GAT Stream User manual

Manual

GAT Stream

creang.technical. uids.

Security

• Maximum working pressure: 8 bar-116 PSI

•Regularlycheckthehosesandvalvecondion.Replacedamagedorworn

partswithnewones.

•Beforeconnecngthesystemtothecompressedair,ensurethatallconneng

partsaresecurelyandsafely.

•NOTE:Aerusereleaseresidualairpressureusingthevalveonthepressuregauge

•Makesurethehosesdonotcomeintocontactwithhotormovingpartsoftheengine.

•CheckthecondionofthefuellterinaluminumcontainerontheGATFlowdevice.

Youcancleanitbyblowingcompressedairintheoppositedirecon.

•CarefullyreadtheadviceforcleaningtheairintakeAirIntakeCleaner.

2

Read carefully.

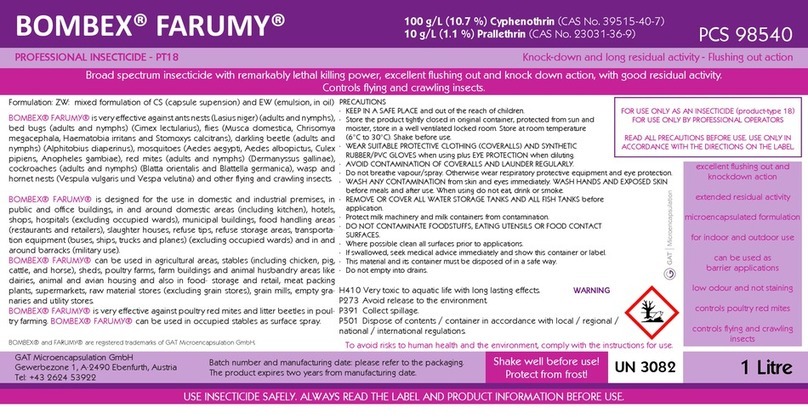

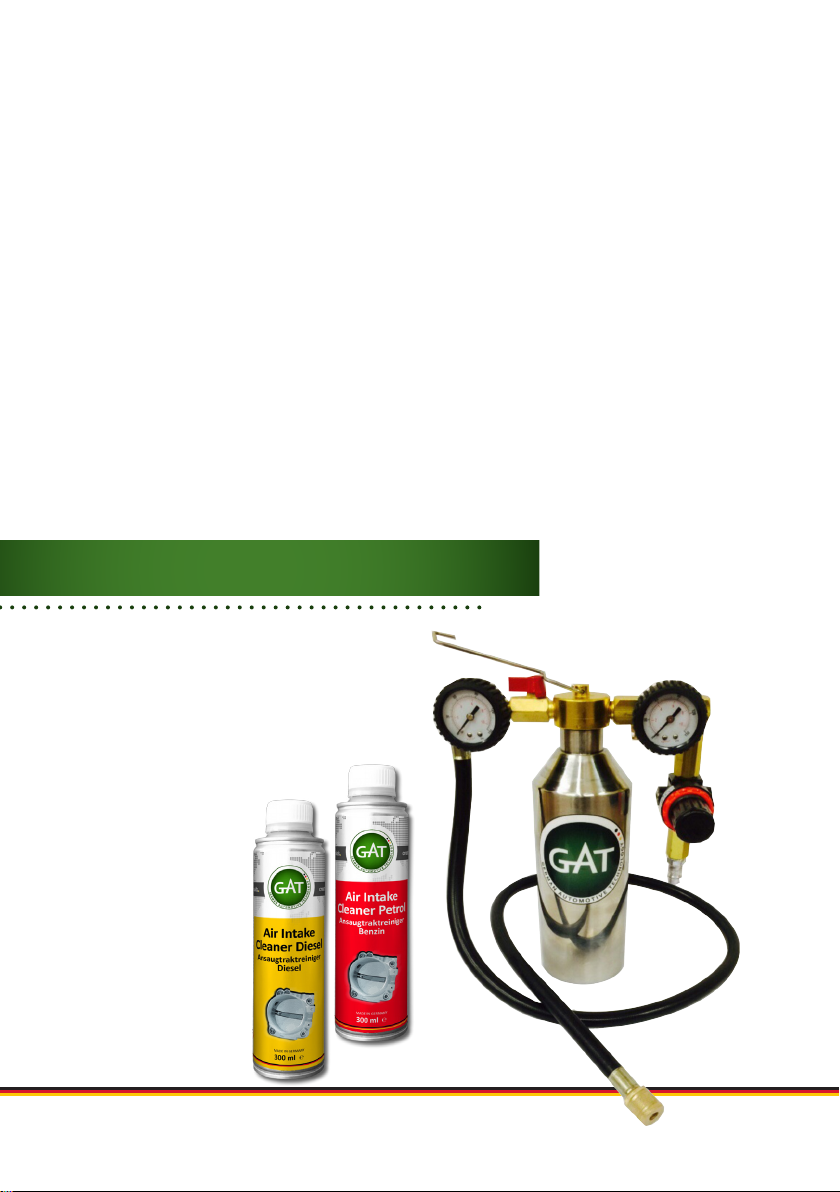

art.nr: 62902

1xGATStream

art.nr: 62022

GATAirIntakeCleanerPetrol

art.nr: 62034

GATAirIntakeCleanerDiesel

Read carefully.

