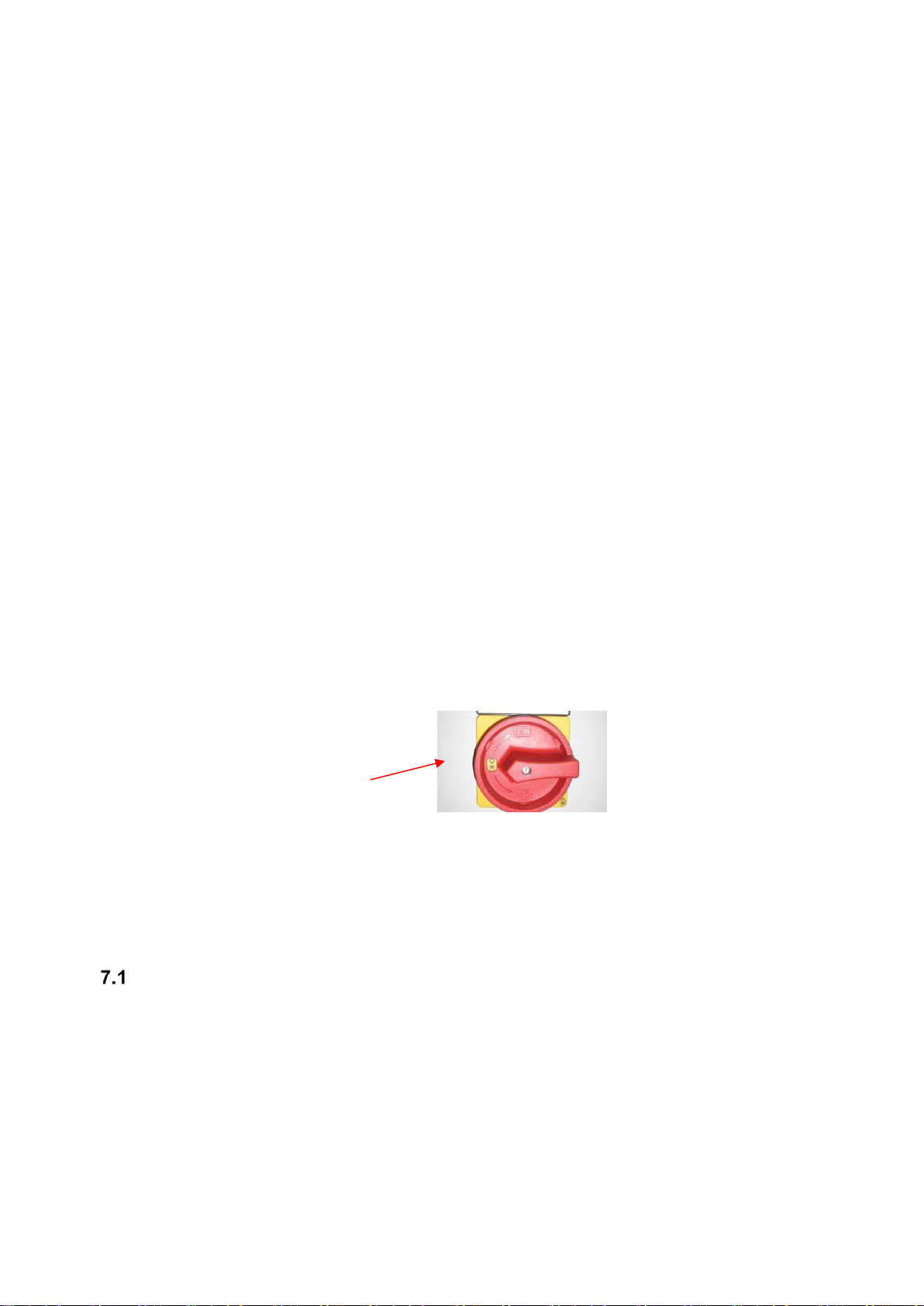

The power supply of the plant can be interrupted by means of a master switch at the switch

cabinet in the control cabinet.

