1

Table of Contents

Chapter 1 Cautions......................................................................................................................................3

1.1 Safety Symbols................................................................................................................................3

1.2 Avoid Self-Modification or Calibration...........................................................................................3

1.3 Static Electricity...............................................................................................................................3

1.4 Ground.............................................................................................................................................3

1.5 Power Supply...................................................................................................................................3

1.6 Warming-Start..................................................................................................................................4

1.7 Device Malfunctions........................................................................................................................4

1.8 Unexpected Termination during Test Process..................................................................................4

1.9 Location and Storage.......................................................................................................................4

1.10 Troubleshooting for Urgent Conditions.........................................................................................4

Chapter 2 General Summary .....................................................................................................................5

2.1 Package and Accessories .................................................................................................................5

2.2 Description of Nouns and Symbols Used in this Manual................................................................5

2.3 Operating Basics..............................................................................................................................6

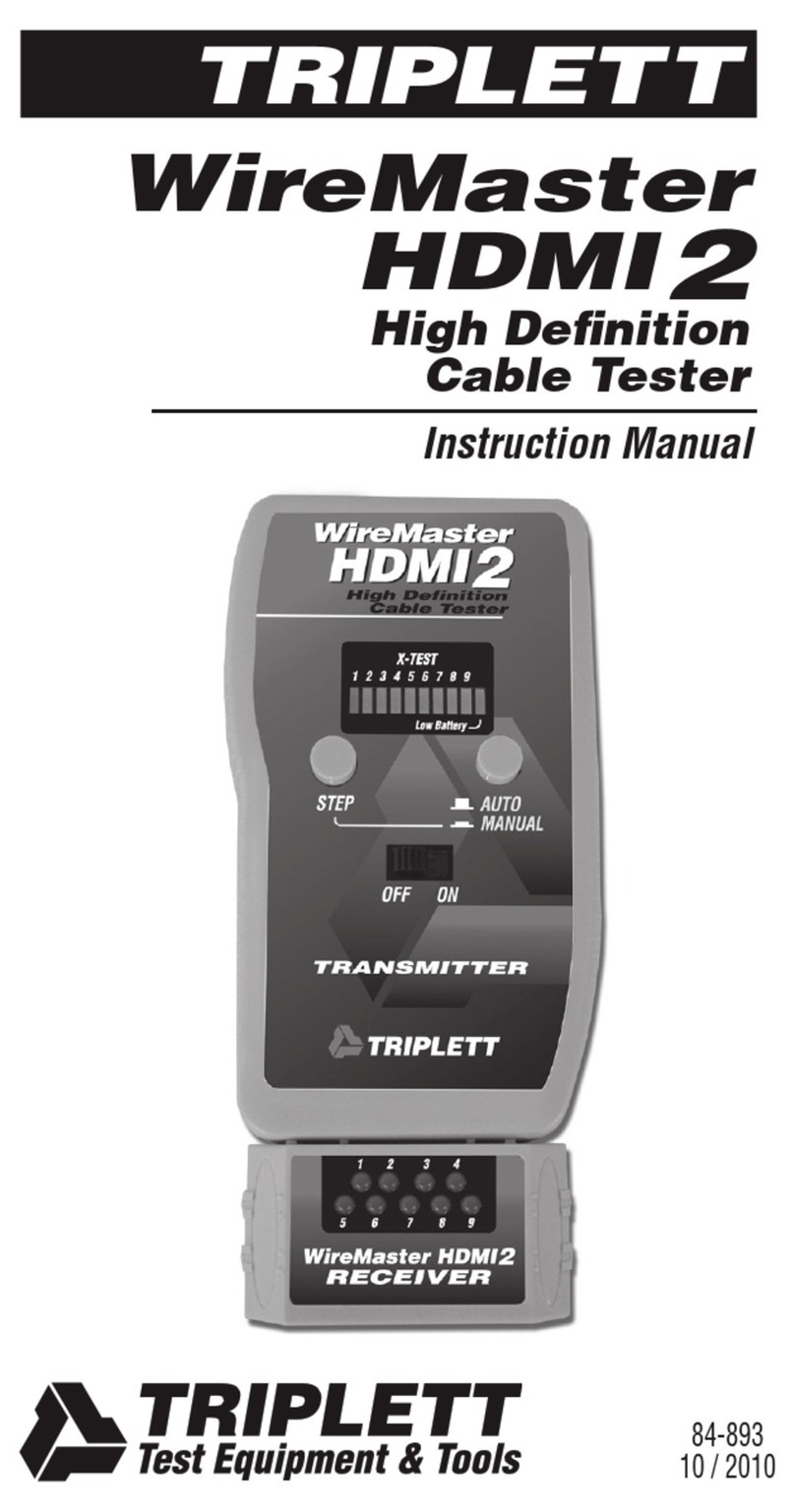

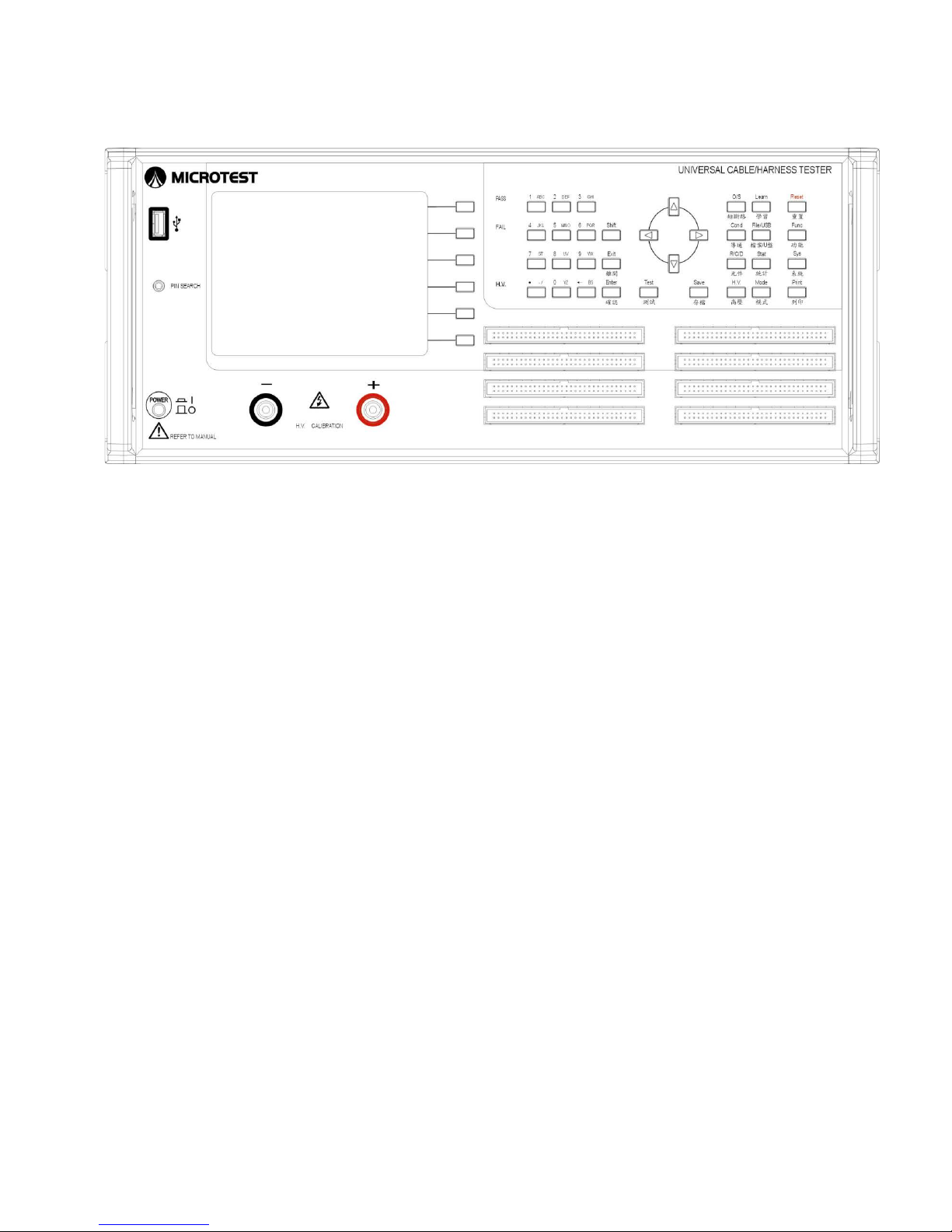

2.4 Front and Rear Panel Displays ........................................................................................................7

2.4.1 Front Panel............................................................................................................................7

2.4.2 Rear Panel.............................................................................................................................9

2.5 Block Diagram of Tester Functions...............................................................................................11

2.6 Installation .....................................................................................................................................12

2.7 Button Usage Instructions..............................................................................................................14

Chapter 3 Function Setting and System Setting.....................................................................................15

3.1 Function Menu...............................................................................................................................15

3.1.1 System Self-Test .................................................................................................................16

3.1.2 RAM Configuration Table..................................................................................................17

3.1.3 Test Parameter Calibration..................................................................................................17

3.1.4 Pin Search...........................................................................................................................21

3.1.5 Meter Mode ........................................................................................................................22

3.1.6 Networking Fixture Setting ................................................................................................26

3.2 System Setting (SYS)....................................................................................................................27

3.2.1 Setting the Operating Environment ....................................................................................28

3.2.2 Setting the Testing Environment.........................................................................................30

3.2.3 Set System Time.................................................................................................................33

3.2.4 Change System Password...................................................................................................34