GAT Flow.

unternehmen.

3

applicaon.

5

Kopplas med till- och från ledningen.

Använd ev stoppare!

Ställ in rätt tryck

Tillförsel

Kopplas med tryckluftsnippeln

Användningsschema

Motor

Bränslepump

Retur

Tillförsel

Anmärkning: För fordon utan retur kopplas endast tillförselledningen och ta bort säkringen i bränslepumpen.

Anmärkning: För dieselmotorer kopplas tillförsel och bränsleretur (pga av det höga trycket i bränslepumpen)

Koppla ihop (7-6) på Clear Flow Maskinen med till- och returen av insprutningspumpen och ställ in det korrekta lufttrycket på manometern.

Retur

Pro-Tec Clear Flow Maskin

Bruksanvisning

Return

Fuelpump

Engine

Retur

Filter

Connect to air compressor

Applicaon diagram.

Supply hose

Connect to supply & return hoses

usingbypasshoseorstoppers.

Supply hose

Applicaon diagram.

Adjust the

correct air pressure

Cleaning the fuel system.

4fuel system.

1) Starttheengineandwaitunlitreachesnormal

operangtemperature.

2) Turnotheengineandremovethefuseorrelay

tothefuelpump.

3) FillthecontainerwithGATPetrolSystemCleaner

PLUS.

4) AssembletheGATStreamequipmentandcheck

thatthevalveisclosed.

5) HanguptheGATStreaminasafeplacewithhook

inthehood.

6) Disconnecttheincomingfuellineandmount

appropriatesuppliedadapter.

7) ConnectthehoseoftheGATStreamadapter.

8) Block the return line to the fuel to prevent

PetrolSystemCleanerPLUSrunsintothefueltank.

9) ConnecttheairsupplytotheGATStreamand

adjustpressuretoabout2bar.

10)ThenopenthevalveontheGATStream.

11)Checkthattherearenoleaks.Startthenthe

carandrunitatidle.Adjustconngent

oponallyairpressureshouldthecarrun

rough.Whenreservoirisempty,stopthecar.

Retallparts,thejobisnished.

Cleaning the fuel system.

preparaon.

5

fuel system.

Why is cleaning of the fuel system important?

Over me carbon deposits in the combuson chamber commonly occur when the engine

doesnotburnthefuelcompletely.Asaresultthismaycausemalfuncons,wearandpoorfuel

economy.Cokedepositscanalso cause engine knockingasdepositsinside the combuson

chamberbecomered-hotandignitesthefuelbeforesparkignionoccurs.

Contaminaonisveryharmfultotheengineandespeciallyit’sperformance!Ifthesparkplugs

areremovedbeforetheapplicaonofGATPetrolSystemCleanerPLUSyoucanoenseethat

theyaresooty.Thissootcausesthesparktoweakenresulnginthefueligniontobeless

eecve.

GATPetrolSystemCleanerPLUSremovessuchdeposits,therebyensuringthecorrectignion

andprolongsparkpluglife.Lesssootalsoprovesthatcombusonimproved.

Prevenve maintenance.

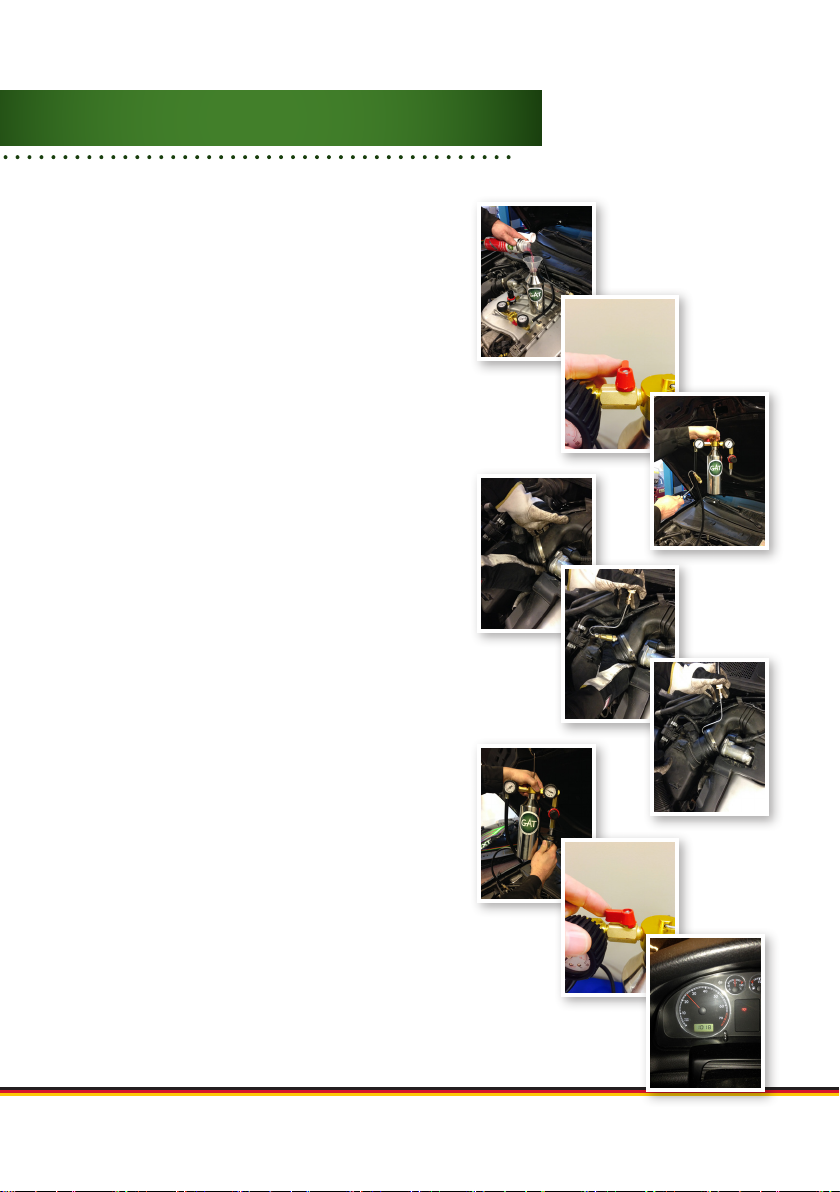

6air intake.

1) Starttheengineandwaitunlithas

reachednormaloperangtemperature.

Turnotheengine.

2) FillthebucketwithGATAirIntake

Cleaner(petrolordiesel).

3) AssembletheGATStreamequipmentand

checkthatthevalveisclosed.

4) ConnectthespraynozzleoftheGATFlow-

hoseandhangGATStreamonasafeplace

withthehookinthehood.

5) Loosen the hose to the air intake and

mountnozzleinairintake.

6) Retthetube,connecttheairtotheGAT

Stream and adjust the pressure to about

2bar.

7) Startthecarandopenthevalve.

8) Adjust the speed of the car to about

1800 - 2500 rpm and let the engine run

unlcanisterisempty.

9) Replacealltheparts,thejobisnished.

Cleaning the fuel system.

Cleaning the air intake.

preparaon.

7

air intake.

When you have to clean the air intake?

Deposits on the injector ps may ruin an injector spray paern which in turn causes fuel

problems and uneven engine running. This can then lead to an injector dosing and distri-

buonmechanismnolongerworkingeecvely.Byremovingcontaminaononeachinjector

thisensuresapropersupplyanddistribuonoffuelandavoidsongoingproblems.Thisalso

preventsthattheunburnedfuelcreangmoreenginedeposits.Bykeepingthevalvesclean

thiswillalsooerbeercompression,engineoperaonandfueleconomy.

Beercombusonmeansbeerulizaonoffuelandlesspolluon.Inaddiontotheim-

provedcombusonitisachievedbythefeaturesthatwehavegonethroughpreviouslywith

GATPetrolCleanerPLUS.

GATPetrolCleanerPLUSimprovescombusonbyreducingthechemicalreaconsinthefuel,

beforeitisignitedbythesparkfromthesparkplugs.Thisensurespropercombusonatthe

right moment. Now triggered energy, when the spark ignites the fuel-air mixture, and not

before! It provides higher temperature and pressure in the combuson chamber and thus

more energy is transferred. When the pressure and temperature rise is also achieved bet-

tercombusonofthefuel,therebyreducingtheamountofcarbonmonoxideandunburned

residuesintheexhaust.

WhenusingairinletcleaningGAT„AirIntakeCleaner“petrol(partno62022)or„AirIntake

Cleaner“diesel(ref62034)mustbepreparedtostrangleallair-introducon into the engine

ifitwouldrunon.

Checkthattherearenofaultswiththetotheairintakethatallowstheenginetoconnueto

run even though you blocked the intake otherwise there could be damage to the engine if the

engineoverspeed.

Alwaysensurethatyoucanchokeallairsupplyandtheenginewillstopimmediately.

Iftheenginerunsonallhosesmustbedrainedofuidthatmayhaveaccumulatedbeforethe

engineisstartedagain.

Aerwards let it stand for a few hours with disconnected hoses so that the vapors can

evaporate.

Intake Cleaning - Precauon.

GAT-GesellschafürKrasto-und

AutomobiltechnologiembH&Co.KG

Alt Saale 2 lD-07407Uhlstädt-Kirchhasel

Fon: +49(0)3672-82446-66

Fax: +49(0)3672-82446-22

eMail: info@gat-international.de

web: www.gat-internaonal.de

Art.:GAT-JD1000

www.facebook.com/gat.germany

Table of contents

Other GAT Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

BorMann

BorMann BVC4100 instruction manual

PREMIER AUTOMATION

PREMIER AUTOMATION HydroCleaner Operator's manual

Kerbl

Kerbl CowCleaner 18700 Instructions for use

Rossle

Rossle BISAM 22 BRUSH operating instructions

Christie

Christie CounterAct UR10 Product safety guide

Osmobil

Osmobil PRO X operating instructions