In emergency cases the plant can be shut down as follows:

Shutdown of the feed pump (P1) and shutdown of the permeate pump (P2) at the control

computer. To switch off the power supply turn the master switch in position “0”.

Operational Sequence and PLC Settings

The operation sequence starts with filling the filtration tank with waste water. Thefilling sequence

is triggered by thelevel sensor in the filtration tank.Filling ends when the max level inthe filtration

tank is reached and starts again when the min level is reached.

The next step is the denitrification phase (if required). During this phase, the aeration is mainly

switched off to maintain anoxic conditions in the filtration tank. The blower is only running for

short amounts of time to ensure the sludge is properly mixed. The duration of the denitrification

phase iscontrolledby a timer and can be adjusted tomatch the local requirements, if notrequired

set TDN to 0.

master switch

18 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

After the denitrification follows the filtration. To start this phase, there is a pre-aeration cycle to

get the sludge mixed. The pre-aeration also serves as an initial cleaning of the membrane

surface. The duration of the pre-aeration is adjustable.

Next comes the filtration, which consist of 4 steps (filtration, relaxation 1, back washing and

relaxation 2), as mentionend previously. During filtration the level inside the filtration tank will go

down. Filtration will continue until the level hits the min level. Once this happens the operation

sequence starts anew with the filling sequence.

The operation sequence as well as the recommended settings are descibed in Table 4: Overview

of operation settings.

Table 4: Overview of operation settings

Operation step

Description

Settings

Recommended

Filling of the

aeration tank (FILL)

Feed pump starts at Lmin and

stopps at Lmax

Blower off

LMIN = 150 –160 cm

LMAX = 165 –175 cm

LMIN = 155 cm

LMAX = 170 cm

Denitrification (DN)

Denitrification with intermittent

aeration for sludge mixing

TDN = 0 - 99 min

TDN = 30 min

Intervall between the aeration

times

Blower off

TDN,DELAY = 0-99 min

TDN,DELAY = 10

min

Aeration for sludge mixing

Blower on

TDN,MIX = 0-99 sec

TDN,MIX = 10 sec

Filtration (FN)

Pre-aeration to make sure the

sludge is well aerated and

mixed

Blower on

TPRE = 0-99 min

TPRE = 10 min

Filtration, Permeate pump is

running

Blower on

TFILT = 0-999 sec

QFILT = 80-250 L/h

TFILT = 510 sec

QFILT = 130 L/h

Relax 1

Back wash (Permeate pump

running in reverse)

Relax 2

Blower on

TR1 = 0-999 sec

TBW = 0-999 sec

QBW = 80 –500 L/h

TR2 = 0-999 sec

TR1 = 50 sec

TBW = 30 sec

QBW = 130 L/h

TR2 = 10 sec

There are start and stop ramps for the permeate pump to avoid sudden pressure shocks in the

system. These rams are pre-set and cannot be changed. The ramping time is set to TRAMP = 5

sec. The up ramp is always part of the pump interval, the down ramp is part of the following

interval.

Example:The permeate pumpis set to runfor 510 sec.,followed by 50 sec. relaxation. Theactual

runtime will be 5 sec. ramping up, 505 sec. running at target flow, 5 sec. ramping down followed

by 45 sec. relaxation.

Figure 6 to 11 show the control panel graphics to navigate trough the PLC settings.

19 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Figure 6: Control Panel –Overview

Figure 7: Control Panel - Plant

20 | 24

MICRODYN BIO-CEL XS-1 Pilot Plant Manual // Revision: A // Date: Jul. 25, 2018

Figure 8: Control Panel –System Control

Figure 9: Control Panel –Parameters 1

Table of contents

Other Microdyn Nadir Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

WOLFF

WOLFF Cleanfox 7.5 Use and maintenance

Omegasonics

Omegasonics RESTORATION PRO 3600PW Operation & instruction manual

Kärcher

Kärcher K 4.94 M manual

Matrix Cleaning Systems

Matrix Cleaning Systems 4x4SD10KW User instructions

Uzin Utz

Uzin Utz WOLFF 168801 Translation of original operating manual

MS Schippers

MS Schippers MS Greenline 0809889 Operation